Automotive Refinishing Policy Manual - Sacramento Metropolitan Air ...

Automotive Refinishing Policy Manual - Sacramento Metropolitan Air ...

Automotive Refinishing Policy Manual - Sacramento Metropolitan Air ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Automotive</strong>, Truck and Heavy Equipment<strong>Refinishing</strong> <strong>Policy</strong> <strong>Manual</strong>November 20, 2008Updated: 4/30/12

A. DESCRIPTIONThis chapter describes requirements needed to apply for and obtain an Authority to Construct andsubsequent Permit to Operate paint spray booths used for automotive, truck, and heavy equipmentrefinishing.B. APPLICATIONS1. Application Requirementsa. A Permit is required for all <strong>Automotive</strong> <strong>Refinishing</strong> Operations performed with or without aPaint Spray Booth that either:• Has not been granted a NESHAP 6H exemption from EPA.• Use more than one gallon of coatings and solvents combined during any one day.• Emit more than 2 lbs of Volatile Organic Compounds (VOCs) for any given 24 hourperiod, calculated without including the benefit of any air pollution control devicesinstalled.b. Each Paint Spray Booth will be permitted individuallyc. VOC content data for all coatings and solvents not exempted below shall be supplied from amanufacturer’s, Product Data Sheet, MSDS, etc., unless the District has received a ProductData Report from the manufacturer for the products. It is the applicant’s responsibility tosupply the data or ensure that the data is provided to the District.d. All combustion based drying equipment with the coating operation shall be permitted with thebooth if the material to be heated comes in direct contact with the products of combustion.e. All proposed air pollution control devices and combustion equipment directly associated withthe Coating Operation except as exempted above in section d. (dryers, etc.) will be permittedseparately from the Coating Operation.f. All coating operations are required to obtain a permit unless the <strong>Air</strong> Pollution Control Officerissues a written exemption letter. (See exemption determinations below)2. Permit to Operate Exemptions:Rule 201 – General Permit Requirements Surface coating operations using a combined total of one gallon per day or less of coatingmaterial and solvent are exempt from needing a permit as long as the coating operation is notsubject to a NESHAP3. Prohibitory Rule Exemptions:Rule 459 – <strong>Automotive</strong> <strong>Refinishing</strong> Aerosol Coating Products - All aerosol coating products packaged in a disposable can forhand-held application or for use in specialized equipment for ground traffic/markingapplications are exempt from this rule. Application Methods – The application methods specified in Section 306 shall not apply to theapplication of underbody coatings, truck bed liner coatings, graphic arts coatings or to anycoating that is applied from a container with a capacity of no more than one fluid ounce in aquantity of no more than one fluid ounce. Assembly Line – Any coatings applied to motor vehicles or mobile equipment, or theirassociated parts and components, during manufacture on an assembly line at an originalequipment manufacturing plant. Touch-up –o Until 6 months after date of adoption, the provisions of this rule do not apply to thesale or use of touch-up coatings dispensed in containers of two ounces or lesso Effective 6 months after date of adoption, coatings that are sold, supplied, or offeredfor sale in containers of 0.5 fluid ounce or less and are intended to be used by thegeneral public to repair tiny surface imperfections are exempt from the provisions ofthis rule.VI-1

Materials for Vehicles – The requirements of section 303 shall not apply to any motor vehicle,mobile equipment, or associated parts and components coating operations at a stationarysource with actual emissions from such operations less than 2.7 tons of VOC prior toemissons control equipment per 12-month rolling period.4. Data FormsThe following forms must be completed by the person submitting an application (these forms areused by the District to characterize the type of product to be coated, coatings and materials to beused, booth size/flow rates, filtration and exhaust control devices):Form G100: Application for Authority to Construct and/or Permit to Operate (2 pages)Form G101: General Information FormForm AC100: <strong>Automotive</strong> Coating Operations (Coating and Solvent Usage form included)Form HRA100: Health Risk Assessment Analysis Information FormC. COMPLETENESSThe following information is needed to make this determination:1. The Authority to Construct application form completely filled out and the initial permit fee mustaccompany the forms. (see Section D below).2. The applicable forms listed in Section B must be completely filled out by the applicant.3. Any additional information needed to calculate the emissions from the source, and to quantifyemissions from the proposed source(s) of offsets (if applicable).4. Any additional information needed to complete a health risk assessment.D. FEES1. New <strong>Automotive</strong> <strong>Refinishing</strong> Operations• Coating Operations with a Paint Spray Booth: Use Schedule 1 (see Rule 301, Section308.2). Fees are based on the rated horsepower of the exhaust fan on the booth. Use theInitial Permit Fee column for new installations or equipment not previously permitted.• Coating Operations without a Paint Spray Booth: Use Schedule 9 (see Rule 301, Section308.10)• Coating operations with a booth and associated dryer use either schedule 1 or 2, whicheverresults in a higher fee2. Modifications:• For modifications of permitted equipment resulting in an increase in the compressor’shorsepower, the fee is assessed in accordance with fee schedule 1 (Rule 301, Section308.2), based on the incremental increase in horsepower resulting from such change (seeRule 301,Section 306.1)• For modifications resulting in no increase in the exhaust fan’s horsepower, the fee shall bebased on Rule 301, Section 306.2.3. Installed Without an Authority to Construct (Existing Equipment):• As per Section 302.1 of Rule 301, any person installing/operating regulated equipmentwithout obtaining a permit from the SMAQMD first, will be required to pay permit renewalback fees for each year of unpermitted operation, to a maximum of 3 years, in addition tothe initial permit fee.E. REGULATIONS<strong>Automotive</strong> <strong>Refinishing</strong> operations within the jurisdiction of the SMAQMD may be subject to some or all ofthe following rules and regulations. The type of operation, size of source, potential to emit, and otherfactors will dictate which rules are appropriate for a refinishing application. Other rules may also apply.1. SMAQMD Rules and Regulations (please refer to the actual rules for applicability andcompliance determinations):a. Rule 102 -- Circumvention:VI-2

This rule makes it unlawful for a person to circumvent any applicable sectionof the SMAQMD rules and regulations.b. Rule 201 -- General Permit Requirements:This rule provides an orderly procedure for the review of new or modifiedsources of air pollution and operation of existing sources through the issuanceof permits.c. Rule 202 -- New Source Review:The purpose of this rule is to provide for the review of new and modifiedstationary sources of air pollution and to provide mechanisms, includingemissions offsets and BACT, by which authorities to construct such sourcesmay be granted without interfering with the attainment or maintenance ofambient air quality standards.d. Rule 207 -- Title V - Federal Operating Permit Program:This rule establishes an operating permit program consistent with therequirements of Title V of the 1990 Clean <strong>Air</strong> Act Amendments and 40 CFR,Part 70.e. Rule 209 -- Limiting Potential to Emit:The purpose of this rule is to eliminate the need for small stationary sources toobtain a Title V operating permit pursuant to Rule 207.f. Rule 210 -- Synthetic Minor Source Status:The purpose of this rule is to allow owner and operators of stationary sourcesthat would otherwise be major stationary sources to request and acceptenforceable emissions limits sufficient to maintain the facility's potential toemit below major source thresholds.g. Rule 214 -- Federal New Source ReviewThe purpose of this rule is to provide for the issuance of authorities toconstruct and permits to operate at new and modified major stationary airpollution sources and to provide mechanisms, including emission offsets, bywhich authorities to construct such sources may be granted without interferingwith the attainment or maintenance of ambient air quality standards.h. Rule 217 -- Public Notice Requirement for Permits:The purpose of this rule is to provide an administrative mechanism for publicnotification and review of the issuance of authorities to construct and permitsto operate at new and modified stationary air pollution sources.i. Rule 301 -- Permit Fees - Stationary Source:The purpose of this rule is to establish fees to be charged to owners/operatorsof a stationary source to obtain a permit.j. Rule 306 -- <strong>Air</strong> Toxics Fees:This rule establishes fees to be charged stationary sources subject to the <strong>Air</strong>Toxics "Hot Spot" Information and Assessment Act (H&S Code, § 44300)k. Rule 401 -- Ringelmann Chart:This rule limits the discharge of air contaminants into the atmosphere bylimiting visible emissions.l. Rule 402 -- Nuisance:The purpose of this rule is to protect the public's health and welfare from theemissions of air contaminants which constitute a nuisance.m. Rule 406 -- Specific Contaminants:For coating operations with a fuel-fired dryer - This rule limits emissions ofsulfur compounds and combustion contaminants through establishment ofemission concentration limitations.n. Rule 420 -- Sulfur Content of Fuels:For coating operations with a fuel-fired dryer - This rule limits the sulfurcontent of gaseous and liquid fuels.o. Rule 459 -- <strong>Automotive</strong>, Truck, and Heavy Equipment <strong>Refinishing</strong> Operations:This source specific rule establishes VOC coating limits, record keepingrequirements, and other requirements for the finishing or refinishing ofvehicles and other heavy equipment.VI-3

