Download pdf - MAPAL Dr. Kress KG

Download pdf - MAPAL Dr. Kress KG

Download pdf - MAPAL Dr. Kress KG

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

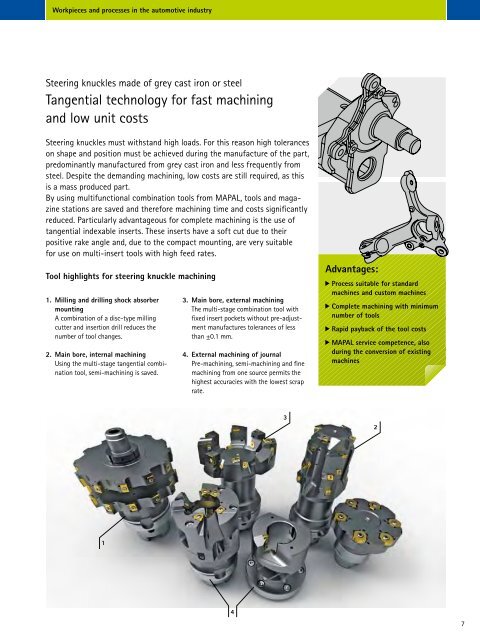

Workpieces and processes in the automotive industrySteering knuckles made of grey cast iron or steelTangential technology for fast machiningand low unit costsSteering knuckles must withstand high loads. For this reason high toleranceson shape and position must be achieved during the manufacture of the part,predominantly manufactured from grey cast iron and less frequently fromsteel. Despite the demanding machining, low costs are still required, as thisis a mass produced part.By using multifunctional combination tools from <strong>MAPAL</strong>, tools and magazinestations are saved and therefore machining time and costs significantlyreduced. Particularly advantageous for complete machining is the use oftangential indexable inserts. These inserts have a soft cut due to theirpositive rake angle and, due to the compact mounting, are very suitablefor use on multi-insert tools with high feed rates.Tool highlights for steering knuckle machining1. Milling and drilling shock absorbermountingA combination of a disc-type millingcutter and insertion drill reduces thenumber of tool changes.2. Main bore, internal machiningUsing the multi-stage tangential combinationtool, semi-machining is saved.3. Main bore, external machiningThe multi-stage combination tool withfixed insert pockets without pre-adjustmentmanufactures tolerances of lessthan ±0.1 mm.4. External machining of journalPre-machining, semi-machining and finemachining from one source permits thehighest accuracies with the lowest scraprate.Advantages:Process suitable for standardmachines and custom machinesComplete machining with minimumnumber of toolsRapid payback of the tool costs<strong>MAPAL</strong> service competence, alsoduring the conversion of existingmachines32147