ifwla - Warehousing and Logistics International

ifwla - Warehousing and Logistics International

ifwla - Warehousing and Logistics International

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

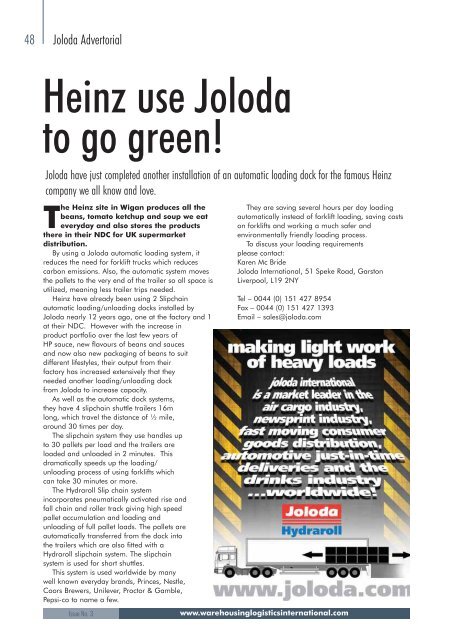

48 Joloda AdvertorialHeinz use Jolodato go green!Joloda have just completed another installation of an automatic loading dock for the famous Heinzcompany we all know <strong>and</strong> love.The Heinz site in Wigan produces all thebeans, tomato ketchup <strong>and</strong> soup we eateveryday <strong>and</strong> also stores the productsthere in their NDC for UK supermarketdistribution.By using a Joloda automatic loading system, itreduces the need for forklift trucks which reducescarbon emissions. Also, the automatic system movesthe pallets to the very end of the trailer so all space isutilized, meaning less trailer trips needed.Heinz have already been using 2 Slipchainautomatic loading/unloading docks installed byJoloda nearly 12 years ago, one at the factory <strong>and</strong> 1at their NDC. However with the increase inproduct portfolio over the last few years ofHP sauce, new flavours of beans <strong>and</strong> sauces<strong>and</strong> now also new packaging of beans to suitdifferent lifestyles, their output from theirfactory has increased extensively that theyneeded another loading/unloading dockfrom Joloda to increase capacity.As well as the automatic dock systems,they have 4 slipchain shuttle trailers 16mlong, which travel the distance of ½ mile,around 30 times per day.The slipchain system they use h<strong>and</strong>les upto 30 pallets per load <strong>and</strong> the trailers areloaded <strong>and</strong> unloaded in 2 minutes. Thisdramatically speeds up the loading/unloading process of using forklifts whichcan take 30 minutes or more.The Hydraroll Slip chain systemincorporates pneumatically activated rise <strong>and</strong>fall chain <strong>and</strong> roller track giving high speedpallet accumulation <strong>and</strong> loading <strong>and</strong>unloading of full pallet loads. The pallets areautomatically transferred from the dock intothe trailers which are also fitted with aHydraroll slipchain system. The slipchainsystem is used for short shuttles.This system is used worldwide by manywell known everyday br<strong>and</strong>s, Princes, Nestle,Coors Brewers, Unilever, Proctor & Gamble,Pepsi-co to name a few.Issue No. 3They are saving several hours per day loadingautomatically instead of forklift loading, saving costson forklifts <strong>and</strong> working a much safer <strong>and</strong>environmentally friendly loading process.To discuss your loading requirementsplease contact:Karen Mc BrideJoloda <strong>International</strong>, 51 Speke Road, GarstonLiverpool, L19 2NYTel – 0044 (0) 151 427 8954Fax – 0044 (0) 151 427 1393Email – sales@joloda.comwww.warehousinglogisticsinternational.com