You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

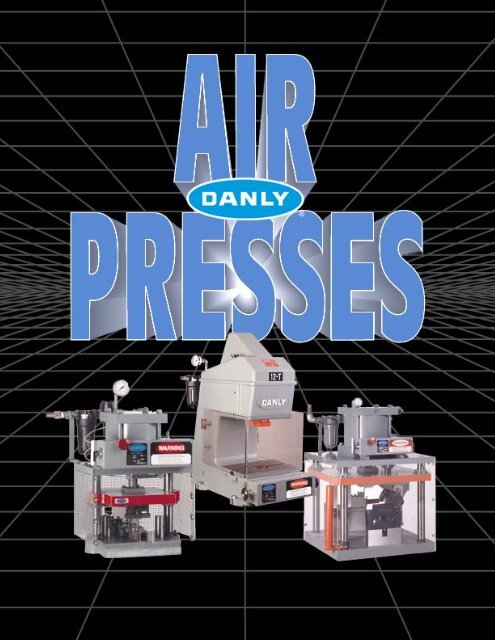

ECONOMICAL DIE STAMPINGDanly <strong>Air</strong> <strong>Press</strong>es are designed for die production runsin piercing, forming, cutting, trimming <strong>and</strong> coining applications,<strong>and</strong> secondary operations. Although small,these full-featured stamping presses are made to theFeatures■ Entirely air powered. No electrical connection required.■ <strong>Air</strong> logic control. Two-h<strong>and</strong> non-tie down singlestroke. Two h<strong>and</strong> non-tie down single strokereversing. Continuous running.■ No air line lubrication required.■ Two post presses with 1/4 to 2 ton capacity,5 1 /4" x 4 3 /4" to 9 3 /4" x 10 1 /2" die area.■ Four post presses with 3 ton capacity, 16" x 16"die area, <strong>and</strong> 5 ton capacity, 19" x 19" die area.■ Die space protected with barrier guards.■ Spring actuated safety blocks provided on fourpost presses.■ Cushioned air cylinders (head end only).■ Barrier guards interlocked with press control ontwo post presses.■ Top plate power unit can be usedinterchangeably with die sets of same sizes.Danly <strong>Air</strong> <strong>Press</strong>es <strong>and</strong> <strong>Air</strong> Toggle <strong>Press</strong>es are built to thesame rigid st<strong>and</strong>ards of Danly Precision Die Sets <strong>and</strong> providethe same dependable service. They perform precision pressoperations at high production speeds with consistent accuracy.This means trouble-free operation for the user, longer dielife, better parts <strong>and</strong> more profitable production runs.With a wide range of sizes, capacities, controls <strong>and</strong> otheroperating features, Danly <strong>Air</strong> <strong>Press</strong>es offer a virtually customtailoredunit, exactly suited to your specific needs.Danly Two Post <strong>Air</strong> <strong>Press</strong>es have capacities of 1 ⁄4, 1 ⁄2, 3 ⁄4,1<strong>and</strong> 2 tons. Four Post <strong>Press</strong>es have 3 <strong>and</strong> 5 ton capacities.<strong>Air</strong> Toggle <strong>Press</strong>es have capacities of 7, 9,10, <strong>and</strong> 12 tons <strong>and</strong>all are available with a choice of controls.Control reliability of Danly <strong>Air</strong> <strong>Press</strong>es is assured by theuse of an air logic control. Along with this control, chosen forits proven dependability, Danly <strong>Air</strong> <strong>Press</strong>es are also equippedwith an air cylinder <strong>and</strong> operating valve carefully selected toprovide long, dependable service without the use of an airline lubricator.Operation without an air line lubricator minimizes air pollutionthat results from oil-bearing exhaust air during pressoperation. Noise level is controlled on Danly <strong>Air</strong> <strong>Press</strong>es bymufflers fitted on the exhaust ports of operating valves.All Danly <strong>Air</strong> <strong>Press</strong>es are shipped fully assembled, includingbarrier guard, an air filter, <strong>and</strong> air regulator. Onlysame high st<strong>and</strong>ards as all Danly products. They areengineered to provide repeatable, consistent accuracy<strong>and</strong> years of trouble-free operation.connection to an air line of sufficient capacity is required tobegin press operation in your plant.Barrier guards on the Two Post <strong>Air</strong> <strong>Press</strong>es must be inposition or the control is rendered inoperative by the interlockingswitches. Spring loaded safety blocks on the FourPost <strong>Press</strong>es are restrained by the barrier guards from enteringthe die space. Both barrier guards must be in position tohold back the safety blocks.For feeding or removing parts from the press, it is necessaryto slot the barrier guards. The Service Manual