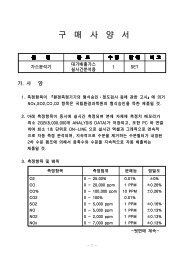

MK 9000

MK 9000

MK 9000

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Robust and all-purpose gas analyserCombination of measuring caseand handy analyserRemovable control modulewith radio transmissionRobust measuring gas pump withoptical flow controlAutomatic condensate drainageFlexible data memory using multi-media cardsApproved acc. to EN 50379-2 and 1 st BImSchV

Measuring case and handheld instrument unifiedThe <strong>MK</strong> <strong>9000</strong> enables the analysis of manyvariables by combustion processes. As universalinstrument it qualifies for the gas analysis at allfiring plants. Thanks to most modern radio technologythe <strong>MK</strong> <strong>9000</strong> combines the advantagesof robust measuring cases with those of hand-heldinstruments. Thanks to the removable control module,measurements at hardly accessible measuringpoints or larger firing plants become unproblematic.Hereby the basic module with the completemeasurement technique is installed directly at themeasuring point (flue gas pipe) while the mobile controlmodule for burner adjustment or for plant componentscheck is taken along. It monitors the basic moduleby radio (coverage approx. 50 m – ca.20 times brighter coverage than Bluetoothconnection).ecom-<strong>MK</strong> <strong>9000</strong> withdetached control moduleFlexible data memory using multi-media cardsThe <strong>MK</strong> <strong>9000</strong> enables the memorisation of measurement data– regardless if punctual measurements or data logging series- onmulti-media cards (4000 data records/MB). Values from punctualmeasurements get stored in a text file and data logging recordsin a csv file. Both data types have the same structure and can beeasily imported in Excel.Recording of several measurement pointsby modulating burnersInsertion of multi-media card in control module slot2

Robust measuring gas pumpThe pump with generous dimensions provides with high operationsafety and minimizes the maintenance costs. It withstands alsotough operation conditions and secures on a long-term basis a sufficientand quick feeding of the sensors with measurement gas.The pump enables the unproblematic use of a pre-filtering systemby solid fuel types analysis.Measuring gas pumpecom-<strong>MK</strong><strong>9000</strong>Measuring gas pumphand-held instrumentOptical flow controlThe volume flow sampled by thepump is constantly measured.By difficult ambient conditionsthe operator can continuouslycheck the measuring gas suction.By decreasing sucking performancean instrument maintenancecan be organized in time.Insensitive power supplyThe proven and robust lead battery provides with the necessaryelectric energy to operate the <strong>MK</strong> <strong>9000</strong>. It has no memory effect,is insensible to deep discharge and is powerful also undertough daily use conditions. The <strong>MK</strong> <strong>9000</strong> can be operated anytime by mains power.High reaction speed ascertainedby high pump performanceThe high pump performance ascertains the reaction speed ofthe <strong>MK</strong> <strong>9000</strong> so that the measurement results are quicklyavailable. A comparison made with other analysers outlines theadvantages of the <strong>MK</strong> <strong>9000</strong> regarding response speed (seediagram). The <strong>MK</strong> <strong>9000</strong> issues the measurement results up to3 times faster than the hand-instruments compared in the tests.The quick values availability is especially important by modernheating plants without heat reduction at the time the measurementis made. In such cases the time available is hardly sufficientto perform a proper flue gas analysis.A further important point which emphasizes the high pump performanceof the <strong>MK</strong> <strong>9000</strong> is the quick regeneration of the sensorsafter the measurement. The performing pump purges withhigh efficiency and contributes herewith decisively to the carefulsensors operation.450400350300Reaction speed CO measurementLead batteryCO (ppm)250200150100500Time (s)ecom-J2KNHandmessgerät AHandmessgerät B4

