163H All-Wheel Drive Motor Grader : AEHQ5269 - Kelly Tractor

163H All-Wheel Drive Motor Grader : AEHQ5269 - Kelly Tractor

163H All-Wheel Drive Motor Grader : AEHQ5269 - Kelly Tractor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Power TrainMatched Caterpillar components deliver smooth, responsive performance and reliability.Cat 3306 engine continues its traditionof powerful, efficient performance andunmatched reliability and durability.The six-cylinder engine is turbochargedwith a high displacement-to-powerratio. This large displacement producesbetter lugging capability, lower internalstresses and extended component life.Superior lugging performance. Hightorque output and high torque rise makethe 3306 engine very responsive. Theengine’s lugging capability allows it topull through sudden, short-termincreases in loads, reducing the need todownshift. As a result, the operator canmaintain desirable working speeds,which means the work gets done faster.Fuel efficiency. High fuel injectionpressures ensure proper mixing of fueland air. This high injection pressure,coupled with the precise metering andtiming of the fuel injection, results insuperior fuel efficiency and reducedemissions. High compression ratiosensure dependable cold-startingperformance and low emissions.Extended engine life. The large borestrokedesign and conservative powerrating help minimize internal stressesand increase component life. The lowengine speeds reduce engine wear andsound levels.Variable horsepower comes standardand can deliver an additional 15 kW(20 hp) in gears 4 - 8 forward whenall-wheel drive is turned off. Whenall-wheel drive is engaged, it deliversfull power in all gears. Variablehorsepower produces higher rimpull formoving heavy loads in applicationssuch as high-speed blading and snowremoval. It also improves gradeabilitywhen roading or working in the highspeedranges.Electronic overspeed protection helpsprevent engine and transmissiondamage from premature downshiftingand grade-induced overspeeding.4

Power shift transmission. Caterpillardesigns and builds transmissionsspecifically for Cat motor graders. Thetransmission provides on-the-go, fullpowershifting as well as inchingcapability.Direct drive delivers superior fuelefficiency and better “feel” of bladeloads, material hardness and groundspeed.Gear selections. Eight forward speedsand six reverse speeds give the operatora wide operating range. With four gearselections below 9.7 km/h (6 mph), theoperator can precisely match workingspeeds to job conditions for maximumproductivity in earthmovingapplications. Gears five, six and sevenprovide the optimal speed range forefficient snow removal operations.Electronic transmission controlproduces easy, smooth shifts, whichenable the operator to maintain uniformsurfaces if shifting is required. Smoothshifts also extend the life of thetransmission by placing less stress ontransmission clutches. A single levercontrols direction, speed and theparking brake.Inching capability. Low pedal effortand excellent modulation provideprecise control of machine movementswhen using the inching pedal. This isespecially important in finish grading orother close-quarter work where machinecontrol is critical.Optional autoshift improves ease ofoperation and maximizes productivityby automatically shifting thetransmission at optimal shift points.Dual air system supplies brakingcapacity to each side of the machine.This system ensures secondary brakingcapability in the event a failure occursin a single brake line. The dual airsystem also has a large reserve forstalled-engine braking.Oil-disc brakes. Caterpillar designs andbuilds multi-disc brakes that arecompletely sealed and adjustment-free.The brakes are oil-bathed, air-actuatedand spring-released. They are located ateach tandem wheel to eliminate brakingloads on the power train and to reduceservicing time. The large brake surfaceprovides dependable braking capabilityand extended life before rebuild.5

Drawbar, Circle & MoldboardEvery component is designed for maximum productivity and durability.Blade positioning. The blade linkagedesign provides extensive moldboardpositioning. This extended range ismost beneficial in mid-range banksloping and in ditch cutting andcleaning.Blade angle. A long wheel base allowsthe operator to obtain an aggressivemoldboard angle. This aggressive anglepermits material to roll more freelyalong the blade, which reduces powerrequirements. This is particularlyhelpful in handling very dry materials,cohesive soils, snow and ice.Rugged construction. The Y-framedrawbar is constructed of two solidbeams. A one-piece forged circle isbuilt to stand up to high stress loads.To resist wear, teeth are inductionhardenedin the critical areas. Formaximum support, the circle is securedto the drawbar by six support shoes.Replaceable wear items. Tough,durable nylon composite wear insertsare located between the drawbar andcircle, and between the support shoesand circle. This wear system helps keepcomponents tight for fine grading andallows easy replacement. In addition toproviding extended life, these insertsallow higher circle turning forces byreducing the friction between the circleand drawbar. Replaceable metallicwear inserts are used in the blade liftand centershift cylinder sockets,draftball surface, moldboard slide railand tip bracket bearings.Circle drive slip clutch protects thedrawbar, circle and moldboard fromshock when the end of the bladeencounters hidden objects. It alsoreduces the possibility of the gradermaking abrupt directional changes,further protecting the machine, operatorand surroundings.Optional blade lift accumulators absorbvertical shocks encountered when themoldboard contacts immovable objects.This option is especially useful in roughgrading and rocky areas.7

