High precision ball bearings - Spekuma Kullager AB

High precision ball bearings - Spekuma Kullager AB

High precision ball bearings - Spekuma Kullager AB

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

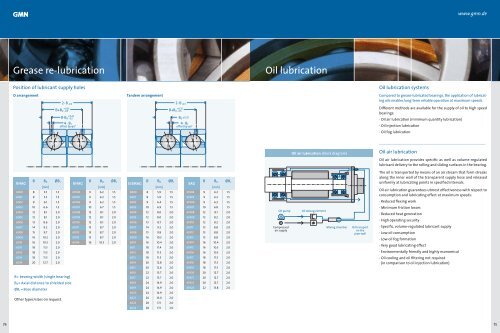

www.gmn.deGrease re-lubricationOil lubricationPosition of lubricant supply holesO arrangementTandem arrangement2 · B -0.52 · B -0.5+0.25B + B 0 - 0.5+0.25B - B 0 - 0.5B 0±0.254 · B 14 · B 1offset by 90° offset by 90°+0.25Oil lubrication systemsCompared to grease-lubricated <strong>bearings</strong>, the application of lubricatingoils enables long-term reliable operation at maximum speeds.Different methods are available for the supply of oil to high speed<strong>bearings</strong>:· Oil air lubrication (minimum quantity lubrication)· Oil injection lubrication· Oil fog lubricationOil air lubrication (block diagram)Oil air lubricationOil air lubrication provides specific as well as volume-regulatedlubricant delivery to the rolling and sliding surfaces in the bearing.KHAGB B 0 ØB 1[mm]6000 8 5.5 1.56001 8 5.5 1.56002 9 6.1 1.56003 10 6.6 1.56004 12 8.1 2.06005 12 8.1 2.06006 13 8.6 2.06007 14 9.2 2.06008 15 9.7 2.06009 16 10.2 2.06010 16 10.3 2.06011 18 11.5 2.06012 18 11.5 2.06013 18 11.5 2.06014 20 12.7 2.0KHAGB B 0 ØB 1[mm]61904 9 6.2 1.561905 9 6.2 1.561906 9 6.2 1.561907 10 6.7 1.561908 12 8.1 2.061909 12 8.1 2.061910 12 8.1 2.061911 13 8.7 2.061912 13 8.7 2.061913 13 8.7 2.061914 16 10.3 2.0S/SMAGB B 0 ØB 1[mm]6000 8 5.9 1.56001 8 5.9 1.56002 9 6.4 1.56003 10 6.9 1.56004 12 8.0 2.06005 12 8.0 2.06006 13 8.7 2.06007 14 9.2 2.06008 15 9.8 2.06009 16 10.3 2.06010 16 10.4 2.06011 18 11.4 2.06012 18 11.5 2.06013 18 11.5 2.06014 20 12.8 2.06015 20 12.6 2.0B + B 0 - 0.5»SAGB B 0 ØB 1[mm]61904 9 6.2 1.561905 9 6.2 1.561906 9 6.2 1.561907 10 6.8 1.561908 12 8.1 2.061909 12 8.2 2.061910 12 8.2 2.061911 13 8.8 2.061912 13 8.8 2.061913 13 8.8 2.061914 16 10.4 2.061915 16 10.3 2.061916 16 10.5 2.061917 18 11.5 2.061918 18 11.5 2.061919 18 11.5 2.0Oil pumpCompressedair supplyOil dosing elementMixing chamberOil transporton thepipe wallThe oil is transported by means of an air stream that form streaksalong the inner wall of the transparent supply hose and releaseduniformly at lubricating points in specified intervals.Oil air lubrication guarantees utmost effectiveness with respect toconsumption and lubricating effect at maximum speeds:· Reduced flexing work· Minimum friction losses· Reduced heat generation· <strong>High</strong> operating security· Specific, volume-regulated lubricant supply· Low oil consumption· Low oil fog formation· Very good lubricating effect· Environmentally friendly and highly economical· Oil cooling and oil filtering not required(in comparison to oil injection lubrication)B= bearing width (single bearing)B 0 = Axial distance to shielded sideØB 1 = Bore diameter6016 22 13.7 2.06017 22 13.7 2.06018 24 14.9 2.06019 24 14.9 2.06020 24 14.9 2.061920 20 12.7 2.061921 20 12.7 2.061922 20 12.7 2.061924 22 13.8 2.0Other types/sizes on request.6021 26 16.0 2.06022 28 17.1 2.06024 28 17.1 2.074 75