Automatic overload protection for CO sensorThe CO sensor is safeguarded from overload by an internal programme.Above a pre-programmed limit, a flushing pump is switchedon (P2) to supply fresh air to the CO sensor (red arrows).The measurement of the other gas components (black arrows)NO x /SO 2filtercan be resumed without problems also during the few secondsuntil automatic re-connection. To extend its life span it is possibleto switch off the CO sensor manually with simultaneous sensorpurging.Purging pumpP2Measuring gas pumpSensorsCOP1 O 2 NO NO 2 SO 2Service-friendly designThe <strong>MK</strong> <strong>9000</strong> is designed insuch a way that all wearing partscan be quickly exchanged. Sensorsand battery can be substitutedwithout instrument disassembly.Important componentsare installed within the robustmetal housing which can bedismounted quickly for repair ormaintenance works.Easy opening of thebattery compartmentEasily exchangeablesensorsMaintenance-free thermal quick printerThe integral thermal quick printer provides with an immediate documentationof the analysed values issued with a printing speedof maximal 75 mm/s. The printout can be personalized with theoperator address (8 x 24 characters). Optionally the <strong>MK</strong> <strong>9000</strong>can be equipped with a matrix printer in order to secure a longlastingprintouts availability.Maintenance-freeMatrix quick printer5

Accessories for every applicationExternal alphanumericalkeyboard for input of notesregarding measuring pointsand operation stands.Different probe pipes lengthsavailable on request.High temperature probe withprotective bag for 750 mmprobe.Multi-media cards4000 data records/MB.T-Room stick for T-Roommeasurement at operatorchoice from control orbasic module.Data interface for radio transferof online measurement data toPC. Illustration and recording ofmeasuring values via gratis softwareDASNT 3.NO x tubing for preventionof dilution losses by NO 2and SO 2 measurement.Magnetic fixation for controlmodule positioning onmagnetic surfaces. Leavesoperator both hands free.External radioantenna forsecuring of radioconnection alsounder extremeconditions.Peltier cooler forgas drying.6

XXL Transport case for additional storage… and for suitable storage ofNO x tubing with extended probelength.Filtering systems for cleaning of measuringgas by solid fuel types analysisFiltering plate for fixation at <strong>MK</strong> <strong>9000</strong>Industry version withheated sampling system… incl. hot gas filter for biomassand power plants applications.Filtering case as separate systemecom-<strong>MK</strong> <strong>9000</strong> the multi-talentat Weishaupt condensing boiler at Viessmann oil boilerat Viessmann large boiler at Jenbacher combined heating and power station7