Operator’s StationCaterpillar sets the standard for comfort, convenience and visibility.8

Exceptional visibility helps improveoperator confidence and productivity.The drawbar has been modified toimprove the view through the circle,allowing the operator to see the materialas it rolls along the moldboard withoutleaning. Large side windows allow aclear view of the moldboard heel andtandem tires. A wide rear window andtapered engine hood provide a goodview to the rear of the machine.Quiet cab. With the doors closed,interior sound level does not exceed77 dB(A) when tested using SAE J919standard. The quiet environment keepsthe operator alert and focused.Low efforts on all pedals, hydrauliccontrols and the transmission shifterreduce operator strain and fatigue.Pedals are angled and raised off the cabfloor to make them easy to reach.<strong>All</strong>-<strong>Wheel</strong> <strong>Drive</strong>. Using the rockerswitch on the transmission console, theoperator can choose from threeoperating modes — automatic, manualor off. The torque control lever allowsthe operator to control theaggressiveness of the front wheels inboth active modes.Roomy interior. Extra leg and foot roomcreate a spacious, open cab. The cabincludes built-in storage space forpersonal items such as a lunch box,cooler and coat.Contour series suspension seat featuresfold-up armrests and a retractable seatbelt. The seat follows the contours ofyour body and can be easily adjusted foroptimal support and comfort. Seatcontrols are located in front and to theleft of the operator in plain view.Optional air conditioner and heaterarrangements create a comfortablework environment for the operator.Both arrangements use high-capacitysystems to ensure the operator staysproductive — even in the bitter cold orheat and humidity. They dehumidify theair as well as pressurize the cab, whichkeeps the air fresh and seals out dust.The adjustable air vents evenlydistribute air throughout the cab,keeping the operator comfortable andthe windows clear of fog or frost.Electronic Monitoring System checksimportant machine systems andprovides the operator with three levelsof warning.Comfort and convenience are designedinto every feature:■ Engine start-stop switch enables theoperator to start and stop engine witha simple key turn.■ Gauges are located inside the cab,■■■■■■■■directly in front of the operator.Controls and switches are located onthe steering console, shift console andright cab post — all within easyreach.Rocker switches and transmissionshifter are backlit for nighttimeoperation.The operator can adjust implementcontrols and steering wheel angleindependently.Cab floor is flush with the bottom ofthe doors, making it easy to sweepout and keep clean.Fresh air filters are located aboveeach cab door for quick replacement.Cab door releases from ground levelor inside the cab.Ashtray, lighter and cupholder arewell-positioned for easy access.Optional 12-V powerport is availablefor use with computers, cellularphones or other electronic equipment.9

<strong>All</strong>-<strong>Wheel</strong> <strong>Drive</strong><strong>All</strong>-wheel drive keeps productivity high, even in poor underfoot conditions.Superior traction. <strong>All</strong>-wheel driveimproves tractive performance in poorunderfoot conditions such as snow, mudand sand. This feature also providesexcellent steering and sidedraft control.More power. The variable horsepowerfeature is standard on the <strong>163H</strong>. Whenall-wheel drive is engaged, variablehorsepower kicks in and deliversmaximum power in all gears.Wide working range. <strong>All</strong>-wheel driveis available in gears 1-7 forward and 1-5reverse, making it effective in both lowspeedand high-speed applications —from ditch cutting to snow winging.Three operating modes are available —automatic, manual or off. The operatorselects the operating mode using arocker switch on the transmissionconsole.■ Automatic mode makes the all-wheeldrive feature easy to use. Itautomatically increases torque to thefront wheels as rear wheel slipincreases. The operator controls theresponsiveness of the front wheels byadjusting the torque control lever.The farther forward the lever, themore rapidly front wheel torque willincrease as slip increases.This mode provides power to thefront wheels only when needed,which reduces hydraulic system heatand lowers power consumption. Italso allows the operator to focus allhis attention on his work.■ Manual mode gives the operator 100percent control. He adjusts the torquecontrol lever to set a constant torquelevel to the front wheels. He canmake torque setting adjustments asoperating conditions change.There are many situations where anoperator may want to control the frontwheels independent of rear wheel slipsuch as when trying to remove amachine from a snow drift; whenmaking a tight turn on snow, mud orsand; or when working on a sideslope.10