2. State Requirementsa. California Health & Safety Code, Part 6 (commencing with section 44300) -- <strong>Air</strong> Toxics "HotSpots Information and Assessment Act of 1987:Facilities subject to this requirement must identify and quantify emissions of toxic aircontaminants. Facilities posing a potential health risk to the public must prepare a health riskassessment and if required, notify the public and implement a risk reduction plan.b. California Health & Safety Code §42301.6 -- Permit Approval: Powers & Duties of APCO:Prior to approving an application for a permit to construct or modify a source which emitshazardous air pollutants, which source is located within 1,000 feet from a school site, theDistrict must prepare a public notice. The notice must be sent to parent or guardians ofchildren enrolled in any school located within 1/4 mile of the source and to each addresswithin a radius of 1,000 feet of the source at least 30 days prior to taking final action on theapplication.In addition, Coating Operations locating within 1,000 feet from a school may be required toreduce hazardous air pollutant emissions and their associated health risk to the maximumextent deemed practicable. This may include, but is not limited to, emissions limitations,stack height requirements, hours of operation restrictions, and add-on control devices.c. California Code of Regulations, Title 17, Section 93112. Hexavalent Chromium and Cadmium<strong>Air</strong>borne Toxic Control Measure (ATCM) -- Motor Vehicle and Mobile Equipment Coatings:This <strong>Air</strong>borne Toxic Control Measure prohibits the use of hexavalent chromium and cadmiumin coatings used for motor vehicles and mobile equipment.3. Federal Requirementsa. 40 CFR PART 52.21 Prevention of Significant Deterioration of <strong>Air</strong> Quality (PSD): A source ormodification triggers PSD if: Its potential to emit any one pollutant is greater than 100 tons/year (if one of the 28selected industrial categories, including utility plants, steel plants, refineries, boilers>250 MMBtu/hr heat inpit) or greater tthan 250 tons/year (all other categories). And The project’s contemporaneous emissions increase and net emissions increase forany pollutant is greater than the significance levels listed below:PollutantLevel of Significance (Tons/Yr)CO 100NOx 40SOx 40PM 25PM10 15PM2.510 (PM2.5) or 40 (SO2) or 40 (NO)Ozone40 of NOx or VOCsLead 0.6Flourides 3Sulfuric acid mist 7H 2 S 10Total reduced sulfur (including H 2 S) 10Reduced sulfur compounds (including H 2 S) 10Greenhouse Gases (CO2e) 75,000b. 40 CFR Part 63, subpart IIII, National Emission Standards for Hazardous <strong>Air</strong> Pollutants:Surface Coating of Automobiles and Light-Duty Trucks: This NESHAP applies to automobileand light-duty truck finishing operations located at or is part of a major source. A majorsource of HAP emissions is defined as a stationary source or group of stationary sourceslocated within a contiguous area and under common control that emits or has the potential toemit 10 tons or more per year of any single HAP or 25 tons per year of any combination ofHAPs.VI-4

c. 40 CFR Part 63, subpart HHHHHH, National Emission Standards for Hazardous <strong>Air</strong>Pollutants: Paint Stripping and Miscellaneous Surface Coating Operations as Area Sources:This rule applies to all motor vehicle and mobile equipment surface coating operations thatuse coatings that contain a target Hazardous <strong>Air</strong> Pollutant (compounds of chromium, lead,manganese, nickel, or cadmium) and are not a major source of Hazardous <strong>Air</strong> Pollutants(HAPs). Major sources of HAPs need to comply with 40 CFR Part 63, subpart IIII (seeSection 3.a, above). A facility may petition US EPA for an exemption if it can demonstratethat none of the coatings sprayed contain a target HAP.Facilities subject to this regulation must submit an initial notification, certify compliance, usecertain management practices, train painters, and keep records. Some facilities may alsohave to submit an annual report.F. STANDARDS AND REQUIREMENTSThe following standards and/or requirements must be met in order to obtain an Authority to Constructand/or a Permit to Operate:1. Regulation 4 -- Prohibitory Rules:a. Rule 401, Section 301: Visible emissions may not exceed No. 1 on the Ringelmann Chart or20% opacity for more than three minutes in any one hour.b. Rule 402, Section 301: A person cannot discharge pollutants which cause injury, detriment,nuisance or annoyance to any considerable number of persons or which endanger thecomfort, repose, health or safety of any such person, or which may cause damage tobusiness or property.c. Rule 406, Section 302: Combustion contaminant concentration at point of discharge shall notexceed 0.1 grains per dry standard cubic foot of gas, corrected to 12% carbon dioxide.d. Rule 420, Section 301: Gaseous fuels shall have a sulfur content not to exceed 50 grains per100 cubic feet of gaseous fuel calculated as hydrogen sulfide at standard conditions. Liquidor solid fuels shall have a sulfur content not to exceed 0.5% by weight. Standard CARBdiesel complies with this requirement at 0.05% sulfur by weight.e. Rule 459 RequirementsStandardsSection 301: Vehicle Coating/Material Limits - VOC regulatory content of coatings/Materialsapplied to any motor vehicle, mobile equipment, or associated parts and components:Coating/Material Category(See following page for Rule 459Definitions)VOC Regulatory Limit As Appliedgrams/liter (lb/gal)Adhesion Promoter 540 (4.5)Clear Coating 250 (2.1)Color Coating 420 (3.5)Multi-color CoatingMobile equipment driven or drawn onrails and its associated parts andcomponents520 (4.3)Any other mobile equipment or motorvehicle and its associated parts andcomponents680 (5.7)Pretreatment Coating 660 (5.5)Primer/Primer Sealer 250 (2.1)Single-Stage Coating 340 (2.8)VI-5

Temporary Protective Coating 60 (0.5)Truck Bed Liner Coating 200 (1.7)Underbody Coating 430 (3.6)Uniform Finish Coating 540 (4.5)Any Other Coating Type 250 (2.1)Gasket/Gasket Sealing Material 200 (1.7)Cavity Wax Material 650 (5.4)Deadener Material 650 (5.4)Lubricating Wax/Compound Material 700 (5.8)Rule Definitions of Coatings -Adhesion Promoter – Any coating which is labeled and formulated to be applied touncoated plastic surfaces to facilitate bonding of subsequent coatings and on which asubsequent coating is applied.Cavity Wax – A material or coating applied into cavities of the vehicle primarily for thepurpose of enhancing corrosion protection.Clear Coating – Any coating that contains no pigments and is labeled and formulated forapplication over a color coating or clear coating.Color Coating – Any pigmented coating, excluding adhesion promoters, primers, andmulti-color coatings, that requires a subsequent clear coating and which is applied over aprimer, adhesion promoter, or color coating. Color coatings include metallic/iridescentcolor coatings.Deadener – A material or coating applied to selected vehicle surfaces primarily for thepurposes of reducing the sound of road noise in the passenger compartment.Gasket/Gasket Sealing Material – Any fluid applied to coat a gasket or replace andperform the same function as a gasket including room temperature vulcanization sealmaterial.Lubricating Wax/Compound – Any protective lubricating material applied to vehicle hubsand hinges.Metallic/Iridescent Topcoat - Any coating that contains more than 5 g/l (0.042 lb/gal) ofmetal or iridescent particles, as applied, where such particles are visible in the dried film.Multi-color Coating – Any coating that exhibits more than one color in the dried film aftera single application, is packaged in a single container, and hides surface defects onareas of heavy use, and which is applied over a primer or adhesion promoter.Pretreatment Coating - Any coating which contains a minimum of 0.5% percent acid byweight and not more than 16% solids by weight, necessary to provide surface etchingand is labeled and formulated for application directly to bare metal surfaces to providecorrosion resistance and adhesion.Primer – Any coating which is labeled and formulated for application to a substrate toprovide: a bond between the substrate and subsequent coats; corrosion resistance; asmooth substrate surface; or resistance to penetration of subsequent coats, and on whicha subsequent coating is applied. Primers may be pigmented.Primer Sealer: - Any coating which is labeled and formulated for application prior to theapplication of a color coating for the purpose of color uniformity, or to promote the abilityof the underlying coating to resist penetration by the color coating.Single-Stage Coating – Any pigmented coating, excluding primers, primer sealers, andmulti-color coatings, labeled and formulated for application without a subsequent clearcoat. Single-stage coatings include single-stage metallic/iridescent coatings.Temporary Protective Coating - Any coating formulated for the purpose of temporarilyprotecting areas from overspray or mechanical damage.Truck Bed Liner Coating – Any Coating, excluding clear, color, multi-color and singlestagecoatings, labeled and formulated for application to a truck bed to protect it fromsurface abrasion.VI-6

Underbody Coating – Any coating labeled and formulated for application to wheel wells,the inside of door panels or fenders, the underside of a trunk or hood, or the underside ofthe motor vehicle.Uniform Finish Coating – Any coating formulated for application to wheel wells, the insideof door panels or fenders, the underside of a trunk or hood, or the underside of the motorvehicle.Section 304: VOC limit Alternative - Use of air pollution control equipment with an overallefficiency of no less than 85% is an acceptable alternative to compliance with VOC coatinglimits.Section 305: Application Equipment - Application of all coatings subject to this rule shall bedone by one the following methods:- Electrostatic application equipment- High Volume Low Pressure (HVLP) spray equipment- Low Volume Low Pressure (LVLP) spray equipment- Brush or Roll coating, dip coat, or flow coat- Any other application method that achieves a transfer efficiency equivalent to orhigher than the above listed application equipment and is approved in writing by the<strong>Air</strong> Pollution Control Officer and submitted to and approved by the U.S. EPASection 306-308: No person shall sell, possess, or specify the use of any coatings that arenon-compliant with Section 301 VOC limits within the jurisdiction of the District unless thecoatings are used exclusively within an emission control system as allowed in Section 304.Section 309: Solvent Cleaning Operations and Storage Requireements – Coating operationsmust meet the following requirements:- Cloths, sponges, and paper used for cleanup and coating removal shall be disposedof in closed containers- All materials containing VOCs shall be kept in closed containers when not in use- A person shall not perform cleaning operations using a solvent with a volatile organiccompound content in excess of 25 grams per liter (0.21 pounds per gallon), asdetermined pursuant to Section 409.- For bug and tar removal, a person shall not use any solvent other than bug and tarremover regulated under the Consumer Products Regulation (California Code ofRegulations Section 94507 et seq.) or a solvent with a volatile organic compoundcontent of no more than 25 grams per liter.Section 310: Coating Remover (Stripper) – Coating removers shall not exceed a VOCcontent of 200 grams/liter (1.7 lbs/gallon)Other Standards:- No Motor Vehicle and/or Mobile Equipment coating used at a facility shall containHexavalent Chromium or Cadmium.- All booths with dry-filter type or waterwash exhaust controls, the exhaust systems shalloperate whenever spraying occurs. The exhaust particulate filters on dry-filter typebooths shall be installed correctly and maintained properly.VI-7

