You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

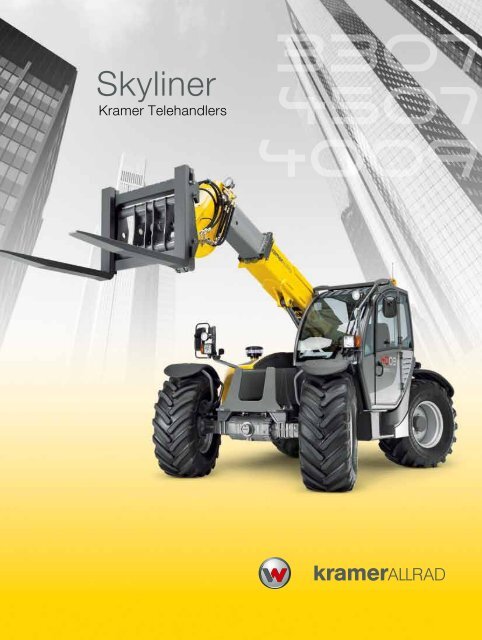

<strong>Skyliner</strong><strong>Kramer</strong> Telehandlers

Kletterkünstler.Gerade beim schwierigenEinsatz ist er ganzin seinem Element.330745074009<strong>Kramer</strong> Wendigkeit:• Lenkeinschlag von 2 x 45°.• Höchste Geländegängigkeit.• Große Bodenfreiheit.• Intelligente Pendelachsemit extragroßem Pendelwinkel.Kein Radius ist ihm zu eng:<strong>Kramer</strong> Teleskopen sind Rangierwunder.Intelligente <strong>Allrad</strong>technik bringt den Vorsprung auf den Punkt:Zentimetergenau. Und höchst komfortabel.- Weil die robusten Planeten-Lenkachsen zu jeder Zeit eineeffiziente Kraftübertragung zwischen Maschine und Geländeschaffen.- Weil wartungsarme und in Öl laufende Lamellenbremsenabsolute Sicherheit beim Fahren und Rangieren garantieren.- Weil die enorme Wendigkeit ein Wenden in einem Zug erlaubtund damit hilft, die Produktivität zu steigern.- Weil ein Lenkeinschlag von 2 x 45° für wirtschaftliches,schnelles und flexibles Arbeiten sorgt.- Weil Zeitersparnis bares Geld bedeutet.- Weil die Geländegängigkeit den Einsatzbereicherweitert.- Weil große Bodenfreiheit und die intelligentePendelachse mit extragroßem Pendelwinkel neueArbeitsspiele erschließt.16_17 KRAMER WENDIGKEIT

Swiss knife on wheels.Never say never with optionsmade for tackling tough jobs,day in, day out with ease.330745074009<strong>Kramer</strong> options:• Increased hydrauliccapacity.• Ecospeed high-speeddrive.• Front and rear attachments.• Oscillating axle interlockand frame levelling.Customise your telehandler to meet your needs.- With a wide range of options to extend the rangeof your machine.- With attachments that make sense from the start.- With <strong>Kramer</strong> <strong>Allrad</strong>’s all-inclusive approach.- With versatility making money. Guaranteed.3 steering modes for even moreversatility:1 All-wheel steeringFull power in minimum space.2 Crab steeringMobility whatever the situation.3 Front-wheel steeringThe convenience of conventionalsteering.1 2 318_19 KRAMER OPTIONS

