meyer neptun portal starts up delivery of the celebrity ... - Meyer Werft

meyer neptun portal starts up delivery of the celebrity ... - Meyer Werft

meyer neptun portal starts up delivery of the celebrity ... - Meyer Werft

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INFORMATION<br />

> IN BRIEF<br />

> DATES<br />

> EVENTS<br />

www.<strong>meyer</strong>werft.de<br />

MEYER NEPTUN PORTAL<br />

STARTS UP<br />

August 2009 | N o 04<br />

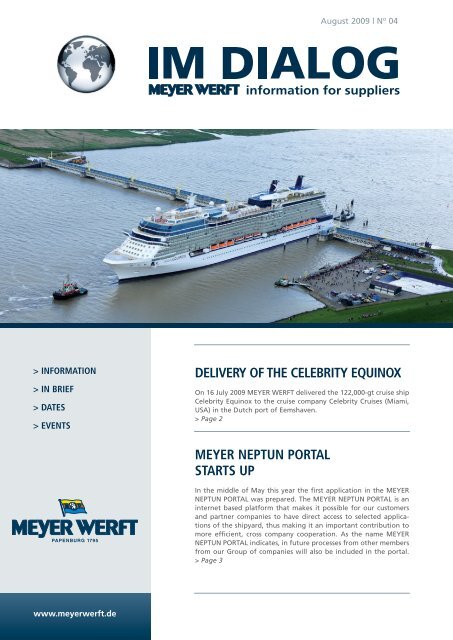

DELIVERY OF THE CELEBRITY EQUINOX<br />

On 16 July 2009 MEYER WERFT delivered <strong>the</strong> 122,000-gt cruise ship<br />

Celebrity Equinox to <strong>the</strong> cruise company Celebrity Cruises (Miami,<br />

USA) in <strong>the</strong> Dutch port <strong>of</strong> Eemshaven.<br />

> Page 2<br />

In <strong>the</strong> middle <strong>of</strong> May this year <strong>the</strong> first application in <strong>the</strong> MEYER<br />

NEPTUN PORTAL was prepared. The MEYER NEPTUN PORTAL is an<br />

internet based platform that makes it possible for our customers<br />

and partner companies to have direct access to selected applications<br />

<strong>of</strong> <strong>the</strong> shipyard, thus making it an important contribution to<br />

more efficient, cross company cooperation. As <strong>the</strong> name MEYER<br />

NEPTUN PORTAL indicates, in future processes from o<strong>the</strong>r members<br />

from our Gro<strong>up</strong> <strong>of</strong> companies will also be included in <strong>the</strong> <strong>portal</strong>.<br />

> Page 3

August 2009 | N o 04<br />

> Editorial<br />

DELIVERY OF THE<br />

CELEBRITY EQUINOX<br />

2 IM DIALOG<br />

With a tonnage <strong>of</strong> 122,000 gt and a length overall<br />

<strong>of</strong> 317.20 m <strong>the</strong> Celebrity Solstice is <strong>the</strong> biggest ship<br />

ever built at MEYER WERFT, and at <strong>the</strong> same time<br />

<strong>the</strong> biggest cruise ship ever built in Germany.<br />

She was not only designed and built in compliance<br />

with <strong>the</strong> latest damage stability calculation, but has<br />

o<strong>the</strong>r special features worth mentioning: 90% <strong>of</strong><br />

all cabins are outside cabins, most <strong>of</strong> <strong>the</strong>se having<br />

a balcony; "real grass" lawn has been sewn on <strong>the</strong><br />

<strong>up</strong>per deck; a photovoltaic plant (covering approx.<br />

470 sqm) was installed. Due to consistently optimized<br />

energy consumption throughout improve-<br />

www.<strong>meyer</strong>werft.de<br />

The Celebrity Equinox is <strong>the</strong> second ship out <strong>of</strong> a series <strong>of</strong><br />

