ST96-32.09 - Tasseron

ST96-32.09 - Tasseron

ST96-32.09 - Tasseron

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

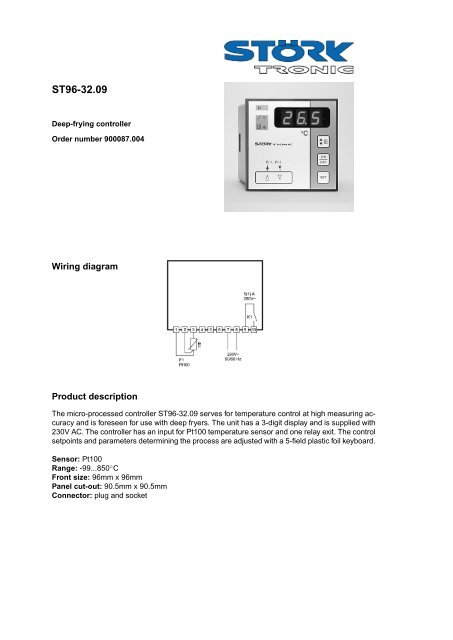

<strong>ST96</strong>-<strong>32.09</strong>Deep-frying controllerOrder number 900087.004Wiring diagramProduct descriptionThe micro-processed controller <strong>ST96</strong>-<strong>32.09</strong> serves for temperature control at high measuring accuracyand is foreseen for use with deep fryers. The unit has a 3-digit display and is supplied with230V AC. The controller has an input for Pt100 temperature sensor and one relay exit. The controlsetpoints and parameters determining the process are adjusted with a 5-field plastic foil keyboard.Sensor: Pt100Range: -99...850 ◦ CFront size: 96mm x 96mmPanel cut-out: 90.5mm x 90.5mmConnector: plug and socket

SOFTWARE .09Features of controllerThe controller features a temperature control circuit. The sensor input measures the temperature ofthe deep fryer, the relay output controls the heating. The temperature is displayed on a three-digitdisplay. The LEDs indicate the switching state and control status.The controller features a control unit with PID characteristic. Four sets of parameters, each with aP-term, I-term, D-term and a cycle time, can be set up separately, and can be pre-selected oractivated as programs. The upper button quickly changes over to maximum heating power afterthe heat-up phase and is referred to as the "turbo button". The controller also features specificalarm messages on the time the fat operating time indicating that the fat has to be replaced andfinally disabling the controller. For heating types starting after a delay, a switch-off delay isimplemented for the switching output.OperationCommissioning the controllerWhen mains supply is turned on, the controller will always be off, i.e. in standby mode (OFF isdisplayed). To turn the controller on/off, press the "ON/OFF" button for approx. 2 seconds. Thedelay ensures that the controller is not switched on or off unintentionally.Heating with cold fatWhen the controller is turned on while the fat is cold, slow heating will always be active to ensuregentle heating of the solid fat. To activate quick heating, press the turbo button. Press the buttonagain to return to slow heating mode. This button must also be pressed for approx. 2 seconds toprevent unintentional switching.Heating with hot fatWhen the fat is already hot when mains supply is turned on and the controller is turned on bypressing the "ON/OFF" button, the control behavior which will be activated depends on the fattemperature. The clock end defined via parameter "P7" is used as the limit value.If the temperature is below this limit when the controller is turned on, slow heating will start basedon the clock times defined in parameters "P1" and "P2", after that "Pr.1" will always be activated. Ifthe temperature is above this limit, "Pr.1" will be active immediately. If "Pr.2...Pr.4" are requiredinstead, the relevant program must always be activated manually after the slow heating phase.Activated program after "ON/OFF"If the controller is switched off, after commissioning, for a short time via the "ON/OFF" button, slowheating mode will only be active if the temperature is below the limit defined in "P7" if it wasalready active before the controller was switched off. However, "Pr.1" will be activated in any case,i.e. "Pr.1" will always be active without a slow heating phase as well as above the defined limit.Programs "Pr.2...Pr.4" must always be activated manually after "ON/OFF". Below the limit value,this is only possible if the limit value was already reached before. Returning from "Pr.1" to slowheating is possible only if the limit value has not been reached before. Above the limit value,programs "Pr.1...Pr.4" can be activated as required after "ON/OFF".

