Advances in the Modelling of Motorcycle Dynamics - ResearchGate

Advances in the Modelling of Motorcycle Dynamics - ResearchGate

Advances in the Modelling of Motorcycle Dynamics - ResearchGate

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

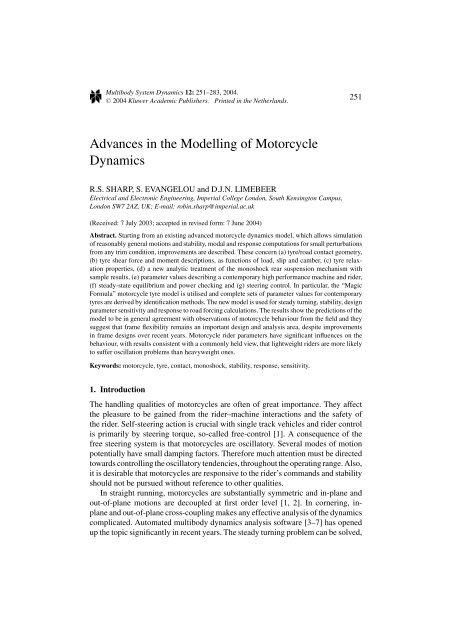

Multibody System <strong>Dynamics</strong> 12: 251–283, 2004.C○ 2004 Kluwer Academic Publishers. Pr<strong>in</strong>ted <strong>in</strong> <strong>the</strong> Ne<strong>the</strong>rlands.251<strong>Advances</strong> <strong>in</strong> <strong>the</strong> Modell<strong>in</strong>g <strong>of</strong> <strong>Motorcycle</strong><strong>Dynamics</strong>R.S. SHARP, S. EVANGELOU and D.J.N. LIMEBEERElectrical and Electronic Eng<strong>in</strong>eer<strong>in</strong>g, Imperial College London, South Kens<strong>in</strong>gton Campus,London SW7 2AZ, UK; E-mail: rob<strong>in</strong>.sharp@imperial.ac.uk(Received: 7 July 2003; accepted <strong>in</strong> revised form: 7 June 2004)Abstract. Start<strong>in</strong>g from an exist<strong>in</strong>g advanced motorcycle dynamics model, which allows simulation<strong>of</strong> reasonably general motions and stability, modal and response computations for small perturbationsfrom any trim condition, improvements are described. These concern (a) tyre/road contact geometry,(b) tyre shear force and moment descriptions, as functions <strong>of</strong> load, slip and camber, (c) tyre relaxationproperties, (d) a new analytic treatment <strong>of</strong> <strong>the</strong> monoshock rear suspension mechanism withsample results, (e) parameter values describ<strong>in</strong>g a contemporary high performance mach<strong>in</strong>e and rider,(f) steady-state equilibrium and power check<strong>in</strong>g and (g) steer<strong>in</strong>g control. In particular, <strong>the</strong> “MagicFormula” motorcycle tyre model is utilised and complete sets <strong>of</strong> parameter values for contemporarytyres are derived by identification methods. The new model is used for steady turn<strong>in</strong>g, stability, designparameter sensitivity and response to road forc<strong>in</strong>g calculations. The results show <strong>the</strong> predictions <strong>of</strong> <strong>the</strong>model to be <strong>in</strong> general agreement with observations <strong>of</strong> motorcycle behaviour from <strong>the</strong> field and <strong>the</strong>ysuggest that frame flexibility rema<strong>in</strong>s an important design and analysis area, despite improvements<strong>in</strong> frame designs over recent years. <strong>Motorcycle</strong> rider parameters have significant <strong>in</strong>fluences on <strong>the</strong>behaviour, with results consistent with a commonly held view, that lightweight riders are more likelyto suffer oscillation problems than heavyweight ones.Keywords: motorcycle, tyre, contact, monoshock, stability, response, sensitivity.1. IntroductionThe handl<strong>in</strong>g qualities <strong>of</strong> motorcycles are <strong>of</strong>ten <strong>of</strong> great importance. They affect<strong>the</strong> pleasure to be ga<strong>in</strong>ed from <strong>the</strong> rider–mach<strong>in</strong>e <strong>in</strong>teractions and <strong>the</strong> safety <strong>of</strong><strong>the</strong> rider. Self-steer<strong>in</strong>g action is crucial with s<strong>in</strong>gle track vehicles and rider controlis primarily by steer<strong>in</strong>g torque, so-called free-control [1]. A consequence <strong>of</strong> <strong>the</strong>free steer<strong>in</strong>g system is that motorcycles are oscillatory. Several modes <strong>of</strong> motionpotentially have small damp<strong>in</strong>g factors. Therefore much attention must be directedtowards controll<strong>in</strong>g <strong>the</strong> oscillatory tendencies, throughout <strong>the</strong> operat<strong>in</strong>g range. Also,it is desirable that motorcycles are responsive to <strong>the</strong> rider’s commands and stabilityshould not be pursued without reference to o<strong>the</strong>r qualities.In straight runn<strong>in</strong>g, motorcycles are substantially symmetric and <strong>in</strong>-plane andout-<strong>of</strong>-plane motions are decoupled at first order level [1, 2]. In corner<strong>in</strong>g, <strong>in</strong>planeand out-<strong>of</strong>-plane cross-coupl<strong>in</strong>g makes any effective analysis <strong>of</strong> <strong>the</strong> dynamicscomplicated. Automated multibody dynamics analysis s<strong>of</strong>tware [3–7] has openedup <strong>the</strong> topic significantly <strong>in</strong> recent years. The steady turn<strong>in</strong>g problem can be solved,

252 R.S. SHARP ET AL.possibly with <strong>the</strong> aid <strong>of</strong> a stabilis<strong>in</strong>g steer<strong>in</strong>g controller, and modal analysis can becompleted for small perturbations from any equilibrium “trim” state.Accuracy <strong>of</strong> predicted behaviour depends, not only on effective conceptual modell<strong>in</strong>gand multibody analysis, but also on good parameter values. Central issues<strong>in</strong> modell<strong>in</strong>g <strong>in</strong>clude <strong>the</strong> representations <strong>of</strong> frame flexibilities, tyre–road contactgeometry and tyre shear forces. Many previous f<strong>in</strong>d<strong>in</strong>gs relate to motorcycle andtyre descriptions which are now somewhat dated and to tyre models which havea limited doma<strong>in</strong> <strong>of</strong> applicability. It is <strong>the</strong>refore <strong>of</strong> <strong>in</strong>terest (i) to obta<strong>in</strong> a parametricdescription <strong>of</strong> a modern mach<strong>in</strong>e, (ii) to utilise a more comprehensive tyreforce model, with parameter values to correspond to a modern set <strong>of</strong> tyres, (iii)to determ<strong>in</strong>e steady turn<strong>in</strong>g, stability, response and parameter sensitivity data forcomparison with older <strong>in</strong>formation, to determ<strong>in</strong>e to what extent it rema<strong>in</strong>s valid,and (iv) to better understand <strong>the</strong> design <strong>of</strong> modern mach<strong>in</strong>es. The paper is subsequentlyan account <strong>of</strong> such work. Novel analysis <strong>of</strong> a “monoshock” rear suspensionsystem is also <strong>in</strong>cluded.2. Parametric Description <strong>of</strong> a Modern <strong>Motorcycle</strong>The authors are currently engaged <strong>in</strong> a measurement campaign to obta<strong>in</strong> <strong>the</strong> relevantparameters <strong>of</strong> a Suzuki GSX-R1000K1 mach<strong>in</strong>e. Such a motorcycle has beendisassembled and many <strong>of</strong> its parts have been measured, start<strong>in</strong>g with <strong>the</strong> lighterones. At this stage, <strong>the</strong> campaign is <strong>in</strong>complete. In particular, <strong>the</strong> frame stiffnessand damp<strong>in</strong>g parameters used and <strong>the</strong> location <strong>of</strong> <strong>the</strong> elastic centre are currentlyonly estimates.2.1. GEOMETRY AND MASSESThe workshop manual for <strong>the</strong> motorcycle <strong>in</strong>cludes pictures to scale and key dimensions,like <strong>the</strong> wheelbase and <strong>the</strong> steer<strong>in</strong>g head angle. Jo<strong>in</strong>ts between componentsat <strong>the</strong> steer<strong>in</strong>g head and <strong>the</strong> sw<strong>in</strong>g arm pivot can be identified <strong>the</strong>re and many keypo<strong>in</strong>ts, <strong>in</strong>clud<strong>in</strong>g those related to <strong>the</strong> monoshock rear suspension, can be locatedwith reasonable precision from <strong>the</strong>se pictures. A scaled diagrammatic representation<strong>of</strong> <strong>the</strong> motorcycle is shown <strong>in</strong> Figure 1, <strong>the</strong> correspond<strong>in</strong>g parameter valuesbe<strong>in</strong>g <strong>in</strong>cluded <strong>in</strong> an Appendix. The front frame has been measured separately togive <strong>the</strong> po<strong>in</strong>ts p3 and p5. The po<strong>in</strong>t p4 is along <strong>the</strong> l<strong>in</strong>e <strong>of</strong> <strong>the</strong> lower front forktranslation relative to <strong>the</strong> upper forks. The estimated location p2 is <strong>the</strong> elastic centre<strong>of</strong> <strong>the</strong> rear frame with respect to a moment perpendicular to <strong>the</strong> steer axis.The rider’s total mass is taken as 72 kg, 62% <strong>of</strong> which is associated with <strong>the</strong>upper body. The masses <strong>of</strong> <strong>the</strong> hands and half <strong>of</strong> <strong>the</strong> lower arms may be consideredto be part <strong>of</strong> <strong>the</strong> steer<strong>in</strong>g system. The rider parameters derive from bio-mechanicaldata [8], account<strong>in</strong>g for his posture on <strong>the</strong> mach<strong>in</strong>e.Circles represent<strong>in</strong>g <strong>the</strong> body mass centres are <strong>in</strong> proportion to <strong>the</strong> massesconcerned, which are known through straightforward weigh<strong>in</strong>g.

