Fasteners - hdgasa

Fasteners - hdgasa

Fasteners - hdgasa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

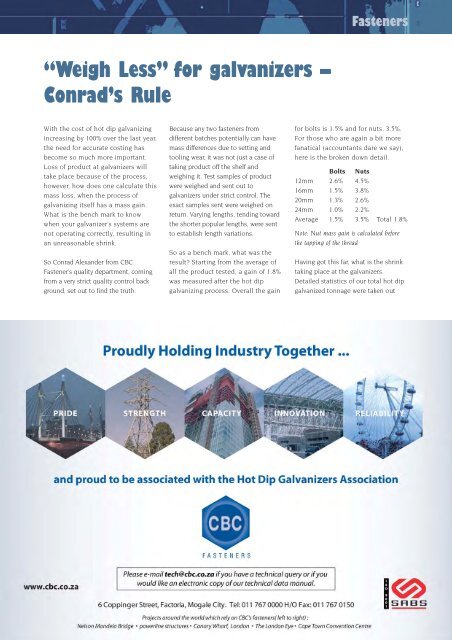

<strong>Fasteners</strong>“Weigh Less” for galvanizers –Conrad’s RuleWith the cost of hot dip galvanizingincreasing by 100% over the last year,the need for accurate costing hasbecome so much more important.Loss of product at galvanizers willtake place because of the process,however, how does one calculate thismass loss, when the process ofgalvanizing itself has a mass gain.What is the bench mark to knowwhen your galvanizer’s systems arenot operating correctly, resulting inan unreasonable shrink.So Conrad Alexander from CBCFastener’s quality department, comingfrom a very strict quality control background, set out to find the truth.Because any two fasteners fromdifferent batches potentially can havemass differences due to setting andtooling wear, it was not just a case oftaking product off the shelf andweighing it. Test samples of productwere weighed and sent out togalvanizers under strict control. Theexact samples sent were weighed onreturn. Varying lengths, tending towardthe shorter popular lengths, were sentto establish length variations.So as a bench mark, what was theresult? Starting from the average ofall the product tested, a gain of 1.8%was measured after the hot dipgalvanizing process. Overall the gainfor bolts is 1.5% and for nuts, 3.5%.For those who are again a bit morefanatical (accountants dare we say),here is the broken down detail.Bolts Nuts12mm 2.6% 4.5%16mm 1.5% 3.8%20mm 1.3% 2.6%24mm 1.0% 2.2%Average 1.5% 3.5% Total 1.8%Note: Nut mass gain is calculated beforethe tapping of the threadHaving got this far, what is the shrinktaking place at the galvanizers.Detailed statistics of our total hot dipgalvanized tonnage were taken out