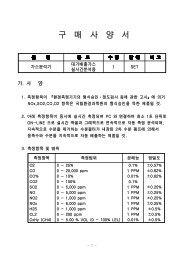

Burner Diagnostic with ecom-<strong>MK</strong> <strong>9000</strong> und ecom-AKEine A professional professionelle burner Brennerdiagnose diagnostic is possible kann mit using Hilfe the deM ecom eco.KNdurchgeführt Hereto the data werden. sampled Hierzu by werden the ecom-AK die vom are ecom-AK sent via ausgelesenen radio to theDaten über Funk zum Bedienteil des ecom-J2KN gesendet und übersichtlichauf 3 Bildschirmseiten angezeigt. Auf der ersten Seite werden dieecom- control module and illustrated in a clear arrangementBetriebszustände on 3 display pages. des Brenners The first grafisch page shows dargestellt. a graphic Eine Verlaufsanzeigeillustration oferlaubt the operation es, die Betriebszustände stands of the über burner. einen A Zeitraum progression von 100 indication Sekundenenables aufzuzeichnen. to record Die the zweite operation Bildschirmseite stands of zeigt the die burner Fehlerhistorie over a time desBrenners period of mit 100 Auflistung seconds. der häufigsten The next Fehler. pages Auf contain Seite drei records sind alle of wichtigenSteuerzeiten des Feuerungsautomaten vermerkt. Auf Tastendrucktheburner error history with a listing of the most frequent errors.erstellt das ecom-J2KN ein Diagnoseprotokoll, das zur Dokumentationgenutzt The last werden pages kann. all important monitoring times of the firing automate.On corresponding key order the ecom- prints outa diagnostic protocol which can be used for documentation.Operation stands of the burner withprogession indicationError history of the burnerMonitoring times of the firing automateFeatures and performance (tested and approved acc. to EN 50379-2 and 1 st BlmSchV)Measuring variables• O 2 ,CO,CO%,CO 2,NO,NO 2,NO x,SO 2 ,H 2S,H 2,NH 3,HCl,CL 2 ,HCN,PH 3N 2 O,C x H y ,THC,CH 4 ,T-Gas,T-Amb, differential pressure, sootCalculation variables• CO 2 ; CO(U); NO x ; efficiency; losses; lambda; dew point; mg/m 3 ,mg/kWh, O 2 reference; mean values calculation (option)Display• LCD-Display; 78 x 58 mm; max. 8 lines• Back-lit, graphic-capableProbe• Pistol grip probe 290 mm* with triple-chamber hose 3 m*• Electric heated probe for dry soot patterns• High temperature probe 750 mm, range up to 1200∞C (option)Preparation of measuring gas• Quick gas transport (measurement values promptly available)• Condensation trap with fine dust filter• Automatic condensate evacuation• Electronic condensate monitoring• Electric gas cooler (option)Safety• Temperature rend indication to locate core flow• CO shut-down without interruption of measurement• Fresh air flushing by CO exceeding; fresh air purging after measuringoperation• Contaminant filter for CO sensorPrinter• Thermal quick printer 58 mm• Matrix printer (option)Connections• Connection for external keyboard• Serial interface for data transferData processing• Internal memory (4000 measured values)• Multi-media card as memory• Measured values series on multi-media card• Data exchange with PC programme (option)• Foil keyboard for data input (option)• Online DAS programme (option)Transport• Transport caseDimensions/Weight• Dimensions (W x H x D): 450 x 300 x 250 mm• Weight: ca. 7.8 kg complete with sampling system* Others lengths available on request.Consult below rbr agency for more informationSEIL INT'L TRADING COMPANY TEL + 82 -02 -837 -6974 . FAX + 82-02 -859 -2059www.rbr.co.kr e-mail info@rbrkorea.co.kr

