154 Rev.F.vp - Reliable Automatic Sprinkler Co.

154 Rev.F.vp - Reliable Automatic Sprinkler Co.

154 Rev.F.vp - Reliable Automatic Sprinkler Co.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

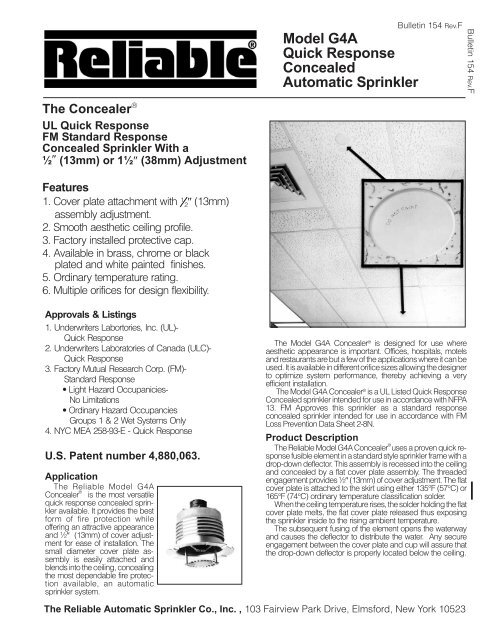

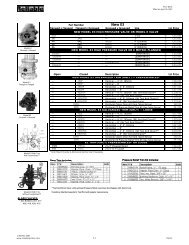

Bulletin <strong>154</strong> <strong>Rev</strong>.FBulletin <strong>154</strong> <strong>Rev</strong>.FModel G4AQuick Response<strong>Co</strong>ncealed<strong>Automatic</strong> <strong>Sprinkler</strong>The <strong>Co</strong>ncealer UL Quick ResponseFM Standard Response<strong>Co</strong>ncealed <strong>Sprinkler</strong> With a½ (13mm) or 1½ (38mm) AdjustmentFeatures1. <strong>Co</strong>ver plate attachment with 1 2 (13mm)assembly adjustment.2. Smooth aesthetic ceiling profile.3. Factory installed protective cap.4. Available in brass, chrome or blackplated and white painted finishes.5. Ordinary temperature rating.6. Multiple orifices for design flexibility.Approvals & Listings1. Underwriters Labortories, Inc. (UL)-Quick Response2. Underwriters Laboratories of Canada (ULC)-Quick Response3. Factory Mutual Research <strong>Co</strong>rp. (FM)-Standard Response• Light Hazard Occupanicies-No Limitations• Ordinary Hazard OccupanciesGroups 1 & 2 Wet Systems Only4. NYC MEA 258-93-E - Quick ResponseU.S. Patent number 4,880,063.ApplicationThe <strong>Reliable</strong> Model G4A<strong>Co</strong>ncealer ®is the most versatilequick response concealed sprinkleravailable. It provides the bestform of fire protection whileoffering an attractive appearanceand ½ (13mm) of cover adjustmentfor ease of installation. Thesmall diameter cover plate assemblyis easily attached andblends into the ceiling, concealingthe most dependable fire protectionavailable, an automaticsprinkler system.The Model G4A <strong>Co</strong>ncealer ® is designed for use whereaesthetic appearance is important. Offices, hospitals, motelsand restaurants are but a few of the applications where it can beused. It is available in different orifice sizes allowing the designerto optimize system performance, thereby achieving a veryefficient installation.The Model G4A <strong>Co</strong>ncealer ® is a UL Listed Quick Response<strong>Co</strong>ncealed sprinkler intended for use in accordance with NFPA13. FM Approves this sprinkler as a standard responseconcealed sprinkler intended for use in accordance with FMLoss Prevention Data Sheet 2-8N.Product DescriptionThe <strong>Reliable</strong> Model G4A <strong>Co</strong>ncealer ® uses a proven quick responsefusible element in a standard style sprinkler frame with adrop-down deflector. This assembly is recessed into the ceilingand concealed by a flat cover plate assembly. The threadedengagement provides ½ (13mm) of cover adjustment. The flatcover plate is attached to the skirt using either 135°F (57C) or165F(74C) ordinary temperature classification solder.When the ceiling temperature rises, the solder holding the flatcover plate melts, the flat cover plate released thus exposingthe sprinkler inside to the rising ambient temperature.The subsequent fusing of the element opens the waterwayand causes the deflector to distribute the water. Any secureengagement between the cover plate and cup will assure thatthe drop-down deflector is properly located below the ceiling.The <strong>Reliable</strong> <strong>Automatic</strong> <strong>Sprinkler</strong> <strong>Co</strong>., Inc. , 103 Fairview Park Drive, Elmsford, New York 10523

