WePack 02/2009 - Wipak

WePack 02/2009 - Wipak

WePack 02/2009 - Wipak

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

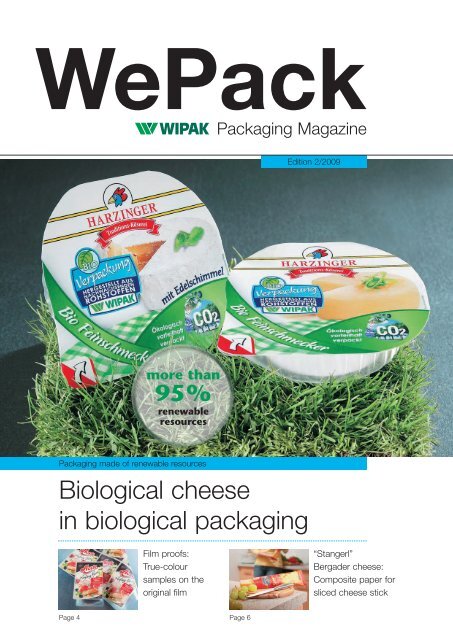

<strong>WePack</strong>Packaging MagazineEdition 2/<strong>2009</strong>more than95%renewableresourcesPackaging made of renewable resourcesBiological cheesein biological packagingFilm proofs:True-coloursamples on theoriginal film“Stangerl”Bergader cheese:Composite paper forsliced cheese stickPage 4Page 6

<strong>Wipak</strong> Group<strong>Wipak</strong> ShanghaiOpening doors with new servicesNew status – more opportunities. Since August thisyear, <strong>Wipak</strong> in China operates under the name <strong>Wipak</strong>Shanghai Trading Company (WSTC.) This formalchange in trade law reflects the fact that the formersales office has now been turned into an independenttrading company. “The new status clearly enhancesour position as we now have more opportunities tosell <strong>Wipak</strong> products and offer improved service to ourcustomers“, explains Jaff Sun, <strong>Wipak</strong> Country Manager,who continues to be supported by Terry Zhang asSales Manager and Helena Wang for Customer Service.Heikki Weijo, Director of <strong>Wipak</strong> Medical, has beenappointed as General Manager of the new company.<strong>Wipak</strong>’s activities in China startedin the mid 1980s, initially using localsales partners and then via the <strong>Wipak</strong>sales office in Shanghai since 1998.For the marketing and developmentof sterile packaging products toChinese hospitals, <strong>Wipak</strong> has beenco-operating with a Hongkongbasedimport company since 1997.The long-time business developmentindeed has paid off as <strong>Wipak</strong> is nowone of the established providers ofhigh-quality packaging solutionsfor food and medical applicationsas well as for hospital sterile supplies.“However the market has seen drasticchanges. Demand for state-of-theartpackaging materials continues toincrease rapidly, just as the requirementsand expectations in termsof service“, says Sun. “Although wealready have excellent contacts tomanufacturers of packaging machinesas well as to key customers inthe food and medical industry, ourprevious structure did not allow usto flexibly react to market changes.“New status – more opportunities:the <strong>Wipak</strong> Shanghai team (left to right):Terry Zhang, Helena Wang and Jaff Sun,Sales Office ManagerWSTC now allows <strong>Wipak</strong> to keeppace with the speed of developmentof the Chinese market. “We willnow be able to react faster andmore flexibly to the demand ofour customers and to offer our fullrange of products and services”,Sun emphasizes. On top of sales andsupport, supplying from local stockwith invoicing in local currency andproduction co-operation projectsare now possible under the businesslicense of WSTC.ISO 22000for <strong>Wipak</strong> Gryspeert<strong>Wipak</strong> Gryspeert complies withthe international hygiene andoccupational safety standards.In June this year the French<strong>Wipak</strong> unit has validated its longlasting involvement for food &consumer safety with the internationalstandard ISO 22000.2 – <strong>WePack</strong>

