Domnick Hunter Compressed Air Dryers - regula servis

Domnick Hunter Compressed Air Dryers - regula servis

Domnick Hunter Compressed Air Dryers - regula servis

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The PNEUDRI modular designThe PNEUDRI design replaces large, heavy, steel pressurevessels with smaller, more compact and lightweight aluminiumextrusionsUnique extrudedaluminium constructionUnlike their welded, carbon steelcounterparts, the unique extrudedaluminium construction of PNEUDRIeliminates these models from thecostly annual pressure vesselinspection. PNEUDRI models are alsotypically half the size and weight oftraditional twin tower dryers.• Distribution manifolds and drying columns are allconstructed from lightweight, high tensile extrudedaluminium• The shape of the extrusion varies on each model range• All extrusions are below 150 mm (6”) in diameter, whichis under the pressure vessel inspection requirementsof ASME• World-wide design approvals include PED, CRN, CE• Fully corrosion protectedTraditionalAdsorption <strong>Dryers</strong>• Typically, adsorption dryersare constructed from carbonor stainless steel• They consist of two large,heavy pressure vesselswhich contain the adsorbentmaterial• Separate, interconnectingpiping is used for valving,etc.• This method of constructionhas a direct impact on theperformance of the dryerand the air quality it provides3Distribution ManifoldDrying Column

Advanced modular drying systemPNEUDRI MiDASand MIDIplus models• PNEUDRI MiDAS & MIDIplus models useonly single extrusions, with a pressuredie-cast inlet and outlet assembly• <strong>Compressed</strong> air capacity within theseranges is increased by varying thelength of the drying columns• The greater the flow required,the longer the drying columnPNEUDRI MAXI models• MAXI models use multiple dryingcolumns of equal length to providerequired compressed air capacity• The greater the flow required, themore drying columns are used(up to the maximum length of themanifold)Upper distributionmanifoldDrying columnsLower distributionmanifoldMulti-bankingUnlike the loose filled adsorbent bed of traditional twin tower dryer designs,PNEUDRI with it’s snowstorm filled adsorbent beds provides an equalresistance to air flow. Therefore, when the system flow of an installationexceeds the capacity of the largest single dryer model, PNEUDRI can bemulti- banked to meet the demand. Should demand increase in the future,there is no need to replace the dryer with a larger unit, additional capacitycan be covered by simply adding an extra bank or banks, a feature onlypossible with PNEUDRI.Flexibility during maintenanceMulti-banking of dryers enables individual banks to be easily isolated forroutine maintenance work. This means minimal interruption to your clean,dry air supply.100% stand-byCompared to traditional twin tower designs, 100% standby is availableat a fraction of the cost as only one extra dryer bank is required.Fits through a standard doorwayUnlike traditional twin tower designs, PNEUDRI dryers will fit through a standarddoorway, eliminating the need for special access or facility structural dismantlingduring installation.4

<strong>Air</strong> qualityAdsorption dryers remove water vapour by passing air over aregenerative adsorbent material known as desiccant, which stripsthe moisture from the air. All adsorption dryers remove water vapourusing this method, however the adsorbent must be periodicallyregenerated to ensure a continuous supply of dry air. A numberof different regeneration methods are available.Pressure Dewpoint (Pdp)Pressure dewpoint is the term used to describethe temperature at which condensation will occurand the water removal efficiency of a dryer isexpressed as a pressure dewpoint (written as atemperature). Adsorption dryers are extremelyefficient and typically provide pressure dewpoint’sof -40°C or -70°C. This means for water vapour tocondense into a liquid, the air temperature wouldneed to drop below -40°C or -70°C respectively.Typically, a pressure dewpoint of -40°C is usedin most applications as compressed air witha dewpoint below -26°C will not only preventcorrosion, it will also inhibit the growth of microorganismswithin the compressed air system.PNEUDRI utilises four key features toguarantee the required pressure dewpoint.OIL-X EVOLUTION pre & after filtrationAdsorption dryers are designed only for the removal of water vapour,and not liquid water, water aerosols, oil, particulates or microorganisms.Only by using Parker domnick hunter OIL-X EVOLUTIONpre and after filtration can the removal of these contaminants beguaranteed and air quality in accordance with ISO 8573-1 : 2001 bedelivered.Adsorbent desiccant materialSelected for optimum dewpoint performance, dryers delivering a -40°Cpressure dewpoint utilise a split bed of activated alumina andmolecular sieve. For critical applications, dryers delivering a -70°Cpressure dewpoint are filled with a special blend of silica gel andmolecular sieve.5PNEUDRI MiDAS DryerAll desiccant materials are specially selected to provide:• Optimum adsorption and regenerationcapacity - to ensure consistentdewpoint• Low dusting - to prevent blockageof downstream filtration• High crush strength - to preventbreakdown of the desiccant duringoperation• High resistance to aggressive andoil-free condensate - for compatibilitywith all types of air compressor, theirlubricants and condensate

