You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

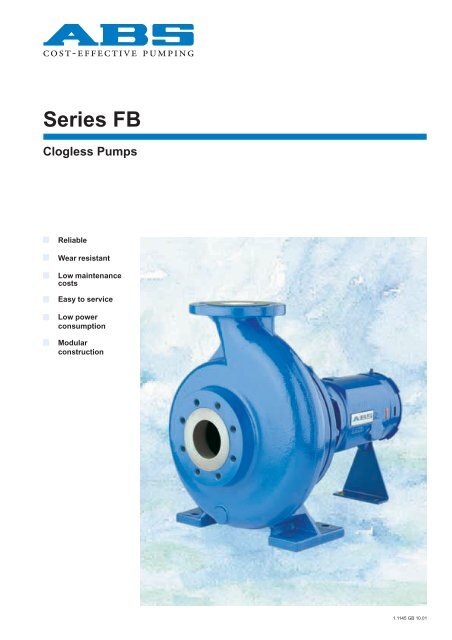

<strong>Series</strong> <strong>FB</strong>Clogless PumpsReliableWear resistantLow maintenancecostsEasy to serviceLow powerconsumptionModularconstruction1.1145 GB 10.01

<strong>Series</strong> <strong>FB</strong><strong>Series</strong> <strong>FB</strong> - a Solid Selection forSolids-carrying LiquidsRange of ApplicationsThe <strong>FB</strong> pump is a solids handling pumpfor all kinds of liquids containing abrasives,large and long contaminants.Typical applications are severely contaminatedwaste paper, sewage,effluent and paper mill rejects.Low EnergyConsumption<strong>Series</strong> <strong>FB</strong> exhibit very high efficienciesfor vortex pumps, due to the specialimpeller vane design. With channelimpellers even higher efficiencies areachieved.Operating ReliabilityThe rigid bearing assembly of thoroughdesign ensures a bearing life exceeding50 000 hours. The sturdy shaft has amaximum deflection of 0.05mm, at theseal, thereby providing the bestpossible working conditions for theshaft seal.Low-cost MaintenanceThe <strong>FB</strong> pumps are incorporated into theABS Modular System TM . Pumps with thesame bearing assembly size havemany spare parts in common.The <strong>FB</strong> Pumpis rigid, reliable and wearresistanthas a large free passagearea and is cloglessis designed according tointernational quality standardhas low maintenance costshas high efficiency givinghigh energy savingsThese <strong>FB</strong> pumps at Stora Enso, Sweden, are pumping the leftovers from paper making. Theliquid contains fibre sludge.CloglessThe spacious pump casing, the wideopenings in the channel impellers andthe even larger passages of the vorteximpellers ensure a clogless pump.Wear ResistantMany applications are highly erosive.The pump casing has generous waIlthicknesses and smooth internal contoursto allow for a long service life.Easy to ServiceThe back-pull out design permits rotorremoval without disturbing the connectingpipework or drive motor. A quick wayof changing shaft seals is to replace theseal cartridge with another cartridgefrom the stock, without even removingthe casing cover. The shaft seal is thenreplaced or reconditioned and thecartridge is stocked. ABS Modularsystem TM means quick and easy service,making down-times short.At the waste water plant in Falkenberg,Sweden, <strong>FB</strong> pumps are handling sewage.

<strong>Series</strong> <strong>FB</strong>DesignPassageThe casings and impellers aredesigned to give maximumfree passage area.Pump CasingCasings have smooth internalcontours and generous walldimensions to give longservice life, when handlingabrasive liquids.Bearing AssemblyThe bearing assembly is a rigiddesign ensuring a long and maintenancefree life of the pump. Asthe shaft has a very limited deflection,max. 0.05mm, the workingconditions for the seal are perfect.ImpellersThe <strong>FB</strong> pumps are equippedwith channel or vorteximpellers.All impellers have backvanes to prevent cloggingbehind the impeller.Quality Standard<strong>FB</strong> pumps are designed toISO 5199 ”Technical Specificationfor Centrifugal pumps Class ll”.Shaft SealingABS PSI TM cartridge for singlemechanical seals is the bestsolution for most applications. OurPump Seal Integration providesperfect conditions for the seal.FlexibilityThe best sealing solutionfor each application:Single or double mechanicalseals or glandpacking.Channel ImpellerOur channel impellers have maximum channel area andcan transport large solids. The high efficiency makes an<strong>FB</strong> pump with a channel impeller suitable also for cleanliquids.Vortex ImpellerThe special advantage of the vortex impeller is its abilityto handle large and long solids. The vortex impeller canalso be installed recessed, as shown, to get an even largerpassage.