five cruise liners <strong>the</strong> Papenburg shipyard is building for<br />

Celebrity Cruises.<br />

MEYER WERFT and Celebrity Cruises have built an<br />

extremely eco-friendly ship. A total energy saving<br />

<strong>of</strong> 30% compared to similar ships is achieved by<br />

highly energy-efficient components such as a<br />

photovoltaic system, an optimised hull design, an<br />

extremely efficient underwater coating or an<br />

energy-saving lighting system using LEDs.<br />

The Celebrity Equinox counts among <strong>the</strong> first ships<br />

that keep <strong>the</strong> new rules and regulations regarding<br />

damaged stability, which will be valid as <strong>of</strong> 2009<br />

and which help to increase safety considerably in<br />

case <strong>the</strong> ship is damaged due to a leak. Along with<br />

its new design and innovative technical equipment,<br />

<strong>the</strong> luxury liner <strong>of</strong>fers <strong>the</strong> passengers numerous<br />

specialities and a great deal <strong>of</strong> convenience:<br />

Roughly 90% <strong>of</strong> <strong>the</strong> passenger cabins are outside<br />

cabins with balconies. The ship features real grass<br />

on <strong>the</strong> open deck, a glass blowing studio, plenty <strong>of</strong><br />

special restaurants and bars, a big indoor pool,<br />

a very spacious pool area on <strong>the</strong> outer deck, night<br />

clubs, a shopping mall, a casino and a breathtaking<br />

atrium, with a 6.5-m high real tree at its centre.<br />

ments <strong>of</strong> 30 % could be implemented. This makes<br />

<strong>the</strong> Celebrity Solstice <strong>the</strong> most efficient cruise ship<br />

in <strong>the</strong> market.<br />

And when <strong>the</strong> term "we" is used here, it refers not<br />

only to <strong>the</strong> company's own shipyard workers, but<br />

also to <strong>the</strong> subcontractors and external s<strong>up</strong>pliers,<br />

to <strong>the</strong> classification society and, not least, to our<br />

customers. All <strong>of</strong> those mentioned have contributed<br />

to making this ship a true "Summer Night’s<br />

Dream". And that's why <strong>the</strong>y deserve our special<br />

thanks: Well done!<br />

Safety as well as entertainment on board in accordance<br />

with <strong>the</strong> latest technical standards is ensured<br />

by a diesel-electric pod propulsion system, complex<br />

alarm and safety systems, interactive communication<br />

systems and state-<strong>of</strong>-<strong>the</strong>-art stage technology.<br />

Moreover <strong>the</strong> highest safety standards are met in<br />

<strong>the</strong> engine room, especially in regard to <strong>the</strong> propulsion<br />

system.<br />

As early as one day after <strong>the</strong> <strong>delivery</strong>, <strong>the</strong> Celebrity<br />

Equinox left <strong>the</strong> Dutch port <strong>of</strong> Eemshaven for<br />

Southampton, with <strong>the</strong> first passengers already on<br />

board, where her naming ceremony took place on<br />

29 July 2009. From <strong>the</strong>re she set sail for a co<strong>up</strong>le <strong>of</strong><br />

mini cruises. The first cruise, to <strong>the</strong> fjords <strong>of</strong><br />

Norway, started on 31 July 2009. Now she is on a<br />

regular cruise schedule in <strong>the</strong> Mediterranean.

MEYER NEPTUN PORTAL STARTS UP<br />

In <strong>the</strong> middle <strong>of</strong> May this year <strong>the</strong> first application in <strong>the</strong><br />

MEYER NEPTUN PORTAL, <strong>the</strong> s<strong>up</strong>pliers self-disclosure, went<br />

online. The self-disclosure presently includes data about<br />

companies that with to cooperate with <strong>the</strong> shipyard.<br />

The data <strong>of</strong> <strong>the</strong> s<strong>up</strong>pliers with<br />

whom we are already doing<br />

business will also be included.<br />

Potential s<strong>up</strong>pliers get registered<br />

on our online s<strong>up</strong>plier registration<br />

on www.<strong>meyer</strong>werft.de.<br />

The shipyard decides on a<br />

case-by-case basis whe<strong>the</strong>r<br />

companies are accepted as<br />

potential s<strong>up</strong>pliers. As soon as<br />

a company becomes a member<br />

<strong>of</strong> <strong>the</strong> <strong>portal</strong> it is required to<br />

provide information requested<br />

by us and – which is new –<br />

takes over sole responsibility<br />

for its own company data.<br />

This form <strong>of</strong> self-disclosure on<br />

an internet based platform is<br />

usual practice today. If a decision<br />

has been taken to include a company in <strong>the</strong><br />

<strong>portal</strong> <strong>the</strong> company will receive its login data from<br />

us in an email. Access to <strong>the</strong> <strong>portal</strong> is meanwhile<br />

also possible via www.<strong>meyer</strong>werft.de.<br />

Since mid July, <strong>the</strong> next functionality in <strong>the</strong><br />

