RDSO's report no. TFC-77 (January 2002) of the ... - eLocoS

RDSO's report no. TFC-77 (January 2002) of the ... - eLocoS

RDSO's report no. TFC-77 (January 2002) of the ... - eLocoS

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

. ,sma ~HCPZ:i' ~a--i:tzCl

Executive Summary'CRB vide his D.a.No. 2001/CRB/Misc.l5 date 4.9.2001 directed ROSa to form aCommittee with representatives from Track, Traffic, Electric Traction and Diesel Traction tostudy and submit a <strong>report</strong> which should look into <strong>the</strong> problems <strong>of</strong> frequent stalling,· requirement<strong>of</strong> additional power and its cost implications. As per this letter under powering <strong>of</strong> trains result in<strong>the</strong> following disadvantages: -: i) Low average speed resultinq in loss <strong>of</strong> line capacity and lower engin'e and wagonutilization;ii) Problem <strong>of</strong> loco maintenance;iii) Damage to <strong>the</strong> track in <strong>the</strong> form <strong>of</strong> wheel burns and lower maintainability <strong>of</strong> track dueto heavier longitudinal forces.Rosa accordingly formed a Committee consisting <strong>of</strong> EDI<strong>TFC</strong>. ED/MP, Sr.ED/Elec.Loco,and EOffrack to assess <strong>the</strong> extent <strong>of</strong> <strong>the</strong> problem being faced in <strong>the</strong> field and give solutionsaccordingly.The Committee collecterl <strong>the</strong> details <strong>of</strong> stalling cases from all <strong>the</strong> Railways. The averagestalling cases on all Indian Railways (excluding E. Railway) are about 3.6 per day. The problemVias found effecting S.E. Railway <strong>the</strong> most. SUbject <strong>of</strong> stalling <strong>of</strong> 58 BaXN in Bilaspur andt..Jagpurdivisions. was earlier studied by ROSa and a <strong>report</strong> No. IR 73 (Nov., 98) was sent toRailway Board.tFor <strong>the</strong> purpose <strong>of</strong> present study it was, decidedthat as a sample case Bilaspur divisionshould be taken up again for in depth study to see <strong>the</strong> trends <strong>of</strong> stalling cases over <strong>the</strong> yearsand steps taken for reductionin stalling <strong>of</strong> freight trains as this division has got predominantgradients <strong>of</strong> 1: 100 to 1:250 in its jurisdiction.' A Committee <strong>of</strong> <strong>of</strong>ficers from Track, Electric Locoand Traffic Directorate visited Bilaspur division and had detailed discussionswith <strong>the</strong> divisional<strong>of</strong>ficers and staff associated with <strong>the</strong> rlJnnin~ f ,rains. The division has shown a uniqueexample <strong>of</strong> reducing stalling cases from 36B in <strong>the</strong> y~ar 1998-99 to 27 cases in <strong>the</strong> year 2000-01, without major financial technical inputs.

i) Improvement in enginemanship;ii) Availability <strong>of</strong> working sanding gears;iii) Use <strong>of</strong> WAG7 (in place <strong>of</strong> WAGS) as banker;iv) Use <strong>of</strong> dynamic braking;Rosawhile examining <strong>the</strong> problem from a technical point <strong>of</strong> view feels that <strong>the</strong> earlier loadtables issued were inadequate because <strong>the</strong>y were based on <strong>the</strong> following conditions:i) Fair wea<strong>the</strong>r conditions i.e. dry rail conditions,ii)Tangent track Le. straight track without any curvature,iii) Adhesions values - taken corresponding to standard track conditions,Iiv) Track maintained to standard conditions.Besides this, in case <strong>of</strong> BaXN wagon loading is permitted up to CC+2 t; <strong>the</strong>refore load <strong>of</strong> 58BOXN rake is being considered as 4850 t as against existing 4700 t. Hence revised loadtables have been issued for both diesel and electric locos.The cost implications however, for following <strong>the</strong> revised load tables will be high. S.E.Railwayvide <strong>the</strong>ir letter No. 48/4 dated 7.3.2001 has asked for additional 130 electric and 40 diesellocos for following <strong>the</strong> existing ROSa load tables. The same may fur<strong>the</strong>r increase if revisedload tables are used. Average additional loco cost is Rs. 3.75 ~rores and homing sheds forabout 100 locos will cost a<strong>no</strong><strong>the</strong>r Rs. 10 crores.Besides this, we should also take into consideration <strong>the</strong> cost <strong>of</strong> streng<strong>the</strong>ning <strong>of</strong> bridges on<strong>the</strong> section, as double-headed operation is <strong>no</strong>t permitted on certain BGML spans. Theapproximate.cost l cti streng<strong>the</strong>ninQ n~~ 8r.11 pf ~5.7 m BGML girder brid~e as per ROSa'sspecifications has been worked out as Rs. 12.50 lakhs.These additional costs might <strong>no</strong>t commensurate with <strong>the</strong> advantages gained except inreducing <strong>the</strong> cases <strong>of</strong> rail burns (extra cost incurred on Bilaspur division during <strong>the</strong> last 4 .years in replacing burnt and scabbed rails is rough~ ·Rs. 14:4~Ocrores) a~dincreasing line

capacilj. Hence, tllis may ue iJdvantageous for those sections only which are operating tonevr sC.JlurC.Jlion level <strong>of</strong> line capacily.I •In ~uch c()ses Zllso, improvement in operating pmctices as clone by Bilaspur division"!.~lJl ;J:, Ir;flU \(:Ifll pllJllIlil1U, fullowing suggestions <strong>of</strong> r~DSO should be implemented on <strong>the</strong>. .1~C.Jil'/lJj~in ;J pll~J~C:'/lise rtliJnncr depending upor/ <strong>the</strong> local needs and resource availability.:I. Running <strong>of</strong> trains hauled both by diesel and electric as per <strong>the</strong> revised loadlaules issued in Annexure VI as it woul8 <strong>no</strong>t only decrease <strong>the</strong> possibility <strong>of</strong>slallinu but also improve <strong>the</strong> speed <strong>of</strong> goods train~ and reduce speeddifferential between freight and coaching trains. generating extra line capacity.II. Follov/illg Rosa guidelines for <strong>the</strong> approach speed versus maximumnegoliClble gradient stretch attached in Annexure VII.III. Deciding about <strong>the</strong> use <strong>of</strong> banker vis-a-vis double heading as per Para 0.3.1.3<strong>of</strong> <strong>the</strong> repqr1.IV, Streng<strong>the</strong>ning <strong>of</strong> bridges to allow double headed operation in accordance withrevised load tables.2~0..(G.~~):' Oi~/MP EO/T ra-;kNfIJc(Ashima Singh)EOrrraffic

INDEX:S.NG. Desc'ript~oll Page No.1.0 Introduction2.0 Incidences <strong>of</strong> stalling & data collection 13.0 Previous study on stalling 64.0 Study <strong>of</strong> Bilaspur dh'isior. <strong>of</strong>S.E.Rly. 7,.J :4.1 Causes for reduction <strong>of</strong> stalling cases 95.0 Study <strong>of</strong> Khurda Road division <strong>of</strong>S.E.Rly. 106.0 Load haulage capability <strong>of</strong> <strong>the</strong> locomotives 1 16.1 Load haulage capability aI)d concept <strong>of</strong>TE 1 16.2 Factors affecting load haulage capability 1 16.3 Haulage chart for locomotives 127.0 Effect on Track 1<strong>77</strong>.1 Cost <strong>of</strong> rail renewal due to wheel burns 187.2 Issue c0nnected 'with bridges 187.3 Cost <strong>of</strong> upgradation <strong>of</strong> bridges 198.0 Summary <strong>of</strong> Discussions & Recommendations 19I9.0 Annexures 23-48

LIST OF ANNEXURESAnncxurc No. Description Page No.CRB's D.O. No. 200l/CRB/Misd5Daleu tl.9.200 I 23JJ !ZJ)SO's leller No. 96rrFC/21 O/Catch SiuingDaled 13.9.2001 24III Summary <strong>of</strong> stalling cases 25[V Gradient in BSP-KTE seelion 26V -~Jength& location <strong>of</strong>whecl burnt/scabbedrail in 13ilaspur division 27-28VJ Revised Haulage charts 29-32VjJApproach speed versus length <strong>of</strong> maximumnegotiable stretch 33-40VIII Month-wise cases <strong>of</strong> wheel burnt/scabbedrail in 13ilaspur division 41-43IX : '-S.E. Rly.'s letter No. 48/4 clat~d 2/7.3.2001 44X Balancing speed and time/distance for 75 kmphopcration for 4850 t load on lcveVtangent track 45XI Comparison <strong>of</strong>loads permitted und loads inactual pnicticc on S.B. Railway 46-48

1.0·Introduction:Adequate powering <strong>of</strong> <strong>the</strong> freight trains is an issue, which has been <strong>of</strong> concern to railwaysall along, especially fo-r <strong>the</strong> graded sections. Though powering <strong>of</strong> <strong>the</strong> trains is broaqlybased on <strong>the</strong> loco load haulage charts, arriving at acceptable loads for a particular sectionis a tight ropewalk between loco haulage capability, operational constraints andinfrastructurallimitations. Whereas under powering will mean low average speeds, stalling<strong>of</strong> loads resulting in loss <strong>of</strong> line capacity, slogging <strong>of</strong> <strong>the</strong> locos resulting in low reliabilitynnd availability, wheel burns and damage to track calling for premature replacement whileon <strong>the</strong> o<strong>the</strong>r hand, providing adequate cushion on every stretch may call for, far morelocos than used at present and consequently lot more infrastructure requirements by way<strong>of</strong> maintenance facilities etc. requiring heavy financial investment. In this scenario,judicious decisions are called for 'keeping both health <strong>of</strong> costly assets and financialposition <strong>of</strong> Railways in mind.Though railways have fixed loads, on <strong>the</strong> basis <strong>of</strong> past experience and on <strong>the</strong> basis <strong>of</strong>trials cunducted, many times <strong>the</strong> trailing Icads have been found to be exceeding <strong>the</strong>prescribed limits. Also sometimes <strong>the</strong>re is wide disparity in 4!,'IC loads for similar class cflocomotives.With above background, a study has been taken up as directed vide CRB's D.O. No.2001/CRB/MISC.lS dated 4.9.2001 (copy enclosed as Annexure <strong>no</strong>. I ).In this <strong>report</strong>,concept <strong>of</strong> loco haulage capabili~1 and factors affecting it, load haulage charts for differenttrack and wea<strong>the</strong>r conditions, minimum speed at which a loco should approach a gradientand <strong>the</strong> maximum length <strong>of</strong> <strong>the</strong> gradiel'lt, which a loco can clear with.out stalling, arediscussed. This will help railways to analyse <strong>the</strong> local conditions realistically and arrive atcorrect trailing loads rationally.I2.0 Incidences <strong>of</strong> stalling & data collection:To assess <strong>the</strong> extent <strong>of</strong> <strong>the</strong> problem being faced in <strong>the</strong> field, all zonal railways lVererequested to provide details <strong>of</strong> stalling cases along with sectional details, loads <strong>of</strong> trains,types <strong>of</strong> locos used etc. vide RDSo's letter No.96/<strong>TFC</strong>/210/Catch Siding dt. 13.9.2001(copy enclosed as Annexure No.n ). ,All railways have responded except E.R. Summary<strong>of</strong> stalling cases over various zonal railways are attached as Annexure <strong>no</strong>. Ill. If totalstalling cases are averaged out on daily basis, it is found that <strong>the</strong>re are about 3.6 cases.per day <strong>of</strong> freight trains stalling over all Indian Hailways (exclusive <strong>of</strong> ER).It seems that all cases <strong>of</strong> actual stallihg may <strong>no</strong>t have been <strong>report</strong>ed - some might havebeen <strong>report</strong>ed under o<strong>the</strong>r categories like 'miscellaneous' etc. and some might <strong>no</strong>t havebeen <strong>report</strong>ed or highlighted at all. The actual Incidences may be much higher. Asproblem <strong>of</strong> stalling <strong>of</strong> trains seriol,lsly affects operation, a review is called for studyingexisting load tables, actual loads <strong>of</strong> trains ve,.~us types <strong>of</strong> locos to be utilized, effect <strong>of</strong>curves, & adverse wea<strong>the</strong>r conditions, length <strong>of</strong> gradients etc. on hauling capacities <strong>of</strong>locos afresh.