Administrative/Recordkeeping RequirementsThe following shall be kept on-site at each coating operation:At all times, a list of currently used coatings and solvents that contains the followinginformation- The material name and manufacturer.- The application method used- The coating type as designated by the coating categories in Section 301 and themix ratio specific to the coating.- Identification of the material as a coating or solvent.- Product data sheets for each coating and solvent that includes the informationoutlined in Section 401.On a monthly basis- Monthly purchase records identifying the coating type,name/code/manufacturer, and purchased volume of each material(gal/month).- For coatings containing tertiary butyl acetate, monthly records regardinguse, including name/code/manufacturer of the coating and content oftertiary butyl acetate contained in each coating.On a quarterly and annual basis- Total VOC emissions from coating operation (lb/qtr, lb/year) (see Section G)2. Nuisance – Public Healtha. Toxics Review:The District evaluates the impact of airborne toxics released from a facility or project pursuantto SMAQMD’s guidance document, HEALTH RISK MANAGEMENT PROGRAMS FOREXISTING, MODIFIED AND NEW STATIONARY SOURCES. The action levels aresummarized below. Please refer to the actual guidance document for more detail on how tocalculate and interpret health risk:Cancer Risk:Excess Cancer Risk≤ 0.1 per millionAction RequiredExempt from further toxic review.> 0.1 per million but ≤ 1 per million No significant risk; No action required.> 1 per million but ≤ 10 per million Acceptable risk; Provide TBACT> 10 per million but ≤ 100 per million Permit denied unless the APCO makes afinding that not approving the project mayresult in a greater negative impact to the publicthan approving the project.> 100 per million Denial of permit.Non-Cancer Health Risk (Acute and Chronic):Hazard Index (HI)HI < 1HI ≥ 1Action RequiredHealth risk is within acceptable rangeConsult OEHHA for further guidanceWhen evaluating the cancer and non-cancer risks, the specific toxic air pollutants that need tobe addressed are those that have potency values or reference exposure levels identified inVI-8

the OEHHA’s Health Risk Assessment Guidelines(http://www.oehha.ca.gov/air/hot_spots/index.html)b. T-BACT Determinations:If the applicant chooses to operate a system that exceeds the health risk limit of one in onemillion, Toxic-Best Available Control Technology (T-BACT) is required. <strong>Automotive</strong><strong>Refinishing</strong> operations that fall into this category must reduce coating usage or proposecoating/solvent replacements that drop the booth and facility risk levels to acceptable limits.Otherwise, the booth shall maintain a 90% capture efficiency and 95% destruction/removalefficiency for emissions of toxic air contaminants. In addition, the health risk number may notexceed 10 in one million for this situation. For projects requesting greater than 10 in onemillion, call the SMAQMD for more information on what is required.The following exhaust controls may be used as T-BACT emission control devices:PollutantROCT-BACT for <strong>Automotive</strong><strong>Refinishing</strong>Catalytic/Thermal IncineratorsCarbon Adsorption3. New Source Review -- BACTa. Applicability:Rule 202, Section 301, requires that any new or modified emissions unit which results in anincrease in potential quarterly emissions for any affected pollutant having the potential to emitat levels exceeding those specified below, must apply Best Available Control Technology(BACT) for that pollutant.PollutantVOCNOxSOxPM10PM2.5COLeadBACT Trigger Level0 lb/day0 lb/day0 lb/day0 lb/day0 lb/day550 lb/day3.3 lb/dayb. VOC BACT Determinations:Applicants must provide BACT for new or modified stationary sources where the unitemission increase for the system exceeds the VOC limit of 0 lbs/day as proposed. BACT forautomotive refinishing operations without add-on controls is currently considered to be low-VOC coatings, high-efficiency spray application, solvent clean-up and surface preparationthat is in compliance with Rule 459 coupled with a 4,700 lb/qtr and 4,700 lb/year VOCemissions limit. This is the limit at which add-on exhaust controls are not cost-effective, aspreviously determined by the District under BACT determination number 22. For larger paintspray booths with exhaust flow rates of 30,000 acfm or more, use of the previously statedlimit to avoid add-on controls does not apply and an individualized BACT determination shallbe performed.The District may require a different more stringent technology/standard as BACT pursuant toRule 202, Section 204.1b.VI-9

4. New Source Review -- Emission OffsetsApplicants must provide emissions offsets for new or modified stationary sources where thecumulative emission increase for the facility exceeds the following levels (Rule 202, §302):PollutantPounds/QuarterVolatile Organic Compounds (VOC) 5,000Nitrogen Oxides (NOx) 5,000Sulfur Oxides (SOx) 13,650PM10 7,300PM2.515 TPYCarbon Monoxide (CO) 49,5005. New Source Review - California Environmental Quality Act (CEQA)The SMAQMD has developed a comprehensive permitting CEQA Guidance document. Projectreviews conducted in accordance with the policy manuals contained therein (including thismanual) have been determined to meet the CEQA criteria of ministerial and do not requireadditional CEQA review.In the event a project falls outside the scope of this policy manual (for example a new BACTdetermination or other situation already described within the CEQA guidance document), theproject shall follow the steps for CEQA review as detailed in the guidance document."6. Rule 217 – Public Notice Requirements for PermitsPrior to approving and Authority to Construct application for a new or modified stationary sourceor emissions unit which has an increase in potential to emit exceeding any of the following limitsor where emission offsets are required pursuant to Rule 202, the District must submit apreliminary decision to CARB and EPA for review and publish the preliminary decision solicitingpublic review and comment at least 30 days prior to final action on the application.PollutantPounds/QuarterVolatile Organic Compounds (VOC) 5,000Nitrogen Oxides (NOx) 5,000Sulfur Oxides (SOx) 9,200PM10 7,300PM2.510 TPYCarbon Monoxide (CO) 49,500VI-10

G. CALCULATING EMISSIONS1. Calculating Volatile Organic Compounds Regulatory Content (VOC Regulatory):G1 =Wv – Ww – WecVm – Vw – VecWhere G1 = Regulatory Content, Weight of volatile organic compound per totalvolume of coating, less water and exempt compounds, in grams per literWv = Weight of volatile compounds including any volatile materials added tothe original coating supplied by the manufacturer, in gramsWw = Weight of water, in gramsWec = Weight of exempt compounds as defined in Rule 459 Section 229, ingramsVm = Volume of coating material, in litersVw = Volume of water, in litersVec = volume of exempt compounds as defined in Rule 459 Section 229, inliters2. Calculating Volatile Organic Compounds Actual Content (VOC Actual) of a coating:G2 =Wv – Ww – WecVmWhere G2 = Actual Content, Weight of volatile organic compound per total volume ofcoating, in grams per literWv = Weight of volatile compounds including any volatile materials added tothe original coating supplied by the manufacturer, in gramsWw = Weight of water, in gramsWec = Weight of exempt compounds as defined in Rule 459 Section 229, ingramsVm = Volume of coating material, in liters3. Calculating Volatile Organic Compounds Actual Content (VOC Actual) of coating removers andsolvents:G3 =Wv – Ww – WecVmWhere G3 = Actual Content, Weight of volatile organic compound per total volume ofmaterial, in grams per literWv = Weight of volatile compounds, in gramsWw = Weight of water, in gramsWec = Weight of exempt compounds as defined in Rule 459 Section 229, ingramsVm = Volume of material, in litersDetermining ROC emissions for quarterly and annual complianceTotal ROC Emissions (lb/qtr) = [Coating Usage (gal/qtr)]*[VOC Actual (G2) (lb/gal)] +[Coating Remover and Solvent Usage (gal/qtr)]*[VOCActual Content (G3) (lb/gal)]4. Calculating Emissions From Fuel-fired DryersEmission factors will be:VI-11

- Supplied with manufacturer’s emissions data- Taken from U.S. EPA AP-42 emission factorsFuelNatural Gas(lb/mmcf)Propane/LPG(lb/10 3 gal)AP-42 Emission FactorsROC NOx SOx PM10 CO5.5 100.0 0.6 7.6 84.00.5 14.0 0.1 0.4 1.9Sample Quarterly Emissions Calculation2 MMBTU/hr natural gas fired dryer1,000 BTU/cf (standard assumption for gaseous fuels)Continuous operationQuarterly NOx emissions from dryer = (2 mmBTU/hr)*(100.0 lb/mmcf)*(1 cf/1,000 BTU)*(24hr/day)*(92 days/qtr)= 441 lb/qtrH. SOURCE TESTING/MONITORING – Not ApplicableI. OVER-THE-COUNTER PERMITS - Not ApplicableJ. ENGINEERING EVALUATION [SAMPLE] -- Refer to Exhibit ‘VI-A’.The sample coating operation meets all BACT and T-BACT requirements as proposed. The paintbooth is assumed to be the only emissions unit at the facility and that it will not be installed within1,000 feet from a school (K-12 th grade).K. PERMIT TO OPERATE [SAMPLES] -- Refer to Exhibit ‘VI-B’.L. PERMIT TO OPERATE [SAMPLES] -- Refer to Exhibit ‘VI-C”VI-12

