UniGas 1000+

UniGas 1000+

UniGas 1000+

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

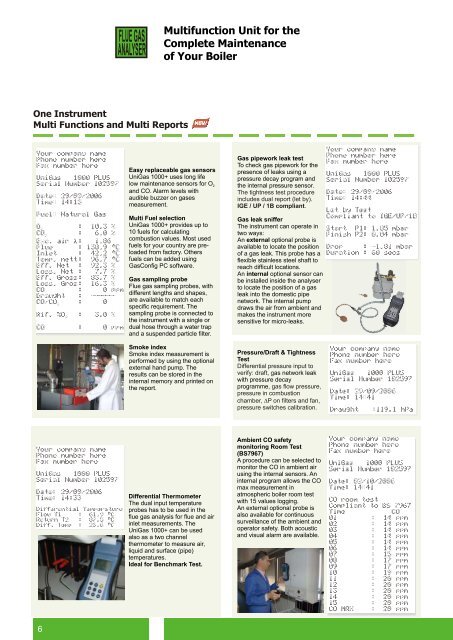

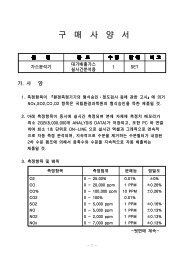

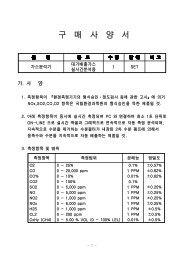

FLUE GASANALYSERMultifunction Unit for theComplete Maintenanceof Your BoilerOne InstrumentMulti Functions and Multi ReportsYour company namePhone number hereFax number here<strong>UniGas</strong> 1000 PLUSSerial Number 102597Date: 29/09/2006Time: 14:15Fuel: Natural GasO2: 10.3 %CO2: 6.0 %Exc. air λ: 1.86Flue : 138.9 °CInlet : 42.2 °CTemp. nett : 96.7 °CEff. Net : 92.3 %Loss. Net : 7.7 %Eff. Gross : 83.7 %Loss. Gros : 16.3 %CO : 0 ppmDraught : ------CO/CO2: 0Rif. %O2: 3.0 %CO : 0 ppmEasy replaceable gas sensors<strong>UniGas</strong> <strong>1000+</strong> uses long lifelow maintenance sensors for O 2and CO. Alarm levels withaudible buzzer on gasesmeasurement.Multi Fuel selection<strong>UniGas</strong> <strong>1000+</strong> provides up to10 fuels for calculatingcombustion values. Most usedfuels for your country are preloadedfrom factory. Othersfuels can be added usingGasConfig PC software.Gas sampling probeFlue gas sampling probes, withdifferent lengths and shapes,are available to match eachspecific requirement. Thesampling probe is connected tothe instrument with a single ordual hose through a water trapand a suspended particle filter.Gas pipework leak testTo check gas pipework for thepresence of leaks using apressure decay program andthe internal pressure sensor.The tightness test procedureincludes dual report (let by).IGE / UP / 1B compliant.Gas leak snifferThe instrument can operate intwo ways:An external optional probe isavailable to locate the positionof a gas leak. This probe has aflexible stainless steel shaft toreach difficult locations.An internal optional sensor canbe installed inside the analyserto locate the position of a gasleak into the domestic pipenetwork. The internal pumpdraws the air from ambient andmakes the instrument moresensitive for micro-leaks.Your company namePhone number hereFax number here<strong>UniGas</strong> 1000 PLUSSerial Number 102597Date: 29/09/2006Time: 14:44Let by TestCompliant to IGE/UP/1BStart P1: 1.85 mbarFinish P2: 0.04 mbarDrop : -1.81 mbarDuration : 60 secsSmoke indexSmoke index measurement isperformed by using the optionalexternal hand pump. Theresults can be stored in theinternal memory and printed onthe report.Pressure/Draft & TightnessTestDifferential pressure input toverify: draft, gas network leakwith pressure decayprogramme, gas flow pressure,pressure in combustionchamber, ∆P on filters and fan,pressure switches calibration.Your company namePhone number hereFax number here<strong>UniGas</strong> 1000 PLUSSerial Number 102597Date: 29/09/2006Time: 14:41Draught:119.1 hPaYour company namePhone number hereFax number here<strong>UniGas</strong> 1000 PLUSSerial Number 102597Date: 29/09/2006Time: 14:33Differential TemperatureFlow T1 : 61.9 °CReturn T2 : 87.5 °CDiff. Temp : 25.6 °CDifferential ThermometerThe dual input temperatureprobes has to be used in theflue gas analysis for flue and airinlet measurements. The<strong>UniGas</strong> <strong>1000+</strong> can be usedalso as a two channelthermometer to measure air,liquid and surface (pipe)temperatures.Ideal for Benchmark Test.Ambient CO safetymonitoring Room Test(BS7967)A procedure can be selected tomonitor the CO in ambient airusing the internal sensors. Aninternal program allows the COmax measurement inatmospheric boiler room testwith 15 values logging.An external optional probe isalso available for continuoussurveillance of the ambient andoperator safety. Both acousticand visual alarm are available.Your company namePhone number hereFax number here<strong>UniGas</strong> 1000 PLUSSerial Number 102597Date: 02/10/2006Time: 14:41CO room testCompliant to BS 7967Time CO01 : 14 ppm02 : 14 ppm03 : 14 ppm04 : 14 ppm05 : 14 ppm06 : 14 ppm07 : 15 ppm08 : 17 ppm09 : 17 ppm10 : 19 ppm11 : 20 ppm12 : 20 ppm13 : 20 ppm14 : 20 ppm15 : 20 ppmCO MAX : 20 ppm6