Brief summary indicating extent <strong>of</strong> problem <strong>of</strong> stalling as <strong>report</strong>ed by railway' is givenbe 10'11: -Central Railway has given position <strong>of</strong> freight train stalling cases as separatelyand electric traction, Brief summary division~wise is given below: -'IIfor dieseloDir;sr:1 Traction -Total <strong>of</strong> 33 cases <strong>of</strong> freight train stalling were <strong>report</strong>ed on this division in one-year periodfrom Sept, 2000 to August 2001. 19 cases took place'in RTA-MUGA section (ruling(]radient 1 in 125), 5 cases took place in GUNA-PGA section (ruling gradient 1 in 200).80th WOM2 u<strong>no</strong> WOG2 locomotives were used.'Totul <strong>of</strong> 37 cases <strong>of</strong> freight trains stalling were <strong>report</strong>ed on this division for one-yearperiod from Sept 2000 to August 2001. Break up is 10 cases in KNW-ET section (rulinggradient 1 in 150). 20 cases in ET-BPL section (ruling gradient 1 in 125) and 7 cases in. BIN-BPL section (ruling gradient 1 in 180). Single/multiple WAGS & WAG7 locomotiveswere used for hauling freight trains.Total <strong>of</strong> 86 cases <strong>of</strong> stalling 'were <strong>report</strong>od on this division for one-year perioe' from Sept2000 to August 2001. Breakup <strong>of</strong> <strong>the</strong>se cases is - 32 cases in KYN-LNL section (rulinggradient 1 in 37), 18 cases in CLA-TR section (ruling gradient 1 in 150), 17 cases tookplace in KYN-IGP section (ruling gradient 1 In 37). 10 cases in PNVL-NSPT section (rulinggradient 1 in 100). 9 cases in KYN-PNVL-ROHA section (ruling gradient 1 in 125).Bankers have been provided in all cases in KYN-LNL & I

Total <strong>of</strong> 22 cases <strong>of</strong> freight stalling were reponed on this division during Jan. 2001 toSept. 2001 - 11 cases in BZM-JHS section "(ruling gradient 1 in 200), 6 cases in BHDA-MKP section (ruling gradient 1 in 150) and 5 cases in BNDA-JHS section (ruling gradient1 in 125). Locomotives used were both WDG2 & WDM2.Total <strong>of</strong> 12 cases <strong>of</strong> freight train stalling were <strong>report</strong>ed on this division in one-year periodfrom Sept 2000 to August 2001. All cases took place in JHS-AGC section (ruling gradient1 in 150). Both WAG5 & WAG? locomotives were used for hauling freight trains.18 cases <strong>of</strong> freight train stalling were <strong>report</strong>ed on this division for one-year period fromSept. 2000 to August 2001. All <strong>the</strong>se cases took place in NKJ-DMO section (rulinggradient 1 in 150). WAG5 & WAG? locomotives were used for hauling <strong>of</strong> th,ese trains.NagpurDivision:Total <strong>of</strong> 14? cases <strong>of</strong> freight train stalling were <strong>report</strong>ed on this division for one-yearperiod from Sept. 2000 to August 2001. Breakup is - 49 cases in NGP-AMF section (rulinggradient 1 in 150), 35 cases in WR-NGP section (ruling gradient 1 in ·132), 26 cases inBD-WR section (ruling gradient 1 in 132), 1? cases in ET-AMF section (ruling gradient 1 in70) and 20 cases in BPQ-WR section (ruling gradient 1 in 150), Single/multiple WAGS &WAG? locomotives were used for hauling <strong>the</strong>se trains.Total <strong>of</strong> 40 cases <strong>of</strong> frelight train stalling were <strong>report</strong>ed on this division for <strong>the</strong> period April2001 to Sept.2001 (Total 6 months) -J 24 cases in SUR-DD section (ruling gradient 1 in150), 8 cases in MMR-DD section (ruling gradient 1 In 100), 6 cases in SUR-WD section(ruling gradient 1 in 100) and 2 cases In o<strong>the</strong>r sections. Single/multiple WDM2M/DG2locomotives have been used Jor hauling <strong>of</strong> Ult1tH~ trains.Nor<strong>the</strong>rnRailway:As per information furnished by NR only 18 cases <strong>of</strong> stalling have been <strong>report</strong>ed (betweenMarch 2000-June 2001) on <strong>the</strong> section falling under Delhi division. In all o<strong>the</strong>r divisions<strong>no</strong> stalling cases have been <strong>report</strong>ed. Out <strong>of</strong> 18 cases <strong>report</strong>ed in Delhi division, in tencasas banker was used for clearing <strong>the</strong> load. BG track under N.Rly. are mostlx plain.3

North EasternRailway:As per details submitted by NER <strong>the</strong>re are <strong>no</strong> cases <strong>of</strong> stalling <strong>of</strong> freight trains in <strong>the</strong>irjurisdiction. NER is completely diesel traction area and WDM2 engines are being used forhauling freight trains. In BG section <strong>the</strong>re is only one gradient section Le. Lalkuan-Haldwani-Kathgodam in Izzatnagar division which has ruling gradient <strong>of</strong> 1 in 70, but in thissection i.e. Lalkuan- Kathgodam. presently <strong>no</strong> freight trains are running.N.F.Railw

gradient <strong>of</strong> 1 in 37, two triple heads <strong>of</strong> WDG21ocosrear.are utilized, one in front and o<strong>the</strong>r inGuntakaJ Division:In GTL division total <strong>of</strong> 31 cases <strong>of</strong> stalling took place. Section wise breakup is 10 casesin RU-NRE'section (ruling gradient 1 in 100), 11 cases in NRE-HX (ruling gradient 1 in100), ? cases in GTL-I-JDL section (ruling gradient 1 in 92) and 3 cases in DMT-GZLsection (ruling gradient 1 in 100). Locomotives used for hauling are yYDM2, WDG2 andWDG4. In most <strong>of</strong> <strong>the</strong> cases bankers were provided.SecunderabadDivision:9 cases have taken place during <strong>the</strong> period in KZJ-BN section (ruling gradient 1 in 100).This is electrified traction area and locomotives used are WAG? (for loads up to 3333tonnes). WAG7 multiple unit and WAG5 multiple unit (for loads up to 4750 tonnes).Bankers were provided in all cases.S.E.Railway have provided position <strong>of</strong> freight train stalling cases for <strong>the</strong> years 1998/99.Current figures for <strong>the</strong> year 2000 & 2001 have <strong>no</strong>t been made available. Position <strong>of</strong>Bilaspur Division is available up to October'2001, as this division has been studied indepth as sample case, as discussed in Para-4. Detailed current position <strong>of</strong> Khurda RoadDivision has been obtained separately.ISummarised position <strong>of</strong> stalling cases. divisionwiseis as follows:IAdra DivisionChakradharpur Div. -Kharagpur Div.Waltair Div.Nagpur Div.Sambalpur Div.Khurda Road Div.-Bilaspur Div.41 cases (<strong>January</strong>'99 to September'99)19 cases (<strong>January</strong>'99 to June'99)09 cases (JarlUary'99 to June'99)06 cases (December'9? to November'98)56 cases (<strong>January</strong>'99 to December'99)28 cases (April'98 to February'99)52 cases (May'2001 to August'2001)27 cases (April'2000 to March'2001)From <strong>the</strong> analysis, it comes out that maximum numbers <strong>of</strong> stalling were taking place onBilaspur division followed by Khurda Road, Nagpur & Adra divisions. Cases <strong>of</strong> stalling inKharagpur, Chakradharpur and Waltair Divisions are comparatively less, In BilaspurDivision, <strong>the</strong>re were 368 cases <strong>report</strong>ed in <strong>the</strong> year 1998-99, 156 in <strong>the</strong> year 1999-2000,27 in <strong>the</strong> year 2000-2001 and only 8 (26 if cases under miscellaneous category are alsoincluded) in <strong>the</strong> year 2001-<strong>2002</strong> (up to October). Number <strong>of</strong> cases, which weresignificantly high on both main line,. and CIC section <strong>of</strong> Bllaspur division have beencontrolled due to number <strong>of</strong> factors as discussed in Para -4.1Stalling <strong>of</strong> freight trains has been <strong>report</strong>ed in Ajmer, Kota and Ratlam divisions <strong>of</strong> WesternRailway. -

In one year (from September 2000 to August 2001), maximum number <strong>of</strong> slallin~ casesi.e. 8 has been <strong>report</strong>:=d in HP-BAR section (On line), which has a ruling gradient <strong>of</strong> 1 in150 with maximum 2.5 0 curve. 4 cases each <strong>of</strong> stalling took place in MOI-KTR (Up line) .and NANA-KVJ (Up line). Bankers were used for clearance after stalling. Maximum loadpermitted in Ajmer Division is 3280 tonnes with WDM2 Loco and 32~0 tonnes with WDG2loco. . .In Kola Division maximum cases <strong>of</strong> stalling occurred in Kanwalpura (KIW)-Dara (DARA) inKota-r\Jagda Section (On line) which has a ruling gradient <strong>of</strong> 1 in 195 with maximum 4.5 0curve. D8tail <strong>of</strong> o<strong>the</strong>r stalling cases is - 9 cases in CMU-SGZ (On line) and 8 cases inI\Jr'-JW-LRU(On line). No neutral section has been provided in <strong>the</strong> gradient section. Herealso bankers were used to clear <strong>the</strong> section after stalling.In Ratlam Division maximum number <strong>of</strong> stalling cases occurred in Limkhera (LMK) toJetok (JKT) in Godhara-Dahod section, which has a ruling gradient <strong>of</strong> 1 in 150 withmaximum 2.5 0curve and length <strong>of</strong> gradient being 20 kms. 40 BCN load with WAG5 arebanked on GDA-RTM (On line).3.0 Previous study on stalling:Subject <strong>of</strong> stalling <strong>of</strong> 58 BOXN trains in Bilaspur and Nagpur Divisions <strong>of</strong> South EasternRailway was earlier studied by RDSO and a Report No. IR-73 November 1998 on 'Study<strong>of</strong> train stalling <strong>of</strong> 58 BOXN hauled by single WAG7 locomotive in Nagpur and BiJaspurDivision <strong>of</strong> S.E.Rail"v;:l-Y'was sent to Railway 8C"ard vice letter No. EU3.1.39 dated10/12/88. This <strong>report</strong> basically concentrated over <strong>the</strong> causes <strong>of</strong> stalling and whe<strong>the</strong>r <strong>the</strong>WAG7 locomotive is performing as .per <strong>the</strong> rated capacity. Thus emphasis was o<strong>no</strong>ptimum loading <strong>of</strong> locomotive along with optimum operations Le. effect on speeds, linecapacity and hold ups etc. The conclusion drawn in above <strong>report</strong> wereThe Railway board's instruction:.i issued viue letter <strong>no</strong>. 03/Elec (TRS)/44-8/3Vol-II dated 27.5.98 on haulage <strong>of</strong> load with single WAG7 locomotive are in linewith <strong>the</strong> experience <strong>of</strong> South East.ern Railway.ORM/Bilaspur's instructions issued vide letter <strong>no</strong>. DRM/G/Sr.DEE(OP) dt.13.4.98 are also in line with Board's Instructions.S.E.Railway's joint Procedure Order No. EUOPTG/SFY/6 dt. 30.5.97 is also inline with Railway Board's instructions. .South Eastern. Railway l~ b .\liA~ ~~lIing cases on 1 in 150 .gra~ient orcompensated gradients,- which are sharper than 1:200. Such a situation ca<strong>no</strong>nly be met under run through conditions as stipulated in para 2 <strong>of</strong> RailwayBoard's letter mentioned above.Brake binding 0.- late releasing <strong>of</strong> brake while negotiating <strong>the</strong> speed restrictions .or passing through <strong>the</strong> restricted aspect <strong>of</strong> signal also contributes <strong>the</strong> stalling <strong>of</strong>load. The rake <strong>of</strong> 58 Box 'N-, <strong>the</strong>refore, be test~d for air leakage tests beforeBrake Power Certificate is issued for CC rake.. 6