High-Tech focus:State-of-the-art manufacturing.<strong>Kramer</strong>-inspired quality.A success story.ALL KRAMER LOADERS COME OFF THE PRODUCTION LINE OF A LEADINGCOMPACT MACHINERY MANUFACTURER BASED IN THE HEART OF EURO-PE. THEY BEAR THE HALLMARK OF QUALITY, STABILITY AND CONSISTEN-CY THAT YOU CAN RELY ON: TYPICALLY “MADE IN GERMANY”. EVERYMODEL IS BUILT TO LAST AND IS A MODULAR ELEMENT OF AN OVERALLSYSTEM.ONE PART FITS INTO ANOTHER, AND EVERYTHING IS FUTURE-PROOFED, FOR LONG-TERM COST-EFFECTIVENESS.MÜNCHENPfullendorfMINILADERMax. engine outputBucket capacityMax. payloadWeightTurning radius (Tyres)Max. speedMax. load-over height250 Canopy 16 kW / 22 PS 0,25 – 0,45 m 3 850 kg 1590 kg 1950 mm 0 – 20 km/h 2680 mm350 Canopy 27 kW / 37 PS 0,35 – 0,55 m 3 970 kg 1670 kg 1950 mm 0 – 20 km/h 2680 mm350 CAB 27 kW / 37 PS 0,35 – 0,55 m 3 970 kg 1720 kg 1950 mm 0 – 20 km/h 2680 mm180 23 kW / 31 PS 0,3 – 0,4 m 3 950 kg 1860 kg 1940 mm 0 – 20 km/h 2458 mm280 28 kW / 40 PS 0,65 – 1,1 m 3 1900 kg 3300 kg 2430 mm 0 – 20 km/h 2820 mmRADLADER750 45 kW / 61 PS 0,75 – 1,15 m 3 2300 kg 4200 kg 2550 mm 0 – 30 km/h 2915 mm850 45 kW / 61 PS 0,85 – 1,3 m 3 2350 kg 4500 kg 2550 mm 0 – 30 km/h 3100 mm950 58 kW / 79 PS 0,95 – 1,6 m 3 2500 kg 4700 kg 2780 mm 0 – 30 km/h 3120 mm1150 58 kW / 79 PS 1,15 – 1,8 m 3 3500 kg 5900 kg 2850 mm 0 – 30 km/h 3235 mm380 45 kW / 61 PS 0,75 – 1,15 m 3 2400 kg 4300 kg 2900 mm 0 – 40 km/h 2915 mm480 45 kW / 61 PS 0,85 – 1,3 m 3 2600 kg 4750 kg 2900 mm 0 – 40 km/h 3100 mm580 58 kW / 79 PS 0,95 – 1,5 m 3 2750 kg 4900 kg 2900 mm 0 – 40 km/h 3050 mm680 58 kW / 79 PS 1,05 – 1,6 m 3 3100 kg 5650 kg 2950 mm 0 – 40 km/h 3050 mm780 58 kW / 79 PS 1,15 – 1,8 m 3 3500 kg 6100 kg 2950 mm 0 – 35 km/h 3200 mm880 88 kW / 120 PS 1,5 – 2,5 m 3 4500 kg 8400 kg 3450 mm 0 – 35 km/h 3530 mmTELERADLADER750T 45 kW / 61 PS 0,75 – 1,15 m 3 2000 kg 5100 kg 2550 mm 0 – 30 km/h 4510 mm680T 58 kW / 79 PS 0,95 – 1,5 m 3 2600 kg 5950 kg 2950 mm 0 – 40 km/h 4450 mmKOMPAKTTELESKOPEN1245 23 kW / 31 PS 0,4 – 1,03 m³ 1200 kg 2530 kg 2607 mm 0 – 20 km/h 4130 mm2506 50 kW / 68 PS 0,85 – 1,8 m 3 2500 kg 4300 kg 3500 mm 0 – 30 km/h 5730 mmTELESKOPEN3307 88 kW / 120 PS 1,2 – 2,5 m 3 3300 kg 7200 kg 3600 mm 0 – 40 km/h 7050 mm4507 88 kW / 120 PS 1,2 – 3,0 m 3 4400 kg 8100 kg 3600 mm 0 – 40 km/h 7050 mm4009 88 kW / 120 PS 1,2 – 3,0 m 3 4000 kg 8600 kg 3850 mm 0 – 40 km/h 8825 mmFind a dealer at: www.kramer.de/Haendler