Exhibit VI-ASample Engineering Evaluation<strong>Automotive</strong>, Truck and Heavy Equipment<strong>Refinishing</strong>Exhibit VI-A

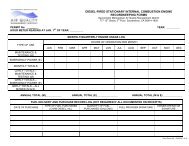

777 12th Street, 3rd Floor SACRAMENTO METROPOLITAN <strong>Sacramento</strong>, CA 95814AIR QUALITYMANAGEMENT DISTRICTAUTHORITY TO CONSTRUCT EVALUATIONAPPLICATION NO.: A/C XXXXXDATE: February 13, 2012ISSUING ENGINEER: XXXXX XXXXXFACILITY NAME:XXX AUTO BODYLOCATION: XXXX XXXXXX ST., SACRAMENTO, CA 95820PROPOSAL:INSTALLATION AND OPERATION OF AN AUTOMOTIVE SPRAY BOOTHINTRODUCTION:XXX Auto Body is proposing to open an automotive refinishing business. They will be installinga paint spray booth.EQUIPMENT DESCRIPTION:Paint Spray BoothEagleModel SDD 26-14-9 SP18’-11”W x 26’-3”L x 11’-1”H<strong>Automotive</strong> Dry Filter-Type2 X 2 HP Exhaust FansPROCESS RATE/FUEL USAGE:Usage of coatings and solvents will be limited by the proposed allowable VOC emissions.OPERATING SCHEDULE:The facility will typically operate 8 hours/day, 5 days/week.CONTROL EQUIPMENT EVALUATION:No add-on control equipment for VOC is proposed. The use of Rule 459 compliant coatings isexpected to result in lower VOC emissions. Solids in paint overspray are controlled by theexhaust paint arrestors. One of the requirements of 40 CFR 63 Subpart HHHHHH is the use ofa spray enclosure equipped with a filter system that can achieve at least 98% capture efficiency.A review of the representative coating products (Matrix coating system) indicate that thesecoatings do not contain any of the target HAP compounds. Therefore, this Subpart HHHHHHfilter control requirement may not be applicable to this source pending their submission to theU.S. EPA and approval of a request for exemption from 40 CFR 63 Subpart HHHHHH.EMISSIONS CALCULATIONS:

Authority to Construct EvaluationA/C XXXXXFebruary 13, 2012Page 21. HISTORIC POTENTIAL TO EMIT:The equipment is a new paint spray booth. Therefore, it has zero historic potential to emit.2. PROPOSED POTENTIAL TO EMIT:The applicant provided estimated or actual coatings and solvents usage. In order toprovide operational flexibility for future growth, the proposed VOC allowable emissions willbe equal to the District’s BACT trigger level.Pollutant (A)Proposed Potential to Emitlb/day lb/quarter lb/yearVOC 861.8 (C) 4,700 (B) 4,700 (B)PM10 2.8 (D) 15 (D) 15 (D)PM2.5 2.8 (D) 15 (D) 15 (D)GHG 0 tons/day 0 tons/quarter 0 tons/year(A) (A) Definitions: VOC is volatile organic compound as defined in SMAQMD Rule101, General Provisions and Definitions. PM10 is particulate matter with anaerodynamic diameter of 10 microns or less. PM2.5 is particulate matter with anaerodynamic diameter of 2.5 microns or less. GHG emission factor is expressed asCO2e and is from EPA’s Mandatory Reporting of Greenhouse Gases Rule (74 FR58260), Tables C-1 & C-2.(B) Potential to emit is based on the SMAQMD BACT Determination No. 22 forautomotive coating operation.(C) Based on a coating spray rate of 6.3 gallons/hour (Binks HVLP gun maximum sprayrate), maximum VOC content of 5.7 lb/gallon (using the highest VOC standard inRule 459) and operating 24 hours/day.(D) PM10 emissions are based on an uncontrolled emission factor of 6.4 lb PM10/ton ofVOC emitted from AIRS Facility Subsystem Source Classification Codes andEmission Factor Listing for Criteria <strong>Air</strong> Pollutants, EPA 450/4-90-003 (March 1990).The PM10 emission factor is assumed to be all PM2.5.

Authority to Construct EvaluationA/C XXXXXFebruary 13, 2012Page 33. CALCULATION OF BACT TRIGGER:NEI = (DPE – DHPE)DPE (BACT) = Daily Potential EmissionsDHPE = Daily Historic Potential Emissions or Daily Actual Emissions if noenforceable daily emissions limitation is present prior to modification.PollutantDPE (BACT)lb/dayDHPENEIlb/dayBACTTrigger Levellb/dayIs BACTRequired?VOC 861.8 0 861.8 >0 YesNOx 0 0 0 >0 NoSOx 0 0 0 >0 NoPM10 2.8 0 2.8 >0 YesPM2.5 2.8 0 2.8 >0 YesCO 0 0 0 >550 NoLead 0 0 0 >3.3 No4. CALCULATION OF OFFSET TRIGGER FOR VOC AND NOx:Permit No.Emissions UnitStationary Source Potential to Emitlb/quarterVOCNOxA/C XXXXX Paint Spray Booth 4,700 0Total 4,700 0Facility Limit N/A N/AOffset Trigger Level ≥5,000 ≥5,0005. CALCULATION OF OFFSET TRIGGER FOR SOx, PM10 AND CO:Permit No.Emissions UnitStationary Source CumulativeEmission Increase Since 01-01-77lb/quarterSOx PM10 COA/C XXXXX Paint Spray Booth 0 15 0Total 0 15 0Facility Limit N/A N/A N/AOffset Trigger Level ≥13,650 ≥7,300 ≥49,500

Authority to Construct EvaluationA/C XXXXXFebruary 13, 2012Page 46. CALCULATION OF OFFSET TRIGGER FOR PM2.5:Permit No.Emissions UnitStationary Source CumulativeEmission Increase Since 01-01-77tons/yearPM2.5A/C XXXXX Paint Spray Booth 0.008Total 0.008Facility LimitOffset Trigger Level7. CALCULATION OF EMISSION OFFSETS FOR VOC AND NOx:Emission offsets are not required for VOC and NOx because emissions are below theoffset threshold.8. CALCULATION OF EMISSION OFFSETS FOR SOx, PM10. PM2.5 AND CO:Emission offsets are not required for SOx, PM10, PM2.5 and CO because emissions arebelow the offset threshold.COMPLIANCE WITH RULES AND REGULATIONS:1. H&S Code § 42301.6 (AB 3205) COMPLIANCE:The equipment is not located within 1,000 feet from the outer boundary of a school site.Therefore, the school public noticing requirements of H&S Code § 42301.6 do not apply.2. NSR COMPLIANCE:Rule 202 - New Source ReviewSection 113 - Exemption - Notification Requirements The potential to emit from thisemissions unit does not meet or exceed the following levels requiring public noticingpursuant to the requirements of Sections 405, 406, 407 and 409.2:Pollutantlb/qtrVOC 5,000NOx 5,000SOx 13,650PM10 7,300PM2.510 (A)CO 49,500(A) Units are in tons/year.N/A≥15

Authority to Construct EvaluationA/C XXXXXFebruary 13, 2012Page 5Section 301 - Best Available Control Technology The proposed potential to emit from thisemissions unit exceeds the BACT thresholds for the affected pollutants as specified inSection 301.1 and below. Therefore, BACT will be required for VOC, PM10 and PM2.5.Pollutantlb/dayVOC 0NOx 0SOx 0PM10 0PM2.5 0CO 550Lead 3.3The SMAQMD BACT determination for automotive coating operations, together with theBay Area AQMD, South Coast AQMD and the San Joaquin Valley Unified APCD BACT<strong>Manual</strong>s were reviewed for automotive refinishing operations.The SMAQMD BACT determination for general coating using a paint spray booth in anautomotive coating operation was issued on 7-28-05 (BACT Determination No. 22). Theanalyses performed for control technologies using catalytic incineration, thermalincineration, and carbon adsorption in coating operations have shown that VOC emissionsof 4,700 lb or less per year from a single paint spray booth exceed the District’s $17,500per ton cost effectiveness level for maximum cost per ton of pollutant controlled. Since theproposed VOC emissions limitation will not exceed this cost effectiveness threshold, BACTas Achieved in Practice shall be required. BACT requirements for the coating operation atCNC Auto Body will be as follows:a) Low VOC coatings compliant with the current Rule 459 standards including thestandards that will become effective February 25, 2012; andb) High transfer efficiency application equipment.XXX Auto Body is proposing the following compliant coatings and solvents as summarizedbelow:Coating Category(Rule 459)Primer/PrimerSealerBACT StandardsRule 459lb/galVOC Contentless water andexempt compoundslb/gal2.1 1.67ProposedCoating MaterialsPCL 901PolyprimerClear Coating 2.1 2.1 Matrix AG 40LVColor Coating 3.5 3.5 Matrix RSB-LVSolvent CleaningGun CleanerWax/Grease Rem0.2100.21Safety-Kleen ClearChoiceDominion LVAPC Wax &Grease Remover