Materials Management/Purchasing section, i.e <strong>the</strong><br />

search in <strong>the</strong> regional s<strong>up</strong>plier network, has been<br />

available. We are developing this network firstly to<br />

<strong>of</strong>fer our national and international shipyard<br />

s<strong>up</strong>pliers <strong>the</strong> possibility to obtain s<strong>up</strong>port from <strong>the</strong><br />

region to work here on site in <strong>the</strong> shipyard.<br />

Secondly, we want to <strong>of</strong>fer a platform for regional<br />

companies to create business links where <strong>the</strong><br />

shipyard is not actively involved but which come<br />

about with <strong>the</strong> help <strong>of</strong> <strong>the</strong> shipyard.<br />

In future additional steps in <strong>the</strong> procurement<br />

process are s<strong>up</strong>posed to be handled via <strong>the</strong> MEYER<br />

NEPTUN PORTAL, with <strong>the</strong> aim <strong>of</strong> streamlining this<br />

process, reducing effort and thus saving time and<br />

money.<br />

Homepage <strong>of</strong> <strong>the</strong> MEYER NEPTUN PORTAL<br />

The second application that is currently active<br />

relates to inspections. Alongside <strong>the</strong> inspections<br />

calendar, in wh ich <strong>the</strong> inspections carried out daily<br />

are shown, <strong>the</strong> owners, <strong>the</strong> classification societies<br />

and staff from our external production department<br />

also have access to <strong>the</strong> inspections that were<br />

already carried out. Inspection-related data is<br />

generated directly from <strong>the</strong> inspection database<br />

and is thus always <strong>up</strong> to date. Using this new type<br />

<strong>of</strong> communication, which reduces paperwork and<br />

makes transfer lists for minutes <strong>of</strong> meeting<br />

s<strong>up</strong>erfluous, simplifies various procedures in <strong>the</strong><br />

cooperation with our customers and <strong>the</strong><br />

classification societies. In <strong>the</strong> middle <strong>of</strong> May <strong>the</strong><br />

first login data was handed to Disney Cruise Line. In<br />

<strong>the</strong> next few weeks more users will be added.<br />

IM DIALOG<br />

3

August 2009 | N o 04<br />

4 IM DIALOG<br />

FIRST-TIME USE OF PREFABRICATED BALCONIES<br />

For S. 677 50 balcony plates have been prefabricated<br />

and assembled in a block. The shipyard<br />

and <strong>the</strong> s<strong>up</strong>plier <strong>of</strong> <strong>the</strong> prefabricated balconies,<br />

Jukova Oy from Finland, are using this pilot phase<br />

to gain experience in production and assembly so<br />

that this knowledge can <strong>the</strong>n be optimally utilised<br />

in building subsequent vessels. With <strong>the</strong> use <strong>of</strong> prefabricated<br />

balconies MEYER WERFT is breaking<br />

new ground and this new challenge requires a<br />

close, cooperative partnership between <strong>the</strong><br />

shipyard and <strong>the</strong> s<strong>up</strong>plier.<br />

On <strong>the</strong> following newbuildings, S. 687 and S. 679,<br />

400 and 830 prefabricated balconies respectively<br />

will be used. The balcony plates, balustrades and<br />

separating walls are made <strong>of</strong> aluminium extruded<br />

sections that are designed and built in accordance<br />

with <strong>the</strong> individual customer's wishes. The balcony<br />

plates <strong>the</strong>mselves are prefabricated completely<br />

with drain gutters and flooring. The balustrade<br />

components are already part-mounted on <strong>the</strong><br />

www.<strong>meyer</strong>werft.de<br />

On our newbuilding S. 677, <strong>the</strong> Celebrity Eclipse, prefabricated balconies are<br />

used for <strong>the</strong> first time as part <strong>of</strong> a pilot phase. By assembling prefabricated<br />

balconies <strong>the</strong> shipyard achieves a higher level <strong>of</strong> outfitting for <strong>the</strong> blocks that<br />

are already completely corrosion-protected at <strong>the</strong> time <strong>of</strong> assembly.<br />

