IKO Polimar MC TDS

IKO Polimar MC TDS

IKO Polimar MC TDS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

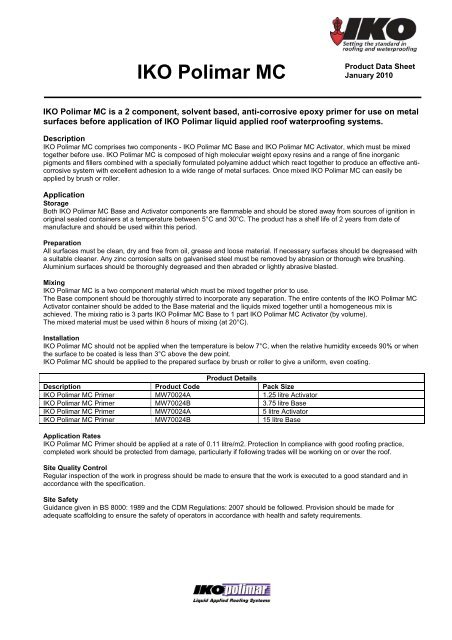

<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong>Product Data SheetJanuary 2010<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> is a 2 component, solvent based, anti-corrosive epoxy primer for use on metalsurfaces before application of <strong>IKO</strong> <strong>Polimar</strong> liquid applied roof waterproofing systems.Description<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> comprises two components - <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Base and <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Activator, which must be mixedtogether before use. <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> is composed of high molecular weight epoxy resins and a range of fine inorganicpigments and fillers combined with a specially formulated polyamine adduct which react together to produce an effective anticorrosivesystem with excellent adhesion to a wide range of metal surfaces. Once mixed <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> can easily beapplied by brush or roller.ApplicationStorageBoth <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Base and Activator components are flammable and should be stored away from sources of ignition inoriginal sealed containers at a temperature between 5°C and 30°C. The product has a shelf life of 2 years from date ofmanufacture and should be used within this period.PreparationAll surfaces must be clean, dry and free from oil, grease and loose material. If necessary surfaces should be degreased witha suitable cleaner. Any zinc corrosion salts on galvanised steel must be removed by abrasion or thorough wire brushing.Aluminium surfaces should be thoroughly degreased and then abraded or lightly abrasive blasted.Mixing<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> is a two component material which must be mixed together prior to use.The Base component should be thoroughly stirred to incorporate any separation. The entire contents of the <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong>Activator container should be added to the Base material and the liquids mixed together until a homogeneous mix isachieved. The mixing ratio is 3 parts <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Base to 1 part <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Activator (by volume).The mixed material must be used within 8 hours of mixing (at 20°C).Installation<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> should not be applied when the temperature is below 7°C, when the relative humidity exceeds 90% or whenthe surface to be coated is less than 3°C above the dew point.<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> should be applied to the prepared surface by brush or roller to give a uniform, even coating.Product DetailsDescription Product Code Pack Size<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Primer MW70024A 1.25 litre Activator<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Primer MW70024B 3.75 litre Base<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Primer MW70024A 5 litre Activator<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Primer MW70024B 15 litre BaseApplication Rates<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Primer should be applied at a rate of 0.11 litre/m2. Protection In compliance with good roofing practice,completed work should be protected from damage, particularly if following trades will be working on or over the roof.Site Quality ControlRegular inspection of the work in progress should be made to ensure that the work is executed to a good standard and inaccordance with the specification.Site SafetyGuidance given in BS 8000: 1989 and the CDM Regulations: 2007 should be followed. Provision should be made foradequate scaffolding to ensure the safety of operators in accordance with health and safety requirements.

Maintenance<strong>IKO</strong> PLC recommend that <strong>IKO</strong> <strong>Polimar</strong> liquid applied roofing systems are inspected and maintained in accordance with theguidelines given in BS 8217. The repair of damage to <strong>IKO</strong> <strong>Polimar</strong> liquid applied roofing systems is by applying a furthercoating of the original product to the damaged area.Uses<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> Primer is designed for use as an all purpose primer for metal surfaces, prior to the application of <strong>IKO</strong><strong>Polimar</strong> liquid applied roof waterproofing systems.Physical PropertiesCharacteristic Method Units ValueDrying and Cure timesat 20 ºC- HoursHoursHoursHoursMonthsDaysUsable lifeTouch dryHard dryMinimum overcoatingMaximum overcoatingFull cureVolume Solids - % 45VOC - g/litre 526Direct Pull Adhesion ASTM D4541 Kg/cm² Steel 38Dry Heat Resistance ASTM D2485 ºC 100Impact Resistance BS 3900 Part E3 Mm DirectReverseScratch Resistance BS 3900 Part E2 No failure at 2.5 kg loadManufacture<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> is produced under a closely controlled system which conforms to the requirements of ISO 9001. Eachcontainer clearly identifies the product name, product code, product amount and the supplier's name and address.Safety Information<strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong> is a hazardous product. Wear suitable protective gloves and ensure adequate ventilation is provided duringuse. Refer to the Safety Data Sheet for <strong>IKO</strong> <strong>Polimar</strong> <strong>MC</strong>.OrderingWhen ordering, reference should be made to the product code in order to avoid mistakes. Product codes can be found underthe section ‘Product Details’ of this data sheet.8416163752.5<strong>IKO</strong> PLCLiterature EnquiriesTel: 0844 412 8554E-Mail: marketing@ikogroup.co.uk Website: www.ikogroup.co.ukSales SupportAppley Lane North, Appley Bridge, Wigan, Lancashire WN6 9ABTel: 0844 873 1062 Fax: 0844 873 1067 E-Mail: sales@ikogroup.co.ukTechnical & Design ServicesAppley Lane North, Appley Bridge, Wigan, Lancashire WN6 9ABTel: 0844 412 7207 Fax: 0844 412 7208 E-Mail: technical@ikogroup.co.ukWhilst every care is taken to see that the information given in this literature is correct and up to date it is not intended to form part of anycontract or give rise to any collateral liability, which is hereby specifically excluded. Intending purchasers of our materials should thereforeverify with the company whether any changes in our specification or application details or otherwise have taken place since this literaturewas issued.Company Registered in England No. 2678296 – Registered Office: Appley Lane North, Appley Bridge, Wigan, Lancashire, WN6 9AB