You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

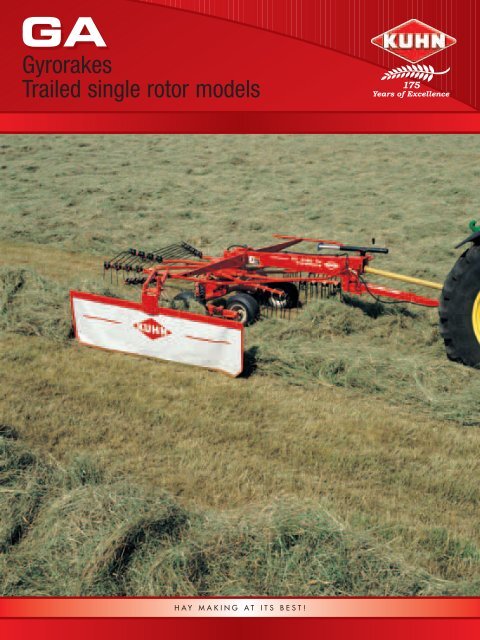

GA<strong>Gyrorakes</strong><strong>Trailed</strong> <strong>single</strong> <strong>rotor</strong> <strong>models</strong>HAY MAKING AT ITS BEST!

KUHN trailed<strong>single</strong> <strong>rotor</strong><strong>Gyrorakes</strong>Meeting the needs of tomorrow’s farmer today.KUHN, the pioneer in rotary rakes continues toprovide farmers with <strong>Gyrorakes</strong> that increaseproductivity while reducing losses in the field.KUHN <strong>Gyrorakes</strong>:• Increase the nutritional quality of hay andforage with gentle raking - higher quality hayand forage that ultimately increase profits.• Expand productivity with extended workingwidths and high capacity designs whilemaintaining maneuverability - reduce operatingcosts in the field.• Benefit from a long list of useful innovationslike double bent tangential tine arms andfully enclosed gearboxes. These innovationsincrease performance and reduce maintenancecosts.• Quality and reliability from the world’sleading manufacturer of rotary rakes -solid support and a high resale value.The production of quality forage is the keyto feeding performance and optimizing profitability.KUHN <strong>Gyrorakes</strong> make this happen!

GA 4120 TH GYRORAKE

KUHN trailed<strong>single</strong> <strong>rotor</strong> <strong>Gyrorakes</strong>Superior raking. Decreased drying time. High qualityhay or haylage. Reliability and resale value.Only a KUHN Gyrorake meets all of these demands.3At the dawn of the 21st Century the need for farmers to remain competitive is stronger thanever. For hay producers the rotary rake is one of the best implements available to increaseprofitability. Clean raking, faster drying times, high productivity, and superior bale quality(from the exceptional windrow formation) are all benefits of using a KUHN rotary rake.In the last hundred years parallel bar and finger wheel rakes have seen little in the way ofimprovements and innovation with some of the greatest changes being the shift in operationfrom horse to tractor. In marked contrast the evolution of the rotary rake, since its debutover 30 years ago, has been continuously improved to meet the ever-changing needs offarms. And KUHN is the undisputed leader in innovation.How a KUHN rotary rake works3112The tines rotate into the raking position and start lifting thecrop from the ground. The long tine length, (24 to 25 inchesdepending on model) allows unequalled capacity. Coilsprings allow the flexibility needed to bypass rocks and soilthat the tines may contact.Tines only contact the crop once from the time the crop isgently picked up until it is placed into the windrow. Thisraking action is as gentle to the crop as if it were raked byhand. Leaves are left intact and remain affixed to the stems.Dirt and stones are not deposited into the windrow.23The patented tangential mounting and double curve of theKUHN tine arm forms a windrow that is large, light, andfluffy. The windrow shape maximizes penetration by air andsunlight accelerating the drying process and reducingdrying time.

