European Recommendations on the Stabilization of Steel ... - Xs4all

European Recommendations on the Stabilization of Steel ... - Xs4all

European Recommendations on the Stabilization of Steel ... - Xs4all

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

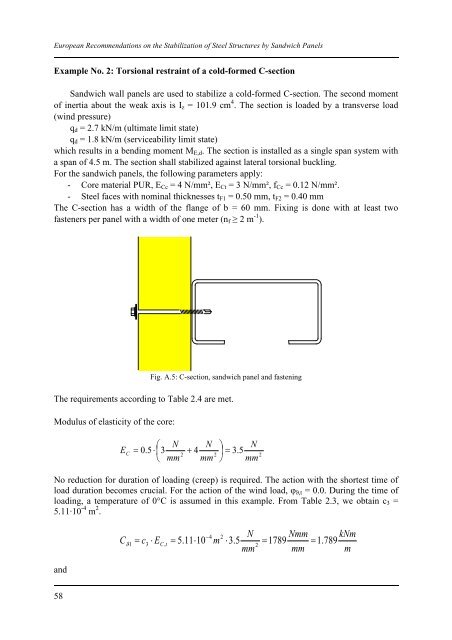

<str<strong>on</strong>g>European</str<strong>on</strong>g> <str<strong>on</strong>g>Recommendati<strong>on</strong>s</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> Stabilizati<strong>on</strong> <strong>of</strong> <strong>Steel</strong> Structures by Sandwich PanelsExample No. 2: Torsi<strong>on</strong>al restraint <strong>of</strong> a cold-formed C-secti<strong>on</strong>Sandwich wall panels are used to stabilize a cold-formed C-secti<strong>on</strong>. The sec<strong>on</strong>d moment<strong>of</strong> inertia about <strong>the</strong> weak axis is I z = 101.9 cm 4 . The secti<strong>on</strong> is loaded by a transverse load(wind pressure)q d = 2.7 kN/m (ultimate limit state)q d = 1.8 kN/m (serviceability limit state)which results in a bending moment M E,d . The secti<strong>on</strong> is installed as a single span system witha span <strong>of</strong> 4.5 m. The secti<strong>on</strong> shall stabilized against lateral torsi<strong>on</strong>al buckling.For <strong>the</strong> sandwich panels, <strong>the</strong> following parameters apply:- Core material PUR, E Cc = 4 N/mm², E Ct = 3 N/mm², f Cc = 0.12 N/mm².- <strong>Steel</strong> faces with nominal thicknesses t F1 = 0.50 mm, t F2 = 0.40 mmThe C-secti<strong>on</strong> has a width <strong>of</strong> <strong>the</strong> flange <strong>of</strong> b = 60 mm. Fixing is d<strong>on</strong>e with at least tw<strong>of</strong>asteners per panel with a width <strong>of</strong> <strong>on</strong>e meter (n f ≥ 2 m -1 ).Fig. A.5: C-secti<strong>on</strong>, sandwich panel and fasteningThe requirements according to Table 2.4 are met.Modulus <strong>of</strong> elasticity <strong>of</strong> <strong>the</strong> core:⎛ N N ⎞E C= 0.5⋅⎜3=⎝ mm mm ⎠+ 4 3. 52 2⎟No reducti<strong>on</strong> for durati<strong>on</strong> <strong>of</strong> loading (creep) is required. The acti<strong>on</strong> with <strong>the</strong> shortest time <strong>of</strong>load durati<strong>on</strong> becomes crucial. For <strong>the</strong> acti<strong>on</strong> <strong>of</strong> <strong>the</strong> wind load, φ ϑ,t = 0.0. During <strong>the</strong> time <strong>of</strong>loading, a temperature <strong>of</strong> 0°C is assumed in this example. From Table 2.3, we obtain c 3 =5.11∙10 -4 m 2 .andCNmm−42 N Nmm kNm= c3⋅ EC,t= 5.11⋅10m ⋅3.5= 1789 1. 7892mm mm mϑ 1=258