VI)' Running <strong>of</strong> 58 Box 'N' rake should be closely monitored during <strong>the</strong> rainy.season as <strong>the</strong> gross weight (~C+2=484LI T) <strong>of</strong> <strong>the</strong> train is expected to increaseby about 1 to 2T pet wclgon due to accumulation/absorption <strong>of</strong> water in coalload, fur<strong>the</strong>r worsened by loss in adhesion.For <strong>the</strong> purpose <strong>of</strong> present study, it was decided that as a sample case, Bilaspur Divisionshould be taken up again Jor in-depth study to see <strong>the</strong> trends <strong>of</strong> stalling cases over <strong>the</strong>years & steps taken for reduction in stalling <strong>of</strong> freight trains as this Division has gotpredominant gradients <strong>of</strong> 1 in 100 to 1 in 250 in its jurisdiction. In depth analysis <strong>of</strong> KhurdaRoad Division, which is predominantly die~el traction, has also been carried out.4.0 Study <strong>of</strong> Bilaspur Division <strong>of</strong> South Eastern Railway:Bilaspur Division is <strong>the</strong> major Coal loading division <strong>of</strong> Indian Railways. Coal is beingloaded mainly from three areas Le. Korba. Chirimiri - Tigerhill-Bisrampur area and BRJNarea. Maximum numbers <strong>of</strong> coal rakes are loaded in Korba area. Loaded BOXN rakes (onaverage 10 rakes per day) are also received at Jharsuguda point <strong>of</strong>- Chakradharpurdivision. Area is rich in minerals with number <strong>of</strong> coal sidings, steel plants, and cementplants situated in <strong>the</strong> area. Part <strong>of</strong> <strong>the</strong> division Le. main line lies on one <strong>of</strong> <strong>the</strong> diagonal <strong>of</strong>Golden quadrilateral routes Le. Mumbai to Howrah line.A team <strong>of</strong> <strong>of</strong>ficers from RDSO visited Bilaspur division for in-depth study <strong>of</strong> stalling <strong>of</strong>freight trains and operating practices <strong>of</strong> running <strong>of</strong> freight trains. Team had detaileddiscussions with divisional <strong>of</strong>ficers including DRM and staff associated with running <strong>of</strong>trains.Belpahar (BPH)-Dagora (DAO) Section: This section has (1 in 100) gradient and in bothdirection banker is being provided which is attached and detached at Raigarh. In rainyseason banker is extended up to BEF if <strong>the</strong> train is started from loop line <strong>of</strong> Raigarh.GIG Section: I •IIBilaspur-Anuppur section: In Khongsara (KGS)-Khodri (KQI) section, which has 1 in 100gradient, banker is used up to Pendra Road station. 58 BOXN loads are cleared ei<strong>the</strong>rwith multiple WAGS or single WAG7 or multiple WAG7. In case <strong>of</strong> single WAG7 andmultiple WAGS, banker Is required which ar~lnvWlably <strong>no</strong>w WAG7- earlier WAGS locoswere used for banking with which soni'e 3talling cases were <strong>report</strong>ed. Now with WAG7banker <strong>no</strong> -stalling is occurring. In case <strong>of</strong> multiple WAG7 Le. two WAG7 <strong>no</strong> banker isrequired as <strong>the</strong>re is sufficient' power for clearing <strong>the</strong> gradients <strong>of</strong> 1 in 100. Normallymultiple WAG7 loco rakes are allowed to run· up to Anuppur only and <strong>the</strong>n <strong>the</strong>y areintercepted.

Trains are ei<strong>the</strong>r hauled by multiple WAG5 or single WAG? All trains·hauled by singleWAG? locos are banked with WAG? loco between Anuppur-Jhalwara (short <strong>of</strong> NKJ).In this section banker is requirecl between Paradol-Boridand. Ei<strong>the</strong>r WAG? or WAG5 isused as banker. 'Gradient chart <strong>of</strong> <strong>the</strong> Division is enclosed as Annexure No.IV. At 16 loc?tions <strong>the</strong>re isrisinG gradient short <strong>of</strong> home signal.On this section, 58 BOXN loads vVerebeing operated with WAG5 multiple, till March'97.Since April'97, <strong>the</strong> Rly has been running 58 BOXN loads with single WAG?, with conditio<strong>no</strong>f run through on those stations where home signal is on compensated rising gradients <strong>of</strong>1:150 or steeper. 40 BeN loads are worked with single WAG5, multiple WAG5 or singleWAG7 locomotives.The year wise stalling <strong>of</strong> 58 Box 'N' and 40 BeN loads are given in followIng tablejLocomotive type ' Yearr-1998-99 1999·2000 2000·2001 2001·<strong>2002</strong> (up to Oct.)G5 SU 27 9 2 0(35 MU 156 104 9 8G7 SU 165 35 12 18-G7 MU 20 8 1 0TOTAL-368 156 27* 26**·Some cases <strong>of</strong> load stalling are <strong>no</strong>t shown though <strong>the</strong>y have been recorded inmiscellaneous category .••All <strong>the</strong> cases <strong>of</strong> load stalling are included.These cases are fur<strong>the</strong>r classified based on factors contributing to stalling, viz, badwea<strong>the</strong>r, cattle run over, Signal given on approach. Loco defect, Temporary restrictionson raising gradient, OHE <strong>no</strong> tension, brake binding in load, poor engine man ship. Thebreak up is as under-YearCAUSEBad Cattle Signal on Lo~o CD No Brake Poor Exces~wea<strong>the</strong>r Run approach defect 'tension binding. engine loadOver on OHE man--._--- -_.__ ._.- --- ------ --- --- ---- ----2..h.!R_ .__ ._--199U 133 3 54 75 36 17 18 12 30-991999 69 1 6 37,20 8 ? ,3 5-00--.---- -,. .._ ...•..•...-02000 2 0 3 5 4 2 3 8-012001 16 0 1 .1 5 0 2 1 0-02 "(Oct) , I

The "table above shows a substantial reduction in stalling cases over <strong>the</strong> years. Acombination <strong>of</strong> measures - operational restrictions and discipline and provision <strong>of</strong>additional motive power - has resulted in this reduction.-• At 10 locations bankers are provided.• At 15 locations instructions are given to receive <strong>the</strong> train, run through withoutstopping .at Home signal.• No engineering speed restriction <strong>of</strong> less than 50 kmph shall be imposed. If speedrestriction is imposed due to any emergency, a banker is utilized.Stalling and associated wheel slip cause auto regression and at times driver in effort toclear <strong>the</strong> section adopts short cuts and by passes <strong>the</strong> relay which results in continuouswheel slips causing rail burns and scabbed rail. Over a stretch <strong>of</strong> around 300 km in <strong>the</strong>section, on 68 locations <strong>the</strong>re are rail burns and scabbed rail. Cases <strong>of</strong> rail burn arE:'enclosed at Annexure V.Maximum starting load for WAG7 loco for fair wea<strong>the</strong>r conditions on tangent track on 1 in150 gradient is 39<strong>77</strong> tonnes and for adverse wea<strong>the</strong>r conditions on 2.5 degree curvetrack, <strong>the</strong> starting load is 2860 tonnes, where as <strong>the</strong> loads worked are 4850 tonnes.4.1 Causes for reduction in stalling cases:Based on <strong>the</strong> discussions held with <strong>the</strong> <strong>of</strong>ficers and staff <strong>of</strong> Bilaspur division, <strong>the</strong> followingreasons are found to be responsible for reducing <strong>the</strong> number <strong>of</strong> stalling cases:-

••• a"·Drivers are <strong>no</strong>w being counseled for use <strong>of</strong> dynamic braking in regulating speed duringobservation <strong>of</strong> temporary/permanent speed restrictions to avoid any brake binding.Imposition <strong>of</strong> speed restriction on <strong>the</strong> approach <strong>of</strong> gradient is being done judiciouslykeeping in mind <strong>the</strong> approach speed requirements and steps are taken forremoval/relaxing <strong>the</strong> same at <strong>the</strong> earliest. Besides this, trains are also examined for <strong>the</strong>ircorrect leakage rates so as to avoid brake binding during running. It was intimated that allIr ;Jirl~; uru t)(:irlU clleckncJ at BHTK for brake binding. .5.0 Study <strong>of</strong> Khurda Road Division <strong>of</strong> S.E.Rly:. IIKUR division <strong>of</strong> S.E. Railway has steep gradients <strong>of</strong> 1 in 100 and 1 in 150, accompaniedwith curves up to 4 degree. Critical gradients, which ,are prone to stalling, are shownbelo'll. In Up direction LOADED 58 BOXN trains are worked and in <strong>the</strong> down directionloaded 40 BCt'J trains are v.orked.r---~i NO.I S. SECTIONt -~: -~1~~~--5~~~~3. 1 GHNH-ROP (On)I 4. I BAV-SPT (On)l~~:-l-~-}~~=·t~~l~~n)TYPE OFLOAD40 BCN58 BOX N40 BCN40 BCN58 BOX N40 BCN'.STEEPESTGRADIENT1 IN150 R1 in 150 R1 in 150 R1 in 150 R1 in 150 R1 in 100 R2 Deqree2 Degree4 Deqree2 Deqree2 Demee20eoree58 BOXN loads are worked with WDM2 multiple or single WOG2 loco. Following tableshows <strong>no</strong>. or stalling cases involving different locos. It can be seen that during fourmonths, <strong>the</strong>re have been 52 stalling cases. Out <strong>of</strong> <strong>the</strong>se 32 (61.5%) are involving singleWDG2, while working 40 BCN loads arid 18(34.65 %) are involving WDM2 multiple, whilev/orking 58 BOXN loads. .MONTH NO.Orr .TYPE OF NO. 0F ST.ALLING NO.OF STALLINGSTALLING LOAD CASES INVOLVING CASES H~VOLVING2001 CASES WDM2 WDG240 58 SU MU SU MU -BeN BOXN.Mav 3 ._ 2 1 - 1 '2 --_. --- ...- ---- _._- •..._--_ •.- ..... AJune 11 7 4 I - 4 7 -_Juh~_ 22 15 5 1 5 ~..- .... _._ ...•. 16........ ......_----Auq 16 7 9 - 8 7 1Total: 52 31 19 1 18 32 1,,, '

