Opportunities and dangers of using residual elements ... - Jernkontoret

Opportunities and dangers of using residual elements ... - Jernkontoret

Opportunities and dangers of using residual elements ... - Jernkontoret

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

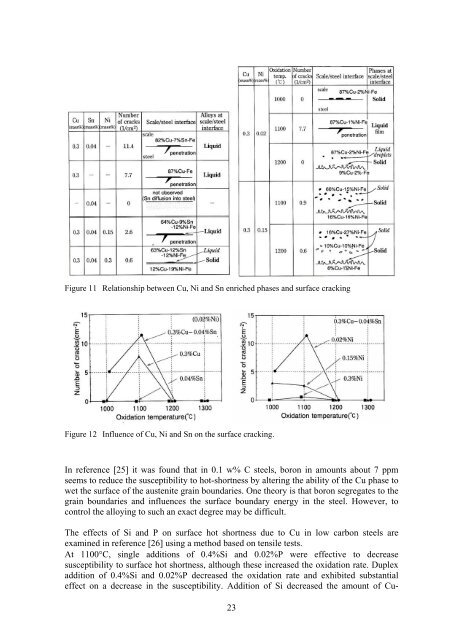

Figure 11 Relationship between Cu, Ni <strong>and</strong> Sn enriched phases <strong>and</strong> surface crackingFigure 12 Influence <strong>of</strong> Cu, Ni <strong>and</strong> Sn on the surface cracking.In reference [25] it was found that in 0.1 w% C steels, boron in amounts about 7 ppmseems to reduce the susceptibility to hot-shortness by altering the ability <strong>of</strong> the Cu phase towet the surface <strong>of</strong> the austenite grain boundaries. One theory is that boron segregates to thegrain boundaries <strong>and</strong> influences the surface boundary energy in the steel. However, tocontrol the alloying to such an exact degree may be difficult.The effects <strong>of</strong> Si <strong>and</strong> P on surface hot shortness due to Cu in low carbon steels areexamined in reference [26] <strong>using</strong> a method based on tensile tests.At 1100°C, single additions <strong>of</strong> 0.4%Si <strong>and</strong> 0.02%P were effective to decreasesusceptibility to surface hot shortness, although these increased the oxidation rate. Duplexaddition <strong>of</strong> 0.4%Si <strong>and</strong> 0.02%P decreased the oxidation rate <strong>and</strong> exhibited substantialeffect on a decrease in the susceptibility. Addition <strong>of</strong> Si decreased the amount <strong>of</strong> Cu-23