<strong>Wipak</strong> Group < < >> Congratulations to <strong>Wipak</strong> Hungary!More than 120 customers, suppliersand employees had come to congratulatein May for the 20th anniversaryof the sales office whichstarted operation in Budapest inspring 1989. Jaakko Knuutila (left),General Manager of the <strong>Wipak</strong>Group, recalled an eventful periodmarked by social, political andeconomical changes and also thebusiness opportunities resultingfrom the opening of markets.Knuutila emphasized that this earlyengagement had paid off. Today<strong>Wipak</strong>, represented by a team offour, is one of the leading providersof sterile supplies for medical applicationsand high-quality vacuumand MAP packaging for the foodindustry.Research & DevelopmentAnniversary<strong>Wipak</strong> Nastola for 40 years>>> Congratulations to <strong>Wipak</strong> Nastola!The roots of the <strong>Wipak</strong> group canbe found about 100 km north ofHelsinki. The success story of theinternational <strong>Wipak</strong> group started40 years ago when the productionsite was moved from Tapiola(Helsinki) to Nastola. The newproduction plant with a facilityof about 4200 square meters wasinaugurated on 13th December1969. Today, more than 450 peopleare employed in development,marketing, sales, customer serviceand production. Business is focusedon multi-layer barrier films for foodand medical applications. Nastolais the key site for medical packaging;under clean room conditions producingbags which meet all internationalstandards.Annual meetingin TampereMajor issues of the <strong>Wipak</strong> R&D meeting heldat Tampere, Finland, were new products, a closercooperation between the <strong>Wipak</strong> sites as well asthe upgrading of services. About 50 developmentand sales specialists from all <strong>Wipak</strong> sites cametogether in summer for their annual exchangeof ideas. An important result is the enhancedcooperation between development, productionand sales of the food and medical fields. Thiswill allow <strong>Wipak</strong> customers to benefit from newdevelopments, from the technology and theexpertise of both fields. Example: products suchas the robust composite films SC and NICE,which are already successfully used for foodapplications, are also suitable for the demandingpackaging of medical instruments and devices.Nastola: Productionin clean room conditionsAwards<strong>Wipak</strong> Nastola was among the candidatesfor the renowned FlexoTechInternational Print & InnovationsAward <strong>2009</strong> which the British publisherWhitmar Publications uses eachyear to recognize excellent work inthe field of package printing. In thecategories “laminated substrates“and “flexible packaging over 50 cm(line &screen)“, two <strong>Wipak</strong> Nastolaproducts were among the favourites.Although the final decision was notin favour of <strong>Wipak</strong>, Tero Ollikainen,who represented <strong>Wipak</strong> at the prizeaward in London in midOctober, was farfrom being disappointed:“Just thefact of our nominationalone is aconfirmation forour work.“<strong>Wipak</strong> U.K. has received the DuPont New HorizonsAward <strong>2009</strong>. Since 2007, the US-based companyawards prizes for excellence in flexo and packagingprinting. The prize recognizes the work, creativity andcontributions of individuals and organizations for theircommitment to develop and advance flexo printing.<strong>WePack</strong> – 3

<strong>Wipak</strong> Group> > >Exhibition highlightsKenji Yamajo,Sales Manager <strong>Wipak</strong> JapanJapan Pack<strong>Wipak</strong> for the first time participated in theJapan Pack in Tokyo. Sales Manager KenjiYamajo draw a positive conclusion after noticingafter the four days exhibition a lot of interestfor medical and food packaging applications –with a special focus on flexible, thermoformingfilms for boiled ham packages. The participationin this event emphasizes the long-term activitieson the Japanese market. <strong>Wipak</strong> has opened thesales office in Yokohama in March 2008.> > >Fairs, Exhibitions, CongressesCome and talk to us at one of the following events:<strong>2009</strong>ZDRAVOOKHRANENIE, Moscow _ _ _ _ _ _ _ _ _ _ _ 07. – 11.12.<strong>2009</strong>What you see is what you get:<strong>Wipak</strong>’s new proofing system reducesthe pre-press and creates true-colourproofs on the original film2010ARAB HEALTH, Dubai _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25. – 28.01.2010MEDTEC Europe, Stuttgart _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23. – 25.03.2010True-colourgetting to the<strong>Wipak</strong> Czech Republic“Tour de <strong>Wipak</strong>” fully successfulHop on the bike and go crosscountry.<strong>Wipak</strong> used this athleticevent last summer to thank theircustomers in the Czech Republicand Slovakia for the good cooperation.However the tour was farfrom being a comfortable sightseeingtrip with extensive discussions.It took some technical skills andendurance to finish the 32km trackleading through the hills and woodsbetween Prague and Brno – worthto mention that the fastest bikerstook about 1 hour and 45 minutes.A total of 40 participants acceptedthe challenge – in the end to berewarded with an impressive eveningbarbecue. A repetition of the“Tour de <strong>Wipak</strong> Czech Republic”has already been scheduled fornext year.Layout, artwork, proof on theoriginal film – the final print imagewill in the future be available faster,more reliably and more efficiently.<strong>Wipak</strong> has invested in a systemwhich creates true-colour proofs.As a leading European film provider,<strong>Wipak</strong> sets new standards in filmprinting. What is really special isthe fact that layouts are printedon the original film; the result isan almost 100% simulation of theprint image.At first sight there is no visibledifference. The printed film layouton the right, the final packageon the left – it takes real experts torecognize the minor differences.These differences are so small thatthey are negligible for judgingand approving the print image.The result is positive, the decisionis quickly taken, the film can beprinted.<strong>WePack</strong> – 4