Similarly starting load for WDM2 multiple for fair wea<strong>the</strong>r conditions, on 1 in 150 gradientis 4518 tonnes, whereas <strong>the</strong> actual load worked by <strong>the</strong> multiple in <strong>the</strong> section is 4850tons.6.0 Load Haulage Capability o,f<strong>the</strong> Locomotive:I6.1 Load Haulage Capability and Concept <strong>of</strong> Tractive Effort (T.E.):Primarily tractive effort <strong>of</strong> <strong>the</strong> loco determines <strong>the</strong> load hauling cap8bility. It is <strong>the</strong>combined adhesive force developed by <strong>the</strong> locomotive wheels on <strong>the</strong> rail. The tractiveeffort transforms into draw bar pull after accounting for <strong>the</strong> locomotive resistance, andpulls <strong>the</strong> trailing load.Tractive effort varies ~i!.h <strong>the</strong> speed. The starting tractive effort is determined by adhesionlimit <strong>of</strong> <strong>the</strong> locomotive and decides <strong>the</strong> starting load~. Tractive effort at varioL.s speeusdetermines acceleration potential <strong>of</strong> <strong>the</strong> locomotive. Starting tractive effort in itself is afunction <strong>of</strong> locomotive weight and adhesion, higher <strong>the</strong> weight higher <strong>the</strong> T.E and higher<strong>the</strong> adhesion, higher <strong>the</strong> T.E.Though weight is constant for a particular locomotive, adhesion is dependent on number<strong>of</strong> factors and it is always <strong>the</strong> endeavor <strong>of</strong> locomotive designer to achieve as highadhesion as possible to maximize <strong>the</strong> loco capability.A locomotive employs <strong>the</strong> friction drive between <strong>the</strong> wheels and rails, and ma~imum forcewhich can be transmitted by this drive is dependent upon thr-:load carried by <strong>the</strong> drivingwheels and is simply referred,to as adhesion. The full weight <strong>of</strong> <strong>the</strong> locomotive is usua!'yemployed for adhesion and increase in T.E. <strong>of</strong> <strong>the</strong> locomotive without proportionateincrease in weight necessitates that <strong>the</strong> value <strong>of</strong> adhesion, <strong>the</strong> ratio between tractive effortand weight, be improved greatly.Drive wheel and rail work as friction gear. In <strong>the</strong> stabilized state <strong>of</strong> torque transmission,<strong>the</strong> tractive effort in <strong>the</strong> starting condition is produced by adhesive friction between drivenwheel and rail. As soon as rolling <strong>of</strong> <strong>the</strong> driven wheel starts, <strong>the</strong> adhesion frk:tion changesto kinematic rolling friction.Both adhesive and kinematic friction and <strong>the</strong>re by tractive effort are dependent on manydesign and external variables. The. factors that affect t~active effort can be broadlyclassified as under.• Locomotive desigf}• Track conditions and rail wr,eel contact• Environmental and wea<strong>the</strong>r conditions

..6.2.1 Loco Design• Axle load ..• Load distribution and weight transfer• Locomotive bqq~1and geometry• Type <strong>of</strong> suspension .• Characteristic <strong>of</strong> transmission• Electrical regulation and adhesion control• Gradient• Rail pr<strong>of</strong>ile• Vertical irregularities• Track curvature• Angle <strong>of</strong> attack• Slip stick effect• Rail surface condition• \filet track• Oily track• Sanding6.3. Haulaqe Charts for Locomotive~The haulage charts currently in vogue, for <strong>the</strong> mainline freight locomotives for electricand diesel traction viz., WAG7, WAGS, WDM2 and WDG2 locomotives are given below:AOE 20 30 40 50 60 70 80 90 100 STARTIEL >4700 >4700 >4700 >4700 >4700 >4700 >4700 4619 2785 >4700~~v 00 >4700 >4700 >4700 >4700 >4700 >4700 3465 2345 1465 >470000-->4700 >4700 >4700 4085 3285 2715 1915 1295 820 >4700l-~ 50 3960 3880 3795 3210 2590 3.150 1515 1020 645 39<strong>77</strong>I 1 00-1-2705- ---- 2665 2625 2225 1805 1500 1055 725 450 3002[ 50 TI345 1335 1320 1120 905 750 515 - - 1700

GRADE 20 30 40 50 60 70 80 STARTLEVEL >4700 >4700 >4700 (>4700 >4700 >4700 4713 >4700:500 .>4700 >4700 >4700 >4700 >4700 3382 2266 >4700200 3602 3512 3411 3310 2714 1762 1233 3810150 2782 272(, 2663 2599 2140 1390 972 3198100 IHl)O._----1863 1832 1798 1485 994 700 240750 4700 >4700 >4700 >4700 >4700 3845 2935 2258 1730 >4700500 >4700 >4700 3875 2760 2140 1725 1390 1125 895 >4700--400 >4700 4515 3335 2385 1860 1510 1225 990 795 4545200 3690 2595 .. 1940 1400 1105 905 740 605 490 3250150 2850 2005 1505 1085 860 705 575 470 380 2725100 1945 1365 1020 735 580 470 385 310 245 2050-_._- -_ ..- -_._-- -_ ...- ._...... _- "-' ....-. -..-. -- ------ -- -_.- -- --50 %0 (J65 4H5 340 255 - - . - 1150.--GRADE 20 30 40 50 60 70 80 90 100 STARTLEVEL >4700 >4700 >4700 >4700 >4700 4610 3490 2660 2090 >4700--_._----_. 500 >4700 >4700 4640 3425 2665 2075 1660 1325 1090 >4700400 >4700 >4700 3990 2960 2320 1815 1460 1170 965 >4700200 >4700 3310 2325 '1745 1385 1095 890 720 600 4400150 . 3865 2565 1805 1355 1075 850 690 560 465 36S0100 2645 17501---' .._- ---_ ...~---- f-_123O 920 730 575 465 370 305 278550 1320 860 590 430 330 - - - - 1570The current load charts are very simple to use and clearly lay down <strong>the</strong> starting capability<strong>of</strong> a locomotive at level and on different gradients for tangent Le. straight track.It is however to be <strong>no</strong>ted that, <strong>the</strong> load charlo; are valid for fair wea<strong>the</strong>r conditionswith track maintenance to requisito standards. .andThe current load charts do <strong>no</strong>t <strong>the</strong>refore truly represent <strong>the</strong> field conditions where a host<strong>of</strong> factors <strong>no</strong>t accounted for in above, like adverse wea<strong>the</strong>r/rail conditions, combination <strong>of</strong>grade with a curve adding substantially to <strong>the</strong> rolling resistance that <strong>the</strong> locomotive has toovercome etc., are regularly present.

As discussed earlier, <strong>the</strong> load hauling capability <strong>of</strong> a locomotive is dependant on <strong>the</strong>adhesion between <strong>the</strong> rail and <strong>the</strong> wheel.Adhesion values vary significantly under different conditions <strong>of</strong> rail Le. whe<strong>the</strong>r it is dry or'1/(:1 8nd v/ho!h(:r sllnc..Jinghas been carried out or <strong>no</strong>t. Following table shows <strong>the</strong> variationin adhosion '/8Iues for different loco under dry e·anded and dry unsanded conditions. It willbe observed that loss <strong>of</strong> adhesion could be around 10%, with sanding <strong>no</strong>t applied.LOCO DRY SANDED DRY UNSANDED'i'WDM2 0.333 0.274: I; ,-. 'NAM4 1--- ---- 0.34 0.32-1--- WAG5 0.31 0.28----_. --------------IWAG? 0.3 ci---0.355I WDG2-0.355---0.361- WAG9N.A.0.37!L- WDG4 0.42---------- '-------_. 0.38 __._----The adhesion values will be still worse for wet conditions <strong>of</strong> rail. The adhesion will be10Vierby around 15%- 20% on wet rails compared to <strong>the</strong> dry rails. Variation in adhesio<strong>no</strong>n dry rail and wet rail is shown below.t:0VIIII..c"0n:l0.45-004 -0.350.30.25 -.•..0 - 0.2:iIII0.150u0.10.05o·0 0.1 0.15 0.2 0.25' 0.3Adhesion on clean dry rail

0.3Coeffecient<strong>of</strong> Adhesion on Oily RailO.L~c:0Vl 0.2 .:-._...NJN STANDA RD TRACK ( Of\OITIG;>oJGiIIt is <strong>the</strong>refore desirable that load tables are redrawn taking adverse effect <strong>of</strong> wet rails intoaccount.

Similar to grade resistance on <strong>the</strong> gradients, on <strong>the</strong> curves, <strong>the</strong> rolling stock encountercurv.e resistance. The curve resistance is significant and is in <strong>the</strong> order <strong>of</strong> 0.4 kg per{annes per degree <strong>of</strong> curvature and can significantly affect <strong>the</strong> loco starting capability.Graded sections are generally associated with curves. A loco, which can start and haul 58UOX N un.1 in 200 qracJient, on a straight section, may <strong>no</strong>t start 50 BOX N on 1 in 200~radi0nt with 4 d&[jree r;urv~. ~!enc.e <strong>the</strong> elemert uf curve resistance Ci:.n play animportant role in <strong>the</strong> stalling or running through <strong>of</strong> a load.Normally, <strong>the</strong> effect <strong>of</strong> curve resistance in a grade is accounted for by designing <strong>the</strong> gradeas 'compensated' or ' <strong>no</strong>n - compe::nsated' grade, Le., a grade <strong>of</strong> 1 in 150 on a straighttrack when compensated for eXisting' curve <strong>of</strong> 4 degree could <strong>of</strong>fer cumulative rollingresistance equal to a grade <strong>of</strong> 1 in 121. -Since <strong>the</strong>re could be a large variety <strong>of</strong> curvesavailable in <strong>the</strong> field, working out loads for each degree <strong>of</strong> curve would <strong>no</strong>t be feasible, itis <strong>the</strong> <strong>no</strong>rmal practice to consider <strong>the</strong> value <strong>of</strong> 'compensated gradient' in <strong>the</strong> load tables.But in <strong>the</strong> field <strong>the</strong> gradient posts indicate <strong>the</strong> actual typical gradient level available in <strong>the</strong>spot and it is this value, which becomes <strong>the</strong> guiding factor when fixing trailing loads, whichneeds to be corrected.On <strong>the</strong> BG system <strong>of</strong> IR, <strong>no</strong>rmally a curve <strong>of</strong> more than 4 deg. is rare. Most curves wouldlie somewhere between 0 to 4

