Testing instructions for IRAVB-2 dual brake system fitted ... - eLocoS

Testing instructions for IRAVB-2 dual brake system fitted ... - eLocoS

Testing instructions for IRAVB-2 dual brake system fitted ... - eLocoS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7.1 With cine corinrassor started cjn .! tuton~ticl "not2 the tind to rai,y the ].lain raservcjir .prassurt. to 10 k,;/'cw with one conpresscrroperatin,: at a tlme.L'i~nd taken t o build upnraswr. to 10 k.:/cn2 should Sa within I P -&-++,.. This tast; shculd bgrepeated with othdr two ccm~rcssors alsc.I7.3 IJ~itd Lhl? t1n. t?k12n fclr charc:in; th3 systsr.1- 4from ~.5k~/c13 tcb 10 kq/cr?, (i.2. bLw2.n cut-in ..and cut-c) lt ~rzssures).It shmld be ahcut' 21a *'90 srlcs. To raduce M,Hp .Pre$.sure below t;,5 kg/cmapply and rel~as e Ind.epexiai?.% b~akds. ).I

Charge the syst2n fully. ' EQka 0.6k:/cn2 - ,:reductiun ln Bp by autonatic hrske valve.Clcse isvla tin;; cock (,IE ) provides near the'::.BP chargin:; C-2 relay valve (~31). 0bscrvf';" Athe. prdssur? drop on thr' 13p''~~u~;e. PrdsSurec .drop should not t.xce-.d 0;7k6/cn2 in,5 ninutas.

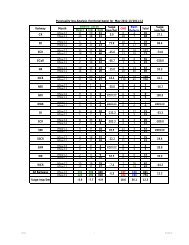

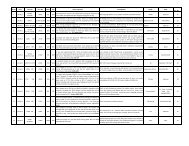

----* . - --.I----&, , ZPV I OFF Hi' 'l' ON QP V Hdmrk~posi- ' :J? 4 nc& encr.;ised. tiun er~er :is dNPV-ON-- -.--.-.----. -_I--1 T 1 ' ! I 1/111-1 Mp '42. -*-. - *-.-';Imm-,,-. -4-,--.-*-.-.-.-*-*-D-.-*-*-.-.-D-*-.-*bL

&UC( IWRCT-C CP. N i 5 J'IL.JJ,---. . .._.__-.____-._-_--I ----10 ,I chi: ck L \"! \~ln,ilerrluvu ~ S ~f L A- ariver '*lui~\ l:.Ltics b mG: valve in pcdti~n <strong>for</strong>~~v~:qant in both the cqbs* BYLrlP .1. 2nj h,. -ci:c. valve handle in ' ~ e ~. ,, n, , t t tho? <strong>brake</strong> prF~sUrSZrAsus t;~, n rannins st 2"d~ at 5.0_+.fkd~ni:

10.2 McxVe the 4-9 !>r:,Lw valv2 h.~niile quickly frin1rdlt?~3?1 v sitic;n t~ chd 'mdr~encyh pcsitim;C11t.c'k th-t the brrllre pin2 nresgure falls , rnnidly Lo I Z L ~ J - l 1 rind thlt t ha mmmm Srskecyl.llllldJ? prc2:;;u re bbc?inL?d is 3.fj"o. lk~/cr~2 .Check t h:~r; v:~cuur.i IS r cps innediate T y t a zero~111d br:ikc-s aredpplied fully. Check thatregressicn t:~kas placa.; a18.3 PlOV€? the !)??lke vzlve . hard le to tralt-'asei~isiticn. N-te that the bralra olpe mressura'wi:urnr, it; rir,i.n,~.l value. . Vd clxm is rest cr#>d tcorih;inrll li!v~l. 3 r d t,l-ic lxakas ?re fully released., . :*.I10.4 .9np 1- ici;z~[;-iLb'r;l.keg :.~ .Re ccdrd th.: i, td.~Lcc? apd licnt i h t inin ;s in fullsez3vie~! 1 :U.I 2 'emi.r,.;ency' v~siti~.,ns. 'linir~.:ssh~uld be taken in bcth 'Gccds' as ns inpass2nn~:clir'r~csit icns -10. 5 .. nl: ._.!.dn......__.ql::... f ~jr 7ktl -.--_ s :