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 253Figure 1. Scaled diagrammatic motorcycle <strong>in</strong> side view.2.2. INERTIAS AND MASS CENTRESWheel and tyre <strong>in</strong>ertias have been obta<strong>in</strong>ed by tim<strong>in</strong>g oscillations <strong>of</strong> bi-filar andtri-filar suspension arrangements, utilis<strong>in</strong>g axial symmetry <strong>in</strong> each set-up. Similarbi-filar suspension systems have been used separately for <strong>the</strong> front and rear frames(Figure 2). Each <strong>of</strong> <strong>the</strong>se is assumed to have a plane <strong>of</strong> symmetry and it is clear that<strong>the</strong> front frame pr<strong>in</strong>cipal axes, <strong>in</strong> <strong>the</strong> plane <strong>of</strong> symmetry, are along and perpendicularto <strong>the</strong> l<strong>in</strong>e <strong>of</strong> <strong>the</strong> forks. Oscillation periods, geometric dimensions and <strong>the</strong> mass <strong>of</strong><strong>the</strong> suspended body lead simply to <strong>the</strong> moment <strong>of</strong> <strong>in</strong>ertia about <strong>the</strong> rotation axisand standard transformations allow <strong>the</strong> determ<strong>in</strong>ation <strong>of</strong> pr<strong>in</strong>cipal <strong>in</strong>ertias and axesfor <strong>the</strong> more complex rear frame [9].Recent measurements on a driv<strong>in</strong>g simulator [10] provide estimates <strong>of</strong> <strong>the</strong>contributions to <strong>the</strong> front frame <strong>in</strong>ertia, steer<strong>in</strong>g stiffness and steer<strong>in</strong>g damp<strong>in</strong>gthat arise from <strong>the</strong> rider’s arms and hands, correspond<strong>in</strong>g to relaxed and tenserid<strong>in</strong>g. These can be added to <strong>the</strong> measured values if it is considered appropriate[11]. The sw<strong>in</strong>g arm <strong>in</strong>ertias are small enough to be obta<strong>in</strong>ed by estimationbased on <strong>the</strong> mass centre location and <strong>the</strong> dimensions. The wheels have <strong>the</strong>ir masscentres at <strong>the</strong>ir geometric centres. O<strong>the</strong>r mass centre locations were found us<strong>in</strong>gplumb l<strong>in</strong>es and tak<strong>in</strong>g photographs (Figure 2). Relevant values are given <strong>in</strong> <strong>the</strong>appendix.2.3. STIFFNESS AND DAMPING PROPERTIESSpr<strong>in</strong>gs and dampers were tested <strong>in</strong> a standard dynamic materials test<strong>in</strong>g mach<strong>in</strong>e[12]. The maximum actuator velocity available was about 0.25 m/s, which constra<strong>in</strong>ed<strong>the</strong> damper characteristic measurements. Uni-directional forc<strong>in</strong>g <strong>of</strong> <strong>the</strong>steer<strong>in</strong>g damper up to <strong>the</strong> maximum rate <strong>of</strong> <strong>the</strong> actuator yielded a substantiallyl<strong>in</strong>ear force/velocity relationship with slope 4340 N/(m/s). Us<strong>in</strong>g <strong>the</strong> effective

254 R.S. SHARP ET AL.Figure 2. Bifilar suspended motorcycle rear frame for <strong>in</strong>ertia measurement.moment arm <strong>of</strong> <strong>the</strong> damper (0.04 m) to convert this value to an equivalent rotationalcoefficient gives a value, 6.944 Nm/(rad/s).The dimensions <strong>of</strong> <strong>the</strong> s<strong>in</strong>gle rear steel spr<strong>in</strong>g, from <strong>the</strong> monoshock suspensionwere measured and <strong>the</strong> standard helical spr<strong>in</strong>g formula, k = Gd 4 /(64R 3 n), wasapplied to calculat<strong>in</strong>g <strong>the</strong> rate, k, as55kN/m. The gas filled damper contributessome suspension preload and a small rate, determ<strong>in</strong>ed from <strong>the</strong> test mach<strong>in</strong>e viastatic measurements as 3.57 kN/m. The damper unit was stroked at full actuator

