Technology Cooperation and Capacity Building - CommDev

Technology Cooperation and Capacity Building - CommDev

Technology Cooperation and Capacity Building - CommDev

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

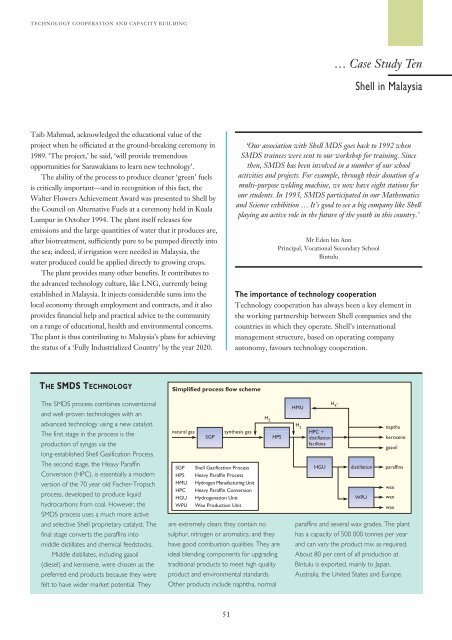

TECHNOLOGY COOPERATION AND CAPACITY BUILDING… Case Study TenShell in MalaysiaTaib Mahmud, acknowledged the educational value of theproject when he officiated at the ground-breaking ceremony in1989. ‘The project,’ he said, ‘will provide tremendousopportunities for Sarawakians to learn new technology’.The ability of the process to produce cleaner ‘green’ fuelsis critically important—<strong>and</strong> in recognition of this fact, theWalter Flowers Achievement Award was presented to Shell bythe Council on Alternative Fuels at a ceremony held in KualaLumpur in October 1994. The plant itself releases fewemissions <strong>and</strong> the large quantities of water that it produces are,after biotreatment, sufficiently pure to be pumped directly intothe sea; indeed, if irrigation were needed in Malaysia, thewater produced could be applied directly to growing crops.The plant provides many other benefits. It contributes tothe advanced technology culture, like LNG, currently beingestablished in Malaysia. It injects considerable sums into thelocal economy through employment <strong>and</strong> contracts, <strong>and</strong> it alsoprovides financial help <strong>and</strong> practical advice to the communityon a range of educational, health <strong>and</strong> environmental concerns.The plant is thus contributing to Malaysia’s plans for achievingthe status of a ‘Fully Industrialized Country’ by the year 2020.‘Our association with Shell MDS goes back to 1992 whenSMDS trainees were sent to our workshop for training. Sincethen, SMDS has been involved in a number of our schoolactivities <strong>and</strong> projects. For example, through their donation of amulti-purpose welding machine, we now have eight stations forour students. In 1993, SMDS participated in our Mathematics<strong>and</strong> Science exhibition … It’s good to see a big company like Shellplaying an active role in the future of the youth in this country.’Mr Eden bin AnnPrincipal, Vocational Secondary SchoolBintuluThe importance of technology cooperation<strong>Technology</strong> cooperation has always been a key element inthe working partnership between Shell companies <strong>and</strong> thecountries in which they operate. Shell’s internationalmanagement structure, based on operating companyautonomy, favours technology cooperation.THE SMDS TECHNOLOGYThe SMDS process combines conventional<strong>and</strong> well-proven technologies with anadvanced technology using a new catalyst.The first stage in the process is theproduction of syngas via thelong-established Shell Gasification Process.The second stage, the Heavy ParaffinConversion (HPC), is essentially a modernversion of the 70 year old Fischer-Tropschprocess, developed to produce liquidhydrocarbons from coal. However, theSMDS process uses a much more active<strong>and</strong> selective Shell proprietary catalyst. Thefinal stage converts the paraffins intomiddle distillates <strong>and</strong> chemical feedstocks.Middle distillates, including gasoil(diesel) <strong>and</strong> kerosene, were chosen as thepreferred end products because they werefelt to have wider market potential. TheySimplified process flow schemenatural gasSGPHPSHMUHPCHGUWPUSGPsynthesis gasShell Gasification ProcessHeavy Paraffin ProcessHydrogen Manufacturing UnitHeavy Paraffin ConversionHydrogenation UnitWax Production UnitHPSare extremely clean; they contain nosulphur, nitrogen or aromatics; <strong>and</strong> theyhave good combustion qualities. They areideal blending components for upgradingtraditional products to meet high qualityproduct <strong>and</strong> environmental st<strong>and</strong>ards.Other products include naphtha, normalHHMU4 -H 2H 2HPC +distillationfacilitiesHGUdistillationWPUnapthakerosenegasoilparaffinswaxwaxwaxparaffins <strong>and</strong> several wax grades. The planthas a capacity of 500 000 tonnes per year<strong>and</strong> can vary the product mix as required.About 80 per cent of all production atBintulu is exported, mainly to Japan,Australia, the United States <strong>and</strong> Europe.51

![[PDF] Community Development Toolkit - CommDev](https://img.yumpu.com/48616495/1/184x260/pdf-community-development-toolkit-commdev.jpg?quality=85)