6.3.4.2 Length <strong>of</strong> <strong>the</strong> Gradient and Approach Speed:Presently <strong>the</strong> load charts only specify <strong>the</strong> maximum loads that a loco can start at differentgradients, on a tangent track, and <strong>the</strong> loads that it can maintain continuously at specifiedbalancing speed on different gradients. While <strong>the</strong> first part <strong>of</strong> <strong>the</strong> information is useful andessential, <strong>the</strong> latter part - regarding loads it can maintain at different balancing speeds ona gradient is <strong>no</strong>t <strong>of</strong> great practical significance in regard to fixing up <strong>the</strong> trailing load. Theweight <strong>of</strong> <strong>the</strong> trailing load is primarily determined by <strong>the</strong> starting capability <strong>of</strong> <strong>the</strong>locomotive only, but when sec.:tionalcapacity approaches saturatic)n point balancing speedalso assumes importance for generation <strong>of</strong> extra capacity.Important point which is <strong>of</strong> practical value in <strong>the</strong> field is <strong>the</strong> information as to what is <strong>the</strong>length <strong>of</strong> a particular gradient that a loco can clear with <strong>the</strong> given .train load alreadydetermined by its starting load capability consideration as mentioned above. This lengthwill be dependent on two factors: firstly, <strong>the</strong> inherent loco design and its capabilityincluding its Tractive Effort (TE) versus speed characteristics and secondly, <strong>the</strong> attackspeed, i.e. <strong>the</strong> speed at which <strong>the</strong> locomotive approaches <strong>the</strong> start <strong>of</strong> <strong>the</strong> gradient.The motive power requirement for clearance <strong>of</strong> different gradients as per actual conditionsavailable in <strong>the</strong> field can be worked out for different train speeds ensuring that <strong>the</strong> tractionmotor currents do <strong>no</strong>t exceed <strong>the</strong> maximum permitted rating etc. <strong>of</strong> <strong>the</strong> locomotive andstalling are avoided.It is <strong>the</strong>refore proposed to include this information also in <strong>the</strong> load charts, in future, forguidance, for smoo<strong>the</strong>r train operations.For various approach speeds, feasibility <strong>of</strong> clearing 58 BOXN loads, maximum stretdl thatcan be cleared and balancing speed are evaluated through computer simulation. lhasehave been worked for four critical gradients, viz., 1in 100, 1in 150, 1 in 200 and 1in 250,both for tangent track and 2.5 degree curve and are shown in Annexure No.VII.It will greatly assist in laying 'down operational guide lines like judicious imposition <strong>of</strong>speed restrictions, location <strong>of</strong> stop/warning signals, need for run through operation at <strong>the</strong>specific locations, provision <strong>of</strong> bankers etc.6.3.5 Based eJn <strong>the</strong> above discussion <strong>the</strong>reforu, taking into account <strong>the</strong> aforesaidoperating/field conditions, <strong>the</strong> load tables have Leen also drawn for wet rail conditiom with -2.5 0 curve for <strong>the</strong> different diesel and electric locos and are shown in Annexure No. VI.The incidences <strong>of</strong> wheel burnt rails / scabb~d r~i1s take place due to continuous \<strong>the</strong>elslipping <strong>of</strong> loco becaw;e <strong>of</strong> inadequate motive p6wer <strong>of</strong> <strong>the</strong> locomotive vis-a-vis 10addemand and efforts on <strong>the</strong> part <strong>of</strong> driver to pull <strong>the</strong> train and clear section in such ad'eiseconditions. The year-wise incidences <strong>of</strong> wheel burnt rails in Bilaspur Division are encbs edas <strong>the</strong> Annexure No. VIII. I

• __ H _________ (unto")The summarized position <strong>of</strong> <strong>the</strong> incidences occurring over <strong>the</strong> year In this Division isas under:SectionYear1995-9( 1996-97 1997-98 1998-99 1999-00 2000-01 2001-02Nov·LM'I{-KTF, 2 I 1 4 10 24 15. - .. - - ---'-V.'II:-/\/'!

7.2.2 The restricfions for double-headed 'operation <strong>of</strong> WDG2 as per speed certificate No.H SD.WDG2.11 dated 27.12.95 are as under:~ 2.2.3 - Double headed operation is permitted on MBG and RBG spans except for12.2 m RBG span where dispersion <strong>of</strong> longitudinal forces should be ensured interms <strong>of</strong> clause 2.8.2.3 <strong>of</strong> Bridge Rules. BGML bridges may be checked for <strong>the</strong>irsuitability for MBG loading in terms <strong>of</strong> guidelines issued for same by ROSa andsubsequent letter No. CBS/DOW dated 31.8.94:Based on revised values <strong>of</strong> TE & BF <strong>of</strong> WOG2 advised as 40.5t and 11.7t (MP Dte's NoteNo. SD.POL.12.8 dated 02.&:2000) double:'headed operation <strong>of</strong> WDG2 is constrained asIunder: .."8GML spans <strong>of</strong> 31.9m and 47.3m (effective) are prollibited."The clearance with regard to' bridges refers to standard design <strong>of</strong> girders, slabs. pipes.culverts, piers and abutments etc. issued by ROSa for BGML, RBG and MBG-1987standard loadings. The constrains specified in 7.2.1 & 7.2.2 above do <strong>no</strong>t include <strong>the</strong><strong>no</strong>n-standard bridges including those to GC loading.7.2.3 The above restriction is necessary to limit <strong>the</strong> longitudinal track forces to 60 t <strong>of</strong> TE ,on such bridges.Additional Member/Electrical's suggestion received vide D.O. No. 2001/Elect (TRS)/440/6dated 17.9.2001 to overcome bridge constraints for multiple operation <strong>of</strong> locos byproviding switch to limit TE on bridges is <strong>no</strong>t considered acceptable for safety <strong>of</strong>permanent vital assets like bridges. Therefore bridge strengtf-tening will be necessary.All those bridges, which do <strong>no</strong>t conform to ROSa. design. <strong>the</strong> superstructure. bearingsand substructure including foundations, are to be checked by Railways on condition basis(case by case) befo,~eevolving <strong>the</strong> cost <strong>of</strong> streng<strong>the</strong>ning/modification for such bridges asit may vary considerably. However. tne appruximate cost per span <strong>of</strong> 45.7m span i3GMLgirder bridge. requiring modifications, has been worked out as Rs. 12.50 lacs.8.0 Summary <strong>of</strong> Discussions & Recommendations:The issues dealt primarily in this <strong>report</strong> are:1. Whe<strong>the</strong>r under powering has really affected <strong>the</strong> Line Capacity <strong>of</strong> crticalsections?2. Whe<strong>the</strong>r <strong>the</strong>re has been substantial damage to <strong>the</strong> track due to wheel burns?3. Can ROSa give any techniGsl Ll.oluU~HJ to overcome <strong>the</strong> problem Of stalling? .4. Cost implications <strong>of</strong> <strong>the</strong> techniCal solutions. .The data collected from <strong>the</strong> field shows that <strong>the</strong>re are about 3.6 cases <strong>of</strong> stallirg <strong>of</strong>freight trains every day on <strong>the</strong> Indian Railways. Each stalling takes an' average 011.519

hours in clearinfJ <strong>the</strong> section through provision <strong>of</strong> an extra power. Test division take" forlfI8 study by RDSO is Bilaspur Division <strong>of</strong> S.E.Railw

plDced at Annexure No. VI. New sets <strong>of</strong> tables - one based on standard conditions anj<strong>the</strong> o<strong>the</strong>r on adverse conditions (taking into consideration <strong>the</strong> wet rDil conditions and 2.5 0<strong>of</strong> curvature) are beir~~rissued. O<strong>the</strong>r factors like conditiol"ls <strong>of</strong> track have <strong>no</strong>t been take ninto consideration as it is hoped that all <strong>the</strong> adverse factors will <strong>no</strong>t occur toge'lher.8.3.1.2 ROSO's guidelines for approach/attack speed versus maximum negotia blegradient length are attached in Annexure No. VII.8.3.1.3 While deciding <strong>the</strong> use <strong>of</strong> banker, vis-a-vis- double heading, it will be pragma ticto have multiple heading when <strong>the</strong>re are stretches <strong>of</strong> steeper gradients throughout <strong>the</strong>section as banking <strong>of</strong> trains on graded sections can lead to transport bottlenecks by way<strong>of</strong> banker movement, loss <strong>of</strong> time in attaching/detaching <strong>of</strong> bankers etc. but when <strong>the</strong>same (graded section) is limited to one or two sub-sections, provision <strong>of</strong> banker iseco<strong>no</strong>mical so that overall hauling capacity does <strong>no</strong>t remain unutilized during most ollherun.Double-headed operation is <strong>no</strong>t permitted on certain BGML spans, This restrictionis necessary to limit <strong>the</strong> longitudinal track force to 60 t <strong>of</strong> TE. Hence, for running <strong>of</strong> dOJbleheaded trains on those bridges, which do <strong>no</strong>t confirm to <strong>RDSO's</strong> design, <strong>the</strong> superstructure, bearings and sub-structure including foundation should be streng<strong>the</strong>ned. Theapproximate cost per span <strong>of</strong> 45.7m span BGML girder bridge, has been worked out asRs. 12.50 lakhs.S.E.Railway vide <strong>the</strong>ir letter No. 48/4 dated 2/7.3.2001 has asked for an addito nal130 electrical and 40 diesel locos for following <strong>the</strong> existing Rosa load tables (AnnexureNo.1X). The same may ~ur<strong>the</strong>r increase if revised load tables'are used. Average additonalloco cost Rs. 3.75 crores approximately, besides <strong>the</strong> cost <strong>of</strong> homing sheds that wI bea<strong>no</strong><strong>the</strong>r Rs. 10 crores for every 100 locos. Hence, <strong>the</strong> benefits/returns may <strong>no</strong>tcommensurate with <strong>the</strong> additional investment in <strong>the</strong> form <strong>of</strong> extra locos and streng<strong>the</strong>n ing<strong>of</strong> bridges.8.5 Finally it is concluded that provision <strong>of</strong> adequate power as per <strong>the</strong> technicalsolutions given in <strong>the</strong> present ROSO load tables may give additional benefits in <strong>the</strong> b rm<strong>of</strong> generation <strong>of</strong> extra path ,due to belter/improved balancing speeds and clearanca <strong>of</strong>critical block sections in lesser time (Annexure No. X). This may be advantageous forthose sections, which are operating to near saturation level <strong>of</strong> line capacity. But '<strong>the</strong>nextra capacity is available to run extra trains, decision should be taken judich.J slykeeping in mind <strong>the</strong> financial implications .. However, It is felt that in large number <strong>of</strong> cases, improvement in oper(ti ngpractices as done by Bilaspur division (Para 4.1 <strong>of</strong> <strong>the</strong> <strong>report</strong>) will greatly help in redLCing<strong>the</strong> incidences <strong>of</strong> stalling <strong>of</strong> freight trains in graded sections at minimal cost.