furnishedwith the press gives instructions for safe operation <strong>and</strong> propermaintenance. Everyone connected with maintaining,operating, tooling, etc. should read <strong>and</strong> underst<strong>and</strong> thoseinstructions.St<strong>and</strong>ard stroke cylinders, control circuits <strong>and</strong> press componentsare carried in stock to provide delivery of thecomplete air press within two to three weeks.Optional specifications such as special stroke or shutheight; special valves, circuits <strong>and</strong> air cylinders; ability tooperate in unusual surroundings are quoted on request, <strong>and</strong>delivery depends on complexity. In addition, special machiningcan be performed to customer specifications.Typical OptionalSpecifications AvailableDie Set■ Special die areas.■ Additional machining suchas die pockets, mountingholes, etc.■ Special strokes or openheights.Operating Conditions<strong>Air</strong> pressure:50 to 125 PSI gageTemperature range:35 to 130˚ F.Up to 180strokes per minute.Special air filters.Control Circuit■ Time delay.■ Speed control.■ Part positioning.■ Cycle counter.■ Unusual operatingconditions.■ Ergonomic light touchbuttons.■ Combination circuits.■ Dwell timer.■ <strong>Press</strong> st<strong>and</strong>s.<strong>Air</strong> Cylinder■ Rod end cushions.2

AIR PRESS STANDARD CONTROL CIRCUITSOPERATIONType ofControlCircuitApply 2 h<strong>and</strong>s to runbuttons <strong>and</strong> holdApply 2 h<strong>and</strong>s to runbuttons, to startmotion down thenremove one or bothh<strong>and</strong>sApply 2 h<strong>and</strong>s to runbuttons, hold untilbottom, remove oneor both h<strong>and</strong>sApply 1 h<strong>and</strong> toeither button <strong>and</strong>holdApply 1 h<strong>and</strong> toeither button with theother button tieddownASingle StrokeTwo-H<strong>and</strong>Non-Tie DownPlaten moves tobottom of stroke,applies pressure,<strong>and</strong> holds on bottomuntil buttons arereleasedStops in downwardmotion, returns to top<strong>and</strong> stopsApplies pressure,returns to top ofstroke <strong>and</strong> stopsInoperativeInoperativeBSingle StrokeTwo-H<strong>and</strong>Non-Tie Down<strong>Press</strong>ureReversalPlaten moves tobottom of stroke,applies pressure,returns to top ofstroke <strong>and</strong> stopsStops in downwardmotion, returns to top<strong>and</strong> stopsApplies pressure,returns to top ofstroke <strong>and</strong> stopsInoperativeInoperativeCContinuous“Start–Stop” Dual Selector Switches. Both switches are spring centered <strong>and</strong> must be moved to “Start” to operate the press. Whenpress begins to operate, both switches can be released <strong>and</strong> they will return to the centered position. In operation, the platen willmove to the bottom of the stroke, apply pressure <strong>and</strong> return to the top. This operating cycle will be repeated continuously. Movingeither selector switch to “Stop” stops the downward motion of the platen <strong>and</strong> returns the platen to the top of the stroke. A frontpositionedEmergency Stop Push Button will also stop the motion of the platen <strong>and</strong> return it to the top of the stroke. In the eventof loss of the air supply while the press in in operation, the press will stop operating <strong>and</strong> the platen will fall to the bottom of thestroke. When the air supply returns, air pressure acting on the underside of the cylinder piston will move the platen to the top ofthe stroke <strong>and</strong> stop. The press must be restarted for it to continue operation.NOTE: Control circuits A <strong>and</strong> B are anti-repeat, meaning that each button must be released <strong>and</strong> again depressed at substantially the same time inorder to initiate another stroke.Ordering InformationWhen ordering two post or four post air