Instrument Manifolds - Zycon

Instrument Manifolds - Zycon

Instrument Manifolds - Zycon

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

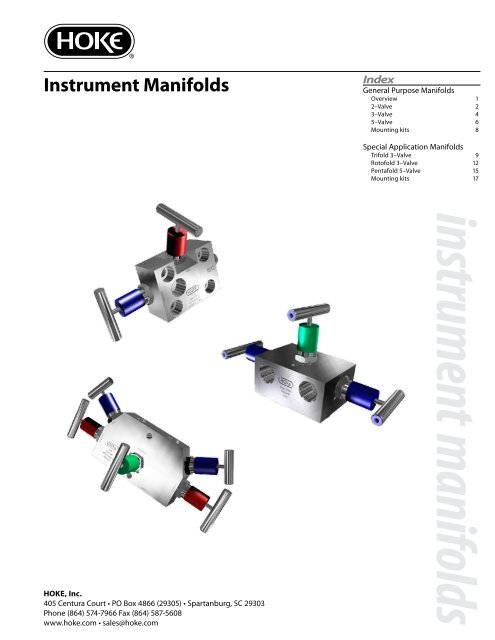

<strong>Instrument</strong> <strong>Manifolds</strong>IndexGeneral Purpose <strong>Manifolds</strong>Overview 12–Valve 23–Valve 45–Valve 6Mounting kits 8Special Application <strong>Manifolds</strong>Trifold 3–Valve 9Rotofold 3–Valve 12Pentafold 5–Valve 15Mounting kits 17HOKE, Inc.405 Centura Court • PO Box 4866 (29305) • Spartanburg, SC 29303Phone (864) 574-7966 Fax (864) 587-5608www.hoke.com • sales@hoke.cominstrument manifolds

General Purpose <strong>Instrument</strong> <strong>Manifolds</strong> at a GlanceHoke offers a variety of 2-,3-, and 5-valve instrument manifolds in direct and remote mount styles with ventconfigurations to meet most flow, pressure, and level measurement application requirements. Hoke 2–valvemanifolds are designed for static pressure and liquid level applications; the 3– and 5–valve manifolds are wellsuited for use with most differential pressure transmitters and can accept both female and flange processimpulse line connections.Valve FeaturesAll valves are hydrostatically tested at 1.5X maximum working pressure to assure leak tight performance. Stempacking is available in PTFE or Grafoil® materials with the metal non-rotating stem tip offered as standard.Gland adjuster packing seal canbe externally adjusted in serviceSafety locknutPacking is below the stem threadsto isolate threads from process mediaDead stem through packing giving easeof operation and less packing wearStem has back seatfor added securityPrecision Machined hard stemtip of AISI 316 stainless steelprovide consistent shutoffPressure vs. Temperature CurvesPTFE Packing* Maximum pressure 6000 psi (413 bar) at 212° F (100° C)Maximum pressure 4000 psi (275 bar) at 392° F (200° C)Grafoil® packing Maximum pressure 6000 psi (413 bar) at 212° F (100° C)Maximum pressure 3300 psi (230 bar) at 842° F (450° C)* PTFE packing rated to maximum temperature of 392° F (200° C)HOKE, Inc.405 Centura Court • PO Box 4866 (29305) • Spartanburg, SC 29303Phone (864) 574-7966 Fax (864) 587-5608www.hoke.com • sales@hoke.comPSI (Bar)8702 (600)7252 (500)5802 (400)4351 (300)2901 (200)1450 (100)Removable “T” bar handle aidslow torque operationDust cap on stem prevents inflowof contamination and protectsactuating threadsStem has rolled threads for smoothacting, strength, and long life. Stemthreads above packing, no processcontamination or lube washoutOne piece non-rotating stemtip joint located above packing,cannot work freeMetal to metal seal with bodysuitable for high pressuretemperature applications. Noneed for O-ring seals.00212(100)932(500)392 572 752(200) (300) (400)Fahrenheit (Celsius)PTFE Packing1112(600)Grafoil® Packinginstrument manifolds