ServiceabilityConveniently placed service points make routine maintenance quick and easy.Easy access to service areas speeds upmaintenance and ensures that routineservice is performed on time:■ Large hinged doors provide easyaccess to the engine and radiatorservice points.■ Spin-on filters make changes quickand clean.■ Lubrication points for the articulationjoint are remote-mounted.■ Disconnect switch and most servicepoints are located on the left side,making them easy to access when asnow wing is mounted on the rightside of the machine.■ Fuse panel is located inside the cab.Its cover clearly identifies circuitsand fuse sizes.■ Tandem oil checkpoint isconveniently located between thewheels in the center of the tandem.■ Service meter is located on the leftside of the steering console, givingthe operator a clear view from theground.■ Sampling ports are provided fordrawing engine and hydraulic oil.■ Lockable battery box cover is easilyremoved without tools.Power train components feature amodular design so you can remove theengine, transmission or final drivesindependently for quick servicing.Diagnostic capabilities offer fastservicing of the transmission andall-wheel drive system. The electroniccontrol modules automatically recordand save any system faults for lateranalysis. S•O•S oil and coolantsampling valves provide a fast,convenient means of obtaining fluidsamples and improve analysisreliability.XT hose. Caterpillar designs andmanufactures its own heavy-duty XThose and installs it in all high-pressurecircuits. Its resistance to abrasion,coupled with its exceptional strengthand flexibility, help minimizemaintenance and extend life.O-ring face seals create a reliable sealand are used in all hydraulic circuits tominimize the possibility of oil leaks.Radiator cleanout access. Removablecovers on each side of the radiatorguard provide access to the front of theradiator for cleanout with compressedair or pressure washer.Extended Life Coolant (ELC) extendscoolant life to 6000 hours. A singleaddition of ELC Extender at 3000hours is the only maintenance required.Separate wiring harnesses connect allelectrical components. This modularharness design provides simpledisconnects for major machine repairsor rebuilds. The wires are also colorcodedand numbered to speed updiagnosis and repairs. Sure-Sealconnectors are made of weatherresistantmaterials that protect againstmoisture, corrosion and abrasion.11

Environmentally Responsible DesignCaterpillar builds machines that help you create a better world.The H-Series motor graders respond toimportant environmental problems suchas noise and air pollution. Today’smachines run smoother, quieter andcleaner than ever before.Quiet cab. The sound-suppressed cabhas an interior sound level notexceeding 77 dB(A) when tested usingSAE J919 standards. The resilientlymounted engine and transmission resultin less engine noise and vibration to theoperator.Quiet machine. On the standardmachine, the drive-by exterior soundlevel will not exceed 84 dB(A) whentested at rated engine speed usingSAE J88 standard test. This quietoperation enables the machine to workwith minimal disturbance to thesurrounding environment.Low emissions. The enginearrangement meets current regulationsof the U.S. Environmental ProtectionAgency, California Air ResourcesBoard and European Union. Thisengine arrangement reduces the amountof particulates and nitrogen oxidesreleased into the air.Dry machine. Lubricant fill points andfilters are designed to minimizespillage. O-ring face seals, XT hoseand Cat hydraulic cylinders protectagainst leaks.Ozone protection. To help protect theearth’s ozone layer, air-conditioningunits use R-134a refrigerant, whichdoes not contain chlorofluorocarbons(CFCs).Complete Customer SupportCaterpillar dealer services help you operate longer with lower costs.Your Cat dealer offers a wide range ofservices that can be set up under acustomer support agreement when youpurchase your equipment. The dealerwill help you choose a plan that cancover everything from machine andattachment selection to replacement, tohelp you get the best return on yourinvestment.Selection. Make detailed comparisonsof the machines you are consideringbefore you buy. How long docomponents last? What is the cost ofpreventive maintenance? What is thetrue cost of lost production? Your Catdealer can give you precise answers tothese questions.Purchase. Look past initial price.Consider the financing options availableas well as day-to-day operating costsand dealer services. Comparative resalevalue is another item to consider.Operation. Improving operatingtechniques can boost your profits. YourCat dealer has training videotapes,literature and other ideas to help youincrease productivity.Maintenance. More and moreequipment buyers are planning foreffective maintenance before buyingequipment. Choose from your dealer’swide range of maintenance services atthe time you purchase your machine.Repair option programs guarantee thecost of repairs up front. Diagnosticprograms such as Scheduled OilSampling and Technical Analysis helpyou avoid unscheduled repairs.Product support. You will find nearlyall parts at our dealer parts counter. Inthe rare case when we don’t have a partin stock, we will get it to you fast —usually within 24 hours. Save moneywith remanufactured parts. You receivethe same warranty and reliability as newproducts at cost savings of 40 to 70percent.Replacement. Repair, rebuild orreplace? Your Cat dealer can help youevaluate the costs involved so you canmake the right choice.12

