You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

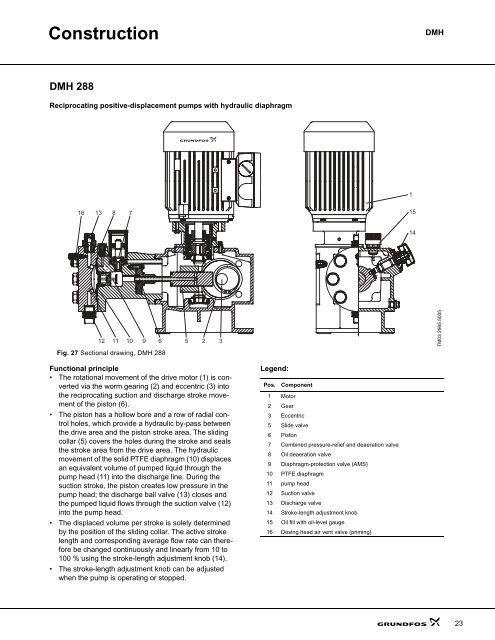

ConstructionDMHDMH 288Reciprocating positive-displacement pumps with hydraulic diaphragm1161387151412 11 10 9 6 5 2 3Fig. 27 Sectional drawing, DMH 288TM03 2965 5005Functional principle• The rotational movement of the drive motor (1) is convertedvia the worm gearing (2) and eccentric (3) intothe reciprocating suction and discharge stroke movementof the piston (6).• The piston has a hollow bore and a row of radial controlholes, which provide a hydraulic by-pass betweenthe drive area and the piston stroke area. The slidingcollar (5) covers the holes during the stroke and sealsthe stroke area from the drive area. The hydraulicmovement of the solid PTFE diaphragm (10) displacesan equivalent volume of pumped liquid through thepump head (11) into the discharge line. During thesuction stroke, the piston creates low pressure in thepump head; the discharge ball valve (13) closes andthe pumped liquid flows through the suction valve (12)into the pump head.• The displaced volume per stroke is solely determinedby the position of the sliding collar. The active strokelength and corresponding average flow rate can thereforebe changed continuously and linearly from 10 to100 % using the stroke-length adjustment knob (14).• The stroke-length adjustment knob can be adjustedwhen the pump is operating or stopped.Legend:Pos. Component1 Motor2 Gear3 Eccentric5 Slide valve6 Piston7 Combined pressure-relief and deaeration valve8 Oil deaeration valve9 Diaphragm-protection valve (AMS)10 PTFE diaphragm11 pump head12 Suction valve13 Discharge valve14 Stroke-length adjustment knob15 Oil fill with oil-level gauge16 Dosing head air vent valve (priming)23