2–Valve General Purpose Manifold–Direct MountDimensionsDimensions in inches (millimeters) are for reference only and are subject to change.VENTINSTRUMENTPORTFront view5.63” (143 mm)3.35” (85 mm)2.125” (54 mm)PROCESS IN2.40 (61 mm)Right side view1.625”(41.3 mm)½” NPT inletconnection0.79”(20 mm)¼” NPT vent plug(supplied loose)(63.5 mm)4.76” (121 mm)Vent valve(dustcap: red)Back viewIsolate valve(dustcap: blue)0.51(13 mm)1.50(38.1 mm)How to Order0.46 (11.8) diaTransmitter interfaceper IEC 61518, Type B2.125 ±0.012 - in.Center2 Mounting holesM8 x 0.47 (12) deeppart number packing Accessories (not included)GP821211F8YL PTFE Mounting kit–Order No. 800000K1 (page 8)GP821212F8YLGrafoil1.5” mounting bolts for Honeywell transmitter(4 required) – Order No. 095-0411-100HOKE <strong>Instrument</strong> <strong>Manifolds</strong>

3–Valve General Purpose Manifold–Remote MountDimensionsDimensions in inches (millimeters) are for reference only and are subject to change.TO INSTRUMENTVENTVENT½” NPT½” NPTPROCESS INTop view2.39 (60.8)Isolate valve(dustcap: blue)Bottom8.15 (207) open½” NPTinletsIsolate valve(dustcap: blue)4.06 (103) Side open2 ¼” NPTvent plugs(supplied loose)½” NPToutlets2.13 (54,0)3.54 (90)2.50 (63.5)Side view1.57 (40.0)0.28 (7) diaEqualize valve(dustcap: green)0.56(14.3)1.46(37.1)0.63(15.875)1.75(44.45)How to Orderpart numberpackingGP833211F8YLPTFEGP833212F8YLGrafoilMounting kit–Order No. 800000K2 (page 8)HOKE <strong>Instrument</strong> <strong>Manifolds</strong>

5–Valve General Purpose Manifold–Direct MountDimensionsDimensions in inches (millimeters) are for reference only and are subject to change.INSTRUMENT PORTVENTVENTPROCESS INSide view3.00 (7.62)Front viewEqualize valve(dustcap: green)0.49(12.4) 1.25(31.8)Isolate valve(dustcap: blue)Vent valve(dustcap: red)5.04 (128) open1.63(41.3)Transmitterinterfaceper IEC61518,Type B4X DIA0.46 (11.8)1.61(41)½” NPTinlet¼” NPTpluggedportHOKE <strong>Instrument</strong> <strong>Manifolds</strong>2.125 (54)3.94 (100)4.02 (102)5.51 (140)6.22 (158)10.83 (275) open¼” NPT VentPLUGS(supplied loose)How to Orderpart numberpackingGP851211F8YLPTFEGP851212F8YLGrafoilMounting kit–Order No. 800000K1 (page 8)1.5” mounting bolts for Honeywell transmitter(4 required) – Order No. 095-0411-100

DimensionsDimensions in inches (millimeters) are for reference only and are subject to change.Vent valve(dustcap: red)½” NPT outletconnections1.61(41)5–Valve General Purpose Manifold–Remote MountTO INSTRUMENTVENTVENTPROCESS INRight side view¼” NPT ventplugs(supplied loose)2.36 (60)3.00 (76.2)2.40 (61)1.61(41)Back view1.125 (28.6)3.42 (87) openIsolate valve(dustcap: blue)0.31 (8) dia1.81 (46)2.125 (54)9.61 (244) open½” NPT inletconnectionsTop viewEqualize valve(dustcap: green)How to Orderpart numberpackingGP853211F8YLPTFEGP853212F8YLGrafoilMounting kit–Order No. 800000K2 (page 8)HOKE <strong>Instrument</strong> <strong>Manifolds</strong>

General Purpose Manifold Mounting Kits800000K1 – For Direct Mount ModelsDimensions are in inches (millimeters) are for reference only and are subject to change.10.5mm hole fordirect mountingof (5) valve manifoldseries GP8512 (2) req'dItem Title Material1 Bracket SST 3042 Clamp Plate SST 3043 U-Bolt SST 3164 Nut, Hex SST5 Washer, Lock SST8.5mm holes fordirect mounting of (2) & (3) valvemanifold series GP8212 & GP831211.18(30)2.60(66)234.92(125)142" pipe (2.375 OD)REF4.72(120)5800000K2 – For Remote Mount ModelsDimensions are in inches (millimeters) are for reference only and are subject to change.4X 7mm wide slots forremote mounting of2-,3- and 5-valve manifoldsseries GP8232, GP8332, and GP8532Item Title Material1 Bracket SST 3042 Clamp Plate SST 3043 U-Bolt SST 3164 Nut, Hex SST5 Washer, Lock SST2.36(60)3.78(96)13215.91(150.1)5(2" pipe, Ø2.375)4HOKE <strong>Instrument</strong> <strong>Manifolds</strong>