Modular aluminium designThe award winning PNEUDRI design first introducedby Parker domnick hunter in 1985, replaces thetraditional, large, heavy carbon steel twin toweradsorption dryer and it’s complex valving andinterconnecting piping, with a smaller, more compactand lightweight design.Aluminium extrusions are used throughout for dryingchambers and distribution manifolds. This designallows the desiccant material to be retained within thedrying chambers and when used in conjunction withthe unique snowstorm filling technique, preventsmovement of the desiccant material during operationand all but eliminates desiccant attrition andbreakdown which leads to loss of pressure dewpoint.PNEUDRI MX <strong>Dryers</strong>Adsorbent fill method -snowstorm fillingUnique to Parker domnick hunter modular dryers isthe snowstorm filling technique used to charge thedrying chambers with adsorbent desiccant material.The benefits of the snowstorm filling techniqueinclude:Maximum Packing Density• Achieves maximum packing density for thedesiccant material, fully utilising all of theavailable space envelopeLoose filled bedSnowstorm filled bed• Prevents channelling of air through thedesiccant as seen on traditional twin towerdesigns. Due to channelling, twin towerdesigns require more desiccant to achievean identical dewpoint, increasing physicalsize, operational and maintenance costs• Prevents desiccant attrition which canlead to dusting, blocked filters and lossof dewpointInconsistent drying anddesiccant attritionConsistent drying withno desiccant attrition• Allows 100% of the available desiccantmaterial to be used for drying, thereforereducing the amount of desiccant requiredand maintenance costs• 100% of the desiccant is regeneratedensuring consistent dewpoint• Provides a low, equal resistance to air flowallowing multiple drying chambers andmultiple dryer banks to be used, a featureonly available with PNEUDRIInconsistent RegenerationConsistent Regeneration• Ensures continuous dewpoint performance6

PNEUDRI OperationDrying of <strong>Compressed</strong> <strong>Air</strong>Adsorption dryers work on the principle of moisture always migrating to thedriest medium possible. Therefore, water vapour is removed from compressedair by passing it over an adsorbent desiccant material.As the air contacts the adsorbent material, water vapourtransfers from the wet air to the dry desiccant, however,adsorbent materials have a fixed adsorption capacity andonce this capacity is reached, they must be regeneratedor replaced.Therefore, to provide a continuous supply of clean, drycompressed air, adsorbent dryers utilise two chambersof desiccant material and at any one time, whilst onechamber is on-line, drying the incoming compressed air,the other is either off-line, being regenerated or isre-pressurised, ready to come on-line. All adsorptiondryers remove water in this manner.The energy consumed by an adsorption dryer can bedirectly attributed to the method used to regenerate theadsorbent material. Parker domnick hunter PNEUDRIdryers utilise either the Heatless PSA or the HeatRegenerative TSA method to regenerate the adsorbentmaterial.PNEUDRI Operation - Drying CycleThe process air enters the dryer throughthe inlet and is directed into the on-linedrying chamber via the inlet valves andlower manifold.(PNEUDRI models can be made up ofeither single or multiple drying columns,depending upon the range)The air is evenly distributed through thedrying columns and passes over thedesiccant material, reducing the watervapour content.The dried process air then combines in theupper manifold and exits the dryer via theoutlet check valves.Dry <strong>Air</strong>DesiccantbeadWet <strong>Air</strong>Column ChangeoverBefore the on-line (drying) and off-line(regenerating) columns change over, thedryer exhaust valve, is closed, allowing thepurge air to re-pressurise the off-linecolumns. This ensures a consistent systempressure and dewpoint when the dryingchambers change over.7

PNEUDRI Operation - Regeneration Cycle(Heatless PSA or Pressure Swing Adsorption)At the start of the regeneration cycle, the exhaust valve ofthe dryer is closed and the off-line chamber is at full linepressure. The air in the off-line chamber has a dewpointequal to the air leaving the dryer.The exhaust valve is then opened and the dry air withinthe chamber expands rapidly as it leaves the dryer via theexhaust silencer, forcing water to be removed from thedesiccant material.Once the off-line chamber has de-pressurised, acontinuous bleed of dried process air is directed into theoff-line upper manifold. This air is known as purge air.With the exhaust valve open, the purge air expands fromline pressure to atmospheric pressure and flowsdownwards through the columns, over the off-linedesiccant material.As the purge air at line pressure contains a fixed amountof water vapour, allowing it to expand means the purgeair becomes even drier, increasing its capacity to removewater from the saturated desiccant bed.Dry Purge<strong>Air</strong>DesiccantbeadWet Purge<strong>Air</strong> toAtmosphereTime(minutes)0 2.5 3Standard Drying / Regeneration CycleChangeover0 2.5 3Side A Regeneration Re-pressurisation DryingSide B Drying Regeneration Re-pressurisationPNEUDRI Operation - Regeneration Cycle(Heat Regenerative TSA or Thermal Swing Adsorption)The regeneration cycle of a TSA dryer is similar to thatof the PSA dryer described above, however to reducethe amount of purge air required, heat is added to assistthe process.Two heater assemblies are strategically placed in eachdrying column to heat the purge air, optimisingregeneration.The heaters are switched on after the column hasde-pressurised, to again reduce energy consumption.The combination of dry purge air and heat uses lessenergy to remove the water from the saturateddesiccant bed than is consumed by purge air alone.After a pre-set time, the heaters are switched off and theoff-line bed is allowed to cool before changeover.HotPurge <strong>Air</strong>DesiccantbeadWet Purge<strong>Air</strong> toAtmosphereTime(minutes)Standard Drying / Regeneration Cycle0 60 74 75 0 60 74 75Side ADepressurisationRegenerationPurge with heaters onPurge withheaters offRepressurisationSide B Drying DepressurisationChangeoverPurge withheaters onDryingRegenerationPurge withheaters offRepressurisation8