Make hay dry faster with a KUHN rakeAGyrorakeBOther rakesFaster Drying and no Roping!The windrow formed by a KUHNGyrorake is not roped (A). The largeevenly formed windrow not only improvesdrying but also feeds better into balerand chopper pickups for more uniformbaling and chopping. Other rake types(B) form a roped windrow that driespoorly and tends to “slug” feed into abaler or chopper.4Maximize productivity!12Decreased drying time through the use ofa rotary rake means hay crops can moreoften be cut, based on maturity instead ofthe weather forecast. Hay benefits fromthe higher feed value gained by cutting atthe proper time and less nutrients are lostdue to bleaching by over-exposure to thesun or rain. Hay produced by this methodputs more milk in the tank, weight gain oncattle, and money in the bank.1. Consistent quality rakingEven when turning, the tine arms sweepalong the same path, so the output of aKUHN rotary rake is even and consistent.Therefore there is no problem cleaningup headlands, corners, and curves. Comparethis with the ability of belt mergers,parallel bar, and wheel rakes whoseraking ability is compromised whenturning.2. Clean cropWith a design that does not require tinecontact with the ground, and with longflexible tines to overcome field irregularitiesand stones, there is little chance ofdirt, dust, or stones ending up in thewindrow. Clean hay or haylage not onlyprevents damage to baling and choppingequipment but also has a higher marketvalue, and is a more palatable feed.Increased palatability increases consumptionand milk or meat production.The climate’s right to go rotary!Dirt andStones inWindrowAll TerrainAbilityHighCapacityRoping ofWindrowFastDryingGentle Rakingof Tedded HayClean Rakingof Tedded HayKEYRotary Parallel Bar Belt Merger WheelNot PossibleNot PossibleMost Favorable Good Fair Least Favorable

KUHN Gyrorake strong points5Since producing the first rotary rake with guided tine arms, KUHN rotary rakes have alwaysbeen considered the “Gyrorake”. The trailed <strong>Gyrorakes</strong> from KUHN feature high flotationtires and standard bogie axles on the GA 4120 TH, GA 4121 GTH and GA 4521 GTH. Thisenables a high working speed while at the same time ensuring maximum raking quality.KUHN <strong>Gyrorakes</strong> also are capable of inverting or merging hay.Ultra-Reliable Rotor DriveThe patented MASTERDRIVE drive gearbox uses a double reduction system to drive the <strong>rotor</strong>.123The first reduction takes place in a rigid 90º, pinion type gearbox. As the pinions are held firmly in place by the gearbox castingthere is no chance for movement that could cause excessive gear lash and broken gear teeth.The second reduction takes place through a spur type “Bull Gear” drive. This arrangement allows for substantially over-sized gearteeth that are unaffected by any movement caused by the rake <strong>rotor</strong> and undercarriage operating under difficult conditions.The MASTERDRIVE design allows the <strong>rotor</strong> rotation to be clockwise. The rake can now discharge a windrow on the right side.As the majority of implements operate to the right side, and as tractor controls are oriented to the right side, windrow delivery tothe right provides a substantial increase in ergonomics. Control of the rake is easier and less fatiguing for the operator with lesschance of operating mistakes and accidents.KUHN quality and innovationAll these <strong>Gyrorakes</strong> are fitted with doublecurved tangential mounted tine arms.3 advantages that make the difference!1. Extra clearance at crop exitpointAdditional clearance provided at the exitpoint in comparison to a straight tine armallows:- The formation of larger, fluffier windrows- No risks of pulling crop out of theformed swath- Easier crop pick-up by the baler orforage harvester with minimum loss.2. The tangential tine positionmeans improved windrowformation- The crop is pushed towards the <strong>rotor</strong>outside, thus towards the windrow,- A cleaner windrow for silage makingand baling.3. A proven tine design for cleanforageThe tine angle provides clean raking andgentle handling with minimal groundcontact.