Trifold Needle Valve ManifoldThe Hoke 3–Valve Trifold manifold is designed for direct mounting to differential pressure transmitters having 2.125 inches (34mm) center-to-center process connections.Pipe by FlangeWhen direct coupling to orifice plate flanges is not desired, the pipe by flange Trifold Manifold allows for two ½” NPT processconnections in addition to direct mounting of the transmitter.Flange by FlangeWhen direct coupling to orifice plate flanges is required, the flange by flange Trifold Manifold mounts directly between theflange and the transmitter. If direct coupling to orifice plate flanges is not required, process futbol connectors may also be used.Technical DataMaximumOperating PressureOperatingTemperature RangeDyna-Pak/Metal Stem Tip• 6000 psig (414 barg) -65° F to +150° F(-54°C to +66° C)• 3000 psig (307 barg) at +450° F (+232° C)Graph-Lock/TFE Wafer Packing• 5000 psig (345 barg) -60° F to +600° F(-51°C to +316° C)• 3000 psig (307 barg) at +450° F (+232° C)Dyna-Pak/Metal Stem Tip• -65° F to +450° F (-54°C to +232° C)Graph-Lock/TFE Wafer Packing• -60° F to +600° F (-51°C to +316° C)Pressure Temperature CurvesPSIG (BARG)6000 (414)5000 (345)4000 (276)3000 (207)2000 (138)1000 (69)0-65(-54)0(-18)Dyna-Pak100(38)200 300(93) (149)400204)Fahrenheit (Celsius)500(260)600(316)Graph-lock/TFEHOKE, Inc.405 Centura Court • PO Box 4866 (29305) • Spartanburg, SC 29303Phone (864) 574-7966 Fax (864) 587-5608www.hoke.com • sales@hoke.comFeatures & Benefits• Purge ports are provided on the process side ofblock valves for applications requiring continuouspurging.• Bleed or vent ports on the instrument side of theblock valves.• Dyna-Pak TFE or high-temperature 600° F (316° C)Graph-lock/TFE wafer packing is standard.• Bonnet locks prevent accidental disengagement ofthe bonnet.• Non-rotating hardened metal stem tip.• Integral backseats on all valve stems preventaccidental removal.• Mounting bolts and TFE gaskets are standard.• Packing below stem threads prevents processliquids from contaminating or washing away thethread lubricants.instrument manifolds

Trifold Needle Valve Manifold– Pipe by FlangeSpecial Application <strong>Manifolds</strong>Dimensions and MaterialsDimensions are in inches (millimeters) are for reference only and are subject to change2.63(66.8)DescriptionMaterial1 Housing 316 stainless steel192 Packing nut 316 stainless steel3 Lock nut 316 stainless steel4 Washer 316 stainless steel2.87(72.9)Open1.02(25.9)13151718161150.59(15.0)5 Wafer Teflon® tape6 Washer 316 stainless steel7 Spacer 316 stainless steel8 Stem 316 stainless steel9 Disc 17-7PH stainless steel10 Stem point 17-4PH stainless steel11 Washer Teflon®12 Spring pin 302 stainless steel13 Manifold block 316 stainless steel14 Cap screw 18-8 stainless steel15 Pipe plug 316 stainless steel1.69(42.9)8.10(205.8)Open4.05(102.9)Open16 Seat insert 316 stainless steel17 Cap lug Polyethylene18 Washer 304 stainless steel19 Handle 316 stainless steel2BLEEDPURGEPURGEBLEED3.75(95.3)32.43(61.7)41.71(43.4)758Outlet2.125(54)3.38(85.9)Outlet11BLEED/PURGEINSTRUMENT PORTS[BLEED/PURGE910152.63(66.8)Handle1.19(30.2)6½” NPT½” NPTPROCESS IN112.88(73.2)3.67(93.2)How to Order Trifold Pipe by FlangeProcessConnections<strong>Instrument</strong>ModelNumberStem PointPacking1/2” Female NPT Flange 8122F8Y Non-rotating 17-4PH Dyna-Pak1/2” Female NPT Flange 8128F8Y Non-rotating 17-4PHGraph-lock/TFE wafers1.80(45.7)14124.15(105.4)Open3166000 PSIG1.32(33.5)0.42(10.7)0.81(20.6)1.63(41.4)Mani-Mount mounting module see page 17 for details (available for 8122F8Y only)10 HOKE <strong>Instrument</strong> <strong>Manifolds</strong>

