GAS PIPING FOR LABORATORY AND HEALTHCA - Mercy

GAS PIPING FOR LABORATORY AND HEALTHCA - Mercy

GAS PIPING FOR LABORATORY AND HEALTHCA - Mercy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

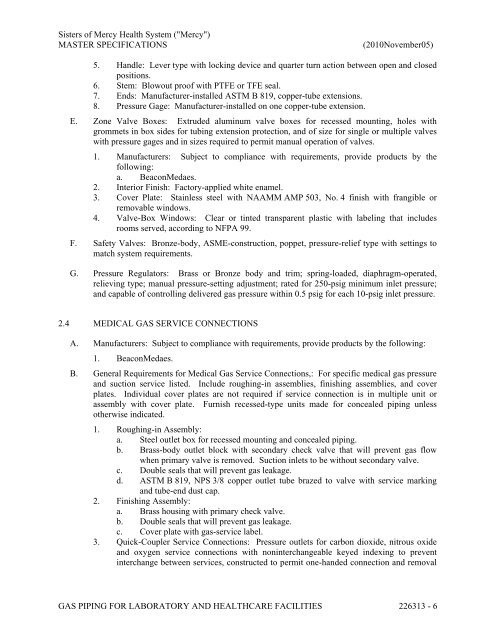

Sisters of <strong>Mercy</strong> Health System ("<strong>Mercy</strong>")MASTER SPECIFICATIONS(2010November05)5. Handle: Lever type with locking device and quarter turn action between open and closedpositions.6. Stem: Blowout proof with PTFE or TFE seal.7. Ends: Manufacturer-installed ASTM B 819, copper-tube extensions.8. Pressure Gage: Manufacturer-installed on one copper-tube extension.E. Zone Valve Boxes: Extruded aluminum valve boxes for recessed mounting, holes withgrommets in box sides for tubing extension protection, and of size for single or multiple valveswith pressure gages and in sizes required to permit manual operation of valves.1. Manufacturers: Subject to compliance with requirements, provide products by thefollowing:a. BeaconMedaes.2. Interior Finish: Factory-applied white enamel.3. Cover Plate: Stainless steel with NAAMM AMP 503, No. 4 finish with frangible orremovable windows.4. Valve-Box Windows: Clear or tinted transparent plastic with labeling that includesrooms served, according to NFPA 99.F. Safety Valves: Bronze-body, ASME-construction, poppet, pressure-relief type with settings tomatch system requirements.G. Pressure Regulators: Brass or Bronze body and trim; spring-loaded, diaphragm-operated,relieving type; manual pressure-setting adjustment; rated for 250-psig minimum inlet pressure;and capable of controlling delivered gas pressure within 0.5 psig for each 10-psig inlet pressure.2.4 MEDICAL <strong>GAS</strong> SERVICE CONNECTIONSA. Manufacturers: Subject to compliance with requirements, provide products by the following:1. BeaconMedaes.B. General Requirements for Medical Gas Service Connections,: For specific medical gas pressureand suction service listed. Include roughing-in assemblies, finishing assemblies, and coverplates. Individual cover plates are not required if service connection is in multiple unit orassembly with cover plate. Furnish recessed-type units made for concealed piping unlessotherwise indicated.1. Roughing-in Assembly:a. Steel outlet box for recessed mounting and concealed piping.b. Brass-body outlet block with secondary check valve that will prevent gas flowwhen primary valve is removed. Suction inlets to be without secondary valve.c. Double seals that will prevent gas leakage.d. ASTM B 819, NPS 3/8 copper outlet tube brazed to valve with service markingand tube-end dust cap.2. Finishing Assembly:a. Brass housing with primary check valve.b. Double seals that will prevent gas leakage.c. Cover plate with gas-service label.3. Quick-Coupler Service Connections: Pressure outlets for carbon dioxide, nitrous oxideand oxygen service connections with noninterchangeable keyed indexing to preventinterchange between services, constructed to permit one-handed connection and removal<strong>GAS</strong> <strong>PIPING</strong> <strong>FOR</strong> <strong>LABORATORY</strong> <strong>AND</strong> <strong>HEALTHCA</strong>RE FACILITIES 226313 - 6