Saving energy with the dewpoint dependentswitching (DDS) energy management systemThe energy required to regenerate the off-line desiccant bed in an absorption dryer is constant, and based upon theassumption that the dryer is operating at its full capacity and the desiccant bed requiring regeneration has been fullysaturated. In reality, a dryer is rarely operating at full capacity all of the time, for example during shift work and periodsof low demand. Daily and seasonal fluctuations in ambient temperature and humidity also change the moisture loadingplaced upon the dryer.Under such conditions, at the point in the drying cycle where the air flow is switched from one drying chamber to theother, there is the potential for drying capacity to remain in the desiccant material about to undergo regeneration. As theenergy used to regenerate this partially saturated bed is based upon the assumption that the bed is fully saturated, moreenergy (purge air) is consumed than is actually necessary.Dewpoint Dependent Switching (DDS) Energy Management SystemWith the DDS Energy Management system installed, the drying cycle remains unchanged, however as the dryingchambers are about to change, the DDS system overrides normal operation to fully utilise the drying capacity of theon-line desiccant material.DDS operationAt column changeover, the exhaust valve is closed to allow the purge air tore-pressurise the off-line column, thus ensuring no loss of system pressure.At this time, both drying chambers are at full line pressure, so that no purgeair is being used and the dryer is in a state of zero energy consumption.Under normal operation, the drying chambers would proceed to change overautomatically, however the DDS energy management system incorporates ahygrometer which is used to monitor the pressure dewpoint of the air leavingthe dryer. If the air is drier than the pre-set dewpoint, the desiccant material isonly partially saturated and has drying capacity remaining within it, thereforechange over is delayed.The hygrometer constantly monitors the outlet dewpoint until the pre-set levelhas been achieved, at which point, change over will occur.The drying and regenerating cycle will then continue normally until the endof the next column changeover when the DDS energy management systemmay again extend the drying period as dictated by the outlet air quality.DDS Operation - Energy Saving Cycle (Heatless Dryer example shown)Time(minutes)Side A0 2.5 3RegenerationDDS Drying / Regeneration Cyclechangeover time dictatedby outlet dewpointEnergy SavingSide B Drying Regenerationchangeover0 2.5 3RepressurisationRepressurisationDryingchangeover time dictatedby outlet dewpointEnergy SavingchangeoverUsing DDS will ensure that the energy consumed by PNEUDRI is directly proportional to the actual air flow, temperatureand moisture loading, not the dryers rated capacity, thus providing significant energy and environmental savings.DDS Energy Saving (Heatless Dryer example shown)<strong>Air</strong> Demand % Energy Saving %Energy SavingP/A KwEnvironmental SavingP/A Kg CO 2100 33.00 95,040 40,86790 40.00 115,200 49,53680 47.00 135,360 58,20570 53.00 152,640 65,63560 60.00 172,800 74,30450 66.00 190,080 81,7349System pressure 6 bar g. Max Temp 35°C. System flow 1700 m 3 /hr (1000 cfm). Average pressure 6.5 bar g. Average Temp 30°C.

Dryer control systemsPNEUDRI ControllersDRYER MODELCONTROLLERMiDAS (DAS) MIDI (DME) MAXI (MX) MAXI (MPX) MAXI (DH)MiDAS•Smart Smart DDS• • Electronic• •AdvancedPneumatic• •PNEUDRI Controller FeaturesControllerOptionsPower onIndicationFaultIndicationDisplay faultconditionvaluesServiceintervalIndicationFUNCTIONServicecountdowntimersConfigurablealarmsettingsRemote VoltFree AlarmContactsFilter ServiceTimerDDS EnergyMgmtSystemMiDAS• •Smart• • • •Smart DDS• • • • •Electronic• • • • • • • • •Advanced• • • • • • • • •PneumaticIf you would like more information about these or other rangesof Parker domnick hunter purification products please visit:www.domnickhunter.com, Email: dhindsales@parker.com orcontact your local Parker domnick hunter representative.<strong>Compressed</strong> <strong>Air</strong>Capabilities17 400 4401PNEUDRIMiDAS17 400 4407PNEUDRIMIDIplus17 400 4408OIL-X EVOLUTIONFilters17 400 4402PNEUDRIMX17 400 4410PNEUDRIMPX17 400 4411PNEUDRIHeat Regenerative17 400 4409MAXIGASNitrogen Generators17 400 470410

PNEUDRI MPXHeatless (PSA) RegenerationHigh Efficiency <strong>Compressed</strong> <strong>Air</strong> <strong>Dryers</strong>PNEUDRI heatless dryers can provide the simpleand cost effective solution for the provision ofclean dry compressed air.Using patented Parker domnick huntertechnology, PNEUDRI heatless dryers provide theultimate in performance, security and reliability.<strong>Compressed</strong> air purification equipment mustdeliver uncompromising performance andreliability whilst providing the right balance of airquality with the lowest cost of operation. Manymanufacturers offer products for the filtration andpurification of contaminated compressed air,which are often selected only upon their initialpurchase cost, with little or no regard for the airquality they provide, the cost of operationthroughout their life or indeed their environmentalimpact. When purchasing purification equipment,delivered air quality, the overall cost of ownershipand the equipment’s environmental impact mustalways be considered.The Parker domnick hunter Design PhilosophyParker domnick hunter has been supplying industry with high efficiency filtrationand purification products since 1963. Our philosophy ‘Designed for <strong>Air</strong> Quality &Energy Efficiency’ ensures products that not only provide the user with clean, highquality compressed air, but also with low lifetime costs and reduced CO 2 emissions.Contact Information:Parker Hannifin Ltddomnick hunter Industrial divisionDukesway, Team Valley Trading EstateGateshead, Tyne and WearEngland NE11 0PZTel: +44 (0)191 402 9000Fax: +44 (0)191 482 6296Email: dhindsales@parker.comwww.domnickhunter.comBenefits:• PNEUDRI dryers provide efficient removalof water vapour from compressed air• Delivered air quality is in accordance withISO 8573-1:2001, the international standardfor compressed air quality• Improves production efficiency and reducesmaintenance costs and downtime• Pressure Dewpoint’s of -70°C, -40°C & -20°C(ISO 8573-1 :2001 Classes 1, 2 & 3) are available• Unlike refrigeration dryers, the -40°C & -70°Cpressure dewpoint’s offered by PNEUDRI notonly eliminates corrosion, it also inhibits thegrowth of micro-organisms• Low noise level