8.6 Reducing <strong>the</strong> speed differE::ntial between freight and coaching trains has been!

q-~1~~JF.y~r, m- ~r~1.[

An nexuroe·.!!f !.Tir:/;'.",;1/ ;lj;;IJ.;)[ I ::

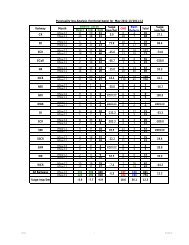

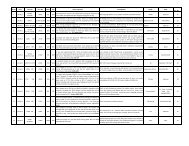

I HL Y- . Di"jsion Total Period T faction Av.C:lSCS Divll. "'illt N\). <strong>of</strong> cases on gr:ldiclllS II I C:1SCS From To Per d:\\' ll1ax. C:lses 1:100 1: 150 1:200 I OlhlTS I\\'.:,;,. i Ajlllcr 19 Sepl.2000 :\u!!.200 I Diesel 0.05 Kola I -Il)- I -I K 49 Sepl.2000 A:Jg.2001 I Dsl/Elect 0.13I- 06 43 Iota -Ratlall1 34 Sepl.2000 AUl!..200 I Dsi/Ekct 0.09 - 30 04 I .SKy. Chenllai 02 Apr.1999 ~!:lr.200 I Diesel - Palghat - - 02 I -P3lgh:Jt 54 Apr.1999 i\lar.200 I Diesel 0.07 20 0: · I ':iI T rivandrul11 15 Apr.1999 ~lar.2001 Diesel 0.02 05 - · I i l)Bangalore 37 Apr.1999 ~lar.200 I Diesel 0.05,-._I - 01 l)l)IMysore ., 38 Apr. 1999 j\ 13r.200 I Diesel 0.05 18I, -- I 20Tiruchchir3ppalli 05 Apr.1999 t\lar.200 I Diesel 0.01 02 - 02 I 01Madurai 06 Apr.1999 Mar.2001 Diesel 0.01 - 02 01 I 03l\'.?Rly. Lumbding 85 Apr.2000 Mar.2001· Diesel 0.23 Lumbding - 57 28 I -Alipurdwar 02 Apr.2000 Mar.2001 Diesel 0.01 - 01 01 I -Kathihar 02 Apr.2000 Mar.2001 Diese. 0.01 - - 01 . I .S.C.Rly. Hubli 55 S-:p1.2000 Aug.2001 Diesel 0.15 Hubli 55 - · I -Guntakal 31 Sept.2000 Aug.2001 Diesel 0.08 31 - - I -Secunc!nbad 09 Sept.2000 AUI!.2001 Electric 0.02 09 - - I -,C.~I) Bhopal 33 Sept.2000 Aug.2001 Diesel 0.09 Nagpur 01 24 08 I -37 Sept.2000 . AU!!.2001 Electric 0.10 - 29 OS I -Bhusaw::1 06 Jan. 2001 Sept.2001 Diesel 0.02 - 05 01 I -30 Sept.2000 Au!!.200J Electric 0.08 - 30 I- I -Jhansi 22 Jan. 2001 Sept.2001 Diesel 0.08 - II 1 I I -12 Sepl.2000 AU\:.2001 Electric 0.03 - 10 02 I --IS Scpl.2000 AU!!.2001 Electric 0.05 I - 02 06 I 10Mumb:;i S6 Scpt.2000 Aug.2001 Diesel 0.24 56 23 07 I - INagpur 1·1] St:pt.2000 Aug.2001 Eleclric 0.40 ! II 124 12 I - ISholapu~ 40 Apr. 2001 I Sept.200 1 Ditsel 0.22 r-TI 26 01 I -S.::.Rly. Adra 41 l:Jn.1999 S~p1.1999 I DslIElcct 0.15 Khurd:l Rd. N.A. I IKhar3~C'!Jr 09 J:ln. 1999 SC;J:.1999 I Dsl/Elect 0.03 - I 07 02 I -Sambalpur 21 Apr.1999 ~!:lr.2000 I DslIElect 0.06 07 I 07 - I 07,Chakr3c!larrur 19 J:ln.1999 St:pL1999 I Dsl/Elect 0.07 IG I OJ - I . INa~pur 56 Jan. 1999 Dec.1999 Electric 0.15 - I 25 "0 I IIKhurd:l Rd. 99 lan. J 999 SepLI999 DslIElect 0.37 N,A. IWaltair 05 Jan. J 998 Dec.199S Dsl/Elcct 001 - I 04 . I 01Bilaspur 27 Apr.2000 Mar.2001 DslIElect 0.07 1 I cases on MIL & 16 cases on C IC:\.Rly. Delhi 18 Mar.2000 Jun. 200 I Dsl/Elect 0.04 - I 18 - I -Avcrage No. <strong>of</strong>c:lsCS lier d3\' on IR - 3.57IJabalpur 10 0IJul2001 .3J lul200 1 Diesel '0.33 03 03 04 I I

S. Section Grade Curvature Length (km)No.(deQree)1. GTK-KGB 1/150 - 1.02. KGB-BIG--- ------1/150 - 0.5,O.25--r3)3. BIG-KGS --_.~- ....1/150 --1.5,0.5 (2)t: KGS-BHTK-------11"00 5.67 7.755. BHTK-KOI -_ .. _-- ---- ---_. __ ..•1/100 5.67 2.0- --- 1/844 ._ •••• ____ ~_5.67 1.06. KOI-F.Jr'JD----- 1/125 3 1.25I'-1/100'-----3 1.01/100 1 1.51/150 1.5..- --- ------7. VKr~-,JTI-_.~_.------ 1/150 2 1.0. 8. .nl-API~----- 1/150. __ .._-------- 1 1.09. AF'R-AAL1---1/150 1.5 1'.0--1/150 1 1.010. AAL-BUH 1/150 1 2.711. \ BUH-SNGP 1/150 2 5.512. SDL-BDWA 1/100 1/3 1.013. BDWA-GGT--- -----_.-_._. 1/100 4 1.25- ----14. GGT-GRC 1/125 31.25-."--- _ ...... _-. --_ ..-----_15. BRC-NRZ8 1/125 21.0-... -._- - ----1E;. r'JRZB-KKI---- 1/150 1.53.0- -_. -------- -17. KKI-UMR 1/150 1.52.75-.--- . - .... _._--_._- 18. .UMI~-CHO ----._---- 1/150 3.02.5019. CHD-RPD 1/140 1.53.25---- ,'--- 20. \ RPD-KTE 1/200 --2.0

__ .' __ 0"_ 0.0.••• 0- __ ••----.-.'-- ·----r--·--· .--------Major Block Location Length Rail Speed Grad icntsection section From Tokm in section Restrictionkm km Yes/No1 2 3 4 5 6 7 8;PH-GAD URGA-KRBA 696/4 696/30 0.600 52 kg Yes 1/150+2°-_ ... _. - KBS-KRBA..706/18 707/8 e-Q.(.50 52 kg Yes 1/150-._ ... __.-- KBS-GAD 709/2 709/12 0.700 _2? kg__ No 1/400._--- _._--- --)UG-DRZ----._"'--GDZ-RSA 897/9 897/10 0.100 52kL- Yes L---'3SP-APR _~LF-APR 868/2 868/3 .0.100 52 kg Yes1/150+ 1°----- _.~PR-KTE APR-AAL 869/31 869/33 0.050 52 kq No 1/2000-------_- .... _. -- 876/31 8<strong>77</strong>/11 0.010 .'§Q.~g--- No1/150+ 1u- .. .... . --_.- ...__ .- -- -_._----- f-----.-.- SOL-SNGP 906/32 906/22 0;050 60 kg No1/150+2°- -- 906/10 906/12 0026 60 kq No 1/150+2 u-_._------- -- 906/4 905/32 0.128 60 kg No 1/150+1 u------------- -- 905/14 805/2 0.500 60 kq-No -00--.- SNGP-YD 904/44 904/40 0.026 60 kq No1/15('+-2 u-- -- 904/22 904/6 0.030 60 kq No -00--- ._- SNG~-CHDX 903/18 903/4 0.580 60 kg No L-- -- 897/24 897/26 0.026 60 k9.-- No1/15(+2°-- -- 89§/1~_ ~ 896/26 .._._~- ------0.014 ~O_~g_ No 1/40(+2°-- _._- -- 896/14 896/10 0.060 60 kq No -00-- CHDX-BUH 896/36 896/34 '0.026 60 kq No -00-- 893/28 893/20 '0.052 60 kg No 1/150--- BUH-AAL 886/24 886/22 0.052 60 kg No1/20(+3 u- AAL-APR 880/14 880/12 0.020 60 kg No 1/200 ._--------- -- 870/26 870/24 0.052 60 kq No 1/200 F-----_._- -- MDXR-GGT 939/26 939/22 0.050 52 kg__ No 1/13~.3+4_3°-- .._---- --- --- GGT-BDWA 925/22 925/18 '0.039 5~_ No 1/1 OCF--.... _- -------- BDWA-SDL 916/10 916/0 0.200 52 kg No 1/400 F- SDL-SNGP 907/12 907/10 0.013 60 kg- No 1/15C+-2°- MDXR-BRS 943/19 943/27 0.250 60 kq No 1/12:- -- 943/31 943/35 0.100 60 kq No 1/12:- BRS-YD 947/3 947/21 0.750 52 kq No 1/20CDBRS-NRZB 948/3 951/3 3.000 52 kq No 1/15(+-3°- -- 954/25 955/5 0.500 52 kg No 1/15C-- -- 963/1 964/1 1.000 52 kg No 1/15C+-1.5°-- NRZB-KKI 964/19 965/1 00400 52 kg No 1/20~-- KKI-UMR 967/1 968/1 1.000 52 kg No 1/15(- -- 9l0/9 972/5 2.80U 52 kg No 1/15

•• _____ 4 ___--•• ' 10 ____ --- -- _--- .- 996/11 996/15 0.070 52 kg No 1/2000-_._-- -- .- 996/31 996/33,0.030, -,_52.kg_ ... No -00-CHD-VYK 997/1'· •..'99iig--- ...•._-- ._.__ . . . '._ .. _~.-.. '" _.__ .. _ .._--- 1.500 52 k~ No 1/250 F- -r. 997/13 997/17 0.140 52 kg No -00--- I -- 998/1 998/3 p.050 52 kg No 1/150-t3 u--- -- 998/11 998/13 0.100 52 kg No -00-._.- . .- '-- _.-~_--. -- 998/25 998/27 0.080 _?1..!5.9- -No -00-----_~ - ---!,PR-KT[ CHD·VYK 998/19 998/21 0.030 52 kg No 1/150-t3 u F..' ... .... -___---- . -- -- .. --- ----- -. 1000/17 1001/17 0.800 52 kg No 1/150-t3 v_._ ..._-- .. _._---_.-- -- 1000/2 1003/1 '0.080 52 kg No 1/140-t1.5 v____ •• 0..- "------.' \j,(K-r~P() ___ 11"'05/1 ._. _w_. __ 1005/5 0.040 52 kg_ No .., , , 1/140-- -- 1006/17 1006/19 0.020 52 ~g_ No 1/200+3U1007/23 1012/1 0.210 52 kg No -00-1010/3 101017 0.140 52 kg No 1/200+2 u= ~---'~-l(~=-=_=~-- ! -. 1011/23 1012/1 0.210 52 kq No -00-_-=~._ ._ .__ _ f~f)D:_~LYV______1016/17 1016/21 0.140 52 kg No L--=---- -----l--~----------.- -_.-- I -- 1017/35 1017/41 0.2Q~ 52 k9- No . JJ150=i~-1019/19 1019/23 0.140 52 kL- No 1/200'-- 1020/5 1020/11 0.210 52 kg No 1/150- --1020/23 1021/27 1.000 52 kg No -00--- -- 1021/35 1021/41 0.210 52 kg No -00--- JLW·YD 1025/5 1025/15 0.350 52 kg No 1/200·-- JLW-NKJ 1025/35 1025/39 0.140 60 kg No -00-f--.---- _.KTE-APR NKJ-JLW 1027/6 1027/10 0.140 ~9~L- No 1/200 F- JLW-RPD 1015/20 1015/14 0.210 60 kg No 1/200 F--.. .. 1006tnf--,1006/4 O.O~C '30 kg No L-1005/26 1005/24 0.050 60 kq No 1/140 F1005/20 1005/18 0.026 52 kg No -00-~-- -- 993/18 993/16 0.040 52 kg No 1/150- -- 990/14 990/12 0.100 52 kg No 1/125- -- 989/14 989/6 0.240 52 kg Yes 1/125+1 v-- -- 998/10 997/28 0.400 52 kq N.o 1/250LOA-UMR 986/22 986/14 0.700 52 kg Yes 1/10Ot-10- -- 985/2 984/2 1.000 52 kq No 1/100-- -- 980/22 980/2 0.800 52 kg Yes 1/100+-3 0- KKI-NRZB 965/2 963/2 2.000 52 kg No 1/150+-1.5 F- - 954/20 954/0 0.500 60 kg No 1/150 F-- NRZB-BRS 948/10 948/2 0.250 60 kg No 1/200---'.- BRS-YD 947/20 947/0 0.500 60 kg_ NoL------_._. --DUG-R DUG-DLBS 864/10 864/18 0.250 60 kg No NA-- DUG·YD 866/10 866/16 0.200 60 kg No NAR-DUG DUG-DLBS :364/9 864117 0.250 60 kg No NAc== BOR-DLBS 861/9 861/13 0.140 60 kg No NA---" ··--r;:TlO"~'-'l',,""':----;-;-

