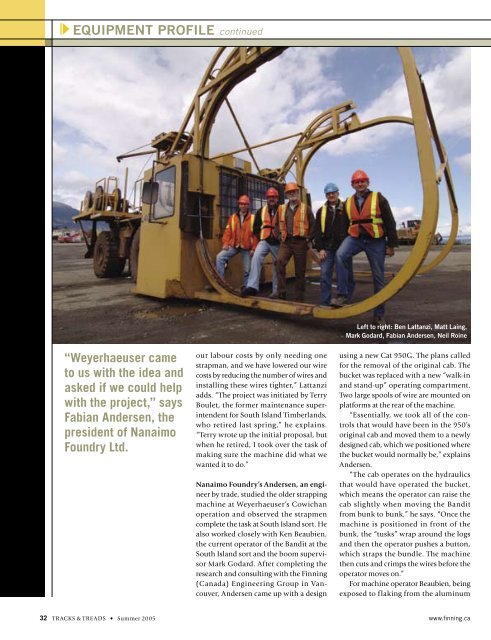

EQUIPMENT PROFILE continued“Weyerhaeuser cameto us with the idea andasked if we could helpwith the project,” saysFabian Andersen, thepresident of NanaimoFoundry Ltd.our labour costs by only needing onestrapman, and we have lowered our wirecosts by reducing the number of wires andinstalling these wires tighter,” Lattanziadds. “The project was initiated by TerryBoulet, the former maintenance superintendentfor South Island Timberlands,who retired last spring,” he explains.“Terry wrote up the initial proposal, butwhen he retired, I took over the task ofmaking sure the machine did what wewanted it to do.”Nanaimo Foundry’s Andersen, an engineerby trade, studied the older strappingmachine at Weyerhaeuser’s Cowichanoperation and observed the strapmencomplete the task at South Island sort. Healso worked closely with Ken Beaubien,the current operator of the Bandit at theSouth Island sort and the boom supervisorMark Godard. After completing theresearch and consulting with the <strong>Finning</strong>(<strong>Canada</strong>) Engineering Group in Vancouver,Andersen came up with a designLeft to right: Ben Lattanzi, Matt Laing,Mark Godard, Fabian Andersen, Neil Roineusing a new Cat 950G. The plans calledfor the removal of the original cab. Thebucket was replaced with a new “walk-inand stand-up” operating compartment.Two large spools of wire are mounted onplatforms at the rear of the machine.“Essentially, we took all of the controlsthat would have been in the 950’soriginal cab and moved them to a newlydesigned cab, which we positioned wherethe bucket would normally be,” explainsAndersen.“The cab operates on the hydraulicsthat would have operated the bucket,which means the operator can raise thecab slightly when moving the Banditfrom bunk to bunk,” he says. “Once themachine is positioned in front of thebunk, the “tusks” wrap around the logsand then the operator pushes a button,which straps the bundle. The machinethen cuts and crimps the wires before theoperator moves on.”For machine operator Beaubien, beingexposed to flaking from the aluminum32 TRACKS & TREADS • Summer 2005 www.finning.ca

“It was a real team effort between Weyerhaeuser,Nanaimo Foundry, the subcontractors and<strong>Finning</strong>,” says Ben Lattanzi, maintenancesuperintendent for Weyerhaeuser’s SouthIsland Timberlands.wires when operating the machine was aconcern. This inspired another innovativeidea for the Bandit.At the end of his shift, the operatorwas often covered with small fragmentsof aluminum. However, during the rainywinter months, Beaubien noticed flakingwas less of a problem because the wirewas wet. The mechanics at South IslandTimberlands came up with a spray systemto keep the wire damp. In the finaldesign, Andersen enhanced the optionwith a system that sprays soapy water onthe wire, alleviating the flaking problemcompletely.One of the biggest challenges on theproject was installing the controls intothe new cab arrangement. “The newmachines are proportionately electronicover hydraulic, so we spent a great dealof time getting the controls in the newcab operating,” Andersen says. “We havewhat looks like an elephant trunk full of18 gauge wire feeding into the new cab.”He enlisted the help of a couple of otherVancouver Island subcontractors for theproject. Cowichan Hydraulics EquipmentService and Supply Ltd. played asignificant role in the hydraulics, whileAmmeter Electric Ltd. contributed on theelectrical work.“It was a real team effort betweenWeyerhaeuser, Nanaimo Foundry, thesubcontractors and <strong>Finning</strong>,” says Weyerhaeuser’sLattanzi. “Without all of thesegroups participating, we could not havegot this project off the ground.”The carrier machine was sold through<strong>Finning</strong> Nanaimo, which brought generalline salesman Matt Laing, and Nanaimobasedproduct support rep Neil Roineinto the project.“Terry Boulet called me up and toldme what he had in mind, so we went outand had a chat about it,” explains Laing.“We sold a 950G loader without the cab,but more importantly, we were able to gothat extra mile to meet Weyerhaeuser’sexpectations and requirements.”For Roine, who spent many hours onthe project for <strong>Finning</strong>, the results wereworth the effort. “We were pleased withthe end result, and the customer waspleased,” he says. “We had worked withNanaimo Foundry on other projects inthe past, but mainly liners, buckets andother attachments,” Roine adds. “Thiswas definitely the biggest project we havecompleted with them.”Other log handling operations in B.C.have expressed interest in the Bandit.With the success at Weyerhaeuser, it mayonly be a matter of time before anotherjoint effort goes on the drawing boards atNanaimo Foundry.Second LifeNanaimo Foundry has a long, varied,and at times, tumultuous history inB.C.’s forest industry. The companywas founded in 1888 in the harbourcity of Nanaimo. In 1992, the companyneeded re-capitalizing. It waspurchased by a group that includescurrent president Fabian Andersen.“The company was in pretty toughshape when we bought it,” he recalls.“We remained in Nanaimo for a fewyears, and then as we started to buildthe business back up again, we movedthe company to Chemainus and constructeda brand new shop.”The new facility, which opened in1999, offers 20,000 square feet ofspace and an overhead crane for movingand positioning large components.Nanaimo Foundry still specializes inthe forest industry, including the pulpand paper sector, but has also completedprojects for construction andcement companies.In addition to custom design, fabricationand machining services, thecompany has a construction side. NFInstallations is a wholly owned subsidiaryof Nanaimo Foundry, specializingon installations for the forest industry.“We have the design, supply, andinstallation capabilities all within onecompany,” notes Andersen. “Thatdiversity has helped us build NanaimoFoundry back up, and will take us intothe future.”www.finning.ca Summer 2005 • TRACKS & TREADS 33