10.9 m~s-m. g-4-9 llms e Wl-vI:Cht. cap~cicy of the valve In the ' Rehase:position whenthe sun~lyis stabili-wd, must! con<strong>for</strong>m to certain 1Jm1,ts in order to anslra4 c crrr:.snsitc i 71 fA!.)r 1 lchage <strong>for</strong> veryLonR trainsi wLLhout lnta i8l'erin~ with the automatic functhn- '\inp of the \-mike. CquyLe a 7.5 mm dia leak holes~l2cia 1 test c mvling-2 TpS1;"-~~~~T6el" to thz!<strong>brake</strong> pipa lil3sa connlin$' of the loc onlotive.Check pressure in th2 locq BP gauge with <strong>brake</strong> ' a*r+ va1.v 3 h?.:~d.l.e ;.;I re lease ~osition. It sh xld' I nc.t la> r,s *!:an 4 Icg/cm h .!$ 1 + '1.2 L' -,:. mdntimed in para 12 ;lv ahwe should ba .*-r jj.,. izal~c.n-.aiu~l rlLn th@ EUI <strong>system</strong> 3h;irged to7. kt',.!c& instdnc! of 10 kg/crn .:.)j12.3 . Yest mzr!ti.c;ned in 12,l;S;and 12.2p should b + , , '.*-. ,?+l-dpe~t~f! h11t :?.fter onening Lhe end cocks .oi- MH, l~ I:C , I: he 12-9 hznd1.e sh ou?-d be mw ad, ,to em;\i-pcncy posi ciorl after 15 secords(~e-tc!;in~l tll,~e) 01' q~nlng of .~nd cocks.12.4 Rci-+at '. :sts as ir. para 1.2.1 a:?J 12.2 above, I ,b l ~ ~ acn! y -lrdqendant brakas aiXer parsing.12.1 1121: 2 in? .-?:-.?, -c. 0 k c>ir~*:: ;lllilrlir,qt- I , I ~ I ) ~ t:%j ~ S '; ~ wi kt.;& f 11l.l applfcaticn,~l.~.~:.~n,:!t;:r: b~'sl

18.2-r a t !.)ositlon;- " ' -,nglngmer to .'.trailJ ~ositio nlacu. ;.il-9 br&e ~a?~~r.e in emargzncy position. ' Check . .that 83 choi12.d. j u t charge in re!.fxsa posit ion2-ilcl In ralll~ cc~..~icf,. nosit ioh of auto brak2val ve 1%: pr?~;~w-e sho!~.ld not dr~p in bothrs! &st3 a.rld full service po~itio~~s.1 ', ,, .18.3 Chrlr5c the sy.stern by placing MU-2EL in 'Lead1and thzn place it iri 'Yrailt position.. MoveA-9 <strong>brake</strong> valve handle 'to full' sellvice in .steps, l'hz <strong>brake</strong>s w:il.l not come and BP' DrasSuFe-;h:~u:Ld 11ot

- 111 .- .22.2 ~irnulah;. the condition of a?~licl.atim of 11 ,dynamir- ln-ak2 s . '.pn ly emcrf;nncy br,?ke s bytl112 :xi(tc):rl'-~ t.ic hl ll~evw 1ve ( 412) . 1)vnatnl.cI, 1.L Ch,clt thd owration of slndilg e uipm~nt.~It should worK ~roparLy batwezn 9-l~kg/crn ,P~s-sz.~~. l'hs sand ejected shluld b3dlr xtdd towrirds t he p3int of contact ofw r ~ w l on rail hcnd.-2 Not...: th,? rat2 ccP sanding* It should beh~t;w,:2:1 0.125 kg./min. to 0.250 kg/mfn. 'w r sa?2~r.3 C!~?ck thld o?crati.ai? of sgnding magnetva l-vl? s arid c qcripment <strong>for</strong> each \directiono t' t. L'LL '! $2 1 .\.2 Chl!cu that dl-fference between hi h and lowcont: horns (with onerntion of di f! ferent howvalves in the cab) is clez ly distinguishab:

a) C'omnr~s.;or s42L'ety valve(!>)bl:ms off11.5+0.ikg/cm2." - 'blows offcloses >.lt'+ ~9.5 to9.8 kghd

~ .~. . ---------A~.,-..I_IL_ L - ---..I-.. z --..-. .. '. . . ,' t ..' ,- *" i1o. QL-. -- l'd~t Standard -:, .: & ".. .',,I' . I'.:,. #.is >$. .,, >; ' '1,-... ." :: , ,:e ' ."r+.:,h c w v,&:-$z+: !.c2 2 :,: .- L.F I b- il::-,.l.i'~, ~;. : ii~,

ho.No..- T3stStandard6.2 AGdasr after full se;rice ?.glication: 1 J-a) BY stabilising pressure ' * 5_+0. lkg/cm2:b) Tim> <strong>for</strong> B? to charge to 2to 4 seerS k%/crn;?.c) Tl1u2 <strong>for</strong> V'S? to build,up to, .530 mm Hg. ,d) r'lrne <strong>for</strong> i-jC ss\: e.sx re to drppt o 0 ./1 !:[;, c tnr- .!. n Goon1 sposition of dlcL;.ibulvor.'3 to 5 secr.&O to-50 sec.)a ) 'Chid <strong>for</strong> UP to drop to 'Otkg/crn 2a to E sec.t,) 'Jj-rns' <strong>for</strong> V'lP to drop to zero 1 to 3 set.em:; of lig. ,,c) lime takan <strong>for</strong> Bc7 pressrz 25 to 30 set.build upf,~ 95$ of m~hutn ....':,- . ...X pres.jur.? in t GoodsIp.~sition of 5-3 -W distributor.,'d) l!rr~? taken <strong>for</strong> jL'pressure 7 to ~d .set.bul. l cl upto 95 10 of ma vitnum\ 1';C pre~:trt! 1.n fPasicngert . .- n3sitim of C-3-W distributor.- . 1A "". 2c) N~.Jrnum 13i: pr3~~1 re3.8-t_0,ll~g/cma) i313 stabilising pressureh) Pime <strong>for</strong> ~ I to J charge to,5. 0 kg,'cm -

Idinimum r~.tduct i;>n 70s ition ofauto brakz vaL v2.-- Standard . Ia) i3P ' should be stabilised at . 4.5to.4.7 kg/cm 2'b) BC pressure should bzProport;ir~nal functioninq of a1 r<strong>brake</strong> in anvlication and relaase11 .. ' " ' I- Proper function - of dist_rBut or: ---- I ILeakag~ in UC pressure (Move , , No leakage/lo mt.auto br~ke valve to emergmcy ..applica5ibn).---- Cnpaclty of nut? brske valve: - '3P pressuxe against 7.6 mm dia. IIleak hold in ',i.zlcase positionhof auto <strong>brake</strong> valve.m4," ki/cm2. 1''" 1*, d,+ ,)i' .--- 131' cut COC~(,I~)I '. ,3rnkz nip2 vressure , Should not ri e(After tnov ins A-9 aut ornstic from 'P fkg/cmg tiA0 min.k'<strong>brake</strong> v slue to drndrgency,nosit ior, , c losu> Bil cut-outcock(A8). Chen move A-9brakc vn lve to I nl!lt?a sen ,sition).L3 J'rT