Innovationborn of tradition:Robust program.State-of-the-artmanufacturing.Competent partners.1925 Founding of the company as a manufacturer of motor mowers.1963 <strong>Kramer</strong> is the first manufacturer to present a hydraulic quick-hitchmechanism.1965 The innovative load stabiliser for the boom arm is developed by <strong>Kramer</strong>engineers.1987 The first all-wheel-steering wheel loader is launched on the market.The steering system continues to be found in all <strong>Kramer</strong> vehicles.Genuine competence only becomes establishedwhen know-how, ability and customer-orientationhave been consolidated over many years tobecome a distinctive style. The success story of<strong>Kramer</strong> is telling proof of this adage:- Over 50 years of experience in the development,design and production of intelligent, durable andversatile construction machinery. Structures thathave grown organically.- Innovation bringing progress to life. <strong>Kramer</strong>constantly strives to make things work better. Thisis how the brand has become the acknowledgedpioneer and market leader that it is today.- Consistent customer orientation, personalcontacts, the flexibility and short decision pathwaysof a medium-sized enterprise, along with the securityof guaranteed and rapid spare parts procurementwith no red tape.- A broad one-stop product and service spectrum:“Made in Germany”, in the Bodensee region. Development,production, purchasing and sales all onone site.- The most up-to-date manufacturing facilities within-house paint shop and an experienced workforce,who personally invest a great deal of value inthe quality of “their machines”.- Robust, long-standing trading partners andwell-trained contacts who represent <strong>Kramer</strong> out ofconviction and for whom one thing counts above allelse: loyal and contented customers.1992 In order to satisfy customer requirements, <strong>Kramer</strong> develops a wheelloader with telescopic boom. The extra pallet height and reach givecustomers what they were looking for.2000 The Neuson and <strong>Kramer</strong> companies merge to become Neuson <strong>Kramer</strong>Baumaschinen AG, a company specialising in the development and manufacturingof compact machinery.2003 <strong>Kramer</strong> presents the first wheel loader series with stepless high-speeddrive (“Ecospeed”) and highway-certified trailer coupling.2005 A new vehicle segment – the telehandler – is developed and unveiled.Through cooperation with the agricultural machinery manufacturer,Claas, telehandlers are successfully marketed to the agricultural sector.2007 A new company is born: Neuson <strong>Kramer</strong> Baumaschinen AG andWacker Construction Equipment AG come together to form WackerNeuson SE, a comprehensive provider of Light and Compact Equipment.2008 Due to increasing demand and the expansion of the product range,<strong>Kramer</strong> builds a new factory from scratch in Pfullendorf. This is oneof the most up-to-date manufacturing sites in Europe.22_23 KRAMER MILESTONES