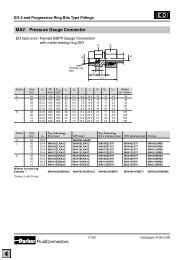

Dryer PerformanceDryer ModelsDewpoint (Standard)Dewpoint (Option 1) ISO 8573-1:2001ISO 8573-1:2001ClassificationClassification (standard)ºC ºF ºC ºF(Option 1)MPXS -40 -40 Class 2 -70 -100 Class 1MPXE -40 -40 Class 2 -70 -100 Class 1Product SelectionPNEUDRI MAXIplus MPXStated flows are for operation at 7 bar g (100 psi g) with reference to 20°C, 1 bar a, 0% relative watervapour pressure. For flows at other pressures apply the correction factors shown.Model Pipe Size L/s m 3 /min m 3 /hr cfmMPX 110 G 4 652 39 2346 1381MPX 112 G 4 782 47 2815 1657MPX 210 G 4 1303 78 4692 2762MPX 212 G 4 1564 94 5630 3314MPX 310 G 4 1955 118 7038 4143MPX 312 G 4 2346 141 8445 4971Correction FactorTemperature Correction Factor CFTMaximum InletTemperature°C 25 30 35 40 45 50°F 77 86 95 104 113 122CFT 1.00 1.00 1.00 1.04 1.14 1.37Pressure Correction Factor CFPMinimumInlet Pressurebar g 4 5 6 7 8 9 10 11 12 13psi g 58 73 87 100 116 131 145 160 174 189CFP 1.60 1.33 1.14 1.00 0.89 0.80 0.73 0.67 0.62 0.57Dewpoint Correction Factor CFDRequiredDewpointPDP °C -40 -70PDP °F -40 -100CFD 0 1.43Dryer SelectionTo correctly select a dryer model, the flow rate of the dryer must be adjusted for the minimum operating pressure and, maximum operationaltemperature of the system. If the dewpoint required is different to the standard dewpoint of the dryer then the flow rate must also be adjustedfor the required outlet dewpoint.1. Obtain the minimum operating pressure, maximum inlet temperature and maximum compressed air flow rate at the inlet of the dryer.Obtain the outlet dewpoint required.2. Select correction factor for maximum inlet temperature from the CFT Table (always round up e.g. for 37°C use 40°C correction factor)3. Select correction factor for minimum inlet pressure from the CFP table (always round down e.g. for 5.3 bar use 5 bar correction factor)4. Select correction factor for required outlet dewpoint from the CFD table5. Calculate minimum drying capacityMinimum Drying Capacity = <strong>Compressed</strong> <strong>Air</strong> Flow x CFT x CFP x CFD6. Using the minimum drying capacity, select a dryer model from the flow rate tables above (dryer selected must have a flow rate equal to or greaterthan the minimum drying capacity)If the minimum drying capacity exceeds the maximum values of the models shown within the tables, please contact Parker domnick hunter foradvice regarding larger multi-banked dryers.

Technical DataDryerModelsMin Operating Max Operating Min Operating Max Operating Max AmbientNoiseElectrical ElectricalPressure Pressure Temp Temp TempThread Levelsupply supplyConnectionsbar g psi g bar g psi g °C °F °C °F °C °F(standard (optional)dB (A)MPXS 4 58 13 190 2 35 50 122 55 131230 V 1ph50/60Hz110 V 1PH50/60HzBSPPor NPT

PNEUDRI MXHeatless (PSA) RegenerationHigh Efficiency <strong>Compressed</strong> <strong>Air</strong> <strong>Dryers</strong>Using patented Parker domnick hunter technology,PNEUDRI MX heatless dryers provide the ultimatein clean and dry compressed air.<strong>Compressed</strong> air purification equipment mustdeliver uncompromising performance and reliabilitywhilst providing the right balance of air quality withthe lowest cost of operation. Many manufacturersoffer products for the filtration and purification ofcontaminated compressed air, which are oftenselected only upon their initial purchase cost, withlittle or no regard for the air quality they provide,the cost of operation throughout their life or indeedtheir environmental impact. When purchasingpurification equipment, delivered air quality, theoverall cost of ownership and the equipment’senvironmental impact must always be considered.The Parker domnick hunter Design PhilosophyParker domnick hunter has been supplying industry with high efficiency filtrationand purification products since 1963. Our philosophy ‘Designed for <strong>Air</strong> Quality &Energy Efficiency’ ensures products that not only provide the user with clean, highquality compressed air, but also with low lifetime costs and reduced CO 2 emissions.Contact Information:Parker Hannifin Ltddomnick hunter Industrial divisionDukesway, Team Valley Trading EstateGateshead, Tyne and WearEngland NE11 0PZTel: +44 (0)191 402 9000Fax: +44 (0)191 482 6296Email: dhindsales@parker.comwww.domnickhunter.comBenefits:• PNEUDRI dryers provide efficient removalof water vapour from compressed air• Delivered air quality is in accordance withISO 8573-1:2001, the international standardfor compressed air quality• Improves production efficiency and reducesmaintenance costs and downtime• Pressure Dewpoint’s of -70°C, -40°C & -20°C(ISO 8573-1:2001 Classes 1, 2 & 3) are available• Unlike refrigeration dryers, the -40°C & -70°Cpressure dewpoint’s offered by PNEUDRI notonly eliminates corrosion, it also inhibits thegrowth of micro-organisms• Low noise level