16321 2 31. Double curved tine arms(A KUHN patent!)The double curve design of the KUHNtine arm offers the following advantages:- Ensure extra tine arm clearance over thewindrow after the crop is released. Thisprevents the tines from packing the cropinto the windrow and retains the lightairy structure of the windrow.- Minimizes wear. The tine coil axis andthe tine arm axis are in alignment. Thisreduces stress and increases the servicelife.2. High quality, specially designedtinesFor a maximum service life, KUHN tinesare manufactured to meet extremely highquality standards. In addition to beingheat-treated, the tines receive a specialfinal process that substantially increasesthe tine’s resistance to fatigue. The curvedprofile of the tine provides clean rakingand uniformly shaped windrows withoutsacrificing capacity. Original KUHN tinesare always stamped with the KUHN logo.Accept no imitations or substitutes. Rotaryrakes are unaffected by the direction ofcut and can operate equally well eitherwith or against the direction of cut.Parallel bar and wheel rakes will oftenonly function acceptably if operated inthe same direction as the direction of thecut. This means that greater efficienciesin operation and flexibility are possiblewith the rotary rake. This advantagehas been maximized through theright hand delivery possible with theMASTERDRIVE system.3. Large, high-flotation tiresKUHN’s use of “Hyper-balloon” tires providessmooth operation over irregularground, increased operating speeds, andprevents the formation of ruts on softground.

GyrorakeGA 3200 GTSimple to operate, economical with ruggedconstruction7First of the trailed KUHN<strong>Gyrorakes</strong>, the GA 3200 GThas a working width of10’5” (3.20 m) includingthe windrow. Very easyto use and requiring nohydraulics, the GA 3200 GTis an economical rake thatwill work well on olderor smaller tractors withlimited or no hydrauliccapability. Ruggedly builtwith high capacity, theGA 3200 GT is ideally suitedfor small and mediumsized farms.TECHNICAL SPECIFICATIONSGA 3200 GTWorking width including windrow 10’5’’ (3.20 m)Clean swept width (approximate) 7’5’’ (2.23 m)AttachmentDrawbar <strong>Trailed</strong>Number of tine arms 9Number of double tines per arm 3Height/Lift adjustmentSpring assisted handleTiresHyper-balloon 18x8.50-8Transport width 8’10’’ (2.70 m)Weight660 lb. (300 kg)

8Bogie wheelsAvailable as an option, bogie wheelsenable increased working speeds andsmoother operation over irregularground.BAConstant velocity PTO shaftFor maximum maneuverability withoutchatter, the GA 3200 GT is fitted with aconstant velocity PTO shaft as standardequipment. Allows the tightest turnswithout the worry of driveline chatter andwear.Adjustable windrow curtainWindrow width can be varied to matchconditions by moving the curtain in andout.In addition, the curtain can be adjusted inheight and from front to rear for preciseadjustment.Simple and straightforwardheight adjustmentFor optimum raking,the tines should beset only as low as required to cleanly rakethe crop without touching the ground. Asstubble height varies, the height of thetines can also change. Adjustment of thetine height is carried out with two simplesteps:ABy using the spring assisted lever (A),the rake tines are set to the requiredheight. This lever is also used to raisethe rake for transport.BCrank (B) is used to level the rakefrom front to rear and to adjust therake to various drawbar heights.

GA 4120 TH - GA 4121 GTH - GA 4521 GTH<strong>Gyrorakes</strong>Rakes that meet demanding applications9With 4 double tines on each arm, standard bogiewheels, and dual-point hydraulic lift, the GA 4120 TH,the GA 4121 GTH, and the GA 4521 GTH are the finesttrailed <strong>single</strong> <strong>rotor</strong> rakes on the market.With unsurpassed capacity these rakes excel even athigher working speeds over irregular ground leavinglarge, fluffy, fast drying windrows.TECHNICAL SPECIFICATIONS GA 4120 TH GA 4121 GTH GA 4521 GTHWorking width including windrow 13’5’’ (4.10 m) 14’9’’ (4.50 m)Clean swept width (approximate) 9’5’’ (2.87 m) 10’4’’ (3.15 m)AttachmentDrawbar <strong>Trailed</strong>Number of tine arms 10 13Number of double tines per arm 4Rotor raisingTiresHydraulicHyper balloon 18x8.50-8Transport width 11’ (3.35 m) 6’ 3’’ (1.95 m) 7’ 3’’ (2.20 m)Weight 1290 Ib. (584 kg) 1370 Ib. (620 kg) 1950 Ib. (885 kg)