EngineFour-stroke cycle, six cylinder Caterpillar ® 3306 turbocharged and aftercooled diesel engine with variable horsepower (vhp).Power ratings (standard power)Ratings at 1900 rpm* kW hpGross power 150 201Net power 134 180The following ratings apply at 1900 rpmwhen tested under the specified standardconditions for the specified standard:Net power kW hp PSCaterpillar 134 180 —ISO 9249 134 180 —SAE J1349 133 178 —EEC 80/1269 134 180 —DIN 70020 — — 186Peak torque (net) @ 1200 rpm903 Nm 664 lb-ftTorque rise 33.5%DimensionsBore 121 mm 4.75 inStroke 152 mm 6.00 inDisplacement 10.45 liters 638 cu inEngine Torque (lb-ft)Engine Power (bhp)8006004002000240220200180160140120100StandardPower ratings (VHP - high power)**Ratings at 1900 rpm* kW hpGross power 165 221Net power 149 200The following ratings apply at 1900 rpmwhen tested under the specified standardconditions for the specified standard:Net power kW hp PSCaterpillar 149 200 —ISO 9249 149 200 —SAE J1349 148 198 —EEC 80/1269 149 200 —DIN 70020 — — 207Peak torque (net) @ 1200 rpm1001 Nm 738 lb-ftTorque rise 33.5%**VHP (variable horsepower) availablein gears 4-8 forward and 3-6 reversewhen <strong>All</strong>-<strong>Wheel</strong> <strong>Drive</strong> is not engaged.When <strong>All</strong>-<strong>Wheel</strong> <strong>Drive</strong> is engaged,VHP is available in all gears.Engine Torque (lb-ft)Engine Power (bhp)8006004002000240220200180160140120100VHP*Power rating conditions■ based on standard air conditions of25°C (77°F) and 99 kPA (29.32 in Hg)dry barometer■ used 35° API gravity fuel having anLHV of 42 780 kJ/kg (18,390 Btu/lb)when used at 30°C (86°F) [ref. afuel density of 838.9 g/L(7.001 lb/U.S. gal)]■ net power advertised is the poweravailable at the flywheel when engineis equipped with fan, air cleaner,muffler and alternator■ no derating required up to 2992 m(9816 ft) altitudeFeatures■ direct injection fuel system withindividual adjustment-free injectionpumps and nozzles■ 3-ring aluminum alloy pistons■ heat-resistant sil-chrome steel intakeand stellite-faced exhaust valves■ forged steel connecting rods■ one-piece cylinder head designed withcast intake manifold■ cast cylinder block with replaceablewet liners■ induction-hardened, forged crankshaft■ direct electric 24-V starting andcharging system■ two 12-V, 150 amp-hour, 950 CCA,low-maintenance batteries■ 50-amp alternator■ tube-type, water-cooled oil cooler■ vertical-flow, steel-fin, tube-typeradiator■ dry-type, radial-seal air cleaner withprimary and secondary elements■ resiliently mounted to rear frame.450.450BSFC (lb/hp-h).350.2501000 1200 1400 1600 1800Engine Speed rpmGrossNet2000 2200BSFC (lb/hp-h).350.2501000 1200 1400 1600 1800Engine Speed rpm2000 2200GrossNet<strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications13