High tech.A winner’s specs.ORSNWith standard bucket andstandard tyres (front view)DCFSTANDARD EQUIPMENTCABSoundproofed, vibration-insulated, 4-point suspension comfortcab with large, tinted windows for excellent all around visibility.A comfortable work environment for more safety and efficiency!Optimised visibility at maximum dump height. The boom islowered into the U-section chassis for 360° all around visibility inthe transport position. Extremely roomy cab with many storagepossibilities.Instrument panel. Neatly laid out display with telltales andergonomically placed switches. Safe load indicator integrated inA column at eye level.Joystick console. Ergonomic position of pilot control consolewith:– Hydraulically pilot-controlled joystick for raising/lowering anddumping in/out the boom with a scroll wheel for selecting thedriving direction.– Proportional controls for extending/retracting the telescopicboom– Proportional control for 3rd control circuit for operation ofhydraulically actuated implements, including a function forcontinuous operationAdjustable console with integrated armrestHeating, ventilation. Easy-to-operate, 3-speed powerful heatingand ventilation system with recirculated-air mode, dust filterand defroster vents.Seat. Comfort seat with mechanical suspension and automaticseat belt, weight, backrest and horizontal adjustment, fabriclined.Roller sun-visor3307 • 4507 • 4009Wipers. Front and rear wipers. Extremely long wiper blade covers85 % of front window glass. Large washer fluid tank allowsfor long refill intervals.Rearview mirror. Large outside mirrors, foldable to notchedpositions on either side12 V socket with cigarette lighterBattery master switchLIGHTSFront and rear working lightsHeadlights with high beamRear lightsReversing lightBrake lightsTurn indicatorsCab light with door contact switchENGINE COVEROpens wide with gas struts for optimal access for maintenanceQUICKHITCH FACILITYMechanicalENGINE AIR INTAKEVia cyclone prefilter and cyclone air filter with integrated safetycartridge in the cyclone prefilterP Q MK J EHLGIABWith standard bucket and standard tyresWith pallet forks and standard tyresDIMENSIONS 3307 4507 4009A Length incl. quick coupler 4760 mm 4760 mm 5590 mmB Length with standard bucket 5690 mm 5690 mm 6440 mmC Max. width 2320 mm 2320 mm 2320 mmD Track width 1920 mm 1920 mm 1920 mmE Height up to cab roof 2450 mm 2450 mm 2450 mmF Inside cab width 920 mm 920 mm 920 mmG Wheelbase 2850 mm 2850 mm 3050 mmH Ground clearance 430 mm 430 mm 430 mmI Distance centre of rear wheel to rear end 900 mm 900 mm 1060 mmJ Height to boom 1710 mm 1710 mm 1760 mmK Rear departure angle 47° 47° 50°L Pallet forks crowd angle in lower position 20° 20° 20°M Standard bucket crowd angle in lower position 45° 45° 45°N Pallet forks dump-out angle in top position 70° 70° 70°O Standard bucket dump-out angle in top position 45° 45° 45°P Load-over height 7050 mm 7050 mm 8825 mmQ Dump height 6370 mm 6370 mm 8080 mmR Dump reach 290 mm 290 mm 270 mmS Max. lift height 7100 mm 7100 mm 8950 mmOPTIONSCABComfort air-suspension seatSeat with multiple adjustment and integrated joystick consoleRadioAdditional front and rear working lightsAir conditioningRight-hand side and rear window heatingRight-hand side mirror heating incl. electric adjustmentSplit doorAdjustable steering columnTool boxPOWER OPTIONSHigh-capacity hydraulic systemHydraulically reversible fan motorTurbo III pre-separatorIndustrial coolerCrab steerHydraulic quickhitch facilityLoad stabiliserSockets for front and rear attachmentsUnpressurised refluxLow-speed control and manual throttleAutomatic bucket resetFrame levellingHydraulic oscillating axle interlockDirt scraper on telescopic boomRange of trailer coupling systemsCentral lubrication systemCarbon particle filterRearview mirror for trailer couplingFront and/or rear hydraulic control circuitsHydraulic trailer brakeCompressed-air brake systemATTACHEMENTSPallet forks, standard bucket, lightweight material bucket,superlightweight material bucket, heavy duty bucket with clamp,load hook, work platform with remote control, pallet forks withhydr. lateral shift, bale clamp, rotary broom, snow plough,PREHEATINGEngineFuelHydraulic oilTYRESIndustrial tyres 15.5-25Traction tyres 17.5 R24Traction tyres 19.5 R24Range of mining tyresConstruction machine tyres 405/70-24Wide-base tyres (non-directional) 500/70 R24Foam-filled tyresTyre puncture protection kit3307 • 4507 • 4009SAFETYRear cardan shaft guardUnderbody guard plateCovering element for drive underneath boomProtective measures for work in aggressive environmentFire extinguisherWarning strips as per DIN 30710Drive interlockBackup warning systemRotating beaconWorking light on telescoping armAutomatic cutout of hydraulic functions in the event of overloadPOWER TRAINProgressive ecospeed high speed gearbox 0–30 / 0–40 kphPAINT OTHER THAN STANDARDBIODEGRADABLE OILPANOLIN HLP Synth46WARRANTY EXTENSION3307 • 4507 • 4009pallet forks with adjustable fork arm height, multipurposebucket, root baller, concrete mixing bucket.Other attachments on request.We reserve the right to make modifications without notice. No responsibility is taken for the accuracy of this information.The provisions of the contractual agreement shall be considered definitive.

