CEIA THS 21

CEIA THS 21

CEIA THS 21

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

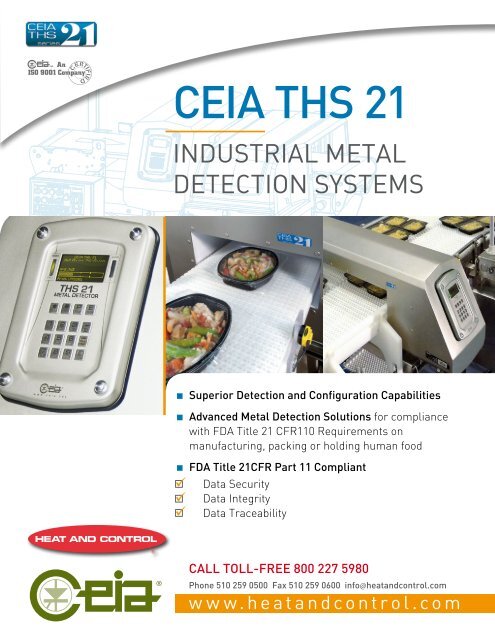

<strong>CEIA</strong> ths <strong>21</strong>industrial metal detection systemsBest Metal Detection Solution for compliance with FDA Title <strong>21</strong>CFR110requirements on manufacturing, packing or holding human foodSubpart E (Production and Process Control) of the FDA Code Title <strong>21</strong> CFR110 requiresthat effective measures shall be taken to protect against the inclusion of metal in food.<strong>CEIA</strong> <strong>THS</strong> <strong>21</strong> Metal Detection Systems offer detection, construction quality and reliabilitycharacteristics that make them the most suitable and effective solution to automaticelimination of metal contaminants.FDA <strong>21</strong> Part 11 CompliantThe <strong>THS</strong> <strong>21</strong> Metal Detector Series is a high-sensitivity, highprecisionmeasuring instrument. The reply from the device isused directly command ejection of the contaminated productand to check that it has in fact been eliminated. The data relatingto each detection and ejection are stored in an eventsmemory and certify production quality, the inspection itself andprogramming operations, as well as the periodic functional testphases using standard test samples.FDA Code Title <strong>21</strong> Part 11 prescribes rigorous criteria foraccess to programming and computer data protection whichhave been fully adopted in the <strong>CEIA</strong> <strong>THS</strong> <strong>21</strong> Series firmware.User access is only possible via specific login with User Nameand Password, under the control of the System Administrator,who programmes the user profile and associates with each userthe functions available to him/her. The requirements regardingSecurity, Integrity and Traceability are therefore satisfied.New Global Auto-Learn System providessimultaneous maximum sensitivity to all metalsstarting from a single learning transitThe <strong>THS</strong> <strong>21</strong> Series employs an exclusive Autolearn system forfood products which allows optimization of the detection sensitivityto all metals with the maximum speed and precision,equivalent to hundreds of conventional learning transits: resultsin levels of precision and efficiency never before obtained.www.heatandcontrol.comContinuous embedded Self-Calibration control formaximum repeatability and performance consistencyover time and with environmental changesBy means of specific signals sent to the transmission and receptionchain of the Metal Detector, constant monitoring of thedetection characteristics is carried out, with consequent constantcompensation for any variations caused by environmentalfactors. The result is system stability and constancy in detectionperformance and product effect neutralization.Heat and Control reserves the right to make changes, at any moment and without notice, to the models (including programming), their accessories and options, to the prices and conditions of sale

