Flamco Flexcon® M-P

Flamco Flexcon® M-P

Flamco Flexcon® M-P

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

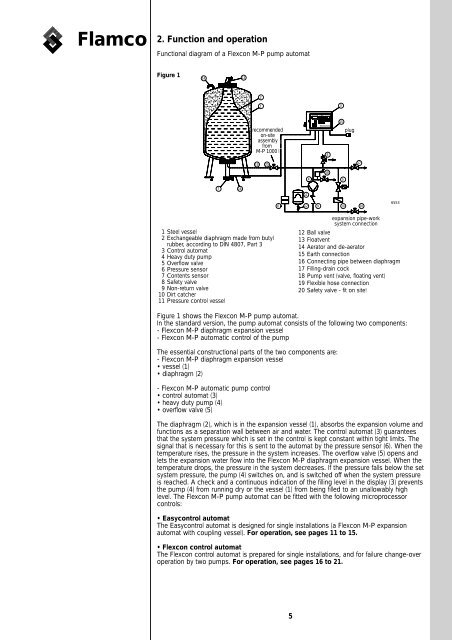

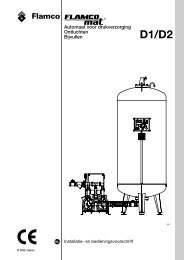

<strong>Flamco</strong>2. Function and operationFunctional diagram of a Flexcon M-P pump automatFigure 114 13213recommendedon-siteassemblyfromM-P 1000 lSteuerautomat815plug19 20171845716116129102065531 Steel vessel2 Exchangeable diaphragm made from butylrubber, according to DIN 4807, Part 33 Control automat4 Heavy duty pump5 Overflow valve6 Pressure sensor7 Contents sensor8 Safety valve9 Non-return valve10 Dirt catcher11 Pressure control vesselexpansion pipe-worksystem connection12 Ball valve13 Floatvent14 Aerator and de-aerator15 Earth connection16 Connecting pipe between diaphragm17 Filling-drain cock18 Pump vent (valve, floating vent)19 Flexible hose connection20 Safety valve - fit on site!Figure 1 shows the Flexcon M-P pump automat.In the standard version, the pump automat consists of the following two components:- Flexcon M-P diaphragm expansion vessel- Flexcon M-P automatic control of the pumpThe essential constructional parts of the two components are:- Flexcon M-P diaphragm expansion vessel• vessel (1)• diaphragm (2)- Flexcon M-P automatic pump control• control automat (3)• heavy duty pump (4)• overflow valve (5)The diaphragm (2), which is in the expansion vessel (1), absorbs the expansion volume andfunctions as a separation wall between air and water. The control automat (3) guaranteesthat the system pressure which is set in the control is kept constant within tight limits. Thesignal that is necessary for this is sent to the automat by the pressure sensor (6). When thetemperature rises, the pressure in the system increases. The overflow valve (5) opens andlets the expansion water flow into the Flexcon M-P diaphragm expansion vessel. When thetemperature drops, the pressure in the system decreases. If the pressure falls below the setsystem pressure, the pump (4) switches on, and is switched off when the system pressureis reached. A check and a continuous indication of the filling level in the display (3) preventsthe pump (4) from running dry or the vessel (1) from being filled to an unallowably highlevel. The Flexcon M-P pump automat can be fitted with the following microprocessorcontrols:• Easycontrol automatThe Easycontrol automat is designed for single installations (a Flexcon M-P expansionautomat with coupling vessel). For operation, see pages 11 to 15.• Flexcon control automatThe Flexcon control automat is prepared for single installations, and for failure change-overoperation by two pumps. For operation, see pages 16 to 21.5