Technische DatenTechnical DataBis 12 elektrochemische Gassensoren oder 12 elekt. + IR-Bank bis 4 Parameter (= 16 Werte)Up to 12 electrochemical sensors or 12 elect. sensors + IR bench up to 4 parameters (= 16 values)Gemessene Werte - Measured valuesParameter Range Unit Genauigkeit / Accuracy Auf. / Res. Verfahren / PrincipleO 2 0-25.00 / 0-100.00 vol. % ± 0.1 vol. % 0.01 vol. % Elektrochemisch / ElectrochemicalCO ppm 0-20000 ppm ± 5 ppm oder / or 2% 1 ppm Elektrochemisch / Electrochemicalvom Messwert / of measured value,grösserer Wert gilt / higher value prevailsCO % (opt.) 0-100000 ppm ± 1% 10 ppm Elektrochemisch / ElectrochemicalNO ppm (opt.) 0-5000 ppm ± 5 ppm o. ± 2% Messwert / meas. value 1 ppm Elektrochemisch / Electrochemicalgrösserer Wert gilt / higher value prevailsNO 2 or PH 3ppm (opt.) 0-2000/20 ppm ± 5 ppm o. ± 2% Messwert / meas. value 1 ppm Elektrochemisch / Electrochemicalgrösserer Wert gilt / higher value prevailsSO 2 or HCN ppm (opt.) 0-5000/100 ppm ± 5 ppm o. ± 2% Messwert / meas. value 1 ppm Elektrochemisch / Electrochemicalgrösserer Wert gilt / higher value prevailsH 2 S ppm (opt.) 0-2000 ppm ** ± 5 ppm o. ± 2% Messwert / meas. value 1 ppm Elektrochemisch / ElectrochemicalCL 2 ppm (opt.)0-200 ppmgrösserer Wert gilt / higher value prevails1 ppm Elektrochemisch / ElectrochemicalH 2 ppm (opt.) 0-20000 ppm ** ± 5 ppm o. ± 2% Messwert / meas. value 1 ppm TCD Sensor / Electrochemicalgrösserer Wert gilt / higher value prevailsNH 3 ppm (opt.) 0-2000 ppm ** ± 5 ppm o. ± 2% Messwert / meas. value 1 ppm Elektrochemisch / ElectrochemicalHCl ppm (opt.) 0-200 ppm ** ± 5 ppm o. ± 2% Messwert / meas. value 1 ppm Elektrochemisch / Electrochemicalgrösserer Wert gilt / higher value prevailsCxHy or CH4 ppm or % LEL(opt) 0-50000 ppm vol. or 0-100 % LEL 0.01 vol.% PellistorCO (opt.) 0-100000 ppm / 0-100 % *** ± 20 ppm o. ± 2% Messwert / meas. value 10 ppm Infrarot / Infraredgrösserer Wert gilt / higher value prevailsCO 2 (opt.) 0-100 vol.% *** ± 0,2 vol. % o. ± 2% Messwert / meas. value 0.1 vol. % Infrarot / Infraredgrösserer Wert gilt / higher value prevailsC x H y or THC(opt.), N 2O(opt.) 0-15000/2000 ppm *** ± 4 ppm o. ± 2% Messwert / meas. value 1 ppm Infrarot / Infrared(Hexan o. Propan)grösserer Wert gilt / higher value prevailsC x H y or CH4 or THC(opt.) 0-60000 ppm *** ± 10 ppm o. ± 2% Messwert / meas. value 1 ppm Infrarot / Infrared(Methan)grösserer Wert gilt / higher value prevailsT-Gas -40-+1200* °C ± 1 °C (0-525°C), ± 2 °C (525-850°C) 1°C Thermoelement type K± 3 °C ( 850-1200°C) Thermocouple type K∆ T1 (opt.) 0-500 °C ditto / idem T-Gas 0.1°C ditto / idem T-GasT-Gas High (opt.) -40-+1800 °C 1°C Thermoel. / Thermoc. type ST-Raum / Room 0-99 °C ± 1°C 1°C Halbleiter / Semi-conductor∆ T2 (opt.) 0-99 °C ± 1°C 0.1°C PT 2000Zug / Draught ± 100 hPa ± 2% 0.01 hPa DMS-Brücke / DMS bridgeDiff. Druck / Diff. Pressure ± 100 hPa ± 2% 0.01 hPa DMS-Brücke / DMS bridgeLuftdruck / Air pressure 300-1100 hPa ± 2 hPa 1 hPa DMS-Brücke / DMS bridgeGeschwindigkeit / Flow (opt.) 0-100 m/s ± 0,2 m/s oder 1% v. Messwert; 0,1 m/s DMS-Brücke / DMS bridgegrösserer Wert gilt / or 1% of meas.value; higher value prevails.Russ / Soot 0-9 Russzahl / Vergleichsskala / Comparison scaleSoot dot* Geprüfter Messbereich / Tested range 0-400°C** Genauigkeitsangabe in Anlehnung an DIN EN 50379. Bezogen auf reines Gas. / Accuracy statement leant on DIN EN 50379. Related to pure gas.*** Angabe gemäss Herstelleraussage / Statement acc. to manufacturer´s dataStand: 05/2010SEIL INT'L TRADING COMPANYwww.rbr.co.kr 9