10Exclusive swath screenadjustmentThe swath screen design uses a parallelogramsystem. No tools and minimaleffort are required for adjustment. Whenextended outward the screen automaticallymoves to the rear and while retractingthe screen automatically moves to thefront. In this way, the screen is alwayscorrectly placed in relation to the croptrajectory. For increased comfort, theGA 4521 is equipped with a windrowcurtain adjustable hydraulically.High ground clearenceThanks to a dual-point hydraulic liftsystem with cylinders fitted to both theundercarriage and the drawbar, theserakes raise level at the front and rear. Thehigh ground clearance obtained allowsthe rake to cross cleanly over windrows inthe field.Standard Bogie axlesThe standard bogie axles allow higherspeeds and smoother operation overrough and irregular terrain. Furthermore,the wheels are positioned closely tothe tine path. Tines follow the groundmore evenly putting more hay and lessdirt in the windrow.Reduced transport width of6’3’’ (1.95 m) - GA 4121 GTH7’3” (2.20 m) - GA 4521 GTHFor significantly reduced transport widthand storage requirements the guards andswath screen are folded up. Easilydetachable tine arms are then stored in arack located at the front of the machine.

TECHNICAL SPECIFICATIONSGA 3200 GT GA 4120 TH GA 4121 GTH GA 4521 GTHWorking width including windrow 10’5’’ (3.20 m) 13’5’’ (4.10 m) 14’9’’ (4.50 m)Clean swept width (approx.) 7’5’’ (2.23 m) 9’5’’ (2.87 m) 10’4’’ (3.15 m)AttachmentDrawbar <strong>Trailed</strong>Number of tine arms 9 10 13Number of double tines per arm 3 4Tangential tine armsStandardRemovable tine arms - StandardTransport width 8’10’’ (2.70 m) 11’ (3.35 m) 6’3’’ (1.95 m) 7’3” (2.20 m)Fully enclosed gearboxConstant velocity PTO shaftStandardStandardRotor diameter 8’8’’ (2.65 m) 10’6’’ (3.20 m) 12’ (3.65 m)TiresHyper-balloon18x8.50-8Bogie axles Optional equipment StandardRotor raising Spring assisted lever Hydraulic w/adjustable stopDrawbar height adjustment Crank Hydraulic w/adjustable stopWeight 660 lb. (300 kg) 1290 lb. (585 kg) 1370 lb. (620 kg) 1950 lb. (885 kg)PTO power requirement 20 hp 30 hp 35 hpOur material is produced in accordance with the European Machinery Directive in the member states of the European Union. In countries outside the E.U., our machinery complies with the safety regulations set bythe country concerned. Some safety devices may have been removed from our leaflets in order to clarify the illustration. Under no circumstances should the machine be operated without the necessary safety devicesin place (as specified by the assembly instructions and operators manual). We reserve the right to change any designs, specifications or materials listed without further notice. Our <strong>models</strong> and trademarks arepatented in more than one country. Machines and equipment in this leaflet can be covered by at least one patent and/or registered design. Registered trademark(s).YOUR KUHN DEALERKUHN S.A. - F 67706 Saverne Cedexwww.kuhnsa.com - E-mail : info@kuhnsa.comKUHN Farm Machinery, Inc.P.O. Box 840, USA. Vernon NY 13476-0840,Tel. (315) 829.2620 - www.kuhn-usa.comE-mail: info@kuhn-usa.comMachinerie de Ferme KUHN, Inc.2620 Chemin de PlamondonSte Madeleine, QC, Canada JOH 1 SO,Tel. (450) 795-3339 - www.kuhn-canada.comE-mail: info@kuhn-canada.comTo protect the environment, this leaflet is printed on chlorine-free paper. / Printed in France - 920 248 US - 12.05 - Copyright KUHN 2005