Trifold Needle Valve Manifold– Flange by FlangeSpecial Application <strong>Manifolds</strong>Dimensions and MaterialsDimensions are in inches (millimeters) are for reference only and are subject to change1916Inlet3.38(85.7)2.13(54.0)Inlet1DescriptionMaterial1 Housing 316 stainless steel2 Packing nut 316 stainless steel183 Lock nut 316 stainless steel4 Washer 316 stainless steel5 Wafer Teflon® tape6 Washer 316 stainless steel7 Spacer 316 stainless steel15BLEEDBLEED8 Stem 316 stainless steel9 Disc 17-7PH stainless steel17OutletOutlet114.08(103.6) Open10 Stem point 17-4PH stainless steel11 Washer Teflon®12 Spring pin 302 stainless steel13 Manifold block 316 stainless steel8.16(207.2) Open14 Cap screw 18-8 stainless steel15 Pipe plug 316 stainless steel2.89(73.4) Open1.63(41.3)0.81(20.6)16 Seat insert 316 stainless steel17 Cap lug Polyethylene18 Washer 304 stainless steel19 Handle 316 stainless steel120.47 (11.9)233.13(79.4)0.47 (11.9)74135140.81(20.6)1.63(41.3)2.41(61.1)BLEED/PURGEINSTRUMENT PORTS[BLEED/PURGE89106½” NPT½” NPTPROCESS INHow to Order Trifold Flange by FlangeProcessConnections<strong>Instrument</strong>ModelNumberStem PointPackingFlange Flange 8132YY Non-rotating 17-4PH Dyna-PakFlange Flange 8138YY Non-rotating 17-4PHGraph-lock/TFE wafers7/16-20UNF-2B4 holesHOKE <strong>Instrument</strong> <strong>Manifolds</strong>11

Rotofold Ball Valve ManifoldThe Hoke Rotofold ball valve manifold has a unique design that utilizes quarter turn ball valves for blockingprocess impulse lines and performing equalizing functions. They also provide easy rod though of all passageswhen clean-out is necessary. PCTFE seats and Teflon® stem packing are easily replaced if maintenanceis required. The pipe by flange Rotofold design allows the manifold to be directly mounted to integral orificetransmitters by simply reversing the flanges and flange fittings. The pipe by pipe Rotofold design allows themanifold to be remotely mounted separately from the process.Technical DataMaximumOperating PressureOperatingTemperature Range6000 psig (414 barg)-65° F to +150° F (-54°C to +66° C)400 psig @ +300° F (28 barg @ +149° C)0° F to +300° F (-18°C to +149° C)Pressure Temperature CurvesPSI (BAR)Rotofold Pressure Temperature Curve6000 (414)5000 (345)4000 (276)3000 (207)2000 (138)1000 (69)00 50 100 150 200 250 300(-18) (10) (38) (66) (93) (121) (149)Fahrenheit (Celsius)HOKE, Inc.405 Centura Court • PO Box 4866 (29305) • Spartanburg, SC 29303Phone (864) 574-7966 Fax (864) 587-5608www.hoke.com • sales@hoke.comFeatures & Benefits• Flange can be reversed for direct mounting to anintegral orifice type transmitter• Connections on instrument side of block valves forbleeding and venting.• Replaceable PCTFE seats on all valves providelonger service life.• All media passages can be rodded for easycleaning.• ¼ turn handle provides visual indication of valvemode.• Mounting bolts and TFE gaskets are standard withflange models.• Cam handles provide error-proof sequencing ofvalves.• Mani-Mount mounting kit available for NPT pipestyle (see Mani-mount mounting system, page 17)Cam-Valve Interlocking Sequencing HandlesThe correct sequencing of opening and closing manifold valvesis critical to eliminating pressure transmitter damage due to overranging. By attaching cams to the equalizing and block valve handles,the inter-locking design assures proper initial service and transmitterzeroing during calibration.Cam kit 8200K5 can be field installed or factory assembled to themanifold at time of order. For factory assembled, add part number8200K5 to the end of the manifold part number.instrument manifolds