Technische DatenTechnical DataBis 12 elektrochemische Gassensoren oder 12 elekt. + IR-Bank bis 4 Parameter (= 16 Werte)Up to 12 electrochemical sensors or 12 elect. sensors + IR bench up to 4 parameters (= 16 values)Berechnete Werte - Calculated valuesParameter Range Auf. / Res. Verfahren / PrincipleAbgasverluste / Exhaust losses qA 0..99,9% 0,1%Berechnet / CalculatedWirkungsgrad / Efficiency ETA 0..120% 0,1%Berechnet / CalculatedLuftüberschuss / Excess air Del. > 1 0 Berechnet / CalculatedKohlendioxid / Carbon dioxide CO2 0... CO2 max 0,1 vol.% Berechnet / CalculatedCO-unverdünnt / CO undiluted CO(u) 1 ppm Berechnet / CalculatedMassenkonzen. / Mass concen. mg/m 3 1 mg/m 3 Berechnet / CalculatedMassenkonzen. / Mass concen. mg/kWh 1 mg/kWh Berechnet / CalculatedTaupunkt / Dew point 1°C Berechnet / CalculatedWeitere Daten / Further DataZugelassen nach / Approved acc. to ● TÜV ByRgG 244, DIN EN 50379-1, DIN EN 50379-2Brennstoffarten / Fuel types ● 5 vorprogrammierte, bis max. 16 möglich / 5 pre-programmed, up to max.16 programmableKalibrierzeit / Calibration time ● 60 Sekunden / 60 secondsEntnahmesystem / Sampling system ● Geräteinnenverschlauchung aus Teflon / Instrument tubing made of Teflon● Sonde 300 mm mit beheizter Rußmessung, mit speziellem NO x -Schlauch 3.5 mzur Vermeidung von Auswaschverluste, Haltekonus / Probe 300 mm with heated sootmeasurement, with special NOx tubing 3.5 m for avoidance of washout effects,fixation cone● Beheiztes System (opt.) für Langzeitmessungen bestehend aus beh. Schlauch 3.4 m,beh. Kopf, Sondenrohr 300 mm, Haltekonus / Heated system (opt.) for long-timemeasurements consisting of heated hose 3.4 m, heated head, probe pipe 300 mm,fixation coneWerteablesung / Values reading ● Kabellose Datenübermittlung Bedienteil / Basiseinheit bis ± 50 m (freie Sicht) / Wirelessdata transfer measurement control / basic modules up to ± 50 m (by free sight)● Bedienteil mit integrierter Magnethalterung zur bequemen Platzierung an Metallflächen /Control module with integral magnet for easy positioning on metal surfaces● Zoomfähiges Display, 320 x 240 Punkte, hintergrundbeleuchtet, ≈ 78 x 58 mmDisplay with zoom function, 320 x 240 dots, backlit, ≈ 78 x 58 mmAusdruck Messwerte / Printout values ● Integrierter Thermoschnelldrucker 58 mm Breite / Integral thermal quick printer 58 mm,oder Nadeldrucker 58 mm Breite (opt.) / or integral matrix printer 58 mm (opt.)Datenverarbeitung / Data processing ● Multimedia-Karte (Zubehör) als Speicher / Multi-Media card (accessory) as memory● Bluetooth (opt.) / Bluetooth (opt.)● Online DAS Programm / Online DAS programme● Messwertreihen auf MM-Karte / Measurement series on MM card● Messwertreihen-Datenübertragung an PC in Excel-Format / Measurement seriesdata transfer to PC in Excel format● Datenaustausch mit PC-Programm MiniDV (opt.) / Data exchange with PCprogramme MiniDV (opt.)● Display-aufrufbare alphanumerische Tastatur / Alphanumeric keyboard displayableon display● Externe Folientastatur z. Dateneingabe (opt.) / External foil keyboard f. data input (opt.)● Störungsdiagnose mit ecom-AK (opt.) / Trouble diagnosis with ecom-AK (opt.)Anschlüsse / Connections ● USB Schnittstelle zur Datenübertragung / USB interface for data transferStand: 05/2010SEIL INT'L TRADING COMPANYwww.rbr.co.kr 10