Continuous Auto-Test function ensuringmaximum Production SafetySpecial electronic stimuli are sent to the transmission andreception chain of the <strong>THS</strong> <strong>21</strong> Metal Detector Series, causingvariations in the detection signals which are not visible to theuser but which provide checks on detection characteristics,analogous to those obtained with manual transits of test samples.These variations are compared with the reference valuesstored in the factory at the time of the calibration test.This produces an automatic certified check of the system’ssensitivity; any deviations from permittedtolerances are followed by a signaland the recording ofthe anomaly.Automatic measurement of the installationQuality and Environmental Compatibility<strong>THS</strong> <strong>21</strong> Series introduces new tools for the installation andmaintenance technicians which allow them to measure theenvironmental compatibility of the Metal Detector. These arefunctions which would otherwise have required the interventionof external instrumentation, now implemented in the microcomputercontrol of the device itself.The measurements include general mechanical and electromagneticenvironmental compatibility, specific electromagneticcompatibility and the automatic examination of thedegree of metal interference from the conveyor belt. This latterfunction becomes even more important when the high levelof sensitivity of the <strong>THS</strong> <strong>21</strong> Metal Detector Series is taken intoconsideration.Modern, rugged and user friendly interface• Industrial rate design• Rapid data entry with extended keyboard• Easy to read, high-contrast graphic display• Rugged, antivandalic stainless steel keyboardThe <strong>THS</strong> <strong>21</strong> Metal Detector Series keeps the full compatibility with programmingand parameter selection procedures already implemented in earlier versions of the<strong>THS</strong>. In addition, there is a new organic graph display with extremely high contrast(3000:1) and a viewing angle up to 180°, and an extended alphanumeric keypad forquick keystrokes.• Quick Access FunctionA new function, activated simply by pressing a dedicated key, allows the most frequently-usedfunctions to be directly recalled. These functions are programmableby the operator, and maintain the access protection criteria according to FDA Title<strong>21</strong> Part 11 requirements.• Large Product Memory: 500+ entries with easyalphabetical sorting and pattern matchingA capacious incorporated memory allows over 500 products to be stored, each identifiableby a specific alphanumeric string. The products are automatically listed in alphabeticalorder, and searches are facilitated by the progressive recognition of thecharacters selected on the keypad.www.heatandcontrol.comHeat and Control reserves the right to make changes, at any moment and without notice, to the models (including programming), their accessories and options, to the prices and conditions of sale

<strong>CEIA</strong> ths <strong>21</strong>industrial metal detection systemsFully HACCP compliant, <strong>CEIA</strong> Metal Detectors are ISO 9001 certifiedand constructed of FDA approved materials.Control Panels for <strong>THS</strong> <strong>21</strong> are listed accordingto UL 508A and CSA-C22.2 No. 14-05<strong>CEIA</strong> <strong>THS</strong>/MS<strong>21</strong>Multi-spectrum Metal Detectorfor Quality Control• Very high sensitivity to all magnetic andnon-magnetic metals, including stainless steel• High immunity to environmental interference• Automatic learning & tracking of product effect• AISI 316L stainless steel construction to IP69K protection level<strong>CEIA</strong> <strong>THS</strong>/FB<strong>21</strong>Conveyor belt systemsfor <strong>THS</strong> <strong>21</strong> Metal Detectors•••• Easy to maintain and inspect•Integrated controls for line speed and rejectionFully compliance with HACCP criteriaAll parts completely reversible and modularHigh level of electronic and mechanical reliability<strong>CEIA</strong> <strong>THS</strong>/MB<strong>21</strong>modular Conveyor belt systemsfor <strong>THS</strong> <strong>21</strong> Metal Detectors• Integrated controls for line speedand rejection• IP69K compliant for high pressurewashdown• Fully compliance with HACCP criteria• Easy to maintain and inspect• Digitally adjustable belt speedwww.heatandcontrol.comHeat and Control reserves the right to make changes, at any moment and without notice, to the models (including programming), their accessories and options, to the prices and conditions of sale

<strong>CEIA</strong> ths <strong>21</strong>industrial metal detection systems<strong>CEIA</strong> <strong>THS</strong>/G<strong>21</strong>for free-falling product applications• Very high sensitivity to all magnetic andnon-magnetic metals, including stainless steel• Designed to inspect powders, liquids, granulesand other loose materials in pipes•level• Automatic learning & tracking of product effectAISI 316L stainless steel construction to IP69K protection<strong>CEIA</strong> <strong>THS</strong>/PL<strong>21</strong>for liquid and viscous productsStandard pipe sizes available to suit all applicationsAISI 316L stainless steel construction to IP69K protection levelHigh immunity to environmental interferenceEasy to clean and inspect• Minimum installation space required<strong>CEIA</strong> <strong>THS</strong>/PLV<strong>21</strong>Integrated system with ejection valvefor liquid and viscous products• Fast acting reject device for a limited quantity of rejectedproductAISI 316L stainless steel construction to IP69K protection levelFull compliance with HACCP criteriaAutomatic learning & tracking of product effect• Standard pipe sizes available to suit all applications<strong>CEIA</strong> <strong>THS</strong>/FFV<strong>21</strong>Integrated system with ejection valvefor granular and powder products• Fast and efficient: achieve fast ejection speeds and accuracy,with the minimum amount of rejected productAISI 316L stainless steel construction to IP69K protection levelFull compliance with HACCP criteria• Pipe in antistatic material, certified for contactwith food products<strong>21</strong>1<strong>21</strong> Cabot Blvd. Hayward, CA 94545 USATel 1 800 227 5980 / 1 510 259 0500 Fax 1 510 259 0600info@heatandcontrol.comwww.heatandcontrol.com Call Toll-Free 800 227 5980Heat and Control reserves the right to make changes, at any moment and without notice, to the models (including programming), their accessories and options, to the prices and conditions of saleDP002K0006v1000US 46517