Authority to Construct EvaluationA/C XXXXXFebruary 13, 2012Page 6Section 302 - Offset The cumulative emission increases for this stationary source doesnot meet or exceed the levels for any of the affected pollutants as specified in Section302.1 and below. Therefore, emission offsets will not be required.Pollutantlb/qtrVOC 5,000NOx 5,000SOx 13,650PM10 7,300PM2.515 (A)CO 49,500Ammonia100 (A)(A) Units are in tons/year.Section 308 – Denial, Failure to Meet CEQA The SMAQMD has developed acomprehensive permitting CEQA Guidance document. Project reviews conducted inaccordance with the policy manuals contained therein have been determined to meet theCEQA criteria of ministerial and do not require additional CEQA review.This project falls within the scope of the <strong>Automotive</strong>, Truck and Heavy Equipment<strong>Refinishing</strong> Permitting <strong>Manual</strong> and has been determined to be ministerial. No furtherreview is required.Rule 217 – Public Notice Requirements for PermitsSections 401-402 – CARB, EPA, and Public Notification: Emissions from this unit arenot required to be offset pursuant to Rule 202, Section 302 and do not exceed theexemption level specified below. Therefore, pursuant to Section 110 of Rule 217, thispermit action is exempt from the public notice requirements of Rule 217._Pollutant_ _lb/qtr_VOC 5,000NOx 5,000SOx 9,200PM10 7,300PM2.5 10 TPYCO 49,5003. PREVENTION OF SIGNIFICANT DETERIORATION (PSD) COMPLIANCE:A source or modification triggers PSD if: Its potential to emit any one pollutant is greater than 100 tons/year (if one of the 28selected industrial categories, including utility plants, steel plants, refineries, boilers>250 MMBtu/hr heat input) or greater than 250 tons/year (all other categories); and The project’s contemporaneous emissions increase and net emissions increase forany pollutant is greater than the significance levels listed below:

Authority to Construct EvaluationA/C XXXXXFebruary 13, 2012Page 7PollutantLevel of Significancetons/yearCO 100NOx 40SOx 40PM 25PM10 15PM2.510 (PM2.5) or 40 (SO 2 ) or 40 (NO)Ozone40 (NOx or VOC)Lead 0.6Fluorides 3Sulfuric Acid Mist 7H 2 S 10Total Reduced Sulfur (including H 2 S) 10Reduced Sulfur Compounds (incl. H 2 S) 10Greenhouse Gases (CO2e) 75,000A more detailed PSD analysis is not required because the contemporaneous emissionsincreases for all pollutants at the facility do not exceed any of the significance levelsshown in the table above.4. PROHIBITORY RULES COMPLIANCE:Rule 401 – Ringelmann ChartThe automotive coating operation at this facility is expected to comply with the RingelmannNo. 1 or 20% opacity requirement of this rule.Rule 402 – NuisanceThe automotive coating operation to be conducted at this facility is not expected to causea public nuisance and will not emit any significant levels of toxic air contaminants.Rule 459 – <strong>Automotive</strong>, Mobile Equipment, and Associated Parts and ComponentsCoating OperationsXXX Auto Body is proposing to use Matrix and PCL coatings that are compliant with theFeb. 25, 2012 VOC standards in Sections 301 and 302 and the equipment requirements.This source will be required to demonstrate compliance with the standards with monitoringand recordkeeping procedures pursuant to Section 502 and as stated in the permitconditions.

Authority to Construct EvaluationA/C XXXXXFebruary 13, 2012Page 85. NEW SOURCE PERFORMANCE STANDARDS (NSPS) COMPLIANCE:NSPS Under 40 CFR Part 60: The list of all adopted New Source PerformanceStandards were reviewed to determine if the proposed project is subject to one or more ofthese regulations. There are currently no 40 CFR Part 60 NSPS sections applicable tothis source category.(http://yosemite,epa.gov/r9/r9nsps.nsf/ViewStandards?ReadForm%Part=60)6. NATIONAL EMISSION STANDARDS FOR HAZARDOUS AIR POLLUTANTS (NESHAP)COMPLIANCE:40 CFR 63 Subpart HHHHHH – National Emission Standards for Hazardous <strong>Air</strong>Pollutants: Paint Stripping and Miscellaneous Surface Coating Operations at Area SourcesThis subpart applies to autobody refinishing operations, among other area sources, thatinclude motor vehicles and mobile equipment spray-applied surface coating operations;and apply coatings that may potentially contain the target HAP compounds of chromium,lead, manganese, nickel, or cadmium. The general compliance requirements for thissubpart include: All spray-applied coatings must be performed in a spray booth, preparation station,or mobile enclosures that are fully enclosed with a full roof with four walls orcomplete side curtains. The enclosure must be ventilated at a negative pressure andequipped with a filter system that can achieve at least 98% capture efficiency. Coatings must be applied with HVLP spray equipment, electrostatic application,airless spray gun, air-assisted airless spray gun, or an equivalent technology forwhich written approval has been obtained from the U.S. EPA. Spray gun cleaning must be conducted such that an atomized mist or spray of guncleaning solvent and paint residue is not created outside of a container that collectsused cleaning solvent.All new and existing personnel who spray-apply surface coatings must be trained inthe proper application of surface coatings. For new affected sources, submit an initial notification after initial startup or July 7,2008, whichever is later. For an existing affected source, submit the initialnotification no later than January 11, 2010.However, owners and operators of an automotive surface coating operation may petitionfor an exemption from this regulation if it can be demonstrated that the automotivecoatings that are spray-applied at the source do not contain the target HAP compounds. The petition must include a description of the coatings that are spray-applied and acertification that such coatings do not contain the target HAP compounds. If after submittal of exemption petition and the source intends to spray-apply coatingscontaining the target HAP, submit the initial notification as required in Section63.11175 and comply with the requirements of this subpart.XXX Auto Body will be required to submit an Initial Notification form pursuant to theNESHAP Subpart HHHHHH. A quick review of the MSDS of the product used for eachcoating category indicate that they do not contain any of the target HAP compounds

Exhibit VI-BSample Authority to Construct<strong>Automotive</strong>, Truck and Heavy Equipment<strong>Refinishing</strong>Exhibit VI-B