NEWS IN BRIEF<br />

VR room in operation<br />

balcony plates. The complete unit is packed in<br />

protective plates and sheeting during preproduction<br />

to minimise later cleaning and to avoid<br />

damage as far as possible. The separating walls <strong>of</strong><br />

<strong>the</strong> individual balconies are laid on <strong>the</strong> finished<br />

deck as a material package and already assembled<br />

in <strong>the</strong> block after <strong>the</strong> balconies have been<br />

mounted. In this way more cost intensive<br />

production time in <strong>the</strong> building dock can be<br />

reduced. By using prefabricated balconies, and due<br />

to <strong>the</strong> fact that corrosion protection has already<br />

been completely applied early, it is possible to carry<br />

out <strong>the</strong> insulation <strong>of</strong> <strong>the</strong> door locks early too,<br />

which in turn allows more timely placing <strong>of</strong> <strong>the</strong><br />

finished cabins in <strong>the</strong> building dock.<br />

Using prefabricated balconies contributes to<br />

a considerable reduction <strong>of</strong> production time, a<br />

fur<strong>the</strong>r, important step to more efficient organisation<br />

<strong>of</strong> our procedures.<br />

Since May this year a Virtual Reality room has been available for <strong>the</strong> Design and Production departments to<br />

improve <strong>the</strong> quality <strong>of</strong> work still fur<strong>the</strong>r and to simplify it. Before a component or room is built specialists<br />

from Design and Production can have a look at <strong>the</strong> product from all sides in <strong>the</strong> virtual space to find any<br />

possible errors or to carry out improvements. In this way designs can be checked for <strong>the</strong>ir practical benefits<br />

before assembly and discussed toge<strong>the</strong>r with <strong>the</strong> owners.<br />

Delivery deadlines 2009<br />

This year, after AIDAluna in March, A-ROSA AQUA in June and Celebrity Equinox in July, no more<br />

additional ships will be delivered. In <strong>the</strong> coming year <strong>the</strong> following <strong>delivery</strong> dates are planned:<br />

S.680 > AIDAblu February 2010<br />

S.677 > Celebrity Eclipse April 2010

NEWS IN BRIEF<br />

Seventh River Cruise Ship for A-ROSA<br />

On 30 June 2009 NEPTUN WERFT in Rostock delivered <strong>the</strong> A-ROSA AQUA, <strong>the</strong> seventh ship, to <strong>the</strong> A-ROSA<br />

Flussschiff GmbH from Rostock. It is now <strong>the</strong> thirteenth river cruise ship that NEPTUN WERFT in<br />

Warnemünde has built since 2002. The ship that has just been delivered is a consistent continuation <strong>of</strong> <strong>the</strong><br />

unmistakeable A-ROSA river ship concept.<br />

The ship is 135 m long, 11.40 m wide, and has a draught <strong>of</strong> approx. 1.60 m; propulsion is effected by four<br />

rudder propeller systems. Due to its dimensions <strong>the</strong> ship can navigate all large European rivers and also <strong>the</strong><br />

Rhine-Main-Danube Canal.<br />

Third Club Ship for German Market Leader AIDA Cruises<br />

The 69.200-gt club ship AIDAluna was<br />

delivered to <strong>the</strong> Rostock-based cruise<br />

company AIDA Cruises in Emden on<br />

16 March 2009.<br />

The AIDAluna is <strong>the</strong> third ship in a<br />

series <strong>of</strong> a total <strong>of</strong> six club ships. More<br />

than 65% <strong>of</strong> <strong>the</strong> cabins are outside<br />

cabins, most <strong>of</strong> <strong>the</strong>se cabins have<br />

<strong>the</strong>ir own balconies. A highlight <strong>of</strong><br />

<strong>the</strong> AIDAluna is <strong>the</strong> first open air cinema<br />

on an AIDA ship. The LED screen,<br />

consisting <strong>of</strong> more than 186,000 LED<br />

lights, is 7.17 metres wide and<br />

4.03 metres high and promises<br />

passengers a very special cinema<br />

experience.<br />

With a diesel-electric propulsion system, interactive communications systems as well as extensive stage and<br />

entertainment technology on board, cutting edge safety and entertainment standards are guaranteed. On<br />