HAULAGE CHARTS FOR DIESEL LOCOS FOR DRY RAIL CONDITIONS--GRADI: 20 30 40 50 60 70 lW \)0 100 START------ -_._- -.--LEVEL ;"\X50 >4X50 >4850 >4850 >4850---~--_. 4610 34\)0------- -- 2660 20\)0---->4850500 >4850 >4850 4640 3425 2665 2075 1660 1325 I O~IO--- ----'-->4850400 >4850 >4850 3990 2960 2320 1815 1460 1170 %5 >4850:-J- .-200 >4850 3310 2::25 1745 1385 . 109'3 890 720 600 4400150 3865 2565 1805 1355 1075 850 690 560 465 3690IOU 2645 1750 1230 920 730 575 465 370 305 278550 1320 860 590 430 330 250 195 - . - 1570GRADE 20 30 40 50 60 70 80 90 100 STARTLEYFI >4850 >4850 >4850 >4850 >4850 3844 2935 2258 1730 >4850---500 >4850 >4850 3875 2760 2140 i725 1390 1125 8\)5" >4850; 400 ;.4850 4515 3335 ,t.385 1860 1510 1225 ()()O 7()5 45i~5200 3690 2595 1940 1400 1105 \)05 7'10 605 it () () ~~5~_~ JJ------- -- ---- -- --- ----- --- ---- --- ---- -------- _ .. ',-- --- ------- -_.--150 2850 2005 150:5 1085 860 705 575 470 3:)0 2725100 1945 1365 1020 735 580 470 385 310 245 205050 900 665 485 340 255 - - - . - 1150-.••....•..,..---- --.----_. ---- --..:..... :~~

IJi\ULi\(;ECIJi\IrI'S !"{»){ ELECTHIC LOCOS Foa D){Y aAl), CONDITIONS(ON TANGENT TRACK) FOR IlOXN LOAD(i!(II,I)!: 2(---- _ .. ~-,--..- --- _._. ,LEVFL :",,1X---- --_ ..- ------~5(JO >4X200 36('-150- 27--- ----._-- ._._--- ----J 30 40.._ ......••.-------50 60 70 lW START-----50------>4850 >4850 >4850 >4850 >4850 4713 >485050 >4850 >4850 >4850 >4850 3382 2266 ---;-4850)2 3512 3411 3310 2714 1762 1233 3810X2 2726 2663 2599 2140 1390 972 3198-j0iJ-----r-1 Xl )() 1863 11532 1798 1485 994 700 2407·--S(j-----r C)20 912 902 893 742 483 330 1438 ------j--- ----_Cil~i\ !2 1 L_,_~___30 40 50 60 70 80 90 100 STARTU:VLL ..... 4X50 >4X50 >4850 >4850 >4850 >4850 >4850 4619- 2785 >4850---5(j-(j--- r-::-4X5fJ----------->4X50 >4850 >4850 >4850 >485.0 3465 2345 1465 >4850------- ---- ----_._--20{) 47JX ,1738 4738 4085 3285 2715 1915 1295 820 4738-- -'--- ---ISO 3%0 3880 3795 3210 2590 2150 1515 1020 645 39<strong>77</strong>100 2705 2665 2625 2225 1805 1500 1055 725 450 300250 1345 1335 1320 1120 905 750 515 --- --- 1700~---'---

~ ___ • _0 ••••---_._ 0 ••• __HAULAGE CHARTS OF DIESEL LOCOS FOR ADVERSE CONDITIONSGRADE-- -20-- ---------30 40 50 60 70 80 90 100 START••----LEVEL >4050 >4850 >4850 >4850 3765 2880 2265 1785 1445 >4850500__----_.->4850----->4850 3500 2605 2050 1610 1300 1045---865 4795400 >4850 4445----3110 2325 1835 14L,5 1170 945 780 4465200 3815- 2820 1985 1490 1185 935 760 615 510 3320150 3045 2255 1585 1190 945 750 605 490 405 2825-_... .... - - _ .._---- _ ..... _--- --- _.- --'---100 2155· 1595 1120 835 660 520 420 335 275 2170f---- -----50 1115 815 555 405 3,10 235 - - - 1250- ._-,.: tlO-_. _.~-_ ...._- 50 60 70 80 90 100 STARTI. >4850 >11850 >4850 3980-3030 2400 _._- 1900 ---1510 ----- _._----- 1190 _._~ >4850>4850 3940 2920 2100 1645 1335 1090 885 710 3~lJO-->4850 3490 2595 1870 1470 1200 980 795 640 36253115 2210 1655 1195 945 <strong>77</strong>5 635 520 415 2690- .. - ._..... _._-2485 1765 1320 955 755 615 505 410 330 2290-_. ._- -_ ..- - ._- ----.._-. --- ------ ---- ---- -----1755 1245 930 665 525 425 345 280 220-.1755905 625 460 320 240 190 145 110 75 1010(iIU\!) ·_jo--'--jO·L1~V 1·:__-- --"'_-0-- _500400.-200150--------10050

HAULAGE CHARTS OF ELECTRIC LOCOS FOR ADVERSE CONDITIONS(WET RAIL WIT~ 2.5 DEGREE CURVE TRACK) FOR BOXN LOADL .~(! .. 1._~~). __~3(-'- -50- --60---' ----70·-- -KO"'" ::-· ..----sTi\l~j=_=.~=~I :.--4850 \ >4850 >4850 >4850 >4850 >4850 3340 >

--_.- ._ ..._._ •.... .... .. .. --- ------_._-._- _ .._--_. --...-S. NO. APPROACH SPEED MAX. STRETCH EXIT SPEED-_ ..._. __ .. IN KMPH.•NEGOTIABLE IN KM IN KMPH. - _ .. _.... - - ---.1----- ---------30 0.5 20.0 ---_.2 40 0.8 20.03 50 1.2 20.0---4 60 1.75 20.05 75 2.0 20.0_..-' ---IS. NO. APPROACH SPEED MAX.STRETCh EXIT SPEEDIN KMPH NEGOTIABLE IN KM IN KMPH1 30 1.2 20.0\2 40 1.6 20.03 50 2.25 20.04 60 2.75 20.05 75 3.5 20.0--S. NO. APPROACH SPEEDMAX.STRETCHEXIT SPEEDIN KMPH NEGOTIABLE IN Kl\ll'll,--' 1 30 NO LENGTH LIMITATION 20.62 40 NO LENGTH LIMITATION 20.6--3 50 NO LENGTH LIMITATION 20.64 60 NO LENGTH LIMITATION 20.65 75 NO LENGTH LIMITATION 20.6S. NO. APPROACH SPEED MAX.STRETCH EXIT SPEEDIN KMPH NEGOTIABLE IN Krvl P II..1 30- NO LENGTH LIMITATION 24.52 40 NO LIiNGTI-l LIMITATION 24.53 50 NOTEN(!fH '-UMITATION 24.5----60 NO LENGTH LIMITATION 24.5_._-- 475 NO LENGTH LIMITATION 24.55..-

APPROACH SPEED VS LENGTH OF MAXIMUM NEGOTIABLE STRETCH;WDG2 LOCO WITH 2.5 DEGREE CURVE_. -- ---_._---CH Syr:EJ MAX. NEGOTIABLF. STRETCH EXIT SPEEDKMPH INKM IN KMPH30 0.5 11.040 0.75 20.050 1.0 20.060-1.5 20.0-.75 2.0 20.0- _.~-_..__. -_. --_.._--------I..'--'S. NO. APPROACH SPEED MAX. NEGOTIABLE STRETCH EXIT SPEEDIN KMPH INKM IN KMPH_._---1 30 0.6 20.0· .2 40 1.0 20.0; 3 50 1.75 20,04 j 60 2.0 20.05 3.0 20.0......______ J.~___________ "_4S. APPROACH SPEED MAX EXIT SPEED ON REMARKSNO. IN KMPH NEGOTIABLE GRADE_. STRETCH IN KM IN KMPH- ..--- ..~1 30 0.50 I 20.0 TRAINWILL RUN2 40 2.25 20.0 AT 17.6 KMPH IF3 50 3.0 20.0 STRETCH LENGTH.4 60 IS MORE THAN

S.NO.- --- -- --- ---_. --.--.----- ...--..0:- -APPHOACIl SPEED MAX. NEGOTIABLE-- ---------EXIT SPEEDIN KMI'Il STRETCH IN KM IN KMPHI 30 0.5 20.02 40 0.6 20.03 50 1.2 20.04 60 1.5 20.0I 5 1 75 1.6 20.0I s.:ii:~-_._-_.-_. _.APPI{()ACII SPEED MAX. NEGOTIABLE EXIT SPEEDI .!=:.._.-IN KMI'II STRETCllIN KM IN KI\II'II -- .._-._---.. 30 1.0 20.040 1.6 20.0SO 2.0 20.0(,0 2.5 20.07S 2.75 20.0------~- .---_ ..._---- .. ------ -_._--_ .. _- ----------,-.S. NO. AI'I'ROACI I SPEED MAX. NEGOTIABLEEXIT SPEEDIN KMI'II STRETCH IN KM IN KMPH----- - -_.-. ----------_._----I :W NO LENGHI LIMITATION18.5-- _.-2 I 40 NO LENGTH LlMrI'ATION18.53 50 NO LENGTII LIMITATION J R.S-_.- - .. ._--.._._ .. _-- - _.. .. -_ ... ---.-----.\ ()O NO LENUTII LIMITATiON I X.5.....- - --_._.... --_.-_.5 75 NO LENGTII LIMITATION 18.5_._-_.- -- - -_ ...-..- ....... _-_ ..----- - -- --- ..S.NO. APPHOACII SPEEDMAX. NEGO'I;IAiiLEEXIT SPEEDIN Kl\lPIl STltET

.0. ___ • ____SI'~~it J) MAX. NEGOTIABLE EXIT SPEED>II STRETCH IN KM IN KMPH0.2 11.0--._-- --. 0.5 20.0.---------1.0 20.01.3-20.01.5 20.0-.._-S. r\O. API'-- 1_-=.1---~-~--- 1----~fn--- - 11 -: IHOACII SPEED MAX. NEGOTIABLE EXIT SPEEDIN KJ\lPIl STRETCH IN KM IN KMPIl30 0.5 20.0'lO 1.0 20.0---51) 1.5- -20.0- .- --_ .. - ------r,!) J.7S 2ll.075 2.0 20.0~---_.--.,~ 3----- ~---- ..- -A ('!'!{OACII SPEED MAX NEGOTIABLE EX IT SPF.EI>IN KMPIl STRETCH IN KM IN Kl\lPlI30 0.50 20.0--_. __ 40.2.0 20.050 2.5.20.060 2.7520.075--3.e 20.0-.- --- ----- ----S.NO. Ai'1'r,--1- ---r--::--r---S--[=-~,---r-.-.-------------l='~---r==-.--_._-.-!{()ACII SPEED MAX. NEGOTIABLEEXIT SPEED._---(N KJ\lI'!1 STRETCII Jr¥ 1)'1\1 IN KMPII.30NO LENGTH'-L'I~nJI:A'i'i6N 18.5·10 NO LENGTH L1MITrATION 18.550 NO LENGTH L1MIlTATION 18.5------(,(JNO LENGTH L1MITIAnON' IS.S75 NO LENGTH L1MIlTI\TION IX.S(