Hydraulic SystemProportional priority pressure compensated system.Output at 2100 rpm and 24 150 kPa (3500 psi) 206 liters/min 54.4 gpmStandby pressure 3100 kPa 450 psiMaximum system pressure 24 150 kPa 3500 psiPump features■ load-sensing, pressure-compensating,variable-displacement piston pump■ low standby pressure■ pump supplies only flow and pressurerequired to move implements plus2100 kPa (300 psi) margin pressureControl features■ eight, closed-center control valvesstandard:— right blade lift— left blade lift— blade sideshift— blade tip— circle drive— centershift— front wheel lean— articulation■ low effort, short throw controlsService Refill Capacitiesliters gallonsFuel tank 341 90.0Cooling system 40 10.4Crankcase 27 7.0Transmission, differentialand final drives 47 12.2Tandem housing (each) 80 20.8Hydraulic system 98 25.5Hydraulic tank 38 9.9Circle drive housing 7 1.8Front wheel spindlebearing housing 0.5 0.13■ controls spaced to allow use of severalcontrols at once■ blade float position built into eachblade lift control valve■ lock valves built into all control valves■ line relief valves for the blade lift,blade tip and blade sideshift circuitsare incorporated into the controlvalves■ if flow requirements exceed pumpoutput, control valves proportion flowto each implement circuitOther features■ steering circuit given priority overimplement circuits■ heavy-duty XT hose■ hose couplings with O-ring face seals■ full-flow filterSteeringTwo-cylinder, hydraulic steering withhand metering unit.DimensionsMinimum turning 7.4 m 24' 3"radius (outsidefront tires)*Steering range 50° Left/RightArticulation angle 20° Left/Right*Using front wheel steering, framearticulation, and with differentialunlocked.Features■ large steer stops and steering reliefvalve help prevent damage whenobject is hit during full turn■ consistent steering response to the leftand right■ optional secondary steering systemprovides secondary steering capabilityin event of a complete loss ofhydraulic pressureTransmissionDirect drive, power shift transmissionwith eight speeds forward.Maximum travel speeds (at rated rpmwith standard 14.00-24 tires)km/h mphForward 1 3.5 2.22 4.8 3.03 7.0 4.34 9.6 6.05 15.0 9.36 20.3 12.67 28.0 17.48 40.7 25.3Reverse 1 2.8 1.72 5.2 3.23 7.6 4.74 11.8 7.35 22.3 13.96 32.1 20.0Features■ electronic shift control■ electronically controlled overspeedprotection■ single lever controls direction, speedand parking brake■ inching pedal■ low efforts on shift lever and inchingpedal■ internal parking brake serviceablewithout removing transmission■ diagnostic connector for easytroubleshooting■ resiliently mounted to frame14 <strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications

FrameFlanged, box-section design.DimensionsFront frame mm inTop and bottom platesWidth 305 12Thickness 25 1Side platesWidth 242 9.5Thickness 12 0.5Linear weightsFront frame kg/m lb/ftMinimum 165 112Maximum 213 144Section modulusFront frame cm 3 in 3Minimum 2083 127Maximum 4785 291Features■ single piece top and bottom plates runfrom bolster to articulation joint■ rear frame has two box-sectionedchannels integral with fully weldeddifferential caseFront AxleTandems■ wheel spindle rotates inside sealed Tandem oscillation 15° Forwardcompartment25° Reverse■ bearings bathed in oilLive spindle design.DimensionsDimensionsFront axlemm inGround clearance 625 mm 24.6" Height 572 22.5Front wheel lean 18° Width 201 7.9Oscillation angle 32° Sidewall thicknessFeaturesInner 16 0.63■ allows use of large outboard bearings Outer 18 0.71for high load-carrying capability of the <strong>Drive</strong> chain pitch 51 2wheel assembly<strong>Wheel</strong> axle spacing 1522 60BrakesMeets the following standards: SAE J1473 OCT 90 and ISO 3450-1996.Tires and RimsService brake features■ air-actuated, oil-disc brakes located ineach of the four wheel spindlehousings■ sealed and adjustment-free■ lubricated and cooled by tandemhousing oil■ 23 948 cm2 (3712 in 2 ) of total brakingsurfaceParking brake features■ multiple oil-disc unit■ located in the transmission on theoutput shaft■ manually actuated■ spring-engaged, air pressure-released■ engaged parking brake neutralizestransmission■ 1916 cm2 (297 in 2 ) of total brakesurface areaSecondary brake features■ separate circuits to right and lefttandems■ malfunction of one circuit still leavesmachine with at least half of originalbraking capacity■ dual chamber air tank provides air toactuate brakes five times after engineand compressor stop■ in the event of total braking loss, thespring-actuated parking/emergencybrake can be used to lock the wheelson any surfaceTires Rims Type14.00-24 10" x 24" MP17.5-25 14" x 25" MPMP = Multi-Piece RimNotes: An assortment of bias or radialtire models are available from variousmanufactures offering different sizes,strength indexes and industry types.Dependent on the weight of additionalequipment, the machine load mayexceed certain tire capabilities.Caterpillar recommends that youcarefully evaluate all conditions beforeselecting a tire model.<strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications15