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 255performance first <strong>in</strong> compression and <strong>the</strong>n <strong>in</strong> extension, achiev<strong>in</strong>g velocities up toabout 0.13 m/s. Allow<strong>in</strong>g for <strong>the</strong> gas pressure forces <strong>in</strong> <strong>the</strong> process<strong>in</strong>g, <strong>the</strong> damp<strong>in</strong>gcoefficient <strong>in</strong> compression was 9.6 kN/(m/s) and <strong>in</strong> rebound 13.7 kN/(m/s). Frontspr<strong>in</strong>g and damper coefficients are estimates, at this stage. Suspension limit stops are<strong>in</strong>cluded at each end, modelled as fifth powers <strong>of</strong> displacement from stop contact.The relevant displacements are known from exam<strong>in</strong>ation <strong>of</strong> <strong>the</strong> parts and from<strong>in</strong>formation given <strong>in</strong> <strong>the</strong> workshop manual.The torsional stiffness <strong>of</strong> <strong>the</strong> ma<strong>in</strong> frame, between <strong>the</strong> steer<strong>in</strong>g head and <strong>the</strong>power unit, rema<strong>in</strong>s to be measured. It is clear from <strong>the</strong> structural design andmaterials used that <strong>the</strong> frame is considerably stiffer than was <strong>the</strong> norm for tubularframed motorcycles <strong>of</strong> some years ago. In those cases, it was established that <strong>the</strong>frame flexibility was an essential contributor to <strong>the</strong> stability <strong>of</strong> <strong>the</strong> wobble mode,<strong>in</strong> particular [13, 14]. It rema<strong>in</strong>s to be seen how significant this area is for modernmach<strong>in</strong>es. The torsional stiffness assumed, at 10 5 Nm/rad, is 3.5 times that measuredstatically for a Yamaha 650S [15] and 2.9 times that measured at about <strong>the</strong> sametime by Koenen [2]. Tyre radial stiffnesses come directly from [7].The rider’s upper body has roll freedom relative to <strong>the</strong> ma<strong>in</strong> frame, while <strong>the</strong>lower body is part <strong>of</strong> <strong>the</strong> ma<strong>in</strong> frame. The upper body is restra<strong>in</strong>ed by a parallelspr<strong>in</strong>g damper system. Stiffness and damp<strong>in</strong>g parameters are chosen <strong>in</strong> alignmentwith <strong>the</strong> experimental results <strong>of</strong> Nishimi et al [16], obta<strong>in</strong>ed by identify<strong>in</strong>g “rider”parameters <strong>in</strong> forced vibration on a mock motorcycle frame. The decoupled naturalfrequency <strong>of</strong> <strong>the</strong> rider upper body <strong>in</strong> roll is 1.27 Hz and <strong>the</strong> correspond<strong>in</strong>g damp<strong>in</strong>gfactor is 0.489. Accord<strong>in</strong>g to this model, rider resonance will not be apparent due to<strong>the</strong> high damp<strong>in</strong>g factor and it will not be tuned to <strong>the</strong> mach<strong>in</strong>e oscillations, where<strong>the</strong>se are at all vigorous.2.4. AERODYNAMICSAerodynamic drag, lift and pitch<strong>in</strong>g moment data come from a Triumph motorcycle<strong>of</strong> similar style and dimensions to <strong>the</strong> GSX-R1000 [1]. This is steady-state dragforce, lift force and pitch<strong>in</strong>g moment data from full scale w<strong>in</strong>d tunnel test<strong>in</strong>g, witha prone rider.3. Tyre–Road Contact Modell<strong>in</strong>gThe geometry <strong>of</strong> <strong>the</strong> contact between <strong>the</strong> front tyre and <strong>the</strong> ground is a relativelycomplex part <strong>of</strong> <strong>the</strong> motorcycle modell<strong>in</strong>g. It is also important to <strong>the</strong> behaviour <strong>of</strong><strong>the</strong> mach<strong>in</strong>e. It has been common to represent <strong>the</strong> tyre as a th<strong>in</strong> disc, with <strong>the</strong> contactpo<strong>in</strong>t migrat<strong>in</strong>g circumferentially for larger camber and steer angles, but Cossalteret al have pioneered <strong>the</strong> <strong>in</strong>clusion <strong>of</strong> tyre width <strong>in</strong> <strong>the</strong>ir descriptions [7, 17–19].If a disc model is used, it needs to be augmented with an overturn<strong>in</strong>g momentdescription [2, 5]. This is not necessary with a thick tyre model, s<strong>in</strong>ce <strong>the</strong> lateralmigration <strong>of</strong> <strong>the</strong> contact po<strong>in</strong>t <strong>the</strong>n occurs automatically and <strong>the</strong> overturn<strong>in</strong>g momentis a consequence <strong>of</strong> that movement. A wide tyre with a circular cross-section

256 R.S. SHARP ET AL.Figure 3. Diagrammatic three-dimensional front wheel contact geometry.crown is now modelled. In addition to mak<strong>in</strong>g <strong>the</strong> overturn<strong>in</strong>g moment automatic,longitud<strong>in</strong>al forces applied to <strong>the</strong> cambered tyre will lead to realistic align<strong>in</strong>gmoments appear<strong>in</strong>g automatically. A necessary test for <strong>the</strong> wide tyre model isthat it gives <strong>the</strong> same results as <strong>the</strong> th<strong>in</strong> tyre model, when physically equivalentsystems are be<strong>in</strong>g represented. This test has been applied, with some significantconsequences.To def<strong>in</strong>e each tyre/ground contact po<strong>in</strong>t (Figures 3 and 4) <strong>the</strong> vertical and <strong>the</strong>wheel sp<strong>in</strong>dle directions are used <strong>in</strong> a vector (cross) product to describe <strong>the</strong> longitud<strong>in</strong>aldirection, with respect to <strong>the</strong> wheel. Similarly, <strong>the</strong> wheel radial direction, OC<strong>in</strong> Figure 3, comes from comb<strong>in</strong><strong>in</strong>g <strong>the</strong> longitud<strong>in</strong>al and wheel sp<strong>in</strong>dle directions.The vector OC is <strong>of</strong> fixed length and so is completely specified. G is vertically belowC and <strong>the</strong> difference between <strong>the</strong> tyre crown radius and <strong>the</strong> distance CG def<strong>in</strong>es<strong>the</strong> change <strong>in</strong> <strong>the</strong> tyre carcass compression from <strong>the</strong> nom<strong>in</strong>al state and hence <strong>the</strong>change <strong>of</strong> <strong>the</strong> wheel load from <strong>the</strong> nom<strong>in</strong>al, via <strong>the</strong> tyre radial stiffness. If <strong>the</strong> roadis pr<strong>of</strong>iled, <strong>the</strong> road height is accounted for <strong>in</strong> work<strong>in</strong>g out <strong>the</strong> wheel load. Thevector OG = OC + CG def<strong>in</strong>es <strong>the</strong> contact po<strong>in</strong>t, which belongs to <strong>the</strong> wheel butmoves with<strong>in</strong> it. G rema<strong>in</strong>s at road surface height but <strong>the</strong> tyre load cannot becomenegative. If <strong>the</strong> tyre leaves <strong>the</strong> ground, <strong>the</strong> shear forces are zero, whatever <strong>the</strong> o<strong>the</strong>rconditions are. Tyre forces are applied to <strong>the</strong> po<strong>in</strong>t G, <strong>in</strong> each case.The longitud<strong>in</strong>al slip is <strong>the</strong> rearward component <strong>of</strong> <strong>the</strong> material contact po<strong>in</strong>tvelocity divided by <strong>the</strong> absolute value <strong>of</strong> <strong>the</strong> roll<strong>in</strong>g velocity, <strong>the</strong> latter be<strong>in</strong>g <strong>the</strong>forward velocity <strong>of</strong> <strong>the</strong> contact po<strong>in</strong>t (or <strong>the</strong> crown centre po<strong>in</strong>t, s<strong>in</strong>ce <strong>the</strong>se are<strong>the</strong> same). The contact po<strong>in</strong>t is def<strong>in</strong>ed by its coord<strong>in</strong>ates <strong>in</strong> <strong>the</strong> parent body <strong>of</strong> <strong>the</strong>wheel and it is de-spun relative to <strong>the</strong> material contact po<strong>in</strong>t. Thus <strong>the</strong> longitud<strong>in</strong>al

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 257Figure 4. Diagrammatic two-dimensional front wheel contact geometry.slip is given by an expression <strong>of</strong> <strong>the</strong> form:κ =−(roll<strong>in</strong>g velocity + sp<strong>in</strong> component <strong>of</strong> longitud<strong>in</strong>al velocity)/abs(roll<strong>in</strong>g velocity)The slip angle is <strong>the</strong> arctangent <strong>of</strong> <strong>the</strong> ratio <strong>of</strong> <strong>the</strong> (negative) lateral velocity <strong>of</strong> <strong>the</strong>tyre contact centre po<strong>in</strong>t to <strong>the</strong> absolute value <strong>of</strong> <strong>the</strong> roll<strong>in</strong>g velocity.In develop<strong>in</strong>g this new model from <strong>the</strong> former one [5], <strong>in</strong> which <strong>the</strong> wheelswere represented as th<strong>in</strong> discs, subtle differences between <strong>the</strong> root locus predictions<strong>of</strong> <strong>the</strong> old and new versions were observed <strong>in</strong> circumstances which were at thatstage thought physically equivalent. Such differences were found to be associatedwith <strong>the</strong> former description <strong>of</strong> <strong>the</strong> slip angles as deriv<strong>in</strong>g from <strong>the</strong> lateral velocitycomponents <strong>of</strong> <strong>the</strong> disc tyre contact po<strong>in</strong>ts. When <strong>the</strong> wheel camber angle ischang<strong>in</strong>g, <strong>the</strong>se po<strong>in</strong>ts have a small lateral velocity component not connected withsideslipp<strong>in</strong>g, s<strong>in</strong>ce with <strong>the</strong> real tyre, <strong>the</strong> contact po<strong>in</strong>t moves around <strong>the</strong> circularsection sidewall <strong>of</strong> <strong>the</strong> tyre. The former model would have provided a more accuratedescription if it had used <strong>the</strong> crown centre po<strong>in</strong>t velocities to derive <strong>the</strong> slip angles.4. Tyre Forces and MomentsThe basis for <strong>the</strong> new tyre modell<strong>in</strong>g is <strong>the</strong> “Magic Formula” [20–22]. The orig<strong>in</strong>aldevelopment was for car tyres [23], <strong>in</strong> which context, it has become dom<strong>in</strong>ant. The