Service < <

ServiceBergader Almkäse “Stangerl“Sophisticatedpackaging conceptA compact cheese stick in the dairy section? For the productdevelopers of the private German cheese dairy Bergader, the ideawas both obvious and innovative. Time not only seemed to beripe, it actually was – as proven by the success of the “Stangerl“(Bavarian slang for “stick”). The cheese snack has been successfullylaunched in German, Austrian and Swiss retail chains in summer.During an interview with <strong>WePack</strong>, Susanne Bagaméry, BergaderProduct Manager, tells the story.What were the requirements for the packagingof the Bergader “Stangerl“ cheese stick?Bagaméry: The Bergader Almkäse brand stands fora natural product, top-quality locally sourced materialsand artisan manufacturing. This said it was importantthat the new package corresponds with the brandimage and elicits consumer associations. The technicalspecifications and requirements only have emergedin the course of the project, in cooperation with <strong>Wipak</strong>.What is the part of the packaging at the PoS?Bagaméry: In addition to the product placement in theshelves, the packaging is of vital importance. The keyfeature of the “Stangerl“ is the colour. The distinct redhas a signaling effect. It is also a new colour code inthe sliced cheese product category, making sure that theproduct catches the eye and stands out from the rest.The print image quality and the brilliant colours areof paramount importance for Bergader. These criteriawere therefore essential for package development.What was the biggest challenge duringthe development stage?Bagaméry: After some initial trials with matt films,we came to the conclusion that the required resultcould only be achieved using paper. Paper is simplydistinctive, it gives a good touch and the consumergets the impression of buying something natural. Ofcourse we had to learn that papers are not identical,but that there are major differences. The main challengetherefore was to find a type of paper which wouldmeet our requirements in terms of haptics, optic orfunctionality. How stiff must or may the paper be?Does the print image show to full advantage? Howdoes the paper behave in combination with the filmand when being machine-processed? To find out allthese answers, we have laminated different types ofpaper with the film and printed it, in numerous trials,not just at <strong>Wipak</strong>, but also at our packaging systemto simulate the real production environment.What are the key criteriafor you in terms of yourcooperation with <strong>Wipak</strong>?Bagaméry: For the “Stangerl“project, we did not give any precisespecifications. Package developmenttherefore was a very productiveand constructive learning processfor both parties. It is also worthmentioning that we had only a fewmonths from the product idea tothe market launch. It was thereforeextremely important for us to havea competent partner to rely on atall stages, being able to developsolutions, to show alternatives andto know the special features of ourproducts. This extensive expertise,and in particular the personal andflexible support, including sales,technical issues or printing, wasextremely helpful to us.Stangerl – the packaging conceptThe cheese snack is enwrappedusing a multi-layer paper composite.Developed by <strong>Wipak</strong>, the packageoffers paper surface feel on one sideand product protection on the otherside. Since in contrast to soft cheese,this cheese matures in the packageonly slightly, generating low amountsof gas, the PE functional layer isequipped with a medium-permeablebarrier (defined barrier layer). Therigidity of the paper and the peelablesealing layer in the back seamarea allow for a reliable mechanicalreclosing: the package can be openedat the back seam. To make sure thecheese remains fresh and does notdry out, the plaits can be folded toclose the package.<strong>WePack</strong> – 6