Dryer PerformanceDryer ModelsDewpoint(Standard)ISO 8573-1:2001Classification(standard)Dewpoint(Option 1)ISO 8573-1:2001Classification(Option 1)Dewpoint(Option 2)ºC ºF ºC ºF ºC ºFISO 8573-1:2001Classification(Option 2)MXS -40 -40 Class 2 -70 -100 Class 1 -20 -4 Class 3MXA -40 -40 Class 2 -70 -100 Class 1 -20 -4 Class 3Product SelectionPNEUDRI MXStated flows are for operation at 7 bar g (100 psi g) with reference to 20°C, 1 bar a, 0% relative water vapourpressure. For flows at other pressures apply the correction factors shown.Model Pipe Size L/s m 3 /min m 3 /hr cfmSingle BankMulti-BankMX 102C G 2 113 6.81 408 240MX 103C G 2 170 10.22 612 360MX 103 G 2 213 12.78 765 450MX 104 G 2 283 17.03 1020 600MX 105 G 2 1 /2 354 21 1275 750MX 106 G 2 1 /2 425 26 1530 900MX 107 G 2 1 /2 496 30 1785 1050MX 108 G 2 1 /2 567 34 2040 1200MX 205 G 2 1 /2 708 43 2550 1500MX 206 G 2 1 /2 850 51 3060 1800MX 207 G 2 1 /2 992 60 3570 2100MX 208 G 2 1 /2 1133 68 4080 2400MX 306 G 2 1 /2 1275 77 4590 2700MX 307 G 2 1 /2 1488 89 5355 3150MX 308 G 2 1 /2 1700 102 6120 3600Correction FactorTemperature Correction Factor CFTMaximum InletTemperature°C 25 30 35 40 45 50°F 77 86 95 104 113 122CFT 1.00 1.00 1.00 1.04 1.14 1.37Pressure Correction Factor CFPMinimumInlet Pressurebar g 4 5 6 7 8 9 10 11 12 13psi g 58 73 87 100 116 131 145 160 174 189CFP 1.60 1.33 1.14 1.00 0.89 0.80 0.73 0.67 0.62 0.57Dewpoint Correction Factor CFDRequiredDewpointPDP °C -20 -40 -70PDP °F -4 -40 -100CFD 0.91 1.00 1.43Dryer SelectionTo correctly select a dryer model, the flow rate of the dryer must be adjusted for the minimum operating pressure and, maximum operationaltemperature of the system. If the dewpoint required is different to the standard dewpoint of the dryer then the flow rate must also be adjustedfor the required outlet dewpoint.1. Obtain the minimum operating pressure, maximum inlet temperature and maximum compressed air flow rate at the inlet of the dryer.Obtain the outlet dewpoint required.2. Select correction factor for maximum inlet temperature from the CFT Table (always round up e.g. for 37°C use 40°C correction factor)3. Select correction factor for minimum inlet pressure from the CFP table (always round down e.g. for 5.3 bar use 5 bar correction factor)4. Select correction factor for required outlet dewpoint from the CFD table5. Calculate minimum drying capacityMinimum Drying Capacity = <strong>Compressed</strong> <strong>Air</strong> Flow x CFT x CFP x CFD6. Using the minimum drying capacity, select a dryer model from the flow rate tables above (dryer selected must have a flow rate equal to or greaterthan the minimum drying capacity)If the minimum drying capacity exceeds the maximum values of the models shown within the tables, please contact Parker domnick hunter foradvice regarding larger multi-banked dryers.

Technical DataDryerModelsMin Operating Max Operating Min Operating Max Operating Max AmbientNoiseElectrical ElectricalPressure Pressure Temp Temp TempThread Levelsupply supplyConnectionsbar g psi g bar g psi g °C °F °C °F °C °F(standard (optional)dB (A)MXS 4 58 13 190 2 35 50 122 55 13185 - 265 V1ph 50/60HzN/ABSPPor NPT