cannot be changed, however. The warning message and control blocking must be acknowledgedby a "Reset". This reset is only possible if the fat which must be replaced has cooled down to atemperature below 100 °C.Deleting the internal fat operating time and alarm resetPress buttons "SET" and "ON/OFF" simultaneously for approx. 10 seconds to reset the internallyregistered hot fat operating time to zero. At the same time, this will delete the fat warning messageand enable control again. The fat must be replaced. With the controller turned on, the reset ispossible in all control levels, provided that the actual value is below 100 °C. The display will read"rES" for approx. 10 seconds. When control is blocked, the controller will return to reference valuelevel in any case and "Pr.2...Pr.4" will be deactivated; after the reset, slow heating will be activebelow the limit value defined in "P7", above this temperature, "Pr.1" will be active.Switch-off delay for gas heating designFor use with heating types which start after a delay due to their design, a switch-off delay can bedefined for the output relay via parameter "P24". In this case, the switching output will be switchedoff after the defined delay. Since this delay is independent of the PID control, the value to bedefined must be considered carefully. Otherwise, there might be uninterrupted heating instead ofthe typical heating pulses. The switch-off delay is not active in the slow heating phase.The control function of the deep fryer controller is explained in the following and will always bevalid while the controller is started.

Heating phase after significant cooling (refer to Figure 3):After significant cooling to temperatures below 50 °C, e.g. loading of large quantities of cold fat, theslow heating function is activated again. The heating relay clocks again like in the initial heatingphase, until the setpoint or the clock end below the setpoint defined in parameter "P7" is reachedagain. This is to ensure gentle heating of the reloaded fat.SetpointHeating phaseafter significant coolingFigure 3Control after heatingAfter the heating phase, the controller works with the PID function based on parameter group"Pr1.". The programs “Pr.2 ... Pr.4” must be activated manually.Heating phase with manual interventionHeating phase after activation (refer to Figure 4):After activation and start, the slow heating phase will start without manual intervention. By pressingthe quick heating button, you can switch over to the normal heating function. Now, the fat will beheated more quickly. The heating relay will no longer clock based on the times set in parameters"P1" and "P2" but based on the PID function set within program “Pr.1”. The clock end defined viaparameter "P7" does not have any influence after the manual intervention.To undo the change-over, press the MELT/TURBO button again. Now, the heating relay will clocklike before the manual change-over again.The manual change-over function can be used for reducing the heating phase if the fat has meltedvisibly and can be heated at a higher rate without any damage. Manual change-over between slowheating and “Pr.1” is possible only if the controller actually is in the heating phase, i.e. below thethreshold set via parameter "P7". Above this threshold, the turbo button switches from program“Pr.1” (or 2,3) to “Pr.4” and back again.

SetpointHeating phase afterwith manual change-overFigure 4Heating phase after significant cooling (refer to Figure 3, top):After significant cooling to temperatures below 50 °C, e.g. loading of large quantities of cold fat, aslow heating phase will start, although the change-over to normal heating mode is effected earlier;the heating relay clocks like in the initial heating phase.Thus, manual change-over to normal heating function is only effective for the current heatingphase and will become ineffective as soon as the setpoint is reached, at the latest. After that, aswell as after mains failure and restart, the controller is in normal operation mode with slow heatingphase when the controller is switched on and started or restarted later or in the case of cool-downto temperatures below 50 °C. The switch-back threshold is can be set via parameter "P79".First control level:Setting the main reference values and reference value setbackThe main reference value can be viewed by pressing the SET button. Press UP or DOWN keyadditionally to change the set value.Please note that the set value is saved permanently as soon as the buttons are released. Thevalue will even be maintained in case of power failure. This applies to the reference value and allcontrol parameters.Para- Description of function Setting range StandardmetersettingS1 Setpoint 1 P4...P5 60.0 °CCustomersetting