Service < <

SustainabilityPoint of viewTo protect packagedfood products andto ensure a shelf lifeexactly adapted toeach food product –that is what we callsustainability.Dr. Annett Kaeding-KoppersUsing high-qualityHead of Research & Development composite and barrierfilms we want to helpto prevent food fromdegrading, to protect resources andto reduce the amount of waste.<strong>Wipak</strong> and sustainabilityThis is our mission that we areworking on by optimizing ourfilms, by reducing the total amountof packaging material and byimproving the carbon footprintof your products. The commitmentto protect our environment is acentral part of our guidelines. Wedevelop packaging films which canbe based on reusable or renewablepolymers, which allow for combinationsof different properties andwhich meet high ecological andeconomical requirements. And weeven raise the bar a little higher: ourgoal is to work out CO 2 optimizedoverall concepts in cooperation withyou. These concepts are focusingon issues such as waste reduction,optimization of packaging processesor packaging and logistics.RepakInnovative film structureReclosable packages considerablyhelp to extend the shelf life offood products –thus protectingprecious resources. The Repakreclosable system for example issubject to continuous development.Thanks to an optimizationof the film structure, <strong>Wipak</strong> wasable to reduce the grammageof the lidding film from initially103 g/sqm to currently 85 g/sqm.The result is improved propertieswith equal thickness while thecarbon footprint of the package isreduced due to the lower weight.<strong>WePack</strong> – 8

FoodVeliscoLifeCare Food Awardfor snack bagNew peelable PP filmsPerfect cooking inthe packagingBaked potatoes, hamburgers, pre-fried steaks orpre-cooked soups – for the fast growing ready-mademeals market, <strong>Wipak</strong> has added sterilizable liddingand bottom films to the product range. The flexiblenew composite films with polypropylene sealing layersmake it even easier for consumers to prepare readymademeals. They can e.g. be heated in the microwavewithout having to remove the packaging so that foodproducts do not dry out – steaks e.g. remain tenderlyjuicy and red.Specially designed for this segment, these film typesare suitable for sterilization using temperatures upto 121°C. Special peeling functions make sure thatthe package has a defined opening and that the insidepressure generated when heating up can escape. Apositive side effect is the fact that the package opensexactly at the moment when the hamburgers or theindividually packed baked potatoes have reachedthe right eating temperature.The defined opening has some benefits for theconsumers, too. They do not require any additionalapplication, nor complex valve solutions or perforationsusing laser engraving. Due to the high punctureresistance and durability of the peelable PP films,even demanding cooking applications such as roastpork or sliced poultry with bones can be safelypackaged.Velisco Geflügel GmbH & Co. KG,headquartered in Rot am See,Germany, has received the LifeCareFood Award <strong>2009</strong> for their snackbags labeled Landbrink. Packagedin practical snack bags, the turkeynuggets, -hamburgers and Cevapciciproducts have fully convinced bothspecialists and consumers duringa test.An additional reason for grantingthe award was the ease of preparationin a microwave oven. This is largelydue to the peelable PP films speciallydeveloped by <strong>Wipak</strong> for microwaveand cooking applications."We have developed an excellentsolution in cooperation with <strong>Wipak</strong>“,explains Manja Behrens, Head ofMarketing at Velisco. “The productremains fresh and, thanks to thesuperb film, does not dry out. Wehave managed to create a true innovation“.At an internal ceremony,Behrens emphasized that she waspleased about the long-term, excellentcooperation.LifeCare is an independent initiativewhich tries to noticeably increase thequality of life of all individuals in asustainable way. LifeCare annuallyawards a prize for food productswhich are a major help for a wellbalancednutrition.New package design for giant barbecue sausageIn Denmark , Moppe Drenge was the biggest seller of the past barbecueseason. In cooperation with the Carlsberg brewery, the Danish meat producerTulip had launched a giant barbecue sausage. A goliath among sausages,marketed by Tulip under the premium brand “Göl“, stood out not just for itsmere size (180 gram). The new package design was an additional advantageof the new Tulip product. The combination of glossy and matt surfaces,specially designed and implemented by <strong>Wipak</strong> for Moppe Drenge, ideallysupported the market launch and highlighted the special position of thegiant barbecue sausage for the entire promotion campaign.<strong>WePack</strong> – 10

