Solutions to selected self-study problems

Solutions to selected self-study problems

Solutions to selected self-study problems

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

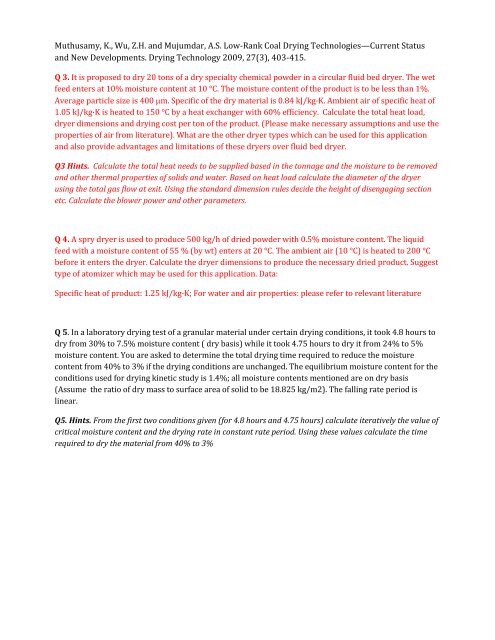

Muthusamy, K., Wu, Z.H. and Mujumdar, A.S. Low-Rank Coal Drying Technologies—Current Statusand New Developments. Drying Technology 2009, 27(3), 403-415.Q 3. It is proposed <strong>to</strong> dry 20 <strong>to</strong>ns of a dry specialty chemical powder in a circular fluid bed dryer. The wetfeed enters at 10% moisture content at 10 °C. The moisture content of the product is <strong>to</strong> be less than 1%.Average particle size is 400 µm. Specific of the dry material is 0.84 kJ/kg·K. Ambient air of specific heat of1.05 kJ/kg·K is heated <strong>to</strong> 150 °C by a heat exchanger with 60% efficiency. Calculate the <strong>to</strong>tal heat load,dryer dimensions and drying cost per <strong>to</strong>n of the product. (Please make necessary assumptions and use theproperties of air from literature). What are the other dryer types which can be used for this applicationand also provide advantages and limitations of these dryers over fluid bed dryer.Q3 Hints. Calculate the <strong>to</strong>tal heat needs <strong>to</strong> be supplied based in the <strong>to</strong>nnage and the moisture <strong>to</strong> be removedand other thermal properties of solids and water. Based on heat load calculate the diameter of the dryerusing the <strong>to</strong>tal gas flow at exit. Using the standard dimension rules decide the height of disengaging sectionetc. Calculate the blower power and other parameters.Q 4. A spry dryer is used <strong>to</strong> produce 500 kg/h of dried powder with 0.5% moisture content. The liquidfeed with a moisture content of 55 % (by wt) enters at 20 °C. The ambient air (10 °C) is heated <strong>to</strong> 200 °Cbefore it enters the dryer. Calculate the dryer dimensions <strong>to</strong> produce the necessary dried product. Suggesttype of a<strong>to</strong>mizer which may be used for this application. Data:Specific heat of product: 1.25 kJ/kg·K; For water and air properties: please refer <strong>to</strong> relevant literatureQ 5. In a labora<strong>to</strong>ry drying test of a granular material under certain drying conditions, it <strong>to</strong>ok 4.8 hours <strong>to</strong>dry from 30% <strong>to</strong> 7.5% moisture content ( dry basis) while it <strong>to</strong>ok 4.75 hours <strong>to</strong> dry it from 24% <strong>to</strong> 5%moisture content. You are asked <strong>to</strong> determine the <strong>to</strong>tal drying time required <strong>to</strong> reduce the moisturecontent from 40% <strong>to</strong> 3% if the drying conditions are unchanged. The equilibrium moisture content for theconditions used for drying kinetic <strong>study</strong> is 1.4%; all moisture contents mentioned are on dry basis(Assume the ratio of dry mass <strong>to</strong> surface area of solid <strong>to</strong> be 18.825 kg/m2). The falling rate period islinear.Q5. Hints. From the first two conditions given (for 4.8 hours and 4.75 hours) calculate iteratively the value ofcritical moisture content and the drying rate in constant rate period. Using these values calculate the timerequired <strong>to</strong> dry the material from 40% <strong>to</strong> 3%