Caterpillar - Finning Canada

Caterpillar - Finning Canada

Caterpillar - Finning Canada

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

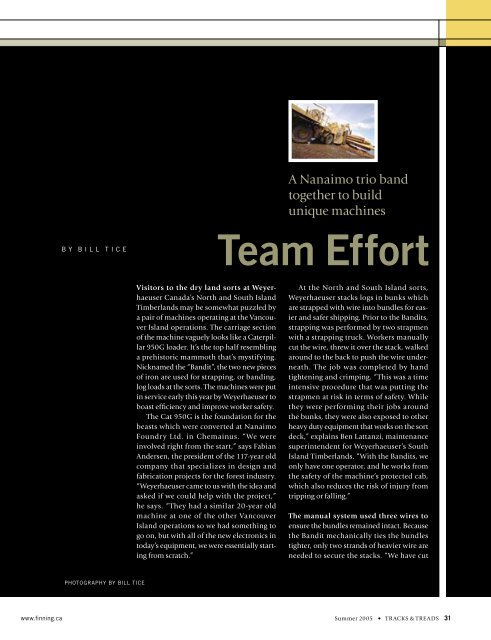

A Nanaimo trio bandtogether to buildunique machinesB Y B I L L T I C ETeam EffortVisitors to the dry land sorts at Weyerhaeuser<strong>Canada</strong>’s North and South IslandTimberlands may be somewhat puzzled bya pair of machines operating at the VancouverIsland operations. The carriage sectionof the machine vaguely looks like a <strong>Caterpillar</strong>950G loader. It’s the top half resemblinga prehistoric mammoth that’s mystifying.Nicknamed the “Bandit”, the two new piecesof iron are used for strapping, or banding,log loads at the sorts. The machines were putin service early this year by Weyerhaeuser toboast efficiency and improve worker safety.The Cat 950G is the foundation for thebeasts which were converted at NanaimoFoundry Ltd. in Chemainus. “We wereinvolved right from the start,” says FabianAndersen, the president of the 117-year oldcompany that specializes in design andfabrication projects for the forest industry.“Weyerhaeuser came to us with the idea andasked if we could help with the project,”he says. “They had a similar 20-year oldmachine at one of the other VancouverIsland operations so we had something togo on, but with all of the new electronics intoday’s equipment, we were essentially startingfrom scratch.”At the North and South Island sorts,Weyerhaeuser stacks logs in bunks whichare strapped with wire into bundles for easierand safer shipping. Prior to the Bandits,strapping was performed by two strapmenwith a strapping truck. Workers manuallycut the wire, threw it over the stack, walkedaround to the back to push the wire underneath.The job was completed by handtightening and crimping. “This was a timeintensive procedure that was putting thestrapmen at risk in terms of safety. Whilethey were performing their jobs aroundthe bunks, they were also exposed to otherheavy duty equipment that works on the sortdeck,” explains Ben Lattanzi, maintenancesuperintendent for Weyerhaeuser’s SouthIsland Timberlands. “With the Bandits, weonly have one operator, and he works fromthe safety of the machine’s protected cab,which also reduces the risk of injury fromtripping or falling.”The manual system used three wires toensure the bundles remained intact. Becausethe Bandit mechanically ties the bundlestighter, only two strands of heavier wire areneeded to secure the stacks. “We have cutPHOTOGRAPHY BY BILL TICEwww.finning.ca Summer 2005 • TRACKS & TREADS 31