PNEUDRI DHHeat Regenerative (TSA) RegenerationHigh Efficiency <strong>Compressed</strong> <strong>Air</strong> <strong>Dryers</strong>The PNEUDRI range of heat regenerative dryershas proven to be the ideal solution for manythousands of compressed air users worldwideand in a wide variety of industries.<strong>Compressed</strong> air purification equipment mustdeliver uncompromising performance andreliability whilst providing the right balance of airquality with the lowest cost of operation. Manymanufacturers offer products for the filtrationand purification of contaminated compressedair, which are often selected only upon theirinitial purchase cost, with little or no regard forthe air quality they provide, the cost of operationthroughout their life or indeed theirenvironmental impact. When purchasingpurification equipment, delivered air quality, theoverall cost of ownership and the equipment’senvironmental impact must always beconsidered.The Parker domnick hunter Design PhilosophyParker domnick hunter has been supplying industry with high efficiency filtrationand purification products since 1963. Our philosophy ‘Designed for <strong>Air</strong> Quality &Energy Efficiency’ ensures products that not only provide the user with clean, highquality compressed air, but also with low lifetime costs and reduced CO 2 emissions.Contact Information:Parker Hannifin Ltddomnick hunter Industrial divisionDukesway, Team Valley Trading EstateGateshead, Tyne and WearEngland NE11 0PZTel: +44 (0)191 402 9000Fax: +44 (0)191 482 6296Email: dhindsales@parker.comwww.domnickhunter.comBenefits:• PNEUDRI dryers provide efficient removalof water vapour from compressed air• Delivered air quality is in accordance withISO 8573-1:2001, the international standardfor compressed air quality• Improves production efficiency and reducesmaintenance costs and downtime• Pressure Dewpoint’s of -70°C, -40°C & -20°C(ISO 8573-1 :2001 Classes 1, 2 & 3) are available• Unlike refrigeration dryers, the -40°C & -70°Cpressure dewpoint’s offered by PNEUDRI notonly eliminates corrosion, it also inhibits thegrowth of micro-organisms• Low noise level

Dryer PerformanceDryer ModelsDewpoint (Standard)Dewpoint (Option 1) ISO 8573-1:2001ISO 8573-1:2001ClassificationClassification (standard)ºC ºF ºC ºF(Option 1)DHE -40 -40 Class 2 -70 -100 Class 1DHS -40 -40 Class 2 -70 -100 Class 1Product SelectionPNEUDRI MAXI DHStated flows are for operation at 7 bar g (100 psi g) with reference to 20°C, 1 bar a, 0% relative water vapourpressure. For flows at other pressures apply the correction factors shown.Model Pipe Size L/S m 3 /min m 3 /hr cfmDH102 G 2 66 3.97 238 140DH104 G 2 132 7.95 476 280DH106 G 2 1 /2 198 11.92 714 420DH108 G 2 1 /2 264 15.88 951 560DH110 G 2 1 /2 330 19.86 1189 700DH208 G 2 1 /2 528 31.76 1902 1120DH210 G 2 1 /2 661 39.71 2378 1400DH308 G 2 1 /2 793 47.65 2853 1679DH310 G 2 1 /2 991 59.57 3567 2100DH408 G 2 1 /2 1057 63.53 3804 2239DH410 G 2 1 /2 1321 79.43 4756 2779Correction FactorsTemperature Correction Factor CFTMaximum InletTemperature°C 25 30 35 40 45 50°F 77 86 95 104 113 122CFT 0.91 1.00 1.00 1.32 1.73 2.23Pressure Correction Factor CFPMinimumInlet Pressurebar g 4 5 6 7 8 9 10 11 12 13psi g 58 73 87 102 116 131 145 160 174 189CFP 1.60 1.33 1.14 1.00 0.89 0.80 0.73 0.67 0.62 0.57Dewpoint Correction Factor CFDPDP °C -40 -70Required DewpointPDP °F -40 -100CFD 1.00 1.43Dryer SelectionTo correctly select a dryer model, the flow rate of the dryer must be adjusted for the minimum operating pressure and, maximum operationaltemperature of the system. If the dewpoint required is different to the standard dewpoint of the dryer then the flow rate must also be adjustedfor the required outlet dewpoint.1. Obtain the minimum operating pressure, maximum inlet temperature and maximum compressed air flow rate at the inlet of the dryer.Obtain the outlet dewpoint required.2. Select correction factor for maximum inlet temperature from the CFT Table (always round up e.g. for 37°C use 40°C correction factor)3. Select correction factor for minimum inlet pressure from the CFP table (always round down e.g. for 5.3 bar use 5 bar correction factor)4. Select correction factor for required outlet dewpoint from the CFD table5. Calculate minimum drying capacityMinimum Drying Capacity = <strong>Compressed</strong> <strong>Air</strong> Flow x CFT x CFP x CFD6. Using the minimum drying capacity, select a dryer model from the flow rate tables above (dryer selected must have a flow rate equal to or greaterthan the minimum drying capacity)If the minimum drying capacity exceeds the maximum values of the models shown within the tables, please contact Parker domnick hunter foradvice regarding larger multi-banked dryers.

