Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

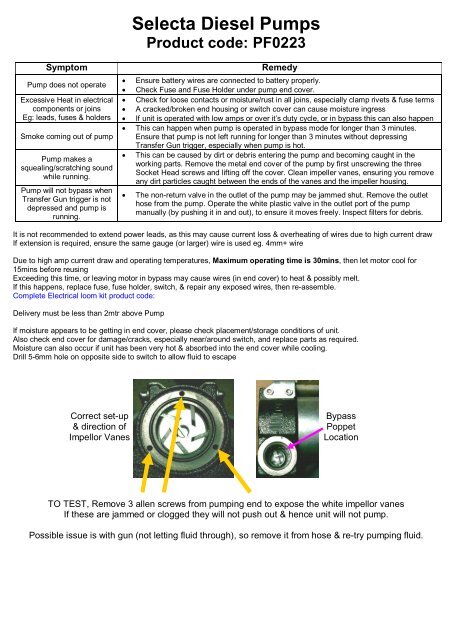

Selecta <strong>Diesel</strong> <strong>Pump</strong>sProduct code: PF0223Symptom<strong>Pump</strong> does not operateExcessive Heat in electricalcomponents or joinsEg: leads, fuses & holdersSmoke coming out of pump<strong>Pump</strong> makes asquealing/scratching soundwhile running.<strong>Pump</strong> will not bypass whenTransfer Gun trigger is notdepressed and pump isrunning.Remedy• Ensure battery wires are connected to battery properly.• Check Fuse and Fuse Holder under pump end cover.• Check for loose contacts or moisture/rust in all joins, especially clamp rivets & fuse terms• A cracked/broken end housing or switch cover can cause moisture ingress• If unit is operated with low amps or over it’s duty cycle, or in bypass this can also happen• This can happen when pump is operated in bypass mode for longer than 3 minutes.Ensure that pump is not left running for longer than 3 minutes without depressingTransfer Gun trigger, especially when pump is hot.• This can be caused by dirt or debris entering the pump and becoming caught in theworking parts. Remove the metal end cover of the pump by first unscrewing the threeSocket Head screws and lifting off the cover. Clean impeller vanes, ensuring you removeany dirt particles caught between the ends of the vanes and the impeller housing.• The non-return valve in the outlet of the pump may be jammed shut. Remove the outlethose from the pump. Operate the white plastic valve in the outlet port of the pumpmanually (by pushing it in and out), to ensure it moves freely. Inspect filters for debris.It is not recommended to extend power leads, as this may cause current loss & overheating of wires due to high current drawIf extension is required, ensure the same gauge (or larger) wire is used eg. 4mm+ wireDue to high amp current draw and operating temperatures, Maximum operating time is 30mins, then let motor cool for15mins before reusingExceeding this time, or leaving motor in bypass may cause wires (in end cover) to heat & possibly melt.If this happens, replace fuse, fuse holder, switch, & repair any exposed wires, then re-assemble.Complete Electrical loom kit product code:Delivery must be less than 2mtr above <strong>Pump</strong>If moisture appears to be getting in end cover, please check placement/storage conditions of unit.Also check end cover for damage/cracks, especially near/around switch, and replace parts as required.Moisture can also occur if unit has been very hot & absorbed into the end cover while cooling.Drill 5-6mm hole on opposite side to switch to allow fluid to escapeCorrect set-up& direction ofImpellor VanesBypassPoppetLocationTO TEST, Remove 3 allen screws from pumping end to expose the white impellor vanesIf these are jammed or clogged they will not push out & hence unit will not pump.Possible issue is with gun (not letting fluid through), so remove it from hose & re-try pumping fluid.