P-='#-2 1-. - ff2st ---- s . .- -- StandardP1. ."3 1 !II-~- pb s t ionyMoV..--~"3-v~BTxorn With A-9 valvc in ')re 112:i sc! to ' ernert;~ncy release ,position ''Time-Sec. bft ex3 15 ~ e c. . of 0 onan UZIDC&IR cocks .Do enii:i? B? BC,kMR cocks 0 & Sl-9 in rzlaass. - j~ Allll~t $ . & Liib < < ~ i i~ 4: - ~ ~ ~ J ~ . m ~ ~ m i r 7 ~ d - --- 7 k g~ rn. .., 1---.---. .. .. +. -- -- r 11; I p-- nj B;' k4L3 z3P ?3&,4Rqaat; th:! t;usts with~ 3-9 valvc.in application position.in hlaasu and Sl-9i' , ?I . -7I 1719 1 ) pfioV,r r~utc brnkc valzc from i2.0 kg/c&I! ~ L - ,'Rr+l+qsz to lparcjalfi" ,{.2n1~:~~.iti3ri' yusit i on - , . 7X prdgsnre.ILL' ) MCJV\! inil(2pd n~!r~t bra1 Ice vil lveto '2ojll.L.r:-Lion1 uf~~itlotl13C ?rod S S I J ~ ~ ~ .- . ,4.0~0. ~k g/crn2

s.130.IC__- 9,--b.'F-3stsStandzrd r I-10. QQ~~:I tion of brqk~ r" 11:"~~ switch(.'l41i: 2, ~(h+ducd the Br' pr,:ssurd by 1.0k /cm ..I; stabilis?d, nr3ss the bra&a release '?(switch). c)Mhzn corresponding I$ prassurr2 fs,a) Check U: nrassure drogs tob) Re laase tha <strong>brake</strong> re l'a sassitch, 9C qrassure should'be rsstoivl, to the originalposit !on.. ,II4i'im,? <strong>for</strong> F build up to 95%of maximum YC nressur? -I . /. < , . . Ie) For passen,yer position ofdi st si but or. I Ib) FOS ?O.XIS ~0sLt;ion ofdist r'ihutor .c) Regression t~kes place. , . = / I .I 'b) ~~ovl.!r sh;311111 cut -in when32 pressure rises to ,Loco shoulmove., -23

Standarda) .I-9 br2ke valve intHdlease f nosit ion -4+0.1kg/d . . - I I " sEC pressure " ,, "Move 2-9 brak,? i~alve tou1n,2ir:y tlcg u~)pllci~t.i~n 1,osil;ionand then chansr= MLJ-2-:3 toi 1 n.3sit ion, :?? thenm w e 1-9 brrkc! vnl1J"L. Lo -a) H~l~2ase n~sitifjn -lhF .CrldssurzIb) Full service -14 .3 (': hnr+ +,lx :II] to 5. 0kg/cm 2iiePpin,; M:J-2-U 1 -id LI ~sitiman1 tnen chant:c Flu-2-'!, trail-1si t ion and t.l?.~ln aovc! 1-9hi-nke valve t~ -will ron from 5.0kg/cm B0.0 ~~:/crn~

' IFsed. vaLvt2 (144) <strong>fitted</strong> in .,auxiliary eke-lbrkal eircili't,(2rovide a ~~uI~L' in tha test;p3 prov3.d~Ij nr.!ar tile feed ' ."valve.)- sdt atFsed vnl-ve (-152) <strong>fitted</strong> int;he f ~ pipd ~ l.im i - Sat atUul-izdr (C35)cut-3.n(,~:ta.rt.s working)cut--c~xl; (buz~cr of:')(PI'W~~~T? a ~:111;

16.8 arakc block clearanca - ., "'(with IK: piston s';rokd

a) Orrereiti:~rl ol' san lers be tw-!en Satisfactary orr 9 ' noti' + I5-10 kg; crw pr e sure ,Ic) Qxr~tia-1 of high tone horn1, :! v:.~on 5-10 1c::/crn2 not. , .I lii 7r1cssur2 . I.I .satisfactory ofI, I..'