presses, it is necessaryto specify: (1) Tonnage, (2) Die Set Size, (3) Stroke, (4)Open Height, (5) Control Circuit. When ordering toggle presses,just specify tonnage <strong>and</strong> control circuit. Regulator <strong>and</strong> filterSafetyAll two post presses are equipped with a clear plastic frontbarrier guard <strong>and</strong> a one-piece perforated metal barrierguard covering the sides <strong>and</strong> rear of the press. The presswill only operate when the guards are in place <strong>and</strong> will stop<strong>and</strong> return to the top position of the stroke if a guard isremoved while the press is running.Four post air presses have a clear plastic guard on allfour sides of the press. They are also equipped with safetyblocks that swing in if the guards are removed.<strong>Air</strong> Toggle <strong>Press</strong>es are equipped with a clear plasticguard <strong>and</strong> will only operate if the guards are in place. Thepress will stop <strong>and</strong> return to the top position of the stroke ifthe guard is removed while the press is running.For maximum safety, keep the slots in the guards justlarge enough to accommodate the stock being fed into theare supplied as st<strong>and</strong>ard equipment. Quotation will be given fordie area mounting holes, machined pockets, special strokes,special control circuits <strong>and</strong> other options upon request. Typicalavailable options are listed on page 2.press. Extra barrier guards are available which can be cutas needed to provide access holes to suit a particular partsize or the size of stock being used.An air filter <strong>and</strong> regulator unit is st<strong>and</strong>ard equipment onair presses to provide operation with clean air <strong>and</strong> minimummoisture content. The air filter unit functionsautomatically <strong>and</strong> keeps the press operating at maximumefficiency. Do not use an air line lubricator in any air line onthese presses. The st<strong>and</strong>ard filter equipment on the presswill remove detrimental particulate matter, includingdroplets of oil <strong>and</strong> water, down to 10 microns, from normalshop air lines. However, a coalescing type filter may berequired, as optional equipment, if the supply air is particularlyoily or wet.3

<strong>DANLY</strong> TWO POST AIR PRESSESTwo post air presses consist of a Danly Precision Die Setoperated by an air cylinder <strong>and</strong> controlled by the circuitsshown on page 3. All presses are equipped with a logic control,circuit, operating valve, air filter-regulator combination withair pressure gauge. They are available in 1 ⁄4, 1 ⁄2, 3 ⁄4, 1 <strong>and</strong> 2 toncapacities <strong>and</strong> have die areas from 5 1 ⁄4" x 4 3 ⁄4" to 9 3 ⁄4" x 10 1 ⁄2".Head end cushion is st<strong>and</strong>ard on all air cylinders.<strong>Press</strong>Tons1⁄41⁄23⁄412Continuous Run Circuit Strokes Per MinuteMin.SizeSupplyPipe1⁄21⁄21⁄23⁄43⁄4<strong>Press</strong>Stroke33333St<strong>and</strong>ardCubicFeet Of<strong>Air</strong>31.332.138.054.670.3StrokesPerMinute180120909065Regulator<strong>Air</strong><strong>Press</strong>ureSetting8080808080The speeds shown above are based on a 3" stroke <strong>and</strong>will vary in approximate inverse proportion with the strokelength up to a maximum of approximately twice the strokingrate shown. For example, if a 3/4 ton press is used with a 2"stroke cylinder, the speed would go up to about 135 SPM.Certain control, piping <strong>and</strong>/or valving changes are possiblefor higher stroking rates than shown in chart. Althoughthe speed of the punch holder during the stroke cannot beadjusted, flow control valves can be added at the cylinderports as optional equipment. Punch holder speed, both up<strong>and</strong> down, can then be adjusted to suit. Timers can also beadded to