Second control level (P parameters):Setting of control parametersPress UP and DOWN keys simultaneously for at least 4 seconds to access a control parameter list(starting with P1).Use the UP and DOWN key to scroll through the list.If you press the SET key, the value of the corresponding parameter is displayed. Press UP orDOWN key additionally to change the value. As soon as you release all keys, the new value issaved permanently.If you press the UP and Down button simultaneously or if you don't press a button for more than 60seconds, the system will return from parameter level to the initial state.ParameterDescription of function Setting range StandardsettingP1 On time of heating clocking 1...300 sec. 60 sec.P2 Off time of heating clocking 1...300 sec. 60 sec.P3 Hysteresis K1 (only if A1=0) 0.1...99.0 K 0.8 KP4 Lower setpoint limit 60.0...999 °C 60.0 °CP5 Upper setpoint limit 60.0...999 °C 190 °CP6 Actual value correction -10...10.0 K 0.0 KP7 Clock end below threshold -99...0.0 K -30 KP8 Proportional term ("Pr.1") 0.1...99.0 K 5.0 KP9 I-term ("Pr.1") 0...15 12P10 D-term ("Pr.1") 0...15 15P11 Cycle time ("Pr.1") 8...100 sec. 12 sec.P12 Proportional term ("Pr.2") 0.1...99.0 K 5.0 KP13 I-term ("Pr.2") 0...15 12P14 D-term ("Pr.2") 0...15 10P15 Cycle time ("Pr.2") 8...100 sec. 12 sec.P16 Proportional term ("Pr.3") 0.1...99.0 K 5.0 KP17 I-term ("Pr.3") 0...15 12P18 D-term ("Pr.3") 0...15 6P19 Cycle time ("Pr.3") 8...100 sec. 12 sec.P20 Proportional term ("Pr.4") 0.1...99.0 K 0.1 KP21 I-term ("Pr.4") 0...15 0P22 D-term ("Pr.4") 0...15 0P23 Cycle time ("Pr.4") 8...100 sec. 8 sec.P24 Switch-off delay for output 0.0...99.0 sec. 6.0 sec.relayP25 Temperature limit for fat 60.0...999 °C 160 °Coperating time registrationP26 Fat operating time until 1..99 hrs. 30 hrs.warning messageP27 Fat operating time until 1..99 hrs. 40 hrs.controller blockedP28 Display of fat operating time (not applicable) (notapplicable)Customersetting

Third control level (A parameters):Setting of control parametersTo access the third control level, enter the second level first and scroll through the parameter listuntil you reach the highest parameter. Then, click the UP button for at least 10 seconds. Themessage "PA" will be displayed.Then, press UP and DOWN buttons simultaneously for at least 4 seconds to access the parameterlist of the third control level (starting with A1).Selection and setting of the A parameters is done in the same way as in the case of the Pparameters. Returning to the initial state is also done in the same way.ParameterDescription of function Setting range StandardsettingA1 Control characteristic in "Pr.4" 0: Thermostat1: PID characteristic 1CustomersettingA2Activation of fat warningmessage0: not active1: active0A3 Activation of control blocking 0: not active1: active0Description of parameters:The following values affect the properties of the appliance andany changes should be considered carefully for this reason:A1: Control characteristic in turbo program "Pr.4"Here, you can define the control characteristic to be used while program "Pr.4" is active. You canchoose between thermostat behavior and PID characteristic based on parameter group "P20-P23".The control philosophy of the controller is such that "Pr.4" has the highest heating power.A2: Activation of fat warning messageHere, you can define if control is to be blocked when the hot fat time set in parameter "P26" haselapsed.A3: Activation of control blockingHere, you can define if control is to be blocked when the hot fat time set in parameter "P27" haselapsed.Important note:Any modifications by the customer at this control level is not permissible and can result indangerous functional changes.Status messagesMessage Cause RemedyF1Sensor error (sensor F1 broken or short check sensorcircuit)EP Data loss in parameter memory Repair of controller

Technical data of <strong>ST96</strong>-<strong>32.09</strong>Measuring inputF1: Resistance thermometer Pt100-3LMeasuring range: -80...850°CMeasuring accuracy: +/- 0.5KOutputsK1: Relay, normally-open contact, 5(1)A 250VDisplayTwo 3-digit LED displays, 13 und 10 mm height, colour red3 LEDs, diameter 3mm, for status displayPower supply230V 50/60HzConnectorsplug and socketAmbient conditions:Storage temperature:Operating temperature:Relative humidity:-20...+70°C0...+55°Cmax. 75% without dewEnclosureFront IP50Installation dataFront size:Panel cut-out:Installation depth:Mounting:96 x 96 mm90.5 x 90.5 mmca. 105 mm with connectorby fixing strapOrder No.: 900087.004