ANCHOR BOLTS - masco.net

ANCHOR BOLTS - masco.net

ANCHOR BOLTS - masco.net

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

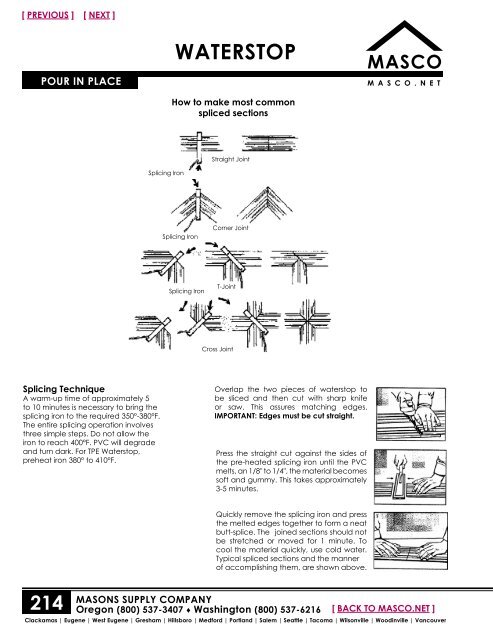

[ PREVIOUS ] [ NEXT ]WATERSTOPPOUR IN PLACEM A S C O . N E THow to make most commonspliced sectionsSplicing IronStraight JointSplicing IronCorner JointSplicing IronT-JointCross JointSplicing TechniqueA warm-up time of approximately 5to 10 minutes is necessary to bring thesplicing iron to the required 350°-380°F.The entire splicing operation involvesthree simple steps. Do not allow theiron to reach 400°F. PVC will degradeand turn dark. For TPE Waterstop,preheat iron 380° to 410°F.Overlap the two pieces of waterstop tobe sliced and then cut with sharp knifeor saw. This assures matching edges.IMPORTANT: Edges must be cut straight.Press the straight cut against the sides ofthe pre-heated splicing iron until the PVCmelts, an 1/8" to 1/4", the material becomessoft and gummy. This takes approximately3-5 minutes.Quickly remove the splicing iron and pressthe melted edges together to form a neatbutt-splice. The joined sections should notbe stretched or moved for 1 minute. Tocool the material quickly, use cold water.Typical spliced sections and the mannerof accomplishing them, are shown above.214MASONS SUPPLY COMPANYOregon (800) 537-3407 ♦ Washington (800) 537-6216[ BACK TO MASCO.NET ]Clackamas | Eugene | West Eugene | Gresham | Hillsboro | Medford | Portland | Salem | Seattle | Tacoma | Wilsonville | Woodinville | Vancouver