InstallationDo not install the G4A <strong>Co</strong>ncealer ®in ceilings which havepositive pressure in the space above.• Cut a 2 5 8 inch (67mm) diameter hole is cut in the ceiling, thesprinkler is easily installed with the Model G4 Wrench. Thewrench has drive tangs which insert into the cup slots.When installing a sprinkler the wrench is first positioned intothe sprinkler/cup assembly until the wrench tangs engagethe drive slots in the top of the cup (there are two sets ofdrive slots in the cup). The sprinkler is then tightened intothe pipe fitting. When inserting or removing the wrench fromthe sprinkler/cup assembly, care should be taken to preventdamage to the sprinkler. DO NOT WRENCH ON ANYOTHER PART OF THE SPRINKLER/CUP ASSEMBLY.Install the cover plate by hand turning the cover in theclockwise direction until it is tight against the ceiling.A protective cap is provided to protect the drop-down sprinklerdeflector from damage which could occur during constructionbefore the cover plate is installed. The cap is factory installedinside the sprinkler cup. Remove cap to install sprinkler, thenre-install cap until the cover plate is installed.MaintenanceThe Model G4A <strong>Co</strong>ncealer should be inspected quarterlyand the sprinkler system maintained in accordance with NFPA25. Do not clean sprinklers with soap and water, ammonia or anyother cleaning fluids. Remove any sprinkler that has beenpainted (other than factory applied) or damaged in any way. Astock of spare sprinklers should be maintained to allow quickreplacement of damaged or operated sprinklers. Prior toinstallation, sprinklers should be maintained in the originalcartons and packaging to minimize the potential for damage tosprinklers that would cause improper operation or non-operation.Technical DataOrdering Information1. <strong>Sprinkler</strong> Model2. Nominal Orifice3. Flat <strong>Co</strong>ver PlateAssembly Finish4. Inlet Type<strong>Co</strong>ver Plate Finishes (1)Standard FinishesBronzeChromeWhite PaintSpecial ApplicationFinishesBright BrassBlack PlatingBlack PaintOff WhiteSatin Chrome(1) Other finishes and colors areavailable on special order.<strong>Co</strong>nsult factory for details.Temperature RatingClassification<strong>Sprinkler</strong>Model G4 <strong>Sprinkler</strong>WrenchUL Listing Category<strong>Sprinkler</strong>s, <strong>Automatic</strong> andOpenQuick Response <strong>Sprinkler</strong>UL Guide NumberVNIV<strong>Co</strong>verPlateMax. AmbientTemp.Ordinary 165F/74C 135F/57C 100F/38COrdinary 212F/100C 165F/74C 150F/66C<strong>Sprinkler</strong> InletTotalNominal Nominal K FactorAdjustment OrificeThreadApprovals<strong>Sprinkler</strong>US MetricIdentifcation (SIN)Non Adjustable ½ (13mm) ½ (15mm) 5.6 80 ½ NPT (R½) 1,2,3,4 R5415Non Adjustable ½ (13mm)716 (11mm) 4.2 60 ½ NPT (R½) 1,2,4 R5413Non Adjustable ½ (13mm)38 (10mm) 2.8 40 ½ NPT (R½) 1,2,3,4 R5411Adjustable 1½ (38mm) ½ (15mm) 5.6 80 1 NPT Male or Female 1,2,4 R5418Adjustable 1½ (38mm)716 (11mm) 4.2 60 1 NPT Male or Female 1,2,4 R5413Adjustable 1½ (38mm)38 (10mm) 2.8 40 1 NPT Male or Female 1,2,4 R5412Fig.1 - ½ NPT Non-Adjustable Inlet Fig. 2 - 1 NPT Male-Adjustable Inlet Fig. 3 - 1 NPT Female-Adjustable InletThe equipment presented in this bulletin is to be installed in accordance with the latest published Standards of the National Fire Protection Association, Factory MutualResearch <strong>Co</strong>rporation, or other similar organizations and also with the provisions of governmental codes or ordinances whenever applicable.Products manufactured and distributed by <strong>Reliable</strong> have been protecting life and property for over 80 years, and are installed and serviced by the most highly qualifiedand reputable sprinkler contractors located throughout the United States, Canada and foreign countries.The <strong>Reliable</strong> <strong>Automatic</strong> <strong>Sprinkler</strong> <strong>Co</strong>., Inc.(800) 431-1588 Sales Offices(800) 848-6051 Sales Fax(914) 829-2042 <strong>Co</strong>rporate Officeswww.reliablesprinkler.com Internet AddressRecycledPaper<strong>Rev</strong>ision lines indicate updated or new data.EG. Printed in USA 4/07 P/N 9999970150