Cleaning for Oxygen Service - Industrial Products

Cleaning for Oxygen Service - Industrial Products

Cleaning for Oxygen Service - Industrial Products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

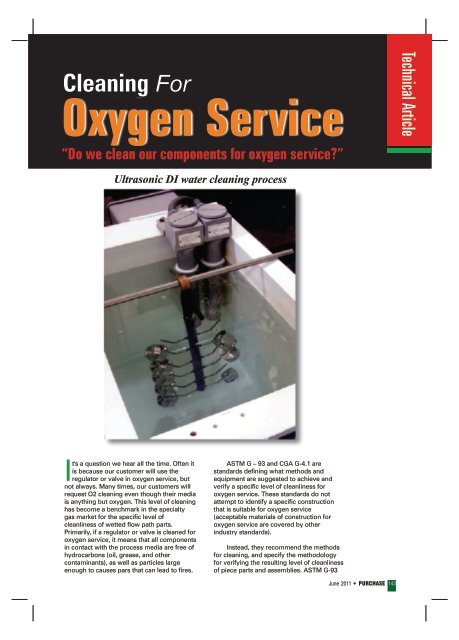

<strong>Cleaning</strong> For<strong>Oxygen</strong> <strong>Service</strong>Technical Article“Do we clean our components <strong>for</strong> oxygen service?”Ultrasonic DI water cleaning processIt's a question we hear all the time. Often itis because our customer will use theregulator or valve in oxygen service, butnot always. Many times, our customers willrequest O2 cleaning even though their mediais anything but oxygen. This level of cleaninghas become a benchmark in the specialtygas market <strong>for</strong> the specific level ofcleanliness of wetted flow path parts.Primarily, if a regulator or valve is cleaned <strong>for</strong>oxygen service, it means that all componentsin contact with the process media are free ofhydrocarbons (oil, grease, and othercontaminants), as well as particles largeenough to causes pars that can lead to fires.ASTM G – 93 and CGA G-4.1 arestandards defining what methods andequipment are suggested to achieve andverify a specific level of cleanliness <strong>for</strong>oxygen service. These standards do notattempt to identify a specific constructionthat is suitable <strong>for</strong> oxygen service(acceptable materials of construction <strong>for</strong>oxygen service are covered by otherindustry standards).Instead, they recommend the methods<strong>for</strong> cleaning, and specify the methodology<strong>for</strong> verifying the resulting level of cleanlinessof piece parts and assemblies. ASTM G-93June 2011PURCHASE 143

Special Industry Review<strong>Industrial</strong> Pollution, Safety, <strong>Cleaning</strong> & Maintenancedefines several levels of cleanliness <strong>for</strong>various applications <strong>for</strong> equipment used inoxygen-enriched environments, along withthe methods used to verify these levels ofcleanliness. Tescom uses ASTM G-93 as itsstandard <strong>for</strong> cleaning. In fact, anycomponent that we sell through theindustrial division is packaged with a labelthat includes the following:“This product is cleaned in accordancewith ASTM G – 93 and CGA G-4.1 (Thisassures removal of visible particles andcombustible residues).”So what does this all mean to the enduser? Essentially, through a series ofcleaning and evaluation steps, thecomponent has been cleaned, assembled,and packaged in a controlled manner thatassures the end user that no particles orcombustible residues are present on thewetted surfaces. These particles andcombustible residue can then act as ignitionmechanisms <strong>for</strong> an oxygen fire under theright conditions.Every day, someone learns about theneed <strong>for</strong> leaning components used inoxygen service the hard way Most commonamong the metal working industry, oxygenfires often occur in the regulator set of anoxy/acetylene welding rig. The welder mayhave carelessly tossed the regulator set onthe ground when changing cylinders, orperhaps didn't cap the end of the cylinderafter a long day of welding, allowing dirt toenter the outlet of the cylinder valve. Whenthe regulator is connected to a cylinder ofoxygen, and the cylinder valve is opened,high pressure oxygen flows into theregulator at a high velocity. The oxygenreaches the main valve of the regulator,which is usually in the closed position. In thissituation two opportunities <strong>for</strong> an oxygen fireexist. The first is from the impingement ofdirt and other particles moving at highvelocity within the component. The secondis due to heat of compression. Heat isgenerated from the conversion ofmechanical energy when a gas iscompressed from a low to a high pressure.High gas temperatures can result if thiscompression occurs quickly to simulatenear – adiabatic conditions. This temperaturerise may be high enough to cause the plasticseat or o-ring material in the regulator toignite. Plastics and elastomers have what iscalled an auto- ignition temperature thatrefers to the temperature at which thematerial will ignite in the presence of 100%oxygen. A seat fire or o-ring fire will promoteconsequential burn of the surroundingmetal. This condition is often referred to aspromoted ignition or kindling chain ignition.Impingement occurs when a particle orparticles entrained in the gas are moving at ahigh velocity through the component, andbegin hitting a wall or other fixed object inthe body of the component. When theparticle impacts the body of the componentat high velocity, there is a chance that aspark is created at the moment of impact.This spark can trigger a fire, selected fueledby the body material, and supported by theoxygen - rich atmosphere. For metals, thereis a property called Absolute ThresholdPressure that refers to the pressure at whichthe metal will support self-sustainedcombustion in oxygen atmospheres. All ofthe 300 series stainless steels have thresholdpressures near 500 psi while aluminumsupports combustion at pressures as low as35 psi. + Once the oxygen fire begins, itcontinues until the system pressure isreduced to a point where combustion is nolonger possible. This usually occurs whenthe fire has burned through the wall of theregulator resulting in a dangerous explosionof fire and material.144 PURCHASE June 2011

<strong>Industrial</strong> Pollution, Safety, <strong>Cleaning</strong> & MaintenanceSpecial Industry ReviewWhen looking <strong>for</strong> a component to beused in an oxygen environment, choosingplastic parts with high auto-ignitiontemperatures and metals with higherthreshold pressures will substantially reducethe potential <strong>for</strong> oxygen fires. Brass andMonel are commonly used metals whilePCTFE and Viton® are commonly used softgoods. For more in<strong>for</strong>mation about oxygencompatibleconstructions, please contactTescom engineers <strong>for</strong> assistance.We've discussed the need <strong>for</strong> specialcleaning <strong>for</strong> oxygen service, but why wouldsomeone specify this level of cleaning <strong>for</strong>applications of other gases? There are noother industry standards that quantify a levelof clean liness as specific as cleaning <strong>for</strong>oxygen service. It is the benchmark of clean,you might say. So, rather than spelling it outin a long, windy text specification how thedevice should be cleaned, verified, andpackaged, the customer simply requestscleaning <strong>for</strong> oxygen service. Of course, thisby no means implies that any componentcleaned <strong>for</strong> oxygen service is suitable <strong>for</strong>oxygen service, but we now know that thedevice is hydrocarbon and particle free,making it suitable <strong>for</strong> all manner of analytical,pharmaceutical, and industrial applications.Tescom's <strong>Industrial</strong> Controls Division cleansand packages all pressure regulators andvalves <strong>for</strong> oxygen service as a standardfeature of our product offering. There is noneed to specify it separately.Compiled by Mr.Rushil shahManaging Director SHAVOTechnologies in Association withTESCOM, USA.SHAVO TECHNOLOGIES PVT. LTD.Shavo House, Survey No.21A/10B, PlotNo.394, South Main Road Koregaon Park,PUNE 411 001Phone No 020-26059641 / 26059642Fax No 020-26059644Website: www.shavogroup.comE-Mail: shavogroup@vsnl.comJune 2011PURCHASE 145