258 R.S. SHARP ET AL.extension for motorcycle tyres is relatively recent, with substantial changes be<strong>in</strong>gnecessary to accommodate <strong>the</strong> completely different roles <strong>of</strong> sideslip and camberforces <strong>in</strong> <strong>the</strong> two cases. In each case, <strong>the</strong> “Magic Formula” is a set <strong>of</strong> equationsrelat<strong>in</strong>g load, slip ratio (longitud<strong>in</strong>al slip), slip angle and camber angle to longitud<strong>in</strong>alforce, sideforce and align<strong>in</strong>g moment (and possibly overturn<strong>in</strong>g moment), withconstra<strong>in</strong>ts on <strong>the</strong> parameters to prevent <strong>the</strong> behaviour from becom<strong>in</strong>g unreasonable<strong>in</strong> any operat<strong>in</strong>g conditions. Only very limited parameter values can be found <strong>in</strong><strong>the</strong> literature, but a certa<strong>in</strong> amount <strong>of</strong> relevant experimental data is available. Suchdata can be used for parameter identification.A complete set <strong>of</strong> parameter values for a given tyre will allow <strong>the</strong> calculation <strong>of</strong><strong>the</strong> steady-state force and moment system for any realistic operat<strong>in</strong>g condition. Itis required here to determ<strong>in</strong>e such a full set <strong>of</strong> parameters for modern front and rearhigh performance motorcycle tyres, impos<strong>in</strong>g <strong>the</strong> condition that <strong>the</strong> modelled tyreshave left/right symmetry. Test data used shows bias and it is necessary to ignoresuch bias and to omit certa<strong>in</strong> <strong>of</strong>fset terms from <strong>the</strong> “Magic Formula” relations, <strong>in</strong>order to model <strong>the</strong> generic, ra<strong>the</strong>r than <strong>the</strong> particular. Significant published datacan be found <strong>in</strong> [2, 20–25]. Naturally, <strong>the</strong> older data refers to older tyres, while <strong>the</strong>newer data relates to contemporary ones. The ma<strong>in</strong> sources relied upon here are[20, 23]. The o<strong>the</strong>r sources are used for check<strong>in</strong>g purposes, as appropriate.4.1. LONGITUDINAL FORCES IN PURE LONGITUDINAL SLIPFrom Pacejka [23], with <strong>the</strong> simplifications expla<strong>in</strong>ed above, <strong>the</strong> “Magic Formula”expressions for <strong>the</strong> pure longitud<strong>in</strong>al slip case are:d f z = (F z − F z0 )/F z0 (1)F x0 = D x s<strong>in</strong>[C x arctan{B x κ − E x (B x κ − arctan(B x κ))}] (2)D x = (p Dx1 + p Dx2 d f z )F z (3)E x = ( p Ex1 + p Ex2 d f z + p Ex3 d fz2 )· (1 − pEx4 sgn(κ)) (4)K xκ = F z (p Kx1 + p Kx2 d f z ) · exp(p Kx3 d f z ) (5)B x = K xκ /(C x D x ) (6)which must satisfy <strong>the</strong> constra<strong>in</strong>ts D x > 0 and E x < 1.Correspond<strong>in</strong>g test results for a 160/70 ZR17 tyre are shown <strong>in</strong> [23]. The sequentialquadratic programm<strong>in</strong>g constra<strong>in</strong>ed optimisation rout<strong>in</strong>e “fm<strong>in</strong>con” wasemployed 1 to iteratively improve <strong>the</strong> elements <strong>of</strong> a start<strong>in</strong>g vector <strong>of</strong> parameters1 Alternatively, for unconstra<strong>in</strong>ed optimization, <strong>the</strong> Nelder Mead Simplex rout<strong>in</strong>e “fm<strong>in</strong>search”was employed. Also occasionally, it was necessary to “<strong>in</strong>vent” data, outside <strong>the</strong> range <strong>of</strong> experimentalresults available, to force <strong>the</strong> identified parameters to give sensible predictions over a wide range <strong>of</strong>operat<strong>in</strong>g circumstances, a problem also referred to <strong>in</strong> [26]. Often, reasonably accurate start<strong>in</strong>g valuesfor <strong>the</strong> parameters were needed to ensure convergence to <strong>the</strong> optimal solution. The methods need tobe judged by <strong>the</strong> results obta<strong>in</strong>ed.

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 259Table I. Best-fit parameter values for longitud<strong>in</strong>al force from 160/70 tyre.C x p Dx1 p Dx2 p Ex1 p Ex2 p Ex3 p Ex4 p Kx1 p Kx2 p Kx31.6064 1.2017 −0.0922 0.0263 0.27056 −0.0769 1.1268 25.94 −4.233 0.3369Figure 5. Tyre longitud<strong>in</strong>al force results for a 160/70 tyre from [23] (thick l<strong>in</strong>es) with best-fitreconstructions (th<strong>in</strong> l<strong>in</strong>es).appear<strong>in</strong>g <strong>in</strong> Equations (1)–(5). The nom<strong>in</strong>al normal load F z0 was chosen to be1600 N based on typical usage <strong>of</strong> such a tyre. That choice is far from critical,<strong>in</strong> fact, a change lead<strong>in</strong>g to compensatory changes <strong>in</strong> o<strong>the</strong>r parameters. Optimalparameters are given <strong>in</strong> Table I and <strong>the</strong> fits are illustrated <strong>in</strong> Figure 5. The twoconstra<strong>in</strong>ts are satisfied for loads less than 20890 N, which <strong>in</strong>cludes all practicalcircumstances.Longitud<strong>in</strong>al force results are not available for any o<strong>the</strong>r tyres, so lateral forcesare considered next.4.2. LATERAL FORCES IN PURE SIDESLIP AND CAMBERIn exactly <strong>the</strong> same way, <strong>the</strong> relevant equations for <strong>the</strong> lateral force are:F y0 = D y s<strong>in</strong>[C y arctan{B y β − E y (B y β − arctan(B y β))}+ C γ arctan{B γ γ − E γ (B γ γ − arctan(B γ γ ))}] (7)

260 R.S. SHARP ET AL.Figure 6. Tyre lateral force results for a 160/70 tyre from [23] (thick l<strong>in</strong>es) with best-fitreconstructions (th<strong>in</strong> l<strong>in</strong>es). Camber angles 5, 0, −5, −10, −20, −30 ◦ .D y = F z p Dy1 exp(p Dy2 d f z )/(1 + p Dy3 γ 2 ) (8)E y = p Ey1 + p Ey2 γ 2 + p Ey4 γ sgn(β) (9)K yα = p Ky1 F z0 s<strong>in</strong>[p Ky2 arctan{F z /((p Ky3 + p Ky4 γ 2 )F z0 )}]/(1 + p Ky5 γ 2 ) (10)B y = K yα /(C y D y ) (11)K yγ = (p Ky6 + p Ky7 d f z )F z (12)B γ = K yγ /(C γ D y ) (13)with <strong>the</strong> constra<strong>in</strong>ts C y + C γ < 2, C y > 0, D y > 0, E y < 1, C g > 0, E g < 1.For <strong>the</strong> same tyre as before, <strong>the</strong> parameter optimisation process, with <strong>the</strong> effectivefriction coefficient limited to values no greater than 1.3, gives <strong>the</strong> results illustrated<strong>in</strong> Figure 6 with parameter values given below <strong>in</strong> Table II. For this particular tyre,p Ky7 <strong>in</strong> Equation (12) was set to zero, because experimental results are only availableTable II. Best-fit parameter values for lateral force from 160/70 (top), 120/70 (middle) and180/55 (bottom) tyresC y p Dy1 p Dy2 p Dy3 p Ey1 p Ey2 p Ey4 p Ky10.93921 1.1524 −0.01794 −0.06531 −0.94635 −0.09845 −1.6416 26.6010.8327 1.3 0 0 −1.2556 −3.2068 −3.998 22.8410.9 1.3 0 0 −2.2227 −1.669 −4.288 15.791p Ky2 p Ky3 p Ky4 p Ky5 C γ p Ky6 p Ky7 E γ1.0167 1.4989 0.52567 −0.24064 0.50732 0.7667 0 −4.74812.1578 2.5058 −0.08088 −0.22882 0.86765 0.69677 −0.03077 −15.8151.6935 1.4604 0.669 0.18708 0.61397 0.45512 0.013293 −19.99