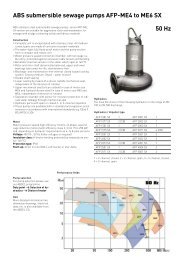

Technical DataFlow 1-1500 m 3 /hHead2-60 mTemperature Max. 190°CPressurePN10/PN16Flanges ISO 7005PN10/16Standard ISO 5199Lubrication Standard: GreaseOption: Oil100m50403020105432132/25-202900 r/min32/25-2050/50-20950 r/min50/50-202950 r/min50/50-2650/50-2080/80-26125/100-38100/100-32150/150-32200/200-38150/150-38200/200-32300/300-381000 rpm1500rpm2 5 10 50 100 500 1000 5000 m 3 /hMaterialsMaterial code 01 03 24Pump casing Grey Cast iron 0120 Grey Cast iron 0120 Duplex Stainl. steel 2324Impeller Grey Cast iron 0120 Duplex Stainl. steel 2324 Duplex Stainl. steel 2324Shaft* Stainless steel 2321 Stainless steel 2321 Stainless steel 2321Shaft sleeve Duplex Stainl. steel 2324 Duplex Stainl. steel 2324 Duplex Stainl. steel 2324*) Protected from pumped liquidABSEquivalent gradesmaterial Germany USA UK France Chemical composition0120 GG20 A48/30B 1452/Gr. 220 Ft 20D Grey Cast iron2321 1.4057 AISI 431 431 S29 Z15 CN16-2 17Cr 2Ni 0.2C2324 1.4460 AISI 329 - - 25Cr 5Ni 1.5Mo 0.10C1 2 5 10 50 100 500 1000 l/sBall Passages for Impeller TypesPump Ball passage in mmtype Vortex Recessed Two-ch.impeller vortex imp. impeller<strong>FB</strong> 32/25-20 20 - -<strong>FB</strong> 50/50-20 - 50 -<strong>FB</strong> 50/50-26 - 50 -<strong>FB</strong> 80/80-26 - 80 -<strong>FB</strong> 100/100-32 65 100 72<strong>FB</strong> 150/150-32 75 130 80<strong>FB</strong> 200/200-32 85 140 80<strong>FB</strong> 125/100-38 60 - 78<strong>FB</strong> 150/150-38 78 - 80<strong>FB</strong> 200/200-38 - - 90<strong>FB</strong> 300/300-38 - - 92**) Three-channel impellerDimensionsPump Bear.Assy. DN1 DN2 h1 h2 g f B2* L1* z* Weight**type size max. max. max. kggDN2f<strong>FB</strong> 32/25-20 1 32 25 160 200 65 390 500 1120 150 55DN1<strong>FB</strong> 50/50-20 2 50 50 180 225 78 550 630 1560 210 85<strong>FB</strong> 50/50-26 50 50 200 250 78 550 630 1560 245 100<strong>FB</strong> 80/80-26 80 80 225 280 98 565 630 1560 235 110<strong>FB</strong> 100/100-32 3 100 100 315 355 130 565 880 1970 295 150<strong>FB</strong> 150/150-32 150 150 315 360 120 580 880 1970 295 205<strong>FB</strong> 200/200-32 200 200 315 410 140 595 880 1970 295 220<strong>FB</strong> 125/100-38 125 100 315 400 130 573 880 1970 295 210<strong>FB</strong> 150/150-38 150 150 315 400 120 579 880 1970 295 230<strong>FB</strong> 200/200-38 200 200 315 440 140 598 880 1970 295 240<strong>FB</strong> 300/300-38 300 300 450 580 171 612 880 1970 295 310*) Varies with motor size and baseplate material **) Pump onlyB2 maxL1 maxh2h1zBaseplate of steel.Alt. baseplate ofconcrete.ABS reserves the right to alter specifications due to technical developments.AustriaTel. +43 2236 642 61Fax +43 2236 642 66BelgiumTel. +32 2 725 79 00Fax +32 2 725 71 19BrazilTel. +55 41 227 81 00Fax +55 41 348 18 79CanadaTel. +1 905 670 4677Fax +1 905 670 3709ChinaTel. +86 21 5234 0472Fax +86 21 5234 1179DenmarkTel. +45 48 17 11 10Fax +45 48 17 19 114EstoniaTel. +372 656 3398Fax +372 656 3385FinlandTel. +358 9 506 88 90Fax +358 9 55 80 53FranceTel. +33 1 49 35 24 50Fax +33 1 48 54 42 82GermanyTel. +49 62 57 9317 0Fax +49 62 57 9317 99Tel. +49 2246 13 0Fax +49 2246 13 200Great BritainTel. +44 1293 744 800Fax +44 1293 543 392GreeceTel. +30 10 95 325 01/02/03Fax +30 10 95 325 04HungaryTel. +36 1 231 60 70Fax +36 1 231 60 80IrelandTel. +353 1 460 88 88Fax +353 1 460 88 89ItalyTel. +39 051 89 00 911Fax +39 051 86 18 48NetherlandsTel. +31 30 242 56 78Fax +31 30 241 03 46NorwayTel. +47 67 554 700Fax +47 67 554 750PolandTel. +48 22 633 82 87Fax +48 22 633 86 44PortugalTel. +351 21 495 01 57Fax +351 21 495 53 64SingaporeTel. +65 4633 933Fax +65 4622 122South AfricaTel. +27 11 397 1612Fax +27 11 397 1795FOR COST-EFFECTIVETel. +34 91 670 28 51PUMPINGTel. +46 31 83 63 00SpainFax +34 91 666 58 68SwedenTel. +46 31 706 16 00Fax +46 31 27 29 20SwitzerlandTel. +41 71 694 6555Fax +41 71 694 6556TurkeyTel. +90 216 455 2256Fax +90 216 455 2265USATel. +1 203 238 2700Fax +1 203 238 0738All other countriesABS Pumps InternationalHead Office, SwedenFax +46 31 16 79 14Agents and distributorsABS has sales and servicerepresentation in more than100 countries the world over.www.abspumps.comABS is a company in theCardo Group