DrawbarSolid steel bars fabricated into Y-framedesign.DimensionsDrawbar frame mm inHeight 127 5Thickness 76 3Features■ yoke plate completely covers top ofcircle■ six shoes support circle■ all shoes have vertical and horizontaladjustment■ 11 replaceable nylon composite wearstrips between circle and drawbar■ six replaceable nylon composite wearstrips between the circle andsupport shoesCircleSingle-piece, rolled ring forging.DimensionsCircle mm inCircle diameter 1553 61.1Blade beamthickness 40 1.6Features■ 64 uniformly spaced, flame-cut teeth■ teeth surfaces hardened on front 240°of circleMoldboard■ raised wear surfaces, top and bottom■ hydraulically driven, circle drivemotor■ 360° circle rotationFabricated from wear-resistant, highcarbonsteel.DimensionsMoldboard mm inLength 4267 168Height 686 27Thickness 25 1Arc radius 413 16.25Throat clearance 90 3.5Cutting edge mm inWidth 203 8Thickness 16 0.63End bit mm inWidth 203 8Thickness 16 0.63Features■ heat-treated sideshift rails■ replaceable metallic wear inserts■ cutting edge and end bit areCaterpillar through-hardened, curvedDH-2 steel■ 19 mm (.75") diameter bolts■ three sideshift mounting locations forstandard 4267 mm (14') moldboardand optional 4877 mm (16')moldboardBlade RangeFull range of blade positioning.mminCircle centershift Right 881 34.7Left 848 33.4Moldboard sideshift Right 943 37.1Left 851 33.5Maximum shoulder reach outside of tires Right 2261 89.0Left 2223 87.5Maximum lift above ground 452 17.8Maximum depth of cut 770 30.3Maximum blade position angle90° Both SidesBlade tip range40° Forward5° BackwardFeatures■ steep ditch-cutting angles possible■ 1.5:1 and 2:1 backsloping can be donewithout putting front tire on slope■ aggressive blade-carrying anglespossibleNotes:Add 305 mm (12") for maximum rightor left moldboard sideshift when usingoptional 4877 mm (16') blade.With the machine in the crab position,add 940 mm (37") to maximum right orleft moldboard sideshift.16 <strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications

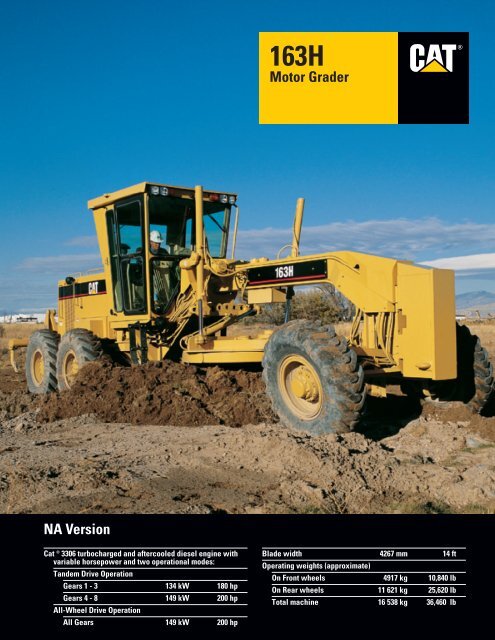

Dimensions<strong>All</strong> dimensions are approximate.3120 mm*10' 3"2091 mm6' 10"2456 mm**8' 1"1523 mm5' 0"6086 mm20' 0"8604 mm***28' 3"2518 mm8' 3"2553 mm**8' 5" 10 012 mm32' 10"Operating weights (approximate)on front wheels 4917 kg 10,840 lbon rear wheels 11 621 kg 25,620 lbtotal machine 16 538 kg 36,460 lbDimensions and operating weights based on standardmachine configuration with 14.00-24 12PR (G-2) tires,full fuel tank, coolant, lubricants and operator.* add 225 mm (8.9") for optional full height cab** add 193 mm (7.6") for optional 17.5-25 tires*** add 201 mm (7.9") for front push plateadd 1207 mm (4') for rear-mounted ripper-scarifierScarifiers and Ripper-ScarifierV-Type Scarifier Straight Scarifier Ripper-ScarifierType (mid-mounted) (mid-mounted) (rear-mounted)Working width 1184 mm 46.6" 1800 mm 71" 2300 mm 91"Scarifying depth, maximum 292 mm 11.5" 317 mm 12.5" 411 mm 16.2"Scarifier shank holders:number 11 17 9spacing 116 mm 4.6" 111 mm 4.38" 267 mm 10.5"Ripping depth, maximum — — 462 mm 18.2"Ripper shank holders:number — — 5spacing — — 533 mm 21"Increase in machine length, beam raised — — 970 mm 38.2"Penetration force* — — 8518 kg 18,778 lbPryout force — — 9281 kg 20,460 lb*Varies with machine configuration.<strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications17