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCTA/C NO.: XXXXX ISSUED BY:DATE ISSUED: APRIL 04, 2012XXXXX XXXXXDATE EXPIRES: APRIL 04, 2014ISSUED TO:XXX AUTO BODYLOCATION: XXXXXXXXXX ST., SACRAMENTO, CA 95820DESCRIPTION: PAINT SPRAY BOOTH, EAGLE, MODEL SDD 26-14-9-SP, 18’-11”W x 26’-3”L x 11’-1”H, AUTOMOTIVE DRY FILTER-TYPE, 2 x 2 HP EXHAUST FANS, HVLPAPPLICATIONSTART-UP REQUIREMENTSAUTHORITY TO CONSTRUCT CONDITIONSS1. Upon acceptance of the conditions authorized in this Authority to Construct, the owner/operator shallcontact the <strong>Sacramento</strong> <strong>Metropolitan</strong> <strong>Air</strong> Quality Management District (SMAQMD) at (916)874-4858 toarrange for a start-up inspection.[Basis: SMAQMD Rule 201, Section 405]S2. This Authority to Construct shall serve as a temporary Permit to Operate provided that:A. The SMAQMD has been notified to conduct a start-up inspection,B. The equipment installed matches the equipment authorized in this Authority to Construct, andC. The equipment is operated in compliance with all conditions listed within this Authority to Construct.[Basis: SMAQMD Rule 201, Section 405]GENERAL1. The equipment shall be properly maintained and operated in accordance with the manufacturer’srecommendations at all times.[Basis: SMAQMD Rule 201, Section 405]2. The <strong>Air</strong> Pollution Control Officer and/or authorized representatives, upon the presentation of credentials,shall be permitted:A. To enter upon the premises where the source is located or in which any records are required to bekept under the terms and conditions of this Authority to Construct, andB. At reasonable times to have access to and copy any records required to be kept under the termsand conditions of this Authority to Construct, andPAGE 1 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)C. To inspect any equipment, operation, or method required in this Authority to Construct, andD. To sample emissions from the source or require samples to be taken.[Basis: SMAQMD Rule 201, Section 405]3. This Authority to Construct does not authorize the emission of air contaminants in excess of thoseallowed by Division 26, Part 4, Chapter 3, of the California Health and Safety Code or the Rules andRegulations of the <strong>Sacramento</strong> <strong>Metropolitan</strong> <strong>Air</strong> Quality Management District.[Basis: SMAQMD Rule 201, Section 405]4. The equipment shall not discharge such quantities of air contaminants or other materials which causeinjury, detriment, nuisance or annoyance to any considerable number of persons or to the public, orwhich endanger the comfort, repose, health, or safety of any such persons or the public, or which cause,or have a natural tendency to cause, injury or damage to business or property.[Basis: SMAQMD Rule 402, Section 301]5. A legible copy of this Authority to Construct shall be maintained on the premises with the equipment.[Basis: SMAQMD Rule 201, Section 401]EMISSION LIMITATIONS6. The coating operation shall not discharge into the atmosphere any visible air contaminants other thanuncombined water vapor, for a period or periods aggregating more than three minutes in any one hour,which are as dark or darker than Ringelmann No. 1 or equivalent to or greater than 20% opacity.[Basis: SMAQMD Rule 401, Section 301]7. Emissions from the coating operation shall not exceed the following limits:[Basis: SMAQMD Rule 201, Section 405 and Rule 202, Section 301 and Section 410.2]Pollutant (A)Maximum Allowable Emissions(lb/day) (lb/quarter) (lb/year)VOC 861.8 (B) 4,700 4,700PM10 2.8 (C) 15 (C) 15 (C)PM2.5 2.8 (C) 15 (C) 15 (C)(A) Definitions: VOC is volatile organic compound as defined in SMAQMD Rule 101, GeneralProvisions and Definitions. PM10 is particulate matter with an aerodynamic diameter of 10 micronsor less. PM2.5 is particulate matter with an aerodynamic diameter of 2.5 microns or less.(B) Based on a coating spray rate of 6.3 gallons/hour (Binks HVLP gun maximum spray rate),maximum VOC content of 5.7 lb/gallon (Based on Rule 459 maximum standards) and operating 24hours/day.(C) Uncontrolled PM10 emission factor of 6.4 lb PM10/ton of VOC emitted is from AIRS FacilityPAGE 2 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)Subsystem Source Classification Codes and Emission Factor Listing for Criteria <strong>Air</strong> Pollutants, EPA450/4-90-003 (March 1990). The PM10 emission factor is assumed to be all PM2.5.8. Compliance with the coating emissions limitation in Condition No. 7 shall be determined as follows:[Basis: SMAQMD Rule 201, Section 405]VOC Emissions = [Coating Usage (A) , gal/quarter] x [VOC as applied (VOC actual) (B) , lb/gal] +(lb/quarter) [Surface Preparation and Cleanup Solvent Usage, gal/quarter] x [VOC, lb/gal](A) Coating usage includes thinner, reducers, hardeners, retarders, catalysts, activators and additives.(B) VOC actual is the actual content weight of volatile organic compounds per total volume of the coatingas defined in Rule 459, Section 408.VOC Emissions = Sum of VOC Emissions [Quarters 1, 2, 3 & 4](lb/year)EQUIPMENT OPERATION9. Vehicle Coating Limits: A person shall not apply to any motor vehicle, mobile equipment, or associatedparts and components, any coating with a VOC Regulatory content in excess of the following limits.[Basis: SMAQMD Rule 459, Section 301]Coating Category(SMAQMD Rule 459 Definition)Maximum VOC Regulatory Content asAppliedgrams/liter (lb/gal)Adhesion Promoter 540 (4.5)Clear Coating 250 (2.1)Color Coating 420 (3.5)Multi-Color CoatingA. Mobile equipment driven or drawn on rails and itsassociated parts and componentsB. Any other mobile equipment or motor vehicle and itsassociated parts and components520 (4.3)680 (5.7)Pretreatment Coating 660 (5.5)Primer/Primer Sealer 250 (2.1)Single-Stage Coating 340 (2.8)Temporary Protective Coating 60 (0.5)PAGE 3 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)Coating Category(SMAQMD Rule 459 Definition)Maximum VOC Regulatory Content asAppliedgrams/liter (lb/gal)Truck Bed Liner Coating 200 (1.7)Underbody Coating 430 (3.6)Uniform Finish Coating 540 (4.5)Any other coating type, excluding materials listed in Rule459, Section 302250 (2.1)10. A person shall not use the following materials on any vehicle if the VOC content exceeds the followinglimits:[Basis: SMAQMD Rule 459, Sections 309 and 310]MaterialMaximum Allowable VOC Contentgrams/liter (lb/gal)Solvent for Coating Removal (Stripper) 200 (1.7)Solvent for Cleaning Operations 25 (0.21)Solvent for Bug and Tar Removal25 (0.21)orBug and Tar Remover regulated under theCalifornia Consumer Products Regulations (A)(A) Title 17 CCR Sections 94507 – 94517.11. All VOC-containing coating and solvent containers shall be kept covered when not in use.[Basis: SMAQMD Rule 459, Section 309.2]12. All cloth or paper used for surface preparation, cleanup and paint removal shall be disposed of in closedcontainers.[Basis: SMAQMD Rule 459, Section 309.1]13. Any end user of coating materials (e.g. autobody shops) shall not possess at any physical location withinthe District any containers containing coatings that are not in compliance with Condition Nos. 9, 10 & 11.[Basis: SMAQMD Rule 459, Section 308]14. No motor vehicle and/or mobile equipment coating used at this facility shall contain hexavalent chromiumor cadmium.[Basis: Title 17 CCR, Section 93112]PAGE 4 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)15. A person shall not apply any coating unless one of the following application methods is used:A. Electrostatic application equipmentB. High Volume Low Pressure (HVLP) spray equipmenti. The spray gun shall be permanently labeled as a HVLP, orii.If the spray gun is not permanently labeled as a HVLP, then the end user shall demonstratethat the spray gun meets the HVLP definition in Rule 459, Section 224 in design and use. Asatisfactory demonstration shall be based on the manufacturer’s published technical materialon the design of the gun by a demonstration of the operation of the gun using an air pressuretip gauge from the manufacturer of the gun.C. Low Volume Low Pressure (LVLP) spray equipmentD. Brush or roll coating, dip coat or flow coatE. Any other application method that achieved a transfer efficiency equivalent to, or higher than, theapplication methods listed in Rule 459, Sections 305.1(a) - (d) as determined by the methodsspecified in Rule 459 Section 504.9. Written approval from the <strong>Air</strong> Pollution Control Officer shall beobtained for each alternative application method prior to use.[Basis: SMAQMD Rule 459, Sections 224, 305.1 and 504.9]16. For all booths, including dry filter-type and waterwash-type, the exhaust fan system shall be in operationwhenever spraying occurs in the booth.[Basis: SMAQMD Rule 201, Section 405]RECORDKEEPING AMD REPORTING17. The following records shall be continuously maintained on-site for the most recent three-year period andshall be made available to the <strong>Air</strong> Pollution Control Officer upon request. Monthly and quarterly recordsas specified in the table below shall be made available for inspection within 30 days following the monthand quarter, respectively.[Basis: SMAQMD Rule 201, Section 405 and Rule 459, Sections 401 and 502]FrequencyAt all timesInformation To Be RecordedList of currently used coatings and solvents including the following information:A. The material name and manufacturerB. The application method usedC. The coating type as designated by the coating categories in SMAQMD Rule 459,Section 301 or 302 and mix ratio specific to the coatingD. Identification of the material as a coating or a solventE. Product data sheeti. For coatings and coating components:a. The volatile organic compound regulatory content for coatings expressed ingrams per liter, calculated pursuant to SMAQMD Rule 459, Section 407.b. The volatile organic compound actual content for coatings expressed inPAGE 5 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)FrequencyInformation To Be Recordedgrams per liter, calculated pursuant to SMAQMD Rule 459, Section 408.c. The weight percentage of volatiles, water and exempt compounds.d. The volume percentage of water and exempt compounds.e. The density of the material (in grams per liter).f. For coatings and coating components containing tertiary butyl acetate, theactual content of tertiary butyl acetate per total volume of coating or coatingcomponent, expressed in grams per liter.ii. For each individual ready to spray mixture (based on the manufacturer’s andrepackager’s stated mix ratio):a. The volatile organic compound regulatory content for coatings expressed ingrams per liter, calculated pursuant to SMAQMD Rule 459, Section 407.b. The volatile organic compound actual content for coatings expressed ingrams per liter, calculated pursuant to SMAQMD Rule 459, Section 408.c. The weight percentage of volatiles, water and exempt compounds.d. The volume percentage of water and exempt compounds.e. The density of the material (in grams per liter).f. For each ready to spray mixture containing tertiary butyl acetate, the actualcontent of tertiary butyl acetate per total volume of the mixture, expressed ingrams per liter.iii. For coating removers and solvents subject to Condition No. 10:a. The volatile organic compound content as calculated pursuant to SMAQMDRule 459, Section 409.MonthlyQuarterly andAnnuallyF. Monthly purchase records identifying the coating type, name/code/manufacturer,and purchased volume of each material (gal/month).G. For coatings containing tertiary butyl acetate, monthly records regarding use,including name/code/manufacturer of the coating and content of tertiary butylacetate contained in each coating.H. Calculation of VOC emissions from the coating operations by the method specifiedin Condition No. 8 (lb/quarter & lb/year).18. The permittee shall, upon determination of applicability and written notification by the District, comply withall applicable requirements of the <strong>Air</strong> Toxics “Hot Spots” Information and Assessment Act (CaliforniaHealth and Safety Code Section 44300 et seq.).[Basis: SMAQMD Rule 201, Section 303.1]PAGE 6 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)NATIONAL EMISSION STANDARDS FOR HAZARDOUS AIR POLLUTANTS: PAINT STRIPPING ANDMISCELLANEOUS SURFACE COATING OPERATIONS (40 CFR 63 SUBPART HHHHHH)Applicability: This regulation applies to paint stripping operations that involve the use of chemical strippersthat contain methylene chloride (MeCl), Chemical Abstract Service number 75092, in paint removal processesand/or autobody refinishing operations that encompass motor vehicle and mobile equipment spray-appliedsurface coating operations.If spray applied coatings do not contain chromium (Cr), lead (Pb), manganese (Mn), nickel (Ni), orcadmium (Cd), and you have filed a petition for exemption, and have received written confirmationfrom the U.S. Environmental Protection Agency (U.S. EPA) approving your petition, and also do notperform paint stripping activities using methylene chloride (MeCl), then your source is not subject tothis NESHAP (40 CFR 63 Subpart HHHHHH) or any of the following conditions (Condition Nos. 20-29).NOTIFICATIONS19. Initial Notification: The source shall notify the U.S. EPA, no later than 180 days from initial startup, thatthe facility is subject to the standards and if not yet in compliance, when the source will be in complianceby submitting an initial notification form.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11175(a)]20. Notice of Compliance: The source shall be in compliance with the applicable requirements upon startup.The source must certify in the initial notification whether the source is in compliance with each of therequirements of this subpart. The source is not required to submit a separate notification of compliancestatus in addition to the initial notification.[Basis: 40 CFR 63 Subpart HHHHHH, Sections 63.11175(a)(8) and 63.11175(b)]GENERAL21. All spray painting must be performed inside a spray booth or prep station with a roof and at least threewalls or curtains (when refinishing vehicle subassemblies), or a roof and four complete walls or completeside curtains (when refinishing complete vehicles or mobile equipment) and must be ventilated so that airis drawn into the booth. The exhaust must be equipped with a filter system that is designed to capture atleast 98% of paint overspray.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11173(e)2(i) - 63.11173(e)2(iii)]22. Spray guns used in the coating operation must be one of the following types:A. High Volume Low Pressure (HVLP)B. ElectrostaticC. Any other equivalent spray method demonstrated to achieve transfer efficiency equal to one of theother allowed types of spray guns, which has been approved in writing by the <strong>Air</strong> Pollution ControlOfficer, and submitted to and approved by the U.S. EPA.PAGE 7 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)23. Paint spray gun cleaning must be done so that an atomized mist or spray of the cleaning solvent is notcreated outside a container that collects used gun cleaning solvent.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11173(e)4]MANAGEMENT PRACTICES/TRAINING24. Each painter must undergo training that includes, but not limited to: painting techniques to minimize paintoverspray and equipment maintenance. Initial painter training will be valid for five years and a refreshercourse will be required once every five years.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11173(f)2(i) – 63.1173(f)2(iv)]25. All painters must complete training no later than 180 days after being hired or January 10, 2011,whichever is later.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11173(g)2]RECORDKEEPING26. The following records shall be maintained on-site and shall be made available for review by the U.S. EPAor the <strong>Air</strong> Pollution Control Officer upon request:A. Records of notifications submitted to the U.S. EPAB. Painter training certificationsC. Documentation of spray both filter efficiencyD. Documentation of spray gun transfer efficiencyE. Any relevant documentation on deviations and corrective actionsAdditional Recordkeeping Requirements for Paint Stripping Operations Using MethyleneChloride:F. Each paint stripping operation must maintain copies of annual usage of paint strippers containingMeCl on site at all times (tons/year).G. Each paint stripping operation with annual usage of more than one ton of MeCl must maintain acopy of their current MeCl minimization plan on site at all times.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11173(a) – 63.11177(g)]MANAGEMENT PRACTICES FOR STRIPPING OPERATIONS27. Each paint stripping operation that is an affected area source must implement management practices tominimize the evaporative emissions of MeCl. The management practices must address, at a minimum,the practices listed below, as applicable, for your operations:A. Evaluate each application to ensure there is a need for paint stripping (e.g., Evaluate whether it ispossible to re-coat the piece without removing the existing coating).B. Evaluate each application where a paint stripper containing MeCl is used to ensure that there is noalternative paint stripping technology that can be used.C. Reduce exposure of all paint strippers containing MeCl to the air.PAGE 8 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)D. Optimize application conditions when using paint strippers containing MeCl to reduce MeClevaporation (e.g., If the stripper must be heated, make sure that the temperature is kept as low aspossible to reduce evaporation).E. Practice proper storage and disposal of paint strippers containing MeCl (e.g., Store stripper inclosed, air-tight containers).[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11175(b)]MINIMIZATION PLAN FOR STRIPPING OPERATIONS WITH McCl USAGE > 1 TPY28. Each paint stripping operation that has annual usage of more than one ton of MeCl must develop andimplement a written MeCl minimization plan to minimize the use and emissions of MeCl. The MeClminimization plan must address, at a minimum, the management practices specified in Condition No. 27,as applicable, for your operations. Each operation must post a placard or sign outlining the MeClminimization plan in each area where paint stripping operations subject to this subpart occur. Paintstripping operations with annual usage of less than one ton of MeCl, must comply with the requirementsof Condition No. 27, as applicable, but are not required to develop and implement a written MeClminimization plan.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11173(b)]PAGE 9 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