hold the punch holder down <strong>and</strong>/or up asdesired. Inquiries relative to these special stroking conditionsor special die spaces <strong>and</strong> special machining can bequoted upon request.Approximate <strong>Air</strong> Volume Required at 80 PSITo find the st<strong>and</strong>ard cubic feet of free air per minute, usethe following formula:SCFM = “K” x SPM x Strokewhere SCFM = St<strong>and</strong>ard cubic feet of free airrequired per minuteK = Constant for a given size air cylinderSPM = Strokes per minuteStroke = Cylinder stroke (inches)1⁄40.058“K” Volume Constant1⁄20.089TonnageExample: 1 ⁄2 ton unit 25 SPM 2” strokeSCFM = K x 25 x 2= .089 x 25 x 2 = 4.5For other air pressures, multiply “K” by the ratio (air pressureused + 15) ÷ 95.3⁄40.14110.20320.366FILTERREGULATORTFSTROKEGAIR LOGICCONTROLSELECTORSWITCHGUARDLA18P O9KNDASEC. A-AMBREJCAPACITY–TONS @ PSI1⁄4@60PSI1⁄2@80PSI3⁄4@77PSI1@71PSI2@80PSIDanlyDieSetTwo Post <strong>Press</strong> Dimension DataTHICKNESSOverall N*TopDie SpacePostG*D**To Clear Die PunchSize Of OpenL**PlateDiametersStrokeOverallHldr.Die Set HeightF T SizeHldr.A B J K O P M R Std. Max. Std. Max. Std. Max. Std. Max.C E0604 5 1 ⁄4 4 3 ⁄40607 5 1 ⁄4 7 1 ⁄20808 7 3 ⁄4 81010 9 3 ⁄4 10 1 ⁄210 5 ⁄8 6 5 ⁄81 1 ⁄2 1 1 ⁄21 1 1 ⁄4 10 5 ⁄8 9 3 ⁄85 1 ⁄2 12 1 ⁄2 3 10 10 1 ⁄4 17 1 ⁄413 101 1 ⁄4 1 1 ⁄2 15 5 ⁄8 12 1 ⁄419 1 ⁄2 33 1 ⁄2 6 1 ⁄2 8 1 ⁄4 12 1 ⁄2 7 1 ⁄420 34 7 9 12 1 ⁄2 920 1 ⁄2 34 1 ⁄2 7 1 ⁄2 11 3 ⁄4 14 920 1 ⁄2 34 1 ⁄2 8 12 3 ⁄4 16 1 ⁄2 11 1 ⁄2White boxes indicate presses available* Stroke lengths <strong>and</strong> open heights available in increments of 1".** For 2 ton press, add 1" to “L” <strong>and</strong> “D” dimensions.4

<strong>DANLY</strong> FOUR POST AIR PRESSESDanly Four Post <strong>Air</strong> <strong>Press</strong>es offer all the basic advantages oftwo post presses, but are made for operations requiringheavier tonnage, plus the additional stability of four post construction.Four post presses are made in capacities of 3 tonswith 16" square die area <strong>and</strong> 5 tons with 19" square die area.They are operated by heavy duty industrial quality pneumaticcontrol valves <strong>and</strong> are available with the control circuitsshown in the chart on page 3. Custom controls <strong>and</strong> otheroptional specifications similar to the options listed on page 2will be quoted upon request, with delivery depending oncomplexity.Nominal<strong>Press</strong>Maximum Speed For Various StrokeLengths - SPMCapacityTon & PSI 4" Stroke 6" Stroke 8" Stroke 10" Stroke3 @ 80 33 29 25 205 @ 802522Above speeds are based on 1" supply line <strong>and</strong> 80 psi supplypressure. Although the speed of the punch holder duringthe stroke cannot be adjusted, flow control valves can beadded at the cylinder ports as optional equipment. Punch2016holder speed, both up <strong>and</strong> down, can then be adjusted tosuit. Timers can also be added to hold the punch holderdown <strong>and</strong>/or up as desired. Inquiries relative to these specialstroking conditions, as well as other options such as specialdie space <strong>and</strong> special machining, will be quoted on request.Approximate <strong>Air</strong> Volume Required at 80 PSITo find the st<strong>and</strong>ard cubic feet per minute, use the followingformula:SCFM = “K” x SPM x StrokeWhere SCFM = St<strong>and</strong>ard cubic feet of free airrequired per minuteK = Constant for a given tonnageSPM = Strokes per minuteStroke = Cylinder stroke (inches)<strong>Press</strong> Tonnage 3 5“K” Volume/Constant .562 .820Example: 3 ton unit –15 SPM – 4" strokeSCFM = “K” x 15 x 4= .562 x 15 x 4SCFM = 33.8AIR LOGIC CONTROLRUN BUTTONGUARDGMANKRBHEJ<strong>Press</strong> CapacityIn Tons3 @ 77PSI5 @ 89PSISt<strong>and</strong>ard Die SpaceTo ClearLeft To RightFront ToBackFour Post <strong>Air</strong> <strong>Press</strong> DimensionsDieHolderJThicknessPunchHolderKSt<strong>and</strong>ard OverallDie Set SizeLeft To Right Front ToBackOpenHeightStrokeOverallBaseHeightA BM R N G H E4 (Std) 325 3316 16 2 1 1 ⁄2 23 23 105 3 ⁄46 347 355 (Std) 356 3619 19 2 1 ⁄2 1 3 ⁄4 26 26 117 378 386 1 ⁄45

