Inspection Checklist for ABSL-3 Laboratories - Select Agent Program

Inspection Checklist for ABSL-3 Laboratories - Select Agent Program

Inspection Checklist for ABSL-3 Laboratories - Select Agent Program

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

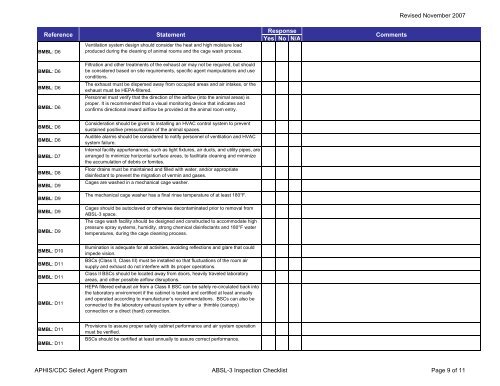

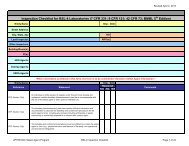

Revised November 2007ReferenceBMBL: D6StatementVentilation system design should consider the heat and high moisture loadproduced during the cleaning of animal rooms and the cage wash process.ResponseYes No N/ACommentsBMBL: D6Filtration and other treatments of the exhaust air may not be required, but shouldbe considered based on site requirements, specific agent manipulations and useconditions.BMBL: D6BMBL: D6The exhaust must be dispersed away from occupied areas and air intakes, or theexhaust must be HEPA-filtered.Personnel must verify that the direction of the airflow (into the animal areas) isproper. It is recommended that a visual monitoring device that indicates andconfirms directional inward airflow be provided at the animal room entry.BMBL: D6BMBL: D6BMBL: D7BMBL: D8BMBL: D9Consideration should be given to installing an HVAC control system to preventsustained positive pressurization of the animal spaces.Audible alarms should be considered to notify personnel of ventilation and HVACsystem failure.Internal facility appurtenances, such as light fixtures, air ducts, and utility pipes, arearranged to minimize horizontal surface areas, to facilitate cleaning and minimizethe accumulation of debris or fomites.Floor drains must be maintained and filled with water, and/or appropriatedisinfectant to prevent the migration of vermin and gases.Cages are washed in a mechanical cage washer.BMBL: D9The mechanical cage washer has a final rinse temperature of at least 180°F.BMBL: D9BMBL: D9Cages should be autoclaved or otherwise decontaminated prior to removal from<strong>ABSL</strong>-3 space.The cage wash facility should be designed and constructed to accommodate highpressure spray systems, humidity, strong chemical disinfectants and 180°F watertemperatures, during the cage cleaning process.BMBL: D10BMBL: D11BMBL: D11BMBL: D11Illumination is adequate <strong>for</strong> all activities, avoiding reflections and glare that couldimpede vision.BSCs (Class II, Class III) must be installed so that fluctuations of the room airsupply and exhaust do not interfere with its proper operations.Class II BSCs should be located away from doors, heavily traveled laboratoryareas, and other possible airflow disruptions.HEPA filtered exhaust air from a Class II BSC can be safely re-circulated back intothe laboratory environment if the cabinet is tested and certified at least annuallyand operated according to manufacturer’s recommendations. BSCs can also beconnected to the laboratory exhaust system by either a thimble (canopy)connection or a direct (hard) connection.BMBL: D11BMBL: D11Provisions to assure proper safety cabinet per<strong>for</strong>mance and air system operationmust be verified.BSCs should be certified at least annually to assure correct per<strong>for</strong>mance.APHIS/CDC <strong>Select</strong> <strong>Agent</strong> <strong>Program</strong> <strong>ABSL</strong>-3 <strong>Inspection</strong> <strong>Checklist</strong> Page 9 of 11