APPROACH SPEED VS LENGTH OF MAXIMUM NEGOTIABLE STRETCHATTACKING SPEED MIN KMPH-----__._----_ '10 .._---- -5060 ..-- .._--70._-AX. LENGTH OF SECTION WHICH CAN EXIT SPEEDBE NEGOTIATED IN KM-. ----------------------- . . --_. --- IN ....KMPH.._ ••-. - 0.5 :~o_ ......_---- - ._ .•. .. . ~._.---- -. .-._._- 1.0._----------- --- - ..._ ..20-- - - -1.5 201.7.5 ·203.0 20---.r----------- .... -.----_.-. ------ATTACKING SPEED MAX. LENGTH OF SECTION WHICH CAN EXIT SPEEDIN KMPH- BE NEGOTIATED IN KM IN KMPH30 0.40 2040 1.5 2050 2.75 20f----_._-_ ...- GO _..---- ..-- -. --- ---3.0 -----_. 2070 4.0---20"",.- ...... - .. -, ..... . ... _--_._ ...~-_..... ---------_._-----_._- ..•-. ------_.- ----[ ATTACKING SPEED MAX. LENGTH OF SECTION WHICH CAN EXIT SPEEDIN KMPH BE NEGOTIATED IN KM IN KMPHI 30 1.25 2040 2.50 2450 4.5 2060 6.0 2070 : .- 6.5 20"-_ .._-- ---'f._t.~.. '.'f. -,'r'q,~ -"~.f- •,_.ATTACKING SPEED MAX. LENGTW ~F ~~~TlqN WHICH CAN EXIT SPEEDI~ r

i70ATTACKING'SPEED'- - .. - MAX:--CEr:rGTH OFSECri6N' WHIC H' CAN EXIT SPEEDIN KMPH BE NEGOTIATED IN KM IN KMPH30 Not recommended ---._. 40 0.50 20.._------50 1.25 2060 1.5 201.75 20.ATTACKING SPEED ~.•ViAX. LENGTH OF SECTION WHICH CAN EXIT SPEEDIN KMPH BE •..JEGOTIATED IN Y:M IN KMPH-------30 0.25 2040 1.25 2050 1.75 2060 2.502070 3.0 20---"-_. -.._._----_.--~'ATTACKING SPEED MAX. LENGTH OF SECTIO-N WHICH CAN EXIT SPEEDIN KMPH BE NEGOTIATED IN KM IN KMPH30 0.75 2040 1.75 .·20-----_. 50 3.502060 4.022-------"- - -------70 4.520--ATTACKING-SP-E'E'b --'-rViAX. LENGTH OF SECTION WHICH CAN EXIT SPEED_.IN KMPH BE Wrti'illA lfO I~ KM IN KMPH~..;3.0 "._---302040 6.02050 9.0 2160 11.0 20-70 12.021.""'"r" •••• _ ••

APPROACH SPEED VS LENGTH OF MAXIMUM NEGOTIABLE STRETCHI APPROAcffsPEEO-iN- --MAX STRETCH NEGOTIABLE EXIT SPEEDKMPH IN KM IN KMPH30 0.50 20.;40 1.0 2050 1.75 20.--60 2.50 20 ..70 3.0 20APPROACH SPEED IN MAX STRETCH NEGOTIABLE EXIT SPEEDKMPH INKM IN KMPH30 1.25 2240 2.75 20_._------_ 50..--_._-5.0 20.5-_ 60 6.024.. ----_ ..._---"_ ..--- -- -70 7.520;i.-_ .. . ..APPROACH SPEEDMAX STRETCH NEGOTIABLE EXIT SPEEDIN KMPH INKM IN KMPH30 No lenQth limitation >2040 . No lenQth limitation >20-------_ ..._50 No length limitation >20..... _--.- ---.->20f.-. 60 No length limitation70 1....• 0 length limitation >20r- ~_1--. J)' ILJ'..."-'-,....-- ..._- ...__.-...._....... - ._-.APPROACH SPEED MAX STRETCH NEGOTIABLEEXIT SPEED---- --_._IN...-KMPH .._----- -_._-INKM IN KMPH30 No length limitation---------->2040 No lenQth limitation >20-50 No lenQth limitation .>20--_._._------ 60 No length limitation >20I 70 No lenqth limitation >20

APPROACH SPEED VS LENGTH OF MAXIMUM NEGOTIABLE STRETCHAPpr~OI\CH SPEEDIN KMPH---------------30-40SO60L. 7_O --MAX'STRETCH NEGOTIABLEIN KM0.2!)0.71.252.02.75---_ ... _...-.- .. __ .. -----EXIT SPEEDINKMPH2020_______ 20•••••••• 42020APPROACH SPEEDIN KMPH--- 30... -... .. --. "._. -_ .. - - _.110- --..50-------- .. 60--._ .. -_. -- -_._---- -70MAX STRETCH NEGOTIABLE EXIT SPEEDINKMIN KMPH0.45 202.0203.25I204.25 20-._--5.2520-- _._-APPROACH SPEED ,-MAX STRETCH-NEGOTIABLEEXIT SPEEDIN KMPH----- ---- -----.-_.INKM IN KMPH30----- -------2.252040-------- 3.020- -. - •• P-. ---- . ------ ---_._._-50 8.02260 10.0 2170 12.0 20~----'-------------------- - ------- --------------APPROACH SPEED MAX STRETCH NEGOTIABLE EXIT SPEEDIN KMPH INKM IN KMPH30 No lenath limitation >2040 No lenQth limitation >20--- --------------_. __ .50 _____________ No length limitation>20... - -.. --. ---60------;20- ----._-- --. ...._----- No length limitation-' . ./-70 No ler.Qth :imitation >20

•• • • # • • ."'"!=.. ••... , • .:--:::: •••.•. :.,.-. :~ ••. :.-.' ••.• ' ••••.• ~~.: •..._---.----- -_._-..,...__ ._ •.-.. . ".I, • : ; _ II 'f :,". ":1\ ,_., ' ." "I I.~ J ; ~.l'\! "",.:Tn.·j":·c~ rJ,rr:'_'·.)I'-·1 J,!c~~-·I.i~D~;C;...(!.J..d~/~~c:.:v.'-'., t:)·· , .I~·:·I:'.' I..." ...•· ,""" T.:· :'\.1- •.•'.••• :."·l·,':' r,. rll·' .. l.n •.·.J "1', I l ':1.," I'.'::1 (TI~·n<strong>no</strong>.l;ol"\ p1fQ/Oc:..l?nr.! l'/,oro! h wIse C

Allllcxurc-VlI1I1,:..~? fJ.7[r(r~::\;J;:~;...,=;~ ~,,-lt.=;~.Pt-,{,....I C'/ ~:-::: ..':.P?r:~r-< . ,

,110'~. •.;...~::.. "(.-:-:A~~ , .·.icA~r:- .• ,r::,...,." ..... ,~. .~--'I _. r- n ' ,...; j'.~,~uJg:2"'i'TE.AP~I •.,.C.::'J\.,.; - C.. ~ ~.,~H·KI~:t' -: :... . . ""'" ,., L,f"(,-J[l·(:,.,,,I.,j 1 '.,,' .~·8~~. [., r,FI~ , 1\1::i. " 1(j~·f1.PK" t'-.. '\~, • <strong>no</strong>.. I'Trf" •. ::.~ j'.r·N.· 1"\ Ic:-_. (;1 :~"K.' A-~ KT-1 ~~UI:J .• ".l I;,\P~ . v.T~lo" A~"":~ .. :

OfT((T or TilLGIlEf OPC:RAllOf\JS Iv1Af\lAGt:I

f:.~"L /\!. ~~~:~'!::}.~:;?,~_Gl~~l~~~i Ti~ ..1t::/!~t2·r.!\.t,1C~2 r=;J R 7:3 i; ;':'1.(.:~_L.0~ [; 0 ~~:T.:.C)~. P_Q.~~_t:·~;)_9 ..ILC;:'.!) Oi·J :_~\I[L1Tf.'.>JGr:.i\T lTU\~!.S•İ,IIIi' . \,,.I• •i ••~-. 45\! ;1

I'V~l_SECTIONAnnexure-XICUMPARISON OF LOADS PERMITTED AND LOADS IN ACTUAL PRACTICE ONS.E.RAILWAY (FOR ELECTRIC LOCOS)RULING AS PER ROSa AS PER ACTUAL PRACTICEGRADIENT WAGS WAG? WAGS WAG?------_TAD.•.--_ ..._- ..- -._--- _._-_. --------------SU SU SU MU SU MU-'~'~'-'---:;,p ----_.- -_._- ------ _.~_._.~--_ t·4PGC 11 GO.. --3150 39<strong>77</strong> 2950 4800 4800., --_..._- -_ ... -_ .._._- -_. - ._.._- -, _ .. - _ ...- -(j-[)(;(j--* ._..-- 1:1~)U 3150 39<strong>77</strong> 2950 4800 4800. -- ..._-- ------ ..---_.-._- ---------[)(fjfW- 11 SO 3150 39<strong>77</strong> 2950 4800 4800-- ..... i [f/:;-L~I/·, (ur 1) 1_._~~-------200--_ 3600 4738 4800 4800... -._--S-p ----I DU(J-[JI/·,·i~ 1(;-- ---- _ .._-1:150 3150 39<strong>77</strong> 3250 4800 4800---rR1G~-Br~jr:.j(oi·jfl·1:100 2200 3002 3250 3250 4800---r------------ --___..~f3.J}.'J-J_?..G__________ 1,:,~ .. ~0 3150 39<strong>77</strong> 4800 3250 4800Yf

;,1,tI I ,IiC;:.:'iJ1_-,- ---------~c(; I iOi'J f::~~;.f~1:~~~·3-·rULli'JGiAS PER ROSa AS PER AC1LJ_~\LF~,'..CT!_::;::- --------GfV~OI- WO~12 IV\.tDG2 I _~VD~:_'______ ::'~QG: !I ENT I SU r.'lUI~ su II r.'lU I SU j IJ'U TLJ SU' i:i~! I -_·_----_·. ___ 0 ______ ---•.... -.,"'"p~P\~\,'S:·~p I 1: 150 I 2510 ~S18 ::2~O I ! ~SOG !~~:~ -,:--,'tv\... _ - ...... ..., 1--., .-. - ...•I I !, 25JO I 4S0: .•.. _ ...... .•.•. :: ....../ I:f

--1S;(F/l\RSU- i 1:100 192G 51 2503 1680 4800 , "1 (\;or TO i,STOP AT 1'..\ :8~m.~I(L) 34IL- I I--~1DNDU''' •I Si'!Oi\'l-HTL: 1:100 1920 51 2503 ----l1680 I 4800I :II 84 I .I Ci'!I-f-\OT PII:100 1920 3456 2503 T 1680 4800 I I! r.4 T A-81'.~F;R , 1:100 1920 3456 I I 2503 , I I 1680 I I I - jIf".r;!\·t\GPn~i~iPi 1:125 1920 34562100 4800 . I/W/\-Cr-~I ! 1:100 I 1920 3456 2503 1900 4800 -.ISJ~·Gi