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 261Figure 7. Tyre lateral force results for 120/70 tyre from [20] (thick l<strong>in</strong>es) with best-fit reconstructions(th<strong>in</strong> l<strong>in</strong>es). Camber angles 0, 10, 20, 30, 40, 45 ◦ .at non-zero camber angle for one load. This is consistent with results obta<strong>in</strong>ed for120/70 and 180/55 tyres (see below), for which p Ky7 is relatively small, be<strong>in</strong>gpositive <strong>in</strong> one case and negative <strong>in</strong> <strong>the</strong> o<strong>the</strong>r. All <strong>the</strong> constra<strong>in</strong>ts are satisfied forcamber angles less than 70 ◦ <strong>in</strong> magnitude.Next, <strong>the</strong> lateral force fitt<strong>in</strong>g is repeated for <strong>the</strong> experimental results <strong>in</strong>cluded<strong>in</strong> [20] for a 120/70 front tyre and a 180/55 rear tyre, first recognis<strong>in</strong>g that <strong>the</strong>former results suffer from an unreasonable positive force <strong>of</strong>fset, especially for <strong>the</strong>smaller loads, which would imply a friction coefficient greater than 2, if <strong>the</strong>y weretrue. To avoid respond<strong>in</strong>g too strongly to <strong>the</strong>se apparently spurious features, D y isallowed to be no greater than 1.3 times F z . Also, <strong>the</strong> measurements for slip anglesgreater than +5 ◦ are ignored. The previous rear tyre value <strong>of</strong> F z0 as 1600 N isreta<strong>in</strong>ed while <strong>the</strong> non-critical value for <strong>the</strong> front tyre was chosen as 1100 N. Bestfitparameters are shown <strong>in</strong> Table II, with Figures 7 and 8 show<strong>in</strong>g <strong>the</strong> quality <strong>of</strong> <strong>the</strong>fits for <strong>the</strong> front and rear tyres respectively. All <strong>the</strong> constra<strong>in</strong>ts are satisfied by <strong>the</strong>separameters.

262 R.S. SHARP ET AL.Figure 8. Tyre lateral force results for 180/55 tyre from [20] (thick l<strong>in</strong>es) with best-fit reconstructions(th<strong>in</strong> l<strong>in</strong>es). Camber angles 0, 10, 20, 30, 40, 45 ◦ .4.3. ALIGNING MOMENTS IN LATERAL SLIP AND CAMBERAlign<strong>in</strong>g moment results are <strong>in</strong>cluded <strong>in</strong> [23] for <strong>the</strong> 160/70 tyre and <strong>in</strong> [20] for120/70 and 180/55 tyres. Three loads are covered <strong>in</strong> <strong>the</strong> former but only two <strong>in</strong><strong>the</strong> latter, which makes <strong>the</strong> model very heavy <strong>in</strong> parameters for <strong>the</strong> amount <strong>of</strong>experimental data available. In sett<strong>in</strong>g <strong>the</strong> parameters for <strong>the</strong> 160/70 tyre <strong>of</strong> [23]assum<strong>in</strong>g <strong>the</strong> full quadratic dependency <strong>of</strong> B t on load, <strong>the</strong> fitt<strong>in</strong>g is good with<strong>in</strong> <strong>the</strong>load range used for <strong>the</strong> measurements but <strong>the</strong> extrapolation is poor, with constra<strong>in</strong>tviolations at low and high loads. With l<strong>in</strong>ear dependency, <strong>the</strong> fitt<strong>in</strong>g is almost as goodand <strong>the</strong> extrapolation problem can be elim<strong>in</strong>ated. Consequently, B t is consideredl<strong>in</strong>ear with load. Even so, <strong>the</strong>re are many parameter comb<strong>in</strong>ations which givealmost equally good fits to <strong>the</strong> limited data. It is advantageous to use some physicalreason<strong>in</strong>g to guide <strong>the</strong> choice between <strong>the</strong> alternatives. The product <strong>of</strong> B t , C t andD t is <strong>the</strong> align<strong>in</strong>g moment stiffness <strong>of</strong> <strong>the</strong> tyre. Accord<strong>in</strong>g to <strong>the</strong> “Brush Model”[23], <strong>the</strong> align<strong>in</strong>g moment stiffness is proportional to load to <strong>the</strong> power 1.5, so thatfeature is used to aid <strong>the</strong> choice <strong>of</strong> <strong>the</strong> secondary parameters q Bz1 and q Bz2 , see (18).It turns out to be quite feasible to match that characteristic closely. Also, as before,

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 263Table III. Best-fit parameter values for align<strong>in</strong>g moment from 160/70 (top), 120/70 (middle)and 180/55 tyre (bottom)C t q Bz1 q Bz2 q Bz5 q Bz6 q Bz9 q Bz101.3115 10.354 4.3004 −0.34033 −0.13202 10.118 −1.05081.0917 10.486 −0.001154 −0.68973 1.0411 27.445 −1.07921.3153 10.041 −1.61e-8 −0.76784 0.73422 16.39 −0.35549q Dz1 q Dz2 q Dz3 q Dz4 q Dz8 q Dz9 q Dz100.20059 0.05282 −0.21116 −0.15941 0.30941 0 0.100370.19796 0.06563 0.2199 0.21866 0.3682 0.1218 0.254390.26331 0.030987 −0.62013 0.98524 0.50453 0.36312 −0.19168q Dz11 q Ez1 q Ez2 q Ez5 q Hz3 q Hz40 −3.9247 10.809 0.9836 −0.04908 0−0.17873 −0.91586 0.11625 1.4387 −0.003789 −0.01557−0.40709 −0.19924 −0.017638 3.6511 −0.028448 −0.009862right/left symmetry and zero <strong>of</strong>fsets are assumed, mak<strong>in</strong>g q Ez4 , q Hz1 and q Hz2 zero.The relevant “Magic Formula” Equations [23] are:M z0 = M zt0 + M zr0 (14)M zt0 =−D t cos[C t arctan{B t β − E t (B t β − arctan(B t β))}]/ √ 1 + β 2 · F y0,γ =0 (15)M zr0 = D r cos[arctan(B r (β + S Hr )] (16)S Hr = (q Hz3 + q Hz4 d f z )γ (17)B t = (q Bz1 + q Bz2 d f z )(1 + q Bz5 |γ |+q Bz6 γ 2 ) (18)D t = F z (R 0 /F z0 )(q Dz1 + q Dz2 d f z )(1 + q Dz3 |γ |+q Dz4 γ 2 ) (19)E t = (q Ez1 + q Ez2 d f z ){1 + q Ez5 γ (2/π) arctan(B t C t β)} (20)B r = q Bz9 + q Bz10 B y C y (21)D r = F z R 0 {(q Dz8 + q Dz9 d f z )γ + (q Dz10 + q Dz11 d f z )γ |γ |}/ √ 1 + β 2 (22)with <strong>the</strong> constra<strong>in</strong>ts: B t > 0, C t > 0 and E t < 1. For <strong>the</strong> 160/70 tyre, q Hz4<strong>in</strong> Equation (17) and q Dz9 and q Dz11 <strong>in</strong> Equation (22) are set to zero, becauseexperimental results are only provided at non-zero camber angle for one load.The tyre crown radius, R 0 , for each tyre derives from <strong>the</strong> cross-sectional geometryas 0.08 m for 160/70, 0.06 m for 120/70 and 0.09 m for 180/55 [7]. Identification<strong>of</strong> <strong>the</strong> rema<strong>in</strong><strong>in</strong>g parameters us<strong>in</strong>g “fm<strong>in</strong>con” as before gives <strong>the</strong> values <strong>in</strong> TableIII. Constra<strong>in</strong>t violations occur only for loads greater than 11 kN, sideslip anglegreater than 45 ◦ or camber angle greater than 60 ◦ . These violations are outside <strong>the</strong>practical runn<strong>in</strong>g range. The fit qualities are shown <strong>in</strong> Figures 9–11.