AIR TOGGLE PRESSESDanly <strong>Air</strong> Toggle <strong>Press</strong>es are designed for high-tonnage productionof metal <strong>and</strong> plastic parts involving piercing, forming,cutting, trimming, embossing, riveting, coining <strong>and</strong> assemblyoperations. They provide compact, reliable operation in 7 to12 ton capacities with shutheight allowances ranging from6 5 ⁄8" to 8 1 ⁄2". Yet, this power is generated through conventionalshop air.Danly’s unique air toggle design multiplies shop air pressuremany times to provide tonnage comparable to smallhydraulic or mechanical presses costing much more. A convenienth<strong>and</strong> wheel lets you adjust the slide throughout the fullrange of the stroke, permitting selection of the shortest <strong>and</strong>safest stroke length, while maintaining high production rates.The rugged construction, dependable operation <strong>and</strong> reliablesafety features of Danly <strong>Air</strong> Toggle presses make themvery competitive with small hydraulic or mechanical presses<strong>and</strong> at a much lower operating cost.Danly’s experienced staff is ready to provide any technicalassistance you may need in selecting the air press or air togglepress that is right for your application. Each is backed bymore than 75 years of leadership in the metalforming industry.SLIDE ADJ.SCREWCOVERREMOVALSCREWS35 1 /4512 7 /817 7 /89 1 /48 5 /16STROKE ADJ.HAND WHEEL7 7TOP OFMTG. TABLE2 1 /4 149x54 1 2/25 3 /4311 11 /16 DIA. X 2 DEEP143 93 1 /249 1 /16 DIA. (2) HOLES<strong>Air</strong> Toggle <strong>Press</strong> SpecificationsModelCapacity —Tons 1/32 up @ 80 PSI***7 T79 T910 T1012 T12Stroke Range — Inches1⁄4 - 3 1 ⁄43⁄16 - 2 1 ⁄21⁄8 - 1 7 ⁄81⁄16 - 1 1 ⁄2Shutheight-Top of bed to bottom of slideStrokedown adjustment up — InchesRam Adjustment — Inches6 - 5 ⁄8Approximate Weight — Lbs. 72017 - 3 ⁄817 - 3 ⁄418 - 1 ⁄21* Note: All models require clearance in table top for stroke adjusting screw extension.** Note: Optional opening in table top for scrap or part drop thru.*** Note: <strong>Press</strong> capacity will change in relation to slide position above bottom of stroke.6

<strong>Air</strong> Consumption for Various Stroke LengthsStrokeAdjustment% FullStroke7TActual Stroke UsedInches9T10T12TSCFMPerStrokeApprox.ContinuousStrokingRate PerMin.SCFM @ContinuousStrokingRate253⁄165⁄81⁄23⁄80.579051501- 5 ⁄81- 1 ⁄415⁄163⁄40.807560752 - 7 ⁄161- 7 ⁄81- 7 ⁄161- 1 ⁄80.976563Full Stroke3 - 1 ⁄42 - 1 ⁄21- 7 ⁄81- 1 ⁄21.16066*Note: Total <strong>Air</strong> Consumption, st<strong>and</strong>ard cubic feet per minute from an 80 psi supply, (SCFM)equals value from chart multiplied by number of strokes per minute. Continuous stroking ratesshown depend upon the quantity of air supplied to the press. Small <strong>and</strong>/or long connection linesbetween the press <strong>and</strong> plant air supply should be avoided.<strong>Press</strong> Capacity at Various Distancesfrom BottomSlide PositionAbove Bottom ofStroke – Inches0.0300.0620.1250.2500.500Approximate Capacity –Tons @ 80 PSI7T*7.09T*9.010T*10.012T*12.04.93.52.71.86.54.73.42.57.35.03.92.88.66.24.53.30.7501.62.12.3–1.0001.41.8––1.2501.21.6––1.5001.1–––*Note: Valve shown is a maximum tonnage <strong>and</strong> should not be exceededin any coining or bottoming operation.7

<strong>DANLY</strong> IEM6779 Engle Road, Suite AClevel<strong>and</strong>, OH 44130www.danly.comCALL TOLL FREE1-800-243-2659FAX 1-800-833-2659DS 106 5/98 10M HB© 1998 Danly Die Set.A Division of Connell Limited Partnership.All Rights Reserved.