<strong>All</strong>-<strong>Wheel</strong> <strong>Drive</strong> SystemThree operating modes: automatic, manual or off.Pump output at 2500 rpm and 35 000 kPa (5080 psi) 175 liters/min 46.2 gpmMaximum operating pressure 35 000 kPa 5080 psiMinimum operating pressure 5500 kPa 800 psi<strong>Motor</strong> displacement:High displacement1650 cc/rev 100.7 cu in/revLow displacement 660 cc/rev 40.2 cu in/revFeatures■ variable horsepower is available in allgears when system is turned on■ variable displacement piston pumpdriven directly from the transmission■ dual displacement, wheel motors■ high motor displacement used ingears 1-4 forward and 1-3 reverse■ low motor displacement used in gears 5-7forward and 4-5 reverse■ front wheels freewheel in 8 forward and 6reverse■ pump displacement and motordisplacement are electronically controlled■ flow divider valve allows differentialflows to the inside and outside motorsduring a machine turn and limits flow to aspinning wheel to assure adequate flow tothe wheel with traction18 <strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications

Cab with ROPS/FOPSCaterpillar cab and Rollover Protective Structure (ROPS) are standard.Cab features■ 77 dB(A) operator sound pressurelevel when measured per SAE J919 atrated speed■ low profile, sound-suppressed cab isstandard■ optional full height, sound-suppressedcab■ engine key start/shutoff switch■ back-lit rocker switches■ adjustable control console■ tilt adjustable steering wheel■ cloth-covered, contour suspensionseat with multiple adjustments■ retractable seat belt■ fuse panel in steering control console■ optional 24-V to 12-V 25-ampconverter■ optional heater/air conditionersystems with adjustable vents andthree-speed fan■ optional defroster fans■ gauges located in the cab— fuel— brake air pressure, two— engine coolant temperature— articulation— hydraulic oil temperature— optional speedometer/tachometer■ service hour meter on steeringconsole■ EMS operator warning system■ wipers and washers, windshield andlower front windows■ optional rear wiper and washer■ optional sliding side windows■ optional rear window sunshade■ fixed lower front windows■ optional opening lower frontwindows■ 10° slanted rear window■ low effort, suspended foot pedals■ sweep-out cab floor■ ground-level door release■ cupholder■ ashtray and 24-V lighter■ optional 12-V power port■ lunch box location■ coat hanger■ location and wiring for two-way orentertainment radioNote:When properly installed andmaintained, the Caterpillar cab, whentested with doors and windows closedaccording to ANSI/SAE J1166 MAY90,meets OSHA and MSHA requirementsfor operator sound exposure limits ineffect at time of manufacture.ROPS/FOPS features■ ROPS (Rollover Protective Structure)meets the following criteria:— SAE J396— SAE J1040 MAY94— ISO 3471-1994■ also meets the following FOPS(Falling Object Protective Structure)criteria:— SAE J231 JAN81— ISO 3449-1992Functions analyzed by ElectronicMonitoring System (EMS)■ Category I — Flashing indicator foralternator problem and parking brakeengagement.■ Category II — Flashing action lampand indicator for engine coolant andhydraulic oil heating problem andtransmission electrical problem.Requires change in machineoperation.■ Category III — Loud action alarm,plus flashing action lamp andindicator to signal problem withengine oil pressure, brake air pressure,supplemental steering, also parkingbrake applied with transmissionengaged. Requires immediate machineshutdown.<strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications19