Rotofold Ball Valve Manifold - Pipe by FlangeSpecial Application <strong>Manifolds</strong>Dimensions and MaterialsDimensions are in inches (millimeters) are for reference only and are subject to change1 2 3 4 5 6 71DescriptionMaterial1 Plug washer Teflon®2 Vent fitting 316 stainless steel3 Pipe plug 316 stainless steel4 Washer Viton®5 Seat retainer 316 stainless steel6 Seat PCTFE97 Ball 316 stainless steel2.125(53.98)88 Insert 316 stainless steel249 O-ring Fluorelastomer10 Handle Aluminum alloy 36011 Stem 316 stainless steel0.63(16.0)12 Retaining ring PH15-7MO13 Stem retainer 316 stainless steel232221206 5 4 71718314 Shim washer 316 stainless steel15 Shim washer 316 stainless steel16 Shim washer Teflon®17 Manifold body 316 stainless steel18 Spiral pin 302 stainless steel1.97(50.0)19 Cap screw Carbon Steel20 Retaining ring 302 stainless steel2.50(63.5)1.25(31.8)3166000 PSIG8221F8Y1421 Flange Carbon Steel22 Flange connector 316 stainless steel23 Washer Teflon®24 End fitting 316 stainless steel19BLEED/PURGEINSTRUMENT PORTS[BLEED/PURGE½” NPT½” NPTPROCESS IN1011Open121413163.38(85.9)1.69(43.0)Outlet10ClosedRotofoldInlet2.06(52.3)4.31(109.5)15OutletOpenInletHow to Order Rotofold-Pipe by FlangeConnectionsBody Outlet style inlet process outletinstrumentationOrderingNumberFlange 1/2” Female NPT Flange 8221F8Y51.6(131.1)10Cam-valve sequencing handles order No. 8200K5Mani-Mount mounting module - see page 17 fordetails (available for 8221F8Y only)HOKE <strong>Instrument</strong> <strong>Manifolds</strong>13

Rotofold Ball Valve Manifold - Pipe by PipeSpecial Application <strong>Manifolds</strong>Dimensions and MaterialsDimensions are in inches (millimeters) are for reference only and are subject to change1 2 3 4 5 6 71DescriptionMaterial1 Plug washer Teflon®2 Vent fitting 316 stainless steel3 Pipe plug 316 stainless steel4 Washer Viton®5 Seat retainer 316 stainless steel6 Seat PCTFE97 Ball 316 stainless steel2.125(53.98)88 Insert 316 stainless steel199 O-ring Fluorelastomer10 Handle Aluminum alloy 36011 Stem 316 stainless steel0.63(16.0)12 Retaining ring PH15-7MO13 Stem retainer 316 stainless steel6 5 4 714 Shim washer 316 stainless steel1718315 Shim washer 316 stainless steel16 Shim washer Teflon®17 Manifold body 316 stainless steel18 Spiral pin 302 stainless steel19 End fitting 316 stainless steel6000 PSIG8211F8Y2.65(67.2)0.68 (17.2)INSTRUMENT PORTSBLEED/PURGE[BLEED/PURGE½” NPT½” NPTPROCESS IN101214111316153.38(85.7)1.69(42.9)OUTLETOUTLET10OPEN OPENCLOSEDINLETINLET2.23(56.6)4.67(118.7)4.61(117.1)10How to Order Rotofold-Pipe by PipeConnectionsBody Outlet style inlet process outlet instrumentationOrderingNumberNPT Pipe 1/2” Female NPT 1/2” Female NPT 8211F8YCam-valve sequencing handles order No. 8200K514 HOKE <strong>Instrument</strong> <strong>Manifolds</strong>