4 April <strong>the</strong> AIDAluna was <strong>of</strong>ficially named in <strong>the</strong> harbour <strong>of</strong> Palma de Mallorca by <strong>the</strong> top model Franziska<br />

Kn<strong>up</strong>pe.<br />

The s<strong>up</strong>plier ratings for this ship and for S. 676, Celebrity Solstice, will serve as <strong>the</strong> basis for <strong>the</strong> award<br />

Partner des Jahres 2009.<br />

IM DIALOG<br />

5

August 2009 | N o 04<br />

6 IM DIALOG<br />

Mr Gerst, please give us a brief overview <strong>of</strong> <strong>the</strong><br />

range <strong>of</strong> products and services <strong>of</strong>fered by Glüpker<br />

Blechtechnologie.<br />

As a high performance contract manufacturer in<br />

<strong>the</strong> sheet metal forming and processing sector we<br />

can produce and s<strong>up</strong>ply anything from simple tailored<br />

blanks, via edged parts <strong>up</strong> to complex welded<br />

subassemblies including mechanical processing and<br />

surface processing.<br />

To do this we can draw on <strong>the</strong> whole value creation<br />

chain <strong>of</strong> <strong>the</strong> Neuenhauser Gro<strong>up</strong> <strong>of</strong> Companies.<br />

The main focal points <strong>of</strong> our production are<br />

lasering, edging, welding, surface processing,<br />

assembly and logistics.<br />

How did you get in touch with MEYER WERFT?<br />

We had already made contact with MEYER WERFT<br />

in <strong>the</strong> past. At last year’s Regional Day <strong>the</strong> decisive<br />

step was made to expand our cooperation.<br />

What do you s<strong>up</strong>ply to MEYER WERFT?<br />

We produce and s<strong>up</strong>ply guide rails in steel and<br />

stainless steel for <strong>the</strong> window washing equipment<br />

for Celebrity Cruises and o<strong>the</strong>r large cruise<br />

companies, as well as gangways for <strong>the</strong> disembarkation<br />

platforms <strong>of</strong> new cruise ships.<br />

Our total volume currently amounts to about half a<br />

million Euros.<br />

Who are your main customers or which sectors do<br />

you mainly focus on?<br />

We s<strong>up</strong>ply customers in <strong>the</strong> automotive, agricultural<br />

machinery, wind energy and textile sectors<br />

and recently <strong>the</strong> shipbuilding sector, too.<br />

Some <strong>of</strong> our reference customers are Schmitz<br />

Cargobull, Claas Erntetechnik, Grimme Landmaschinenfabrik,<br />

Enercon and now MEYER WERFT<br />

as well.<br />

What do you think <strong>of</strong> MEYER WERFT’s idea <strong>of</strong><br />

building <strong>up</strong> a regional network? What does it<br />

promise for you?<br />

www.<strong>meyer</strong>werft.de<br />

SEIZE A CHANCE AS MEMBER OF THE REGIONAL SUPPLIER NETWORK<br />

Interview with Mr Jürgen Gerst,<br />

Technical Manager <strong>of</strong> Glüpker Blechtechnologie GmbH<br />

It’s a good idea to build <strong>up</strong> a regional network,<br />

particularly with <strong>the</strong> ongoing tendency for<br />

companies to specialise.<br />

As a member <strong>of</strong> your network we want to seize <strong>the</strong><br />

chance to make our products, services and<br />

specialisations accessible to a selected gro<strong>up</strong>.<br />

Making knowledge and expertise available but also<br />

receiving ideas and food for thought from network<br />

partners, for example in product development.<br />

I understand networks to mean give and take in<br />

equal measure in a partnership relationship.<br />

Elke Seitz from MEYER WERFT's Purchase Dept.<br />

talking to Jürgen Gerst<br />

How do you assess <strong>the</strong> future development <strong>of</strong><br />