264 R.S. SHARP ET AL.Figure 9. Tyre align<strong>in</strong>g moment results for 160/70 tyre from [23] (thick l<strong>in</strong>es) with best-fitreconstructions (th<strong>in</strong> l<strong>in</strong>es). Camber angles 5, 0, −5, −10, −20, −30 ◦ .Figure 10. Tyre align<strong>in</strong>g moment results for 120/70 tyre from [20] (thick l<strong>in</strong>es) with best-fitreconstructions (th<strong>in</strong> l<strong>in</strong>es). Camber angles 0, 10, 20, 30, 40, 45 ◦ .Figure 11. Tyre align<strong>in</strong>g moment results for 180/55 tyre from [20] (thick l<strong>in</strong>es) with best-fitreconstructions (th<strong>in</strong> l<strong>in</strong>es). Camber angles 0, 10, 20, 30, 40 and 45 ◦ .

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 2654.4. COMBINED SLIP RESULTS4.4.1. Longitud<strong>in</strong>al ForcesIn <strong>the</strong> “Magic Formula” scheme, <strong>the</strong> loss <strong>of</strong> longitud<strong>in</strong>al force due to sideslipp<strong>in</strong>g isdescribed by a “loss function” to be applied to <strong>the</strong> pure slip force described above.Presum<strong>in</strong>g as before that <strong>the</strong> generic tyres <strong>of</strong> <strong>in</strong>terest will be symmetric (S Hxα = 0)and, <strong>in</strong> <strong>the</strong> absence <strong>of</strong> any <strong>in</strong>dication to <strong>the</strong> contrary, assum<strong>in</strong>g that wheel camberwill not affect <strong>the</strong> loss <strong>of</strong> longitud<strong>in</strong>al force due to sideslipp<strong>in</strong>g (r Bx3 = 0), <strong>the</strong>equations describ<strong>in</strong>g <strong>the</strong> loss are:F x = cos[C xα arctan(B xα β)]F x0 (23)B xα = r Bx1 cos[arctan(r Bx2 κ)] (24)with <strong>the</strong> constra<strong>in</strong>ts that F x > 0 and B xα > 0.The only relevant comb<strong>in</strong>ed slip data available is from [23] for <strong>the</strong> 160/70 tyrefor 3 kN load and zero camber angle. The same parameter identification processas before yielded <strong>the</strong> best values as r Bx1 = 13.476; r Bx2 = 11.354; C xα = 1.1231,with <strong>the</strong> fit quality shown <strong>in</strong> Figure 12. The constra<strong>in</strong>t on B xα is always satisfiedwhile that on F x is satisfied for slip angles less than 23 ◦ , which is considered toprovide an adequate operat<strong>in</strong>g range.4.4.2. Lateral ForcesIn <strong>the</strong> same way (with S Vyκ = S Hyκ = r By4 = 0), <strong>the</strong> equations describ<strong>in</strong>g <strong>the</strong> loss<strong>of</strong> lateral force due to longitud<strong>in</strong>al slip are:F y = cos[C yκ arctan(B yκ κ)]F y0 (25)B yκ = r By1 cos[arctan{r By2 (β − r By3 )}] (26)with constra<strong>in</strong>ts F y > 0 and B yk > 0.Data aga<strong>in</strong> comes from Pacejka [23] and is for <strong>the</strong> 160/70 tyre at 3 kN and zerocamber. It yields <strong>the</strong> best-fit parameters as r By1 = 7.7856, r By2 = 8.1697, r By3 =−0.05914 and C yκ = 1.0533. The fit quality is shown <strong>in</strong> Figures 13 and 14.4.4.3. Align<strong>in</strong>g MomentsThe relevant equations (with s = S Vyκ = S Hyκ = 0) are:M z =−D t cos[C t arctan{B t λ t − E t (B t λ t − arctan(B t λ t ))}]/ √ 1 + β 2 · F y,γ =0 + M zr (27)F y,γ =0 = cos[C yκ arctan(B yκ κ)] · F y0,γ =0 (28)M zr = D r cos[arctan(B r λ r )]√(29)λ t = β 2 + (K xκ κ/K yα,γ =0 ) 2 sgn(β) (30)√λ r = (β + S Hr ) 2 + (K xκ κ/K yα,γ =0 ) 2 sgn(β + S Hr ) (31)

266 R.S. SHARP ET AL.Figure 12. Influence <strong>of</strong> sideslip on longitud<strong>in</strong>al force for 160/70 tyre at 3kN load and zerocamber from [23] (thick l<strong>in</strong>es) with best-fit reconstructions (th<strong>in</strong> l<strong>in</strong>es). Theoretical curves for+2 and −2 ◦ camber are <strong>in</strong>dist<strong>in</strong>guishable.The term s · F x <strong>in</strong> <strong>the</strong> orig<strong>in</strong>al [23] is omitted, s<strong>in</strong>ce s here is zero, by virtue <strong>of</strong><strong>the</strong> reference po<strong>in</strong>t for moments be<strong>in</strong>g <strong>the</strong> actual contact po<strong>in</strong>t.Expressions for K xκ , F y0 , K yα , B t , E t , D r , C yk and B yκ are given by (5), (7), (10),(18), (20), (21), (22), (25) and (26) respectively, and C t is given <strong>in</strong> Table III. Thusfur<strong>the</strong>r parameter identification is unnecessary and <strong>the</strong> comb<strong>in</strong>ed slip moments canbe predicted from what is known already. The align<strong>in</strong>g moment for <strong>the</strong> 160/70 tyreat 3 kN load, as a function <strong>of</strong> longitud<strong>in</strong>al slip, for several slip angles, is shown <strong>in</strong>Figure 15.4.5. LONGITUDINAL FORCE MODELS FOR 120/70 AND 180/55 TYRESLongitud<strong>in</strong>al forces for 120/70 and 180/55 tyres were not measured <strong>in</strong> [20]. Inorder to complete a general description <strong>of</strong> those tyres, it is necessary to make up,us<strong>in</strong>g <strong>the</strong> best evidence available, appropriate parameter values to describe <strong>the</strong>irproperties. The strategy for do<strong>in</strong>g this is to use <strong>the</strong> 160/70 tyre as a model andto scale its data to obta<strong>in</strong> those for <strong>the</strong> o<strong>the</strong>r tyres. Longitud<strong>in</strong>al pure slip parametersfor <strong>the</strong> 160/70 tyre are given above <strong>in</strong> Table I, while those for pure lateralslip appear <strong>in</strong> Table II. In particular, <strong>the</strong> ratio <strong>of</strong> peak forces D x /D y is evaluated

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 267Figure 13. Influence <strong>of</strong> sideslip on lateral force for 160/70 tyre at 3 kN load and zero camberfrom [23] (thick l<strong>in</strong>es) with best-fit reconstructions (th<strong>in</strong> l<strong>in</strong>es).Figure 14. Influence <strong>of</strong> sideslip on longitud<strong>in</strong>al and lateral forces for 160/70 tyre at 3 kN loadand zero camber from [23] (thick l<strong>in</strong>es) with best-fit reconstructions (th<strong>in</strong> l<strong>in</strong>es).