330745074009Load diagram(with load centre 500 mm)3307Load diagram(with load centre 500 mm)4507Load diagram(with load centre 500 mm)Left: 4009 with hydraulic frame levelling and oscillating axle interlocRight: 4009 without frame levelling and without oscillating axle interlockSPECIFICATIONS 3307 4507 4009Bucket capacity 1.2 – 2.5 m 3 1.2 – 3.0 m 3 1.2 – 3.0 m 3Weight without attachment 7200 kg 8100 kg 8600 kgTurning radius between kerbs /with pallet forks3600 / 4550 mm 3600 / 4550 mm 3850 / 5300 mmTotal tilt angleof quick-change 163 ° 163 ° 163 °ENGINEMake/Type/designOutputMax. torqueEngine displacement 4040 cm 3Deutz TCD 2012 L04 2V, 4 cylinder in-line water-cooled turbocharged enginewith charge-air cooler88 kW / 120 hp at 2400 rpm420 Nm at 1600 rpmEmissions Tested and certified as per 97/68 EC, emissions standard level 3POWER TRANSMISSIONDriveDrive speedAxlesOscilation angle rear axle 20 °Differential lockService brakeParking brakeStandard tyres 405/70-24STEERING AND WORK HYDRAULICSMode of functionAutomotive, progressive hydrostatic axial-piston gearbox, 4 wheel drive0 – 20 km/h, ecospeed 0 – 30 km/h (option), ecospeed 0 – 40 km/h (option)Planetary drive and steering axlesLocking power 100 % (front)Hydraulic multidisc brake in front axleHydraulic dual-circuit multidisc brake in front and rear axles (option) 1Electrohydraulically controlled spring-loaded multidisc brakeHydrostatic 4 wheel steering with electronic steering synchronisationMax. steering angles 2 x 45 ° 2 x 45 ° 2 x 40 °Work pumpFlow rateGear pumpAxial-piston variable displacementpump (option)110 l/min150 l/min (option)Gear pumpAxial-piston variable displacementpump (option)110 l/min150 l/min (option)Axial-piston variabledisplacement pump–150 l/min–Pressures 210 bar 250 bar 250 barKINEMATICSMax. payload 3300 kg 4400 kg 4000 kgMax. lift height 7100 mm 7100 mm 8950 mmCrowd/dump angles 45° / 45° 45° / 45° 45° / 45°Payload @ max. lift height 2400 kg 3800 kg 500 / 3000 kg 3Payload @ max. reach 1000 kg 1500 kg 1000 kgLift height @ max. load 5100 mm 4400 mm 4338 / 8000 mm 3Reach @ max. load 1380 mm 1250 mm 1730 / 1745 mm 3Max. reach (pallet forks) 3750 mm 3750 mm 5080 mmScraping depth 143 mm 143 mm 143 mmLift ram raise 9.6 / 7.4 sec 2 9.6 / 7.4 sec 2 8.5 secLift ram lower 6.0 / 5.6 sec 2 6.0 / 5.6 sec 2 6.5 secPush-out ram extension 7.3 / 6.2 sec 2 7.3 / 6.2 secPush-out ram retraction 5.7 / 5.5 sec 2 5.7 / 5.5 secCrowd 3.6 / 2.5 sec 2 3.6 / 2.5 sec2 8.2 sec2 7.6 sec2 2.5 secDump 3.0 / 2.2 sec 2 3.0 / 2.2 sec 2 2.2 secWork cycles: raise and extend 17.4 / 12.4 sec 2 17.4 / 12.4 secWork cycles: lower and retract 10.3 / 7.9 sec 2 10.3 / 7.9 secCAPACITIESFuel tank / Hydraulic oil tankHydraulic systemNOISE EMISSIONSAs per 2000/14/EGELECTRIC SYSTEMOperating voltageBattery / AlternatorStarter190 / 100 l170 l12 V135 Ah / 95 A3 kW2 16.0 sec2 9.8 sec1 Only with 30/40 kph version 2 Only with load sensing variable piston pump 3 With frame levelling and oscillating axle interlock

You won’t find the original just anywhere:AUTHORIZED KRAMER PARTNERS ARE ALWAYS THE BEST ADDRESS.www.kramer.de/Haendler07/2010 art.nr. 1000159537<strong>Kramer</strong>-Werke GmbHWacker Neuson Straße 1D-88630 PfullendorfTel. 00 800 90 20 90 20Fax +49(0)7552 92 88-234info@kramer.dewww.kramer.de<strong>Kramer</strong>-Werke GmbH is an affiliate of Wacker Neuson SE, Munich.