Pentafold 5–Valve ManifoldThe Hoke Pentafold 5-valve manifold is specifically designed for use with differential pressure transmitters when applied to gasflow measurement. This manifold design uses two PCTFE seated ball valves and three needle valves with non-rotating PCTFEstem tips as bypass or equalizing valves and vent valves. The two by-pass valves assure no leakage across the high and low sideof the orifice meter for critical gas flow measurement. The pipe by pipe Pentafold design allows the manifold to be mountedaway from the process but close to a differential pressure transmitter through the use of impulse piping.Technical DataMaximumOperating PressureOperatingTemperature Range6000 psig (414 barg)-20° F to +150° F (-29°C to +66° C)400 psig @ +300° F (28 barg @ +149° C)0° F to +300° F (-18°C to +149° C)Pressure Temperature CurvesPSI (Bar)Pentafold Pressure Temperature Curve6000 (414)5000 (345)4000 (276)3000 (207)2000 (138)1000 (69)00 50 100 150 200 250 300(-18) (10) (38) (66) (93) (121) (149)Fahrenheit (Celsius)HOKE, Inc.405 Centura Court • PO Box 4866 (29305) • Spartanburg, SC 29303Phone (864) 574-7966 Fax (864) 587-5608www.hoke.com • sales@hoke.comFeatures & Benefits• Static or vent ports provided on instrument side.• Replaceable ball seats and stem tips extend servicelife, reducing cost.• Threaded mounting hole provided on all models.• Single manifold block has fewer potential leakpaths than individually assembled valves.• TFE standard packing in all valves.instrument manifolds

Pentafold 5–Valve ManifoldSpecial Application <strong>Manifolds</strong>Dimensions and MaterialsDimensions are in inches (millimeters) are for reference only and are subject to change2212 345DescriptionMaterial1 Washer Fluorelastomer0.62(15.7)OutletInlet2 Seat retainer 316 stainless steel3 Seat PCTFE4 Ball 316 stainless steel5 Plug washer Teflon®6 End fitting 316 stainless steel2.13(54.1)257 Handle 316 stainless steel8 Packing nut 316 stainless steel9 Packing Teflon®OutletInlet10 Spacer 316 stainless steel11 Housing 316 stainless steel12 Spindle 316 stainless steel1.00(25.4)13 Seat retainer 316 stainless steel14 Seat PCTFE77615 Stem 316 stainless steel16 Retaining ring Stainless steel17 Stem retainer 316 stainless steel18 Shim washer 316 stainless steel19 Shim washer 316 stainless steel20 Shim washer Teflon®8128921 Handle Aluminum alloy 36022 Body 316 stainless steel9101113142610112323 Seat retainer 316 stainless steel24 Seat PCTFE25 Screw 18-8 stainless steel26 O-ring Fluorelastomer27 Spring pin 302 stainless steel2421TO INSTRUMENTVENTVENT27PROCESS IN16181720197.06(179.3)Open1.69(42.9)3.38(85.8)How to Order PentafoldConnectionsinlet processoutlet instrumentationOrdering Number1/2” Female NPT Flange 8613F8Y1.10(27.9)2.75(69.9)4.56(115.8)2.56(65.0)1.84(46.7)Open16HOKE <strong>Instrument</strong> <strong>Manifolds</strong>

Manifold AccessoriesMani-Mount Manifold Mounting System*This installation method provides for rigid mounting of a Trifoldor Rotofold manifold to a 2 inch pipe stand instead of a differentialpressure transmitter. Only the manifold is mounted duringconstruction, which permits storage of the transmitter untilneeded. The Mani-Mount not only provides a simple universalmounting solution, but also converts the manifold to a singleflange design for direct mounting to the transmitter. The Mani-Mount can be used with any standard transmitter having 2 1/8”center to center process connections. Typical installation hardwarecosts are reduced because transmitter mounting bracketsare not necessary.*Available for Special Application Trifold 8122F8Y and Rotofold 8221F8Y models onlyFeatures & Benefits• Allows for rigid mounting of the manifold, instead of thetransmitter.• Simple universal mounting system for vertical, horizontal oreither side of 2 inch pipe stand.• Only the manifold needs to be mounted during construction;the transmitter can be securely stored until final installation.• Transmitter mounting bracket is not necessary, reducingcosts.• Provides easy access to the transmitter by loosening 4 flangebolts.• Fast installation process, saving time and money on costlyconventional installations.• Converts the manifold to a single flange style for directmounting to the transmitter cell.How to Order Kit*part number8200K9* manifold not included17