Technical DataDryerModelsMin Operating Max Operating Min Operating Max Operating Max AmbientNoiseElectrical ElectricalPressure Pressure Temp Temp TempThread Levelsupply supplyConnectionsbar g psi g bar g psi g °C °F °C °F °C °F(standard (optional)dB (A)DHS 4 58 10.5 154 2 35 50 122 55 131415V 3ph50Hz+NeutralN/ABSPPor NPT

PNEUDRI MIDIplusHeatless (PSA) RegenerationHigh Efficiency <strong>Compressed</strong> <strong>Air</strong> <strong>Dryers</strong><strong>Compressed</strong> air contamination problems can besimply avoided by installing a Parker domnickhunter PNEUDRI MIDIplus High Efficiency<strong>Compressed</strong> <strong>Air</strong> Dryer package fitted withOIL-X EVOLUTION filtration. The packages aresuitable for use with any compressor type and aresuited to point of use applications.<strong>Compressed</strong> air purification equipment mustdeliver uncompromising performance and reliabilitywhilst providing the right balance of air quality withthe lowest cost of operation. Many manufacturersoffer products for the filtration and purification ofcontaminated compressed air, which are oftenselected only upon their initial purchase cost, withlittle or no regard for the air quality they provide,the cost of operation throughout their life or indeedtheir environmental impact. When purchasingpurification equipment, delivered air quality, theoverall cost of ownership and the equipment’senvironmental impact must always be considered.The Parker domnick hunter Design PhilosophyParker domnick hunter has been supplying industry with high efficiency filtrationand purification products since 1963. Our philosophy ‘Designed for <strong>Air</strong> Quality &Energy Efficiency’ ensures products that not only provide the user with clean, highquality compressed air, but also with low lifetime costs and reduced CO 2 emissions.Contact Information:Parker Hannifin Ltddomnick hunter Industrial divisionDukesway, Team Valley Trading EstateGateshead, Tyne and WearEngland NE11 0PZTel: +44 (0)191 402 9000Fax: +44 (0)191 482 6296Email: dhindsales@parker.comwww.domnickhunter.comBenefits:• PNEUDRI dryers provide efficient removalof water vapour from compressed air• Delivered air quality is in accordance withISO 8573-1:2001, the international standardfor compressed air quality• Improves production efficiency and reducesmaintenance costs and downtime• Pressure Dewpoint’s of -70°C & -40°C(ISO 8573-1 :2001 Classes 1 & 2) are available• Unlike refrigeration dryers, the -40°C & -70°Cpressure dewpoint’s offered by PNEUDRI notonly eliminates corrosion, it also inhibits thegrowth of micro-organisms• Ideal for both compressor room and pointof use applications• Low noise level

Dryer PerformanceDryer ModelsDewpoint (Standard)Dewpoint (Option 1) ISO 8573-1:2001ISO 8573-1:2001ClassificationClassification (standard)ºC ºF ºC ºF(Option 1)DME -40 -40 Class 2 -70 -100 Class 1DMOP -40 -40 Class 2 -70 -100 Class 1Product SelectionStated flows are for operation at 7 bar g (100 psi g) with reference to 20°C, 1 bar a, 0% relative water vapour pressure.For flows at other pressures, apply the correction factors shown.Model PIPE SIZE L/S m 3 /min m 3 /hr cfmDME012 G 1 /2 11 0.68 41 24DME015 G 1 /2 15 0.91 55 32DME020 G 1 /2 20 1.19 71 42DME025 G 1 /2 25 1.50 90 53DME030 G 1 /2 31 1.84 110 65DME040 G 3 /4 42 2.49 149 88DME050 G 1 50 3.01 180 106DME060 G 1 61 3.69 221 130DME080 G 1 83 4.99 299 176Correction FactorTemperature Correction Factor CFTMaximumInletTemperature°C 25 30 35 40 45 50°F 77 86 95 104 113 122CFT 1.00 1.00 1.00 1.04 1.14 1.37Pressure Correction Factor CFPMinimumInlet Pressurebar g 4 5 6 7 8 9 10 11 12 13 14 15 16psi g 58 73 87 100 116 131 145 160 174 189 203 218 232CFP 1.60 1.33 1.14 1.00 0.89 0.80 0.73 0.67 0.62 0.57 0.54 0.5 0.47Dewpoint Correction Factor CFDRequiredDewpointPDP °C -40 -70PDP °F -40 -100CFD 1.00 1.43Dryer SelectionTo correctly select a dryer model, the flow rate of the dryer must be adjusted for the minimum operating pressure and, maximum operationaltemperature of the system. If the dewpoint required is different to the standard dewpoint of the dryer then the flow rate must also be adjusted for therequired outlet dewpoint.1. Obtain the minimum operating pressure, maximum inlet temperature and maximum compressed air flow rate at the inlet of the dryer.Obtain the outlet dewpoint required.2. Select correction factor for maximum inlet temperature from the CFT Table (always round up e.g. for 37°C use 40°C correction factor)3. Select correction factor for minimum inlet pressure from the CFP table (always round down e.g. for 5.3 bar use 5 bar correction factor)4. Select correction factor for required outlet dewpoint from the CFD table5. Calculate minimum drying capacityMinimum Drying Capacity = <strong>Compressed</strong> <strong>Air</strong> Flow x CFT x CFP x CFD6. Using the minimum drying capacity, select a dryer model from the flow rate tables above (dryer selected must have a flow rate equal to or greaterthan the minimum drying capacity)If the minimum drying capacity exceeds the maximum values of the models shown within the tables, please contact Parker domnick hunter foradvice regarding larger multi-banked dryers.