777 12 TH STREET, 3 RD FLOOR SACRAMENTO METROPOLITANAIR QUALITYMANAGEMENT DISTRICTSACRAMENTO, CA 95814AUTHORITY TO CONSTRUCT(CONTINUED)Your application for this air quality Authority to Construct was evaluated for compliance with <strong>Sacramento</strong><strong>Metropolitan</strong> <strong>Air</strong> Quality Management District (SMAQMD), state and federal air quality rules. The followinglisted rules are those that are most applicable to the operation of your equipment. Other rules may also beapplicable.SMAQMD RULENO.RULE TITLE201 GENERAL PERMIT REQUIREMENTS (8-24-06)202217NEW SOURCE REVIEW (8-23-12)PUBLIC NOTICE REQUIREMENTS FOR PERMITS (8-23-12)301 PERMIT FEES – STATIONARY SOURCE (10-27-05)401 RINGELMANN CHART (4-19-83)402 NUISANCE (8-3-77)45990440 CFR 63SUBPART HHHHHHAUTOMOTIVE, MOBILE EQUIPMENT, AND ASSOCIATED PARTS ANDCOMPONENTS COATING OPERATIONS (8-25-11)TITLE 17 CCR, SECTION 93112 – AIR TOXICS CONTROL MEASURE FOREMISSIONS OF HEXAVALENT CHROMIUM AND CADMIUM FROM MOTORVEHICLE AND MOBILE EQUIPMENT COATINGS (5-26-11)_NATIONAL EMISSION STANDARDS FOR HAZARDOUS AIR POLLUTANTS:PAINT STRIPPING AND MISCELLANEOUS SURFACE COATINGOPERATIONS AT AREA SOURCESIn addition, the conditions on this Authority to Construct may reflect some, but not all, requirements ofthese rules. There may be other conditions that are applicable to the operation of your equipment. Futurechanges in prohibitory rules may establish more stringent requirements which may supersede theconditions listed here.For further information, please consult your SMAQMD rulebook or contact the SMAQMD for assistance.PAGE 10 of 10THIS IS NOT A PERMIT TO OPERATEA/C NO.:XXXXX

Exhibit VI-CSample Permit to Operate<strong>Automotive</strong>, Truck and Heavy Equipment<strong>Refinishing</strong>Exhibit VI-C

777 12 TH STREET, 3 RD FLOOR (916) 874-4800SACRAMENTO, CA 95814-1908 FAX (916) 874-4899PERMIT TO OPERATEISSUED TO:XXX AUTO BODYEQUIPMENT LOCATION: XXXXXXXXXX ST., SACRAMENTO, CA 95820PERMIT NO.XXXXXEQUIPMENT DESCRIPTIONPAINT SPRAY BOOTH, MAKE: EAGLE, MODEL: SDD 26-14-9-SP, 18’-11”W x 26’-3”L x11’-1”H, 2 EXHAUST FANS AT 2 HP EACH, DRY FILTER-TYPE, HVLP APPLICATIONSUBJECT TO THE FOLLOWING CONDITIONS:GENERAL1. The equipment shall be properly maintained and operated in accordance with the manufacturer’srecommendations at all times.[Basis: SMAQMD Rule 201, Section 405]2. The <strong>Air</strong> Pollution Control Officer and/or authorized representatives, upon the presentation of credentialsshall be permitted:A. To enter upon the premises where the source is located or in which any records are required to be keptunder the terms and conditions of this Permit to Operate, andB. At reasonable times to have access to and copy any records required to be kept under terms andconditions of this Permit to Operate, andC. To inspect any equipment, operation, or method required in this Permit to Operate, andD. To sample emissions from the source or require samples to be taken.[Basis: SMAQMD Rule 201, Section 405]LARRY GREENEDATE ISSUED: 05-12-2012 AIR POLLUTION CONTROL OFFICERDATE EXPIRES: XX-XX-XXXX (UNLESS RENEWED)BY:PAGE 1 OF 9 PAGESPERMIT NOS.: XXXXXREVOCABLE AND NON-TRANSFERABLE

