Fasteners - hdgasa

Fasteners - hdgasa

Fasteners - hdgasa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

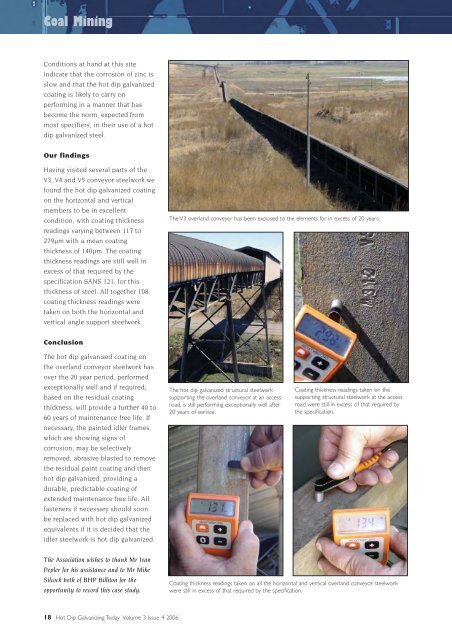

Coal MiningConditions at hand at this siteindicate that the corrosion of zinc isslow and that the hot dip galvanizedcoating is likely to carry onperforming in a manner that hasbecome the norm, expected frommost specifiers, in their use of a hotdip galvanized steel.Our findingsHaving visited several parts of theV3, V4 and V5 conveyor steelwork wefound the hot dip galvanized coatingon the horizontal and verticalmembers to be in excellentcondition, with coating thicknessreadings varying between 117 to279µm with a mean coatingthickness of 140µm. The coatingthickness readings are still well inexcess of that required by thespecification SANS 121, for thisthickness of steel. All together 108coating thickness readings weretaken on both the horizontal andvertical angle support steelwork.The V3 overland conveyor has been exposed to the elements for in excess of 20 years.ConclusionThe hot dip galvanized coating onthe overland conveyor steelwork hasover the 20 year period, performedexceptionally well and if required,based on the residual coatingthickness, will provide a further 40 to60 years of maintenance free life. Ifnecessary, the painted idler frames,which are showing signs ofcorrosion, may be selectivelyremoved, abrasive blasted to removethe residual paint coating and thenhot dip galvanized, providing adurable, predictable coating ofextended maintenance free life. Allfasteners if necessary should soonbe replaced with hot dip galvanizedequivalents if it is decided that theidler steelwork is hot dip galvanized.The hot dip galvanized structural steelworksupporting the overland conveyor at an accessroad, is still performing exceptionally well after20 years of service.Coating thickness readings taken on thesupporting structural steelwork at the accessroad were still in excess of that required bythe specification.The Association wishes to thank Mr IvanPepler for his assistance and to Mr MikeSilcock both of BHP Billiton for theopportunity to record this case study.Coating thickness readings taken on all the horizontal and vertical overland conveyor steelworkwere still in excess of that required by the specification.18 Hot Dip Galvanizing Today Volume 3 Issue 4 2006