Technical DataDryerModelsMin OperatingPressureMax OperatingPressureMin OperatingTemperatureMax OperatingTemperatureMax AmbientTemperatureElectricalSupply(Standard)ElectricalThreadSupplyConnection(Optional)bar g psi g bar g psi g °C °F °C °F °C °F dB(A)NoiseLevelDME012 -DME0404 58 16 232 2 35 50 122 55 131230V 1ph50/60Hz110V 1ph50/60HzBSPP orNPT

PNEUDRI MiDASA totally clean and dry<strong>Compressed</strong> <strong>Air</strong> System (CDA)The Parker domnick hunter PNEUDRI MiDASrange of desiccant air dryers, offers the useruncompromised performance from a dedicated“point of use” Clean Dry <strong>Air</strong> system. It is easy toinstall and will transform an ordinary process intoa highly reliable and efficient production operation.<strong>Compressed</strong> air purification equipment mustdeliver uncompromising performance and reliabilitywhilst providing the right balance of air quality withthe lowest cost of operation. Many manufacturersoffer products for the filtration and purification ofcontaminated compressed air, which are oftenselected only upon their initial purchase cost, withlittle or no regard for the air quality they provide,the cost of operation throughout their life or indeedtheir environmental impact. When purchasingpurification equipment, delivered air quality, theoverall cost of ownership and the equipment’senvironmental impact must always be considered.The Parker domnick hunter Design PhilosophyParker domnick hunter has been supplying industry with high efficiency filtrationand purification products since 1963. Our philosophy ‘Designed for <strong>Air</strong> Quality &Energy Efficiency’ ensures products that not only provide the user with clean, highquality compressed air, but also with low lifetime costs and reduced CO 2 emissions.Contact Information:Parker Hannifin Ltddomnick hunter Industrial divisionDukesway, Team Valley Trading EstateGateshead, Tyne and WearEngland NE11 0PZTel: +44 (0)191 402 9000Fax: +44 (0)191 482 6296Email: dhindsales@parker.comwww.domnickhunter.comBenefits:• PNEUDRI dryers provide efficient removalof water vapour from compressed air• Delivered air quality is in accordance withISO 8573-1:2001, the international standardfor compressed air quality• Improves production efficiency and reducesmaintenance costs and downtime• Pressure Dewpoint’s of -70°C & -40°C(ISO 8573-1 :2001 Classes 1 & 2) are available• Unlike refrigeration dryers, the -40°C & -70°Cpressure dewpoint’s offered by PNEUDRI notonly eliminates corrosion, it also inhibits thegrowth of micro-organisms• Ideal for both compressor room and pointof use applications• Low noise level

Dryer PerformanceDryer ModelsDewpoint (Standard)Dewpoint (Option 1) ISO 8573-1:2001ISO 8573-1:2001ClassificationClassification (standard)ºC ºF ºC ºF(Option 1)DAS -40 -40 Class 2 -70 -100 Class 1Product SelectionStated flows are for operation at 7 bar g (100 psi g) with reference to 20°C, 1 bar a, 0% relative water vapour pressure.For flows at other pressures, apply the correction factors shown.Model Pipe Size L/S m 3 /min m 3 /hr cfmDAS1 G 3 /8 1 0.09 5.1 3DAS2 G 3 /8 2 0.14 8.5 5DAS3 G 3 /8 4 0.23 13.6 8DAS4 G 3 /8 5 0.28 17.0 10DAS5 G 3 /8 6 0.37 22.1 13DAS6 G 3 /8 7 0.43 25.5 15DAS7 G 3 /8 9 0.57 34.0 20Correction FactorTemperature Correction Factor CFTMaximumInletTemperature°C 25 30 35 40 45 50°F 77 86 95 104 113 122CFT 1.00 1.00 1.00 1.04 1.14 1.37Pressure Correction Factor CFPMinimum InletPressurebar g 4 5 6 7 8 9 10 11 12psi g 58 73 87 102 116 131 145 160 174CFP 1.60 1.33 1.14 1.00 1.03 0.93 0.85 0.78 0.71Dewpoint Correction Factor CFDRequiredDewpointPDP °C -40 -70PDP °F -40 -100CFD 1.00 1.43Dryer SelectionTo correctly select a dryer model, the flow rate of the dryer must be adjusted for the minimum operating pressure and, maximum operationaltemperature of the system. If the dewpoint required is different to the standard dewpoint of the dryer then the flow rate must also be adjusted for therequired outlet dewpoint.1. Obtain the minimum operating pressure, maximum inlet temperature and maximum compressed air flow rate at the inlet of the dryer.Obtain the outlet dewpoint required.2. Select correction factor for maximum inlet temperature from the CFT Table (always round up e.g. for 37°C use 40°C correction factor)3. Select correction factor for minimum inlet pressure from the CFP table (always round down e.g. for 5.3 bar use 5 bar correction factor)4. Select correction factor for required outlet dewpoint from the CFD table5. Calculate minimum drying capacityMinimum Drying Capacity = <strong>Compressed</strong> <strong>Air</strong> Flow x CFT x CFP x CFD6. Using the minimum drying capacity, select a dryer model from the flow rate tables above (dryer selected must have a flow rate equal to or greaterthan the minimum drying capacity)If the minimum drying capacity exceeds the maximum values of the models shown within the tables, please contact Parker domnick hunter foradvice regarding larger multi-banked dryers.

Technical DataDryerModelsMin OperatingPressureMax OperatingPressureMin OperatingTemperatureMax OperatingTemperatureMax AmbientTemperaturebar g psi g bar g psi g °C °F °C °F °C °FDAS 4 58 12 175 2 35 50 122 55 131DryerModelsElectrical Supply(Standard)Tolerance ± 10%Electrical Supply(Optional)Tolerance ± 10%ThreadConnectionNoise Level(average)dB(A)ElectronicControllerOptionsDPower OnIndicationFunctionServiceIntervalIndicationDAS 230 / 1ph / 50Hz 115 / 1ph / 60Hz BSPP or NPT