Glüpker Blechtechnologie GmbH?<br />

We are working very intensively on continuing our<br />

strong growth <strong>of</strong> <strong>the</strong> past few years. We react with<br />

appropriate measures to changing market<br />

conditions. Alongside even greater flexibility and<br />

quicker reaction times, this particularly includes<br />

advanced training for our staff so that we can also<br />

be successful in <strong>the</strong> future in <strong>of</strong>fering our customers<br />

top service.<br />

Our declared aim is to increase our market share.<br />

Find more information on<br />

www.gluepker-blechtechnologie.de<br />

Contact<br />

Jürgen Gerst, Technical Management<br />

Glüpker Blechtechnologie GmbH<br />

Rudolf-Diesel-Straße 10<br />

49828 Neuenhaus, Germany<br />

Phone +49-5941 - 607-103

DEVELOPMENT OF MEYER WERFT LASERZENTRUM IS ON SCHEDULE<br />

Laser technology – this term is considered <strong>the</strong> epitome <strong>of</strong> future-oriented<br />

technologies. Here at MEYER WERFT Laserzentrum <strong>the</strong> future has already<br />

begun.<br />

Panel production line<br />

In <strong>the</strong> area <strong>of</strong> steel pre-production, <strong>the</strong> so called<br />

panel production, lasers are utilised to weld <strong>up</strong><br />

panel joints and pr<strong>of</strong>iles.<br />

Through investing a total <strong>of</strong> € 80 million, a completely<br />

new production line is being installed<br />

alongside <strong>the</strong> existing panel production line, with<br />

a maximum processing width <strong>of</strong> 20 m. This production<br />

line is in a position to produce 30 m long<br />

section elements and uses so-called disc lasers for<br />

<strong>the</strong> first time to weld <strong>up</strong> plate joints. In this way<br />

3 x 10 m steel plates become ship sections<br />

measuring 25 x 30 m.<br />

With <strong>the</strong> four CO2 laser systems already installed,<br />

having a total output <strong>of</strong> 72 kWh, <strong>the</strong> largest laser<br />

centre in Europe is being created with <strong>the</strong><br />

installation <strong>of</strong> <strong>the</strong> new disc lasers and an additional<br />

CO2 laser having an installed total output <strong>of</strong> 104 kWh.<br />

Synchronised serial production with defined<br />

procedures makes MEYER WERFT Laserzentrum a<br />

high-tech company employing 250 people.<br />

The finishing is taking shape. The steel work in <strong>the</strong><br />

new hall 10 is nearly complete. The cranes have<br />

been installed and <strong>the</strong> transport facilities are being<br />

built. Currently extensive tests are being carried<br />

out on <strong>the</strong> new disc laser. Thus nothing stands in<br />

<strong>the</strong> way <strong>of</strong> final commissioning as scheduled at <strong>the</strong><br />

end <strong>of</strong> November.<br />

IM DIALOG<br />

7

August 2009 | N o 04<br />

> Imprint<br />

Editor:<br />

MEYER WERFT GmbH<br />

Industriegebiet Süd<br />

D - 26871 Papenburg<br />

Materials Management/Purchasing<br />

Industriegebiet Süd<br />

D - 26871 Papenburg<br />

Tel. +49 (0)4961 / 81-0<br />

Fax +49 (0)4961 / 81-42 99<br />

Layout:<br />

eskalade werbeagentur GmbH<br />

info@eskalade.de<br />

www.eskalade.de<br />

Photos:<br />

MEYER WERFT, Ingrid Fiebak Fotografie,<br />

Hero Lang<br />

Fur<strong>the</strong>r information<br />

www.<strong>meyer</strong>werft.de<br />

www.<strong>meyer</strong>werft.de<br />

PAPENBURG FESTIVAL 22,000 VISITORS AND ONE SHIP<br />

Under bright sunshine 22,000 visitors turned <strong>up</strong> to <strong>the</strong> Papenburg Festival<br />

on <strong>the</strong> premises <strong>of</strong> MEYER WERFT on 13 June 2009. Against <strong>the</strong> impressive<br />

backdrop <strong>of</strong> <strong>the</strong> Celebrity Equinox, which had left <strong>the</strong> covered building<br />

dock one week earlier, Van Velzen, Ich & Ich, James Morrison, Stefanie<br />

Heinzmann and Reamonn created a great atmosphere for <strong>the</strong> visitors.<br />

After sunset <strong>the</strong> brightly lit Celebrity Equinox, which was also ba<strong>the</strong>d in<br />

coloured light from twelve searchlights, was a particular highlight. The<br />

evening ended with <strong>the</strong> current hits from Reamonn and a wonderful<br />

fireworks display.