Unbalancer 9-pin.pdf - Tube CAD Journal

Unbalancer 9-pin.pdf - Tube CAD Journal

Unbalancer 9-pin.pdf - Tube CAD Journal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

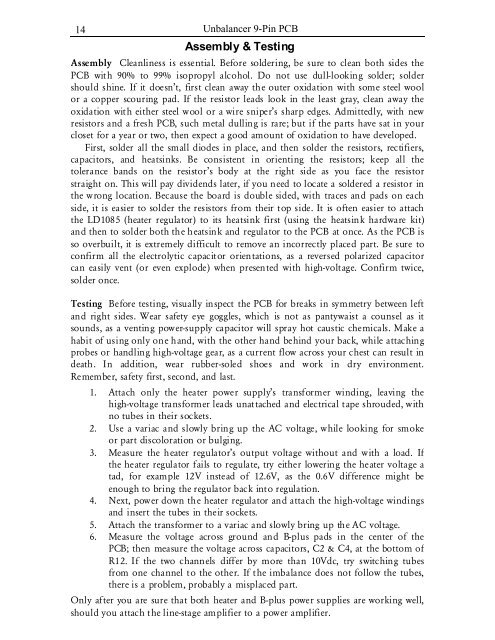

14<strong>Unbalancer</strong> 9-Pin PCBAssembly & TestingAssembly Cleanliness is essential. Before soldering, be sure to clean both sides thePCB with 90% to 99% isopropyl alcohol. Do not use dull-looking solder; soldershould shine. If it doesn’t, first clean away the outer oxidation with some steel woolor a copper scouring pad. If the resistor leads look in the least gray, clean away theoxidation with either steel wool or a wire sniper’s sharp edges. Admittedly, with newresistors and a fresh PCB, such metal dulling is rare; but if the parts have sat in yourcloset for a year or two, then expect a good amount of oxidation to have developed.First, solder all the small diodes in place, and then solder the resistors, rectifiers,capacitors, and heatsinks. Be consistent in orienting the resistors; keep all thetolerance bands on the resistor’s body at the right side as you face the resistorstraight on. This will pay dividends later, if you need to locate a soldered a resistor inthe wrong location. Because the board is double sided, with traces and pads on eachside, it is easier to solder the resistors from their top side. It is often easier to attachthe LD1085 (heater regulator) to its heatsink first (using the heatsink hardware kit)and then to solder both the heatsink and regulator to the PCB at once. As the PCB isso overbuilt, it is extremely difficult to remove an incorrectly placed part. Be sure toconfirm all the electrolytic capacitor orientations, as a reversed polarized capacitorcan easily vent (or even explode) when presented with high-voltage. Confirm twice,solder once.Testing Before testing, visually inspect the PCB for breaks in symmetry between leftand right sides. Wear safety eye goggles, which is not as pantywaist a counsel as itsounds, as a venting power-supply capacitor will spray hot caustic chemicals. Make ahabit of using only one hand, with the other hand behind your back, while attachingprobes or handling high-voltage gear, as a current flow across your chest can result indeath. In addition, wear rubber-soled shoes and work in dry environment.Remember, safety first, second, and last.1. Attach only the heater power supply’s transformer winding, leaving thehigh-voltage transformer leads unattached and electrical tape shrouded, withno tubes in their sockets.2. Use a variac and slowly bring up the AC voltage, while looking for smokeor part discoloration or bulging.3. Measure the heater regulator’s output voltage without and with a load. Ifthe heater regulator fails to regulate, try either lowering the heater voltage atad, for example 12V instead of 12.6V, as the 0.6V difference might beenough to bring the regulator back into regulation.4. Next, power down the heater regulator and attach the high-voltage windingsand insert the tubes in their sockets.5. Attach the transformer to a variac and slowly bring up the AC voltage.6. Measure the voltage across ground and B-plus pads in the center of thePCB; then measure the voltage across capacitors, C2 & C4, at the bottom ofR12. If the two channels differ by more than 10Vdc, try switching tubesfrom one channel to the other. If the imbalance does not follow the tubes,there is a problem, probably a misplaced part.Only after you are sure that both heater and B-plus power supplies are working well,should you attach the line-stage amplifier to a power amplifier.