268 R.S. SHARP ET AL.Figure 15. Align<strong>in</strong>g moment for 160/70 tyre at 3 kN load and zero camber as a function <strong>of</strong>longitud<strong>in</strong>al slip for each <strong>of</strong> four sideslip cases.for 1, 2 and 3 kN load as 1.066, 1.028 and 0.989 respectively. The same ratiosare assumed to apply to <strong>the</strong> 120/70 and 180/55 tyres, with <strong>the</strong>ir shapes assumedto be <strong>the</strong> same as those for <strong>the</strong> 160/70 tyre. The only new parameters needed arep Dx1 and p Dx2 , with values 1.381 for 120/70 and 1.355 for 180/55 and −0.04143for 120/70 and −0.0603 for 180/55 respectively. Longitud<strong>in</strong>al force peaks areabout 1.33 times <strong>the</strong> tyre load <strong>in</strong> <strong>the</strong> usual operat<strong>in</strong>g range <strong>of</strong> loads, which iscompatible with acceleration and brak<strong>in</strong>g performances obta<strong>in</strong>able from a contemporarymotorcycle. Parameters apart from p Dx1 and p Dx2 <strong>in</strong> Table I apply to thiscase.4.6. COMBINED SLIP FORCE MODELS FOR 120/70 AND 180/55 TYRESIn <strong>the</strong> same way, <strong>the</strong> comb<strong>in</strong>ed slip parameters given for <strong>the</strong> 160/70 tyre <strong>in</strong> Sections4.4.1 and 4.4.2 are regarded as describ<strong>in</strong>g <strong>the</strong> behaviour <strong>of</strong> <strong>the</strong> 120/70 and 180/55tyres also. Comb<strong>in</strong>ation <strong>of</strong> longitud<strong>in</strong>al force under pure longitud<strong>in</strong>al slip with <strong>the</strong>loss function data from Section 4.4.1 and <strong>of</strong> lateral force under pure lateral slipwith <strong>the</strong> loss function data <strong>of</strong> Section 4.4.2 allows <strong>the</strong> prediction <strong>of</strong> comb<strong>in</strong>ed slipforces generally.

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 2694.7. CHECKING AGAINST OTHER DATAThe complete tyre model has been used to calculate <strong>the</strong> force and moment systemcorrespond<strong>in</strong>g to runn<strong>in</strong>g conditions for which data has been published [2, 7, 24, 25,27, 28]. In each case, <strong>the</strong> results compare reasonably with <strong>the</strong> orig<strong>in</strong>als, provid<strong>in</strong>greassurance that <strong>the</strong> generic model with its parameter values can be employed withconfidence.4.8. RELAXATION LENGTH DESCRIPTION AND DATATo replicate <strong>the</strong> properties <strong>of</strong> <strong>the</strong> higher frequency modes <strong>in</strong> particular, it is essentialto model motorcycle tyres with relaxation lags <strong>in</strong>cluded [1]. Conventionally, aconstant relaxation length for each tyre is employed but it was found <strong>in</strong> [20] that<strong>the</strong> tyre relaxation length typically varies with load roughly as <strong>the</strong> corner<strong>in</strong>g stiffnessdoes and that it grows with speed. Us<strong>in</strong>g <strong>the</strong> data from [20] for 120/70 front and180/55 rear tyres and fitt<strong>in</strong>g a quadratic function <strong>of</strong> speed to <strong>the</strong> results <strong>in</strong> each case,we obta<strong>in</strong> <strong>the</strong> descriptions:andσ f = K yα f (8.633e − 6 + 3.725e − 8.V + 8.389e − 10.V 2 )σ r = K yαr (9.694e − 6 − 1.333e − 8V + 1.898e − 9V 2 )The corner<strong>in</strong>g stiffnesses come out <strong>of</strong> <strong>the</strong> “Magic Formula” computations, Equation(11). Relaxation is applied to <strong>the</strong> sideslip ra<strong>the</strong>r than <strong>the</strong> sideforces, throughequations <strong>of</strong> <strong>the</strong> form: σ ˙β 1 /V + β 1 = β. This implies that forces and momentsaris<strong>in</strong>g from wheel camber are treated as occurr<strong>in</strong>g without delay, while those aris<strong>in</strong>gfrom sideslip are lagged. This is considered to be <strong>the</strong> most physically accuraterepresentation, s<strong>in</strong>ce camber leads to forces geometrically while sideslip leads t<strong>of</strong>orces via distortion <strong>of</strong> <strong>the</strong> tyre carcass, which distortion requires time (or distancerolled) to establish.5. “Monoshock” Rear SuspensionThe motorcycle rear suspension arrangement is shown diagrammatically <strong>in</strong> Figure16. It uses a s<strong>in</strong>gle spr<strong>in</strong>g/damper unit with a mechanical l<strong>in</strong>kage connection to<strong>the</strong> sw<strong>in</strong>g<strong>in</strong>g arm. Many modern rear suspensions are <strong>of</strong> this type, although severalvariants <strong>of</strong> it exist. It <strong>in</strong>volves a closed k<strong>in</strong>ematic loop. Such a suspension can bemodelled on-l<strong>in</strong>e literally, l<strong>in</strong>k by l<strong>in</strong>k and jo<strong>in</strong>t by jo<strong>in</strong>t, or <strong>of</strong>f-l<strong>in</strong>e, via a separategeometric pre-analysis. Such a pre-analysis yields an analytic relationship between<strong>the</strong> sw<strong>in</strong>g arm angle change and <strong>the</strong> moment <strong>of</strong> <strong>the</strong> spr<strong>in</strong>g force about <strong>the</strong> sw<strong>in</strong>g armpivot, which is used directly <strong>in</strong> <strong>the</strong> multibody model build<strong>in</strong>g. Alternatively, if <strong>the</strong>pre-analysis were too complex to give an analytic result, a numerical relationship

270 R.S. SHARP ET AL.Figure 16. Geometry <strong>of</strong> monoshock suspension arrangement on GSX-R1000 motorcycle. Distancesbetween various po<strong>in</strong>ts are also def<strong>in</strong>ed <strong>in</strong> <strong>the</strong> diagram.between <strong>the</strong> angle and <strong>the</strong> moment could be found. This could be replaced by anapproximate functional relationship cover<strong>in</strong>g <strong>the</strong> practical range <strong>of</strong> <strong>the</strong> sw<strong>in</strong>g armmovement. A low order polynomial will usually suffice [29]. The literal modell<strong>in</strong>gis <strong>the</strong> simpler, but it will provide equations <strong>of</strong> motion which <strong>in</strong>tegrate relativelyslowly, s<strong>in</strong>ce <strong>the</strong> simulation has to solve <strong>the</strong> k<strong>in</strong>ematic loop equations at each<strong>in</strong>tegration step. The analysis follows.Po<strong>in</strong>ts p11, p13 and p19 are fixed to <strong>the</strong> ma<strong>in</strong> frame. l 1 , l 4 and ϕ 0 are dimensions<strong>of</strong> <strong>the</strong> sw<strong>in</strong>g<strong>in</strong>g l<strong>in</strong>k and l 2 <strong>the</strong> length <strong>of</strong> <strong>the</strong> pull rod. The length l 3 <strong>in</strong> <strong>the</strong> sw<strong>in</strong>g armis fixed. The spr<strong>in</strong>g/damper unit is <strong>of</strong> variable length l. θ is <strong>the</strong> angle <strong>of</strong> <strong>the</strong> sw<strong>in</strong>garm to <strong>the</strong> horizontal x-axis, while δ is <strong>the</strong> correspond<strong>in</strong>g angle for <strong>the</strong> sw<strong>in</strong>g<strong>in</strong>gl<strong>in</strong>k. Travers<strong>in</strong>g <strong>the</strong> loop p11-p22-p20-p19-p11, both x and z displacements are nil,s<strong>in</strong>ce we end where we beg<strong>in</strong>. Therefore:x 11 − x 19 − l 3 cos θ + l 2 cos ζ + l 1 cos δ = 0and z 11 − z 19 + l 3 s<strong>in</strong> θ + l 2 s<strong>in</strong> ζ − l 1 s<strong>in</strong> δ = 0Form<strong>in</strong>g l 2 2 as (l2 2 s<strong>in</strong>2 ζ + l 2 2 cos2 ζ ) and substitut<strong>in</strong>g:c 1 =−x 11 + x 19 + l 3 cos θ and c 2 =−z 11 + z 19 − l 3 s<strong>in</strong> θwe obta<strong>in</strong>: l 2 2 = (c 1 − l 1 cos δ) 2 + (c 2 − l 1 s<strong>in</strong> δ) 2 from which it can be shown that:( l2δ = arcs<strong>in</strong> 2− l1 2 − c2 1 − ) ( )c2 2c1+ arctan ,2l 1√c1 2 + c c2 22which is a function <strong>of</strong> θ only. Also:x 21 = x 19 − l 1 cos δ + l 4 cos(φ 0 + δ)and z 21 = z 19 + l 1 s<strong>in</strong> δ − l 4 s<strong>in</strong>(φ 0 + δ)

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 271Figure 17. Spr<strong>in</strong>g / damper unit length to wheel displacement relationship for GSX-R1000motorcycle.withl = √ (x 13 − x 21 ) 2 + (z 13 − z 21 ) 2so that l can be found as a function <strong>of</strong> θ, l = f 1 (θ) say, by substitution for x 21 andz 21 <strong>in</strong> this expression. Figure 17 illustrates <strong>the</strong> outcome. If a small change δθ <strong>in</strong> θoccurs, <strong>in</strong> which <strong>the</strong> correspond<strong>in</strong>g change <strong>in</strong> l is δl, <strong>the</strong> moment M correspond<strong>in</strong>gto a spr<strong>in</strong>g/damper force f 2 (l, ˙l) is f 2 (l, ˙l) · dl/dθ by virtual work. The properties<strong>of</strong> <strong>the</strong> spr<strong>in</strong>g/damper unit can thus be expressed <strong>in</strong> terms <strong>of</strong> an equivalent momentM(θ, ˙θ) about <strong>the</strong> sw<strong>in</strong>g-arm pivot, as:M = f 2{f 1 (θ), d f 1(θ)˙θdθwhich can be fully automated.} d f1 (θ),dθ6. Speed and Steer ControllersTo ma<strong>in</strong>ta<strong>in</strong> a desired forward speed pr<strong>of</strong>ile, driv<strong>in</strong>g torque is applied to <strong>the</strong>rear wheel and reacted on <strong>the</strong> ma<strong>in</strong> frame. The torque is produced by a proportional/<strong>in</strong>tegralcontrol on <strong>the</strong> speed error with fixed ga<strong>in</strong>s. Although <strong>the</strong> referencemach<strong>in</strong>e has a cha<strong>in</strong> drive to <strong>the</strong> rear wheel, this representation is <strong>of</strong> a shaft drivesystem and it needs updat<strong>in</strong>g to deal with issues like <strong>the</strong> prediction <strong>of</strong> suspensionmovements and body attitudes under heavy acceleration. For milder longitud<strong>in</strong>almanoeuvr<strong>in</strong>g, <strong>the</strong>re will be little difference between shaft drive and cha<strong>in</strong> drive.The target speed is provided as data <strong>in</strong> a table function, with time as <strong>the</strong> <strong>in</strong>dependentvariable.A steer<strong>in</strong>g feedback controller is also necessary to stabilise <strong>the</strong> mach<strong>in</strong>e <strong>in</strong> manoeuvres<strong>in</strong> which it is not self-stable. In particular, stabilis<strong>in</strong>g control allows <strong>the</strong>solution <strong>of</strong> <strong>the</strong> steady turn<strong>in</strong>g equilibrium state problem by simply runn<strong>in</strong>g a simulationto steady state. The controller devised is a proportional/<strong>in</strong>tegral/derivative

272 R.S. SHARP ET AL.(PID) feedback <strong>of</strong> motorcycle lean angle error to steer<strong>in</strong>g torque, with <strong>the</strong> leanangle target be<strong>in</strong>g set by an <strong>in</strong>itial value and a constant rate <strong>of</strong> change. The targetlean angle must <strong>the</strong>refore be a ramp function <strong>of</strong> time. This would be easy to alterif it were considered restrictive.The steer<strong>in</strong>g control ga<strong>in</strong>s need to be speed adaptive and <strong>the</strong>y need choos<strong>in</strong>gwith considerable care to achieve effective stabilisation. Especially difficult arecases <strong>in</strong>volv<strong>in</strong>g very low or very high speed and high lean angles. Each <strong>of</strong> <strong>the</strong> threePID ga<strong>in</strong>s is l<strong>in</strong>early related to speed, as <strong>in</strong>dicated by <strong>the</strong> relations:G p = spg0 + spg1 · u; G i = sig0 + sig1 · u; G d = sdg0 + sdg1 · u;correspond<strong>in</strong>g to <strong>the</strong> control law:∫ tτ = G p (φ − φ ref ) + G i (φ − φ ref )dt + G d ˙φ;0where u is <strong>the</strong> forward speed, τ is <strong>the</strong> steer<strong>in</strong>g control torque, φ is <strong>the</strong> lean angleand φ ref is <strong>the</strong> target lean angle.7. Equilibrium State Check<strong>in</strong>g and Power Balanc<strong>in</strong>gWith suitable stabilisation, <strong>the</strong> motorcycle can be run to equilibrium at any feasiblespeed and lean angle. To describe such an equilibrium state, force and momentbalance equations can be set up, as was done <strong>in</strong> [5, 30]. As described <strong>in</strong> [30], <strong>the</strong>check<strong>in</strong>g process <strong>in</strong>cludes a power balance, whereby <strong>the</strong> eng<strong>in</strong>e power is shown toaccount precisely for <strong>the</strong> aerodynamic and tyre losses. In steady turn<strong>in</strong>g, <strong>the</strong> forcebalance check is to ensure that <strong>the</strong> sum <strong>of</strong> <strong>the</strong> external forces is equal to <strong>the</strong> sum <strong>of</strong><strong>the</strong> <strong>in</strong>ertial and gravitational forces. The force error calculated is:F error = ∑ iF i + ∑ jm j (g − ω j × v j ),<strong>the</strong> first sum conta<strong>in</strong><strong>in</strong>g all <strong>the</strong> external forces, while <strong>the</strong> second deals with gravitationaland centripetal effects. The external forces <strong>in</strong>clude: (i) aerodynamic liftand drag forces, (ii) <strong>the</strong> front and rear wheel normal loads, (iii) <strong>the</strong> tyre side forcesand (iv) <strong>the</strong> tyre longitud<strong>in</strong>al forces, <strong>in</strong>clud<strong>in</strong>g <strong>the</strong> driv<strong>in</strong>g force at <strong>the</strong> rear tyresufficient to ma<strong>in</strong>ta<strong>in</strong> <strong>the</strong> steady speed. In <strong>the</strong> second term, m j represents <strong>the</strong> mass<strong>of</strong> <strong>the</strong> jth body, ν j is <strong>the</strong> velocity <strong>of</strong> <strong>the</strong> body’s mass centre, w j is <strong>the</strong> body’s angularvelocity vector and g is <strong>the</strong> gravitational acceleration vector. Invariably, <strong>in</strong> a fullyestablished steady turn, |F error |〈0.02 N.In much <strong>the</strong> same way, <strong>the</strong> follow<strong>in</strong>g moment error should be zero:M error = ∑ il i × F i + ∑ j{l j × m j (g − v j × ω j ) − ω j × H j }+ ∑ kM k ,

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 273where l i and l j are moment arm vectors referred to <strong>the</strong> rear wheel contact po<strong>in</strong>tand H j is <strong>the</strong> moment <strong>of</strong> momentum <strong>of</strong> body j about its mass centre. The firstsum accounts for <strong>the</strong> moments generated by <strong>the</strong> external forces listed above, while<strong>the</strong> second conta<strong>in</strong>s a part treat<strong>in</strong>g gravitational moments and moments <strong>of</strong> <strong>in</strong>ertialforces on <strong>the</strong> body mass centres and a part account<strong>in</strong>g for <strong>the</strong> rate <strong>of</strong> change <strong>of</strong>moment <strong>of</strong> momentum <strong>of</strong> each body, with respect to its mass centre. The thirdsummation deals with aerodynamic pitch<strong>in</strong>g and tyre align<strong>in</strong>g moments.Each <strong>of</strong> <strong>the</strong> terms w × H is calculated as w × (H x i + H y j + H z k), with Hhav<strong>in</strong>g components H x , H y and H z <strong>in</strong> directions denoted by <strong>the</strong> unit vectors i, jand k, which must be chosen so that <strong>the</strong> moment <strong>of</strong> momentum components are<strong>in</strong>variant, when <