777 12 TH STREET, 3 RD FLOOR (916) 874-4800SACRAMENTO, CA 95814-1908 FAX (916) 874-4899SACRAMENTO METROPOLITANAIR QUALITY MANAGEMENT DISTRICT3. This Permit to Operate does not authorize the emission of air contaminants in excess of those allowed byDivision 26, Part 4, Chapter 3, of the California Health and Safety Code or the Rules and Regulations ofthe <strong>Sacramento</strong> <strong>Metropolitan</strong> <strong>Air</strong> Quality Management District (SMAQMD).[Basis: SMAQMD Rule 201, Section 405]4. The equipment shall not discharge such quantities of air contaminants or other materials which causeinjury, detriment, nuisance or annoyance to any considerable number of persons or to the public, or whichendanger the comfort, repose, health or safety of any such persons or the public, or which cause, or have anatural tendency to cause, injury or damage to business or property.[Basis: SMAQMD Rule 402, Section 301]5. A legible copy of this Permit to Operate shall be maintained on the premises with the equipment.[Basis: SMAQMD Rule 201, Section 401]EMISSIONS LIMITATIONS6. The coating operation shall not discharge into the atmosphere any visible air contaminants other thanuncombined water vapor, for a period or periods aggregating more than three minutes in any one hour,which are as dark or darker than Ringelmann No. 1 or equivalent to or greater than 20% opacity.[Basis: SMAQMD Rule 401, Section 301]7. The emissions from the coating operation shall not exceed the following limit:[Basis: SMAQMD Rules 201, Section 405 and Rule 202, Section 301 and 410.2]Pollutant (A)Maximum Allowable Emissionslb/day lb/quarter lb/yearVOC 861.8 (B) 4,700 4,700PM10 2.8 (C) 15 (C) 15 (C)PM2.5 2.8 (C) 15 (C) 15 (C)GHG 0 tons/day 0 tons/quarter 0 tons/year(A) Definitions: VOC is volatile organic compound as defined in SMAQMD Rule 101, General Provisionsand Definitions. PM10 is particulate matter with an aerodynamic diameter of 10 microns or less.PM2.5 is particulate matter with an aerodynamic diameter of 2.5 microns or less. GHG emissionfactor is the CO 2 e emission factor as per Tables C1 and C2 of Subpart C of EPA’s MandatoryReporting for Greenhouse Gases rule (40 CFR, Part 98).(B) Based on a coating spray rate of 6.3 gallons/hour (Binks HVLP gun maximum spray rate), maximumVOC content of 5.7 lbs/gallon (based on Rule 459 maximum standards), and operating 24 hours/day.(C) PM10 emissions are based on an uncontrolled emission factor of 6.4 lb PM10/ton of VOC emittedfrom <strong>Air</strong>s Facility Subsystem Source Classification Codes and Emission Factor Listing for Criteria <strong>Air</strong>Pollutants, March 1990, EPA 450/4-90-003. The PM10 emission factor is assumed to be all PM2.5.PAGE 2 OF 9 PAGESREVOCABLE AND NON-TRANSFERABLEPERMIT NOS.: XXXXX

777 12 TH STREET, 3 RD FLOOR (916) 874-4800SACRAMENTO, CA 95814-1908 FAX (916) 874-4899SACRAMENTO METROPOLITANAIR QUALITY MANAGEMENT DISTRICT8. Compliance with the coating emissions limitation in Condition No. 7 shall be determined as follows:[Basis: SMAQMD Rule 201, Section 405]VOC Emissions = [Coating Usage (A) , gal/qtr][VOC As Applied (VOC Actual) (B) , lb/gal] +(lb/qtr)[Surface Preparation and Cleanup Solvent Usage, gal/qtr][VOC, lb/gal](A) Coating usage includes thinner, reducers, hardeners, retarders, catalysts, activators, additives,gasket/gasket sealing material, cavity wax, deadener, and lubricating wax/compound.(B) VOC Actual is the actual content weight of volatile organic compounds per total volume of the coatingas defined in Rule 459, Sec. 408.VOC Emissions = Sum of VOC Emissions (Quarters 1, 2, 3, & 4)(lb/year)EQUIPMENT OPERATION9. Vehicle Coating Limits: A person shall not apply to any motor vehicle, mobile equipment, or associatedparts and components, any coating with a VOC Regulatory content in excess of the following limits.[Basis: SMAQMD Rule 459, Section 301]Coating Category(SMAQMD Rule 459 Definition)Maximum VOC Regulatory Content asAppliedgrams/liter (lb/gal)Adhesion Promoter 540 (4.5)Clear Coating 250 (2.1)Color Coating 420 (3.5)Multi-Color CoatingA. Mobile equipment driven or drawn on rails and itsassociated parts and componentsB. Any other mobile equipment or motor vehicle and itsassociated parts and components520 (4.3)680 (5.7)Pretreatment Coating 660 (5.5)Primer/Primer Sealer 250 (2.1)Single-Stage Coating 340 (2.8)Temporary Protective Coating 60 (0.5)Truck Bed Liner Coating 200 (1.7)Underbody Coating 430 (3.6)Uniform Finish Coating 540 (4.5)Any other coating type, excluding materials listed in Rule459, Section 302250 (2.1)PAGE 3 OF 9 PAGESREVOCABLE AND NON-TRANSFERABLEPERMIT NOS.: XXXXX

777 12 TH STREET, 3 RD FLOOR (916) 874-4800SACRAMENTO, CA 95814-1908 FAX (916) 874-4899SACRAMENTO METROPOLITANAIR QUALITY MANAGEMENT DISTRICT10. A person shall not use the following material on any vehicle if the VOC content exceeds the following limit:[Basis: SMAQMD Rule 459, Sections 309 and 310]MaterialMaximum Allowable VOC Contentgrams/liter (lb/gal)Solvent for Coating Removal (Stripper) 200 (1.7)Solvent for Cleaning Operations 25 (0.21)Solvent for Bug and Tar Removal 25 (0.21)orBug and Tar Remover regulated under theCalif. Consumer Products Regulation (A)(A) Title 17 CCR, Sections 94507 - 9451711. All VOC-containing coating and solvent containers shall be kept covered when not in use.[Basis: SMAQMD Rule 459, Section 309.2]12. All cloth or paper used for surface preparation, cleanup and paint removal shall be disposed of in closedcontainers. Paper used for masking does not need to be disposed of in closed containers.[Basis: SMAQMD Rule 459, Section 309.1]13. Any end user of coating materials (e.g. autobody shops) shall not possess at any physical location withinthe District any containers containing coatings that are not in compliance with Condition Nos. 9 and 10.[Basis: SMAQMD Rule 459, Section 308]14. No motor vehicle and/or mobile equipment coating used at this facility shall contain hexavalent chromiumor cadmium.[Basis: Title 17 CCR, Section 93112]15. A person shall not apply any coating unless one of the following application methods is used:A. Electrostatic application equipment.B. High Volume Low Pressure (HVLP) spray equipment.i. The spray gun shall be permanently labeled as a HVLP, orii. If the spray gun is not permanently labeled as a HVLP, then the end user shall demonstrate that thespray gun meets the HVLP definition in Rule 459, Section 224 in design and use. A satisfactorydemonstration shall be based on the manufacturer’s published technical material on the design ofthe gun and by a demonstration of the operation of the gun using an air pressure tip gauge from themanufacturer of the gun.C. Low Volume Low Pressure (LVLP) spray equipment.D. Brush or roll coating, dip coat, or flow coat.E. Any other application method that achieves a transfer efficiency equivalent to, or higher than, theapplication methods listed in Rule 459, Sections 305.1(a)-(d) as determined by the methods specified inRule 459 Section 504.9. Written approval from the <strong>Air</strong> Pollution Control Officer shall be obtained foreach alternative application method prior to use.[Basis: SMAQMD Rule 459, Sections 224, 305.1, and 504.9]PAGE 4 OF 9 PAGESREVOCABLE AND NON-TRANSFERABLEPERMIT NOS.: XXXXX

777 12 TH STREET, 3 RD FLOOR (916) 874-4800SACRAMENTO, CA 95814-1908 FAX (916) 874-4899SACRAMENTO METROPOLITANAIR QUALITY MANAGEMENT DISTRICT16. For all booths, including dry filter-type and waterwash-type, the exhaust fan system shall be in operationwhenever spraying occurs in the booth.[Basis: SMAQMD Rule 201, Section 405]RECORDKEEPING17. The following records shall be continuously maintained on-site for the most recent three-year period andshall be made available to the <strong>Air</strong> Pollution Control Officer upon request. Monthly and quarterly recordsas specified in the table below shall be made available for inspection within 30 days following the monthand quarter, respectively.[Basis: SMAQMD Rule 201, Section 405 and Rule 459, Sections 401 and 502]FrequencyAt all timesInformation To Be RecordedList of currently used coatings and solvents including the following information:A. The material name and manufacturerB. The application method usedC. The coating type as designated by the coating categories in SMAQMD Rule 459,Section 301 or 302 and mix ratio specific to the coatingD. Identification of the material as a coating or a solventE. Product data sheeti. For coatings and coating components:a. The volatile organic compound regulatory content for coatings expressed ingrams per liter, calculated pursuant to SMAQMD Rule 459, Section 407.b. The volatile organic compound actual content for coatings expressed ingrams per liter, calculated pursuant to SMAQMD Rule 459, Section 408.c. The weight percentage of volatiles, water and exempt compounds.d. The volume percentage of water and exempt compounds.e. The density of the material (in grams per liter).f. For coatings and coating components containing tertiary butyl acetate, theactual content of tertiary butyl acetate per total volume of coating or coatingcomponent, expressed in grams per liter.ii. For each individual ready to spray mixture (based on the manufacturer’s andrepackager’s stated mix ratio):a. The volatile organic compound regulatory content for coatings expressed ingrams per liter, calculated pursuant to SMAQMD Rule 459, Section 407.b. The volatile organic compound actual content for coatings expressed ingrams per liter, calculated pursuant to SMAQMD Rule 459, Section 408.c. The weight percentage of volatiles, water and exempt compounds.d. The volume percentage of water and exempt compounds.e. The density of the material (in grams per liter).f. For each ready to spray mixture containing tertiary butyl acetate, the actualcontent of tertiary butyl acetate per total volume of the mixture, expressed ingrams per liter.iii. For coating removers and solvents subject to Condition No. 10:a. The volatile organic compound content as calculated pursuant to SMAQMDRule 459, Section 409.PAGE 5 OF 9 PAGESREVOCABLE AND NON-TRANSFERABLEPERMIT NOS.: XXXXX