Technische DatenTechnical DataBis 12 elektrochemische Gassensoren oder 12 elekt. + IR-Bank bis 4 Parameter (= 16 Werte)Up to 12 electrochemical sensors or 12 elect. sensors + IR bench up to 4 parameters (= 16 values)Weitere Daten / Further DataAnschlüsse / Connections ● Anschluss Fernbedienung über Kabel / Connection remote control upon cable● Dateninterface-Box (opt.) für Verbindung an Grossanzeige 9 Werte / Datainterface box (opt.) for connection to giant display 9 values● Beheizte Russsonde Ø 10 mm, 300 mm Länge, mit 3 m Entnahmeschlauch /Heated soot probe Ø 10 mm, 300 mm length, with 3 m sampling hose● Anschluss NOx-Schlauch / Connection NOx hose● Anschluss beheiztes System / Connection heated system● Anschluss Grossanzeige 9 Werte / Connection giant display 9 valuesGasaufbereitung / Gas Processing ● Elektrischer Peltier-Kühler / Electric Peltier cooler● Elektronische Kondensatüberwachung / Electronic condensate monitoring● Automatische Kondensatentleerung / Automatic condensate evacuationBetriebssicherheit / Operation safety ● Temp.-Trendanzeige zur Kernstromsuche / Temp. trend indication f. core stream search● CO-Abschaltung o. Messunterbrechung / CO switch-off w/o. measurement interruption● Frischluftspülung bei CO-Überlast / Fresh air purging by CO exceeding● Frischluftspülung nach Messbetrieb / Fresh air purging after operation● Kontroll-LEDs Netz-/Akkubetrieb und Fehlermeldungen / Control LEDs mains power/battery operation and error messages● Sicherheitsventil, automatische Messgasumschaltung / Safety valve, automaticswitch to measurement gas● Durchflussmesser zur optischen Kontrolle der Pumpenleistung / Flow meter for opticalcheck of pump performance● Verdeckte Miniantenne an Basiseinheit zur Funkverstärkung bei erschwertenUmgebungsbedingungen / Hidden mini antenna at basic module for radio transferreinforcement under difficult ambient conditionsGasfilterung / Gas filtering ● Feinstaubfilter an Peltier-Kühler / Fine dust filter at Peltier cooler● NO x /SO 2 -Filter für CO-Sensor / NO x /SO 2 filter for CO sensor● Mini-Filterplatte (opt.) für Feststoffmessung / Mini filtering plate (opt.) for solidcombustibles measurement● Filterkoffer (opt.) für Feststoffmessung / Filtering case (opt.) for solid combustiblesmeasurementSpannungsversorgung / Power ● Bleigel-Akku / Lead battery 6 V / 7.2 Ah● Internes Netzteil / Internal charger 230V 50 Hz / 110V 60 Hz● Netz- und Akkubetrieb auch bei gleichzeitiger Zuschaltung der Sondenheizung(Standardsonde) / Mains and accu operation also by simultaneous activationof the probe heating (standard soot probe)Transport ● Standard: Robuster Alu-Rahmenkoffer / Robust alu-framed transport caseOption: Robuster Alu-Rahmenkoffer Version Industry, Unterkoffer mit Trolley /Robust alu-framed transport case Version Industry, under case with trolleyZulässige Umgebungstemperatur /Tolerated ambient temperature ● -5...+ 50°CZulässige Lagertemperatur /Tolerated storage temperature ● -20 / + 60° CWartungsintervall / Maintenance interval ● 1 Mal pro Jahr empfohlen / Yearly check recommendedAbmessungen / Dimensions ● ≈ 500 x 300 x 250 mm Standardkoffer Industrieversion / standard case industry version≈ 510 x 470 x 250 mm optionaler Industry-Koffer mit Unterkoffer und Trolley /optional Industry transport case with undercase and trolleyGewicht / Weight ● ≈ 7.4 kg (im Standardkoffer Industrieversion / in standard case industry version)≈ 7.8 kg (im Industry-Koffer / in Industry case)Stand: 05/2010SEIL INT'L TRADING COMPANY TEL + 82 -02 -837 -6974 FAX + 82-02 -859 -2059www.rbr.co.kr e-mail : info@rbrkorea.co.kr 11