Medical < <

ServiceSales officesAUSTRIA<strong>Wipak</strong> AustriaTel. +43 664 120 3330info.austria@wipak.comCZECH REPUBLIC<strong>Wipak</strong> PrahaTel. +420 22 05 61 644info.czech@wipak.comHUNGARY<strong>Wipak</strong> BudapestTel. +36 12 18 51 52info.hungary@wipak.comITALY<strong>Wipak</strong> Italia S.r.L.Tel. +39 <strong>02</strong> 93 92 23 92info@wipak.itNORWAY<strong>Wipak</strong> OsloTel. +47 22 90 13 10info.norway@wipak.comPOLAND<strong>Wipak</strong> Polska Sp. z o.o.Tel. +48 22 65 81 705info.poland@wipak.comPORTUGALHafri Ltda.Tel. +351 21 469 1728hafrilda@sapo.ptPR CHINA<strong>Wipak</strong> ShanghaiTel. +86 21 52 34 06 75info.china@wipak.comRUSSIA<strong>Wipak</strong> OOO, MoscowTel. +7 49 99 40 <strong>02</strong> 54info.russia@wipak.comRUSSIA<strong>Wipak</strong> OOO, St. PetersburgTel. +7 81 23 36 97 49info.russia@wipak.comSWEDEN<strong>Wipak</strong> ABTel. +46 40 19 16 00info.sweden@wipak.comSWITZERLAND<strong>Wipak</strong> ZürichTel. +41 44 39 21 214info.switzerland@wipak.comManufacturing unitsFINLAND<strong>Wipak</strong> OyP.O. Box 4515561 NastolaTel. +358 20 510 311info.fi.wn@wipak.comFINLAND<strong>Wipak</strong> Avans OyTeollisuustie 4 B27510 EuraTel. +358 20 510 311info.fi.wa@wipak.comFRANCE<strong>Wipak</strong> Gryspeert S.A.S.Zone des Bois, BP 20006 Bousbecque59558 Comines CédexTel. +33 320 115 656info.france@wipak.comGERMANY<strong>Wipak</strong> Kempten GmbHWestendstrasse 787488 BetzigauTel. +49 831 57 1440info.germany@wipak.comPOLAND<strong>Wipak</strong> Polska Sp. z o.o.Ul. Sikorskiego 2049-340 Lewin BrzeskiTel. +48 77 404 200biuro@maan.opole.plUNITED KINGDOM<strong>Wipak</strong> UK Ltd.Buttington Business ParkWelshpool, Powys, SY21 8SLTel. +44 1938 555 255info.uk@wipak.com<strong>WePack</strong>FINLANDBiaxis OyTeknikonkatu 215520 LahtiTel. +358 20 510 312info@biaxis.comFINLAND<strong>Wipak</strong> Valkeakoski OyKaivolankatu 537630 ValkeakoskiTel. +358 20 510 311info.fi.wv@wipak.comGERMANY<strong>Wipak</strong> Walsrode GmbH & Co. KGPostfach 166129656 WalsrodeTel. +49 5161 44 3903info.germany@wipak.comNETHERLANDS<strong>Wipak</strong> B.V.Nieuwstadterweg 176136 KN SittardTel. +31 46 420 2999info.benelux@wipak.comSPAIN<strong>Wipak</strong> Iberica S.L.P. I La Creuta, Apdo. Correos 17408130 Santa Perpetua de Mogoda(Barcelona)Tel. +34 935 742 094info.spain@wipak.comwww.wipak.cominfo@wipak.com<strong>WePack</strong> – 12Editor-in-chief:Astrid Reinke, <strong>Wipak</strong>Editors:Astrid Reinke, <strong>Wipak</strong>astrid.reinke@wipak.comLayout:Buchholz Grafik-DesignText:Ulrich Kommunikation,Holger UlrichTranslator:Jürgen ZiegenbeinImages:Thomas Weidner, <strong>Wipak</strong>, FotoliaPrinted by:Druckpunkt Coels