Standard EquipmentStandard and optional equipment may vary. Consult your Caterpillar dealer for details.ElectricalAlarm, back upAlternator, 50-amp, sealedBatteries, two low-maintenance,950 CCABattery box cover, lockableElectrical system, 24-VLights, stop and tail<strong>Motor</strong>, startingOperator EnvironmentAccelerator-deceleratorAshtray and lighterCoat hookControl console, adjustableCupholderEMS, operator warning systemGauges inside the cab— articulation— engine coolant temperature— fuel— hydraulic oil temperature— brake air pressure, twoHydraulic controls, load-sensing— articulation— blade lift, right and left with floatposition— blade sideshift— blade tip— centershift— circle drive— front wheel leanMirror, wide angle, inside rearviewPower steering, hydraulicROPS cab, sound-suppressed,77 dB(A), low profileSeat, cloth-covered, contour suspensionSeat belt, retractable, 3"Service hour meterSteering wheel, tilt adjustableStorage area, cooler/lunch boxThrottle, handWindows, fixed lower frontWipers and washers, windshield andlower front windowsPower TrainAir cleaner, dry type, radial seal withservice indicatorBlower fanBrakes, oil-disc, four-wheel,air actuatedDifferential, lock-unlockEngine, 3306 DITA diesel withvariable horsepower, low emissionsMuffler, under hoodParking brake, multi-disc, sealed andoil-cooledPrecleaner, automatic dust ejectorPrescreenerPriming pump, fuelTandem driveTransmission, 8-speed forward and6-speed reverse power shift, directdrive with electronic shift controland overspeed protectionOther Standard EquipmentBumper, rear, with hitchCap locks for hydraulic tank, radiatoraccess cover and fuel tank, withlocksCircle drive slip clutchCutting edges, 203 mm x 16 mm(8" x 5/8") curved DH-2 steelDoors, engine compartment, withlocksDrawbar, six shoe with replaceablenylon composite wear stripsEnd bits, 16 mm (5/8") DH-2 steelFrame, articulated, with safety lockFuel tank, 341-liter (90-gallon)Horn, airMoldboard, 4267 mm x 686 mm x25 mm (14' x 27" x 1")Rims, refer to Tires and Rimssection, page 15S•O•S ports, engine and hydraulicTires, refer to Tires and Rimssection, page 15Tool box, with lock20 <strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications

Optional EquipmentWith approximate change in operating weight.kglbAccumulators, blade lift 71 156Air conditioner with heater and pressurizer 73 162Air dryer 13 29Alternator, 75-amp 10 23Alternator, 100-amp 11 25Autoshift, transmission — —Batteries, extreme-duty, 1300 CCA 15 32Blade, 4877 mm x 688 mm x 25 mm(16' x 27" x 1") 220 484Cab, ROPS, high profile, sound suppressed 77 170Canopy, ROPS, high profile,with rear wall and window -41 -90Converter, 25-amp, 24-V to 12-V 5 11Covers, louver 7 15Cutting edges, 203 mm x 19 mm (8" x 3/4") 23 50Endbits, overlay, reversible 9 20Ether starting aid 0 1Extensions, blade, 610 mm (2') 147 325Fan, defroster, front and rear 2 4Fan, reversible, with rear grill cover 9 20Fuel tank, 454-liter (120-gallon) 36 80<strong>Grader</strong>bit system, standard bit type 150 331Guard, lower platform 23 50Guard, transmission 98 215Heater, engine coolant 1 3Heater, with pressurizer 18 40Hydraulic arrangements with one or more additional hydraulicvalves are available for front scarifier, rear ripper-scarifier,dozer, dozer angle, snow plow and snow wingkglbInstrument panel cover, canopy 4 10Lighting systems:bar mounted lights, directional andheadlights 13 28cab mounted lights, directional andheadlights 9 20cab and bar mounted lights, directional,headlights and work lights 22 48work lights, front and rear 6 13snow wing light, right 18 40warning light, cab or canopy mounted 3 6Mirrors, dual, inside mounted — —Mirrors, outside mounted 8 18Power port, 12-V 2 5Protection, tire chain 18 39Push plate, front mounted 497 1095Radio ready, entertainment 4 9Rims, refer to Tires and Rims section, page 15Ripper, shank/tooth, one 33 72Ripper-scarifier, rear 961 2119Scarifier, front mounted, V-type 845 1862Scarifier, front mounted, straight type 903 1988Scarifier, shanks/teeth, nine 65 144Seat, vinyl-covered, contour suspension — —Snow arrangements, refer to Snow Arrangement SupplementSpeedometer/tachometer 0 1Steering system, secondary 50 111Sunshade, rear window 3 7Tires, refer to Tires and Rims section, page 15Windows, lower front, opening 3 6Windows, sliding side 4 8Wiper and washer, rear 7 16<strong>163H</strong> <strong>Motor</strong> <strong>Grader</strong> specifications21

Notes22

Notes23