Notes

Notes

Notes

405 Centura CourtPO Box 4866 (29305)Spartanburg, SC 29303Tel (864) 574-7966Fax (864) 587-5608www.circortechnologies.comCircle Seal Controls, Inc.2301 Wardlow CircleCorona, CA 92880Tel (951) 270-6200Fax (951) 270-6201www.circlesealcontrols.comGO Regulator405 Centura CourtPO Box 4866 (29305)Spartanburg, SC 29303Tel (864) 574-7966Fax (864) 587-5608www.goreg.comHOKE, Inc.405 Centura CourtPO Box 4866Spartanburg, SC 29303Tel (864) 574-7966Fax (864) 587-5608www.hoke.comCIRCOR <strong>Instrument</strong>ation, Ltd.1-3 Bouverie RoadHarrowMiddlesex, HA1 4HBUKTel +44 (0) 20 8423 0113Fax +44 (0) 20 8864 7008www.circor.co.ukHOKE Controls2054 Francis St.Ontario, CA 91761Tel (909) 923-3770Fax (909) 923-2550Panels Plus2054 Francis St.Ontario, CA 91761Tel (909) 923-3770Fax (909) 923-2550www.circor-panelsplus.comCIRCOR Tech405 Centura CourtPO Box 4866 (29305)Spartanburg, SC 29303Tel (864) 574-7966Fax (864) 587-5608www.circortech.comHOKE GmbHWeitzesweg 11Postfach 15 41D-61118 Bad Vilbel–DortelweilGermanyTel +49-6101-82 56 0Fax +49-6101-82 56 40www.hoke.deTOMCO405 Centura CourtPO Box 4866 (29305)Spartanburg, SC 29303Tel (864) 574-7966Fax (864) 587-5608www.tomcoquickcouplers.comCIRCOR <strong>Instrument</strong>ation TechnologiesCentral EuropeLeeuwenhoekweg 242661 CZ BergschenhoekThe NetherlandsTel +31-10-4206011Fax +31-10-4566774www.circortechnologies.comLIMITED WARRANTYALL CIRCLE SEAL CONTROLS, INC., GO REGULATOR, AND HOKE INC. PRODUCTS ARE MADE TO EXACTING STANDARDS OF DESIGN, MATERIAL, WORKMANSHIP AND QUALITY CONTROL AND ARE WARRANTED TO BE FREE OF DEFECTS IN MATERIALAND WORKMANSHIP AND REASONABLY FIT FOR THE USES SET FORTH IN SELLER’S CATALOG OR THE CONTRACT SPECIFICATIONS FOR A PERIOD OF ONE YEAR AFTER SALE IF PROPERLY INSTALLED AND MAINTAINED AND UNDER THE NORMAL USEAND SERVICE FOR WHICH THE EQUIPMENT IS INTENDED. BUYER TO INSPECT THE GOODS WITHIN TEN DAYS OF DELIVERY AND TO THEN IMMEDIATELY NOTIFY SELLER OF ANY DEFECTS IN ORDER TO CLAIM A DEFECT. THIS WARRANTY IS IN LIEU OFALL OTHER WARRANTIES WHETHER THEY ARE STATUTORY, EXPRESS OR IMPLIED, INCLUDING AMONG OTHER THINGS ANY IMPLIED WARRANTY OF MERCHANTABILITY FITNESS FOR A PARTICULAR PURCHASE NOT SET FORTH IN SELLER’S CATALOG,AND ALSO DOES NOT APPLY TO ANY PRODUCTS OF SELLER WHICH HAVE BEEN REPAIRED, ALTERED OR MODIFIED OR HAVE BEEN SUBJECT TO MISUSE OR ABUSE. SELLER IS NOT LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGESRESULTING DIRECTLY OR INDIRECTLY FROM THE DESIGN, MATERIAL, WORKMANSHIP, OPERATION OR INSTALLATION OF ANY OF ITS PRODUCTS AND NEITHER ASSUMES NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR IT ANY OTHER LIABILITYIN CONNECTION THEREWITH. BUYER’S EXCLUSIVE REMEDY SHALL BE THE REPAIR OR REPLACEMENT OF ANY SUCH DEFECTIVE PRODUCT AFTER VERIFICATION BY SELLER.THIS WARRANTY IS IN EFFECT UNLESS SUPERSEDED BY LIMITED WARRANTY, FORM NO. 2299 (4/83)79011 • 10/06