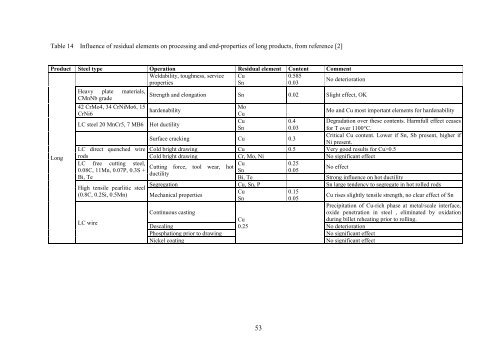

Table 14 Influence <strong>of</strong> <strong>residual</strong> <strong>elements</strong> on processing <strong>and</strong> end-properties <strong>of</strong> long products, from reference [2]Product Steel type Operation Residual element Content CommentWeldability, toughness, service Cu0.585No deteriorationpropertiesSn0.03LongHeavy plate materials,CMnNb gradeStrength <strong>and</strong> elongation Sn 0.02 Slight effect, OK42 CrMo4, 34 CrNiMo6, 15MohardenabilityCrNi6CuMo <strong>and</strong> Cu most important <strong>elements</strong> for hardenabilityLC steel 20 MnCr5, 7 MB6 Hot ductilityCu0.4Degradation over these contents. Harmfull effect ceasesSn0.03 for T over 1100°C.Surface cracking Cu 0.3Critical Cu content. Lower if Sn, Sb present, higher ifNi present.LC direct quenched wire Cold bright drawing Cu 0.5 Very good results for Cu>0.5rods Cold bright drawing Cr, Mo, Ni No significant effectLC free cutting steel,Cu0.25Cutting force, tool wear, hotNo effect0.08C, 11Mn, 0.07P, 0.3S +Sn0.05ductilityBi, TeBi, Te Strong influence on hot ductilitySegregationHigh tensile pearlitic steelCu, Sn, P Sn large tendency to segregate in hot rolled rods(0.8C, 0.2Si, 0.5Mn) Mechanical propertiesCu rises slightly tensile strength, no clear effect <strong>of</strong> SnLC wireContinuous castingDescalingPhosphationg prior to drawingNickel coatingCuSnCu0.250.150.05Precipitation <strong>of</strong> Cu-rich phase at metal/scale interface,oxide penetration in steel , eliminated by oxidationduring billet reheating prior to rolling.No deteriorationNo significant effectNo significant effect53

1. References1 Gartz R, Nylén M, “Miljöaspekter vid produktion, användning och recirkulering avmetaller, IM report 3424, 1996.2. Marique C., ”Tramp <strong>elements</strong> <strong>and</strong> steel properties: a progress state <strong>of</strong> the Europeanproject on scrap recycling”, La revue de Métallurgie-CIT pp.433-441, 1998.3 Houpert C, Jallon M, Confente M, Lanteri V, Jolivet JM, Guttmann M, Birat JP,“Production <strong>of</strong> high quality steels <strong>using</strong> the scrap/electric arc furnace route”, 15 th PTDconference proceedings, pp.67-77, 1996.4. Sano N, Hiroyuki K, Sasabe M, Shigeki M, “Research activities on removal <strong>of</strong><strong>residual</strong> <strong>elements</strong> from steel scrap in Japan”, Sc<strong>and</strong>inavian journal <strong>of</strong> metallurgy,vol.27, no.1, pp.24-30, 1998.5 Tsukihashi F, “Thermodynamics <strong>of</strong> removal <strong>of</strong> tramp <strong>elements</strong> from steel scrap”, Met.<strong>and</strong> mat. Processing, vol. 1, pp.927-936, 2003.6. Sarov L., Janke D., “Recycling <strong>of</strong> scrap in steelmaking in view <strong>of</strong> the tramp elementproblem”, Metall 52, Nr6, 1998.7. Nilles PE, “Recycling <strong>and</strong> virgin materials in the changing European steel industry”,Iron <strong>and</strong> Steelmaker vol.24, n0.4, pp.33-40, 19978 Birat JPL, “Residuals <strong>and</strong> tramp <strong>elements</strong> in scrap <strong>and</strong> steel”, 15 th PTD conferenceproceedings, pp.53-65, 1996.9 Skrotboken 2000, utgåva 1, revised 2005.10. Kor GJW, “Residual <strong>elements</strong> in steelmaking”, 54 th electric furnace conferenceproceedings, pp.477-495, 1997.11 Menad M, Björkman B, “Tramp <strong>elements</strong> in Steelmaking, literature survey”, reportfrom Luleå university <strong>of</strong> technology, April 199812 Cho WD, Fan P, Han G, “A new approach for the removal <strong>of</strong> Copper from solidferrous scarp”, AIS Tech. Proceedings vol.1, pp 861-867, 2004.13 Hawkins RJ, “Problem <strong>of</strong> <strong>residual</strong>s in Steel- current situation in the ECSC”, Vol.12,no.6, pp.286-287, 1985.14 Yuuji Kimura, Setsuo Takaki, “Phase Transformation Mechanism <strong>of</strong> Fe-Cu Alloys”,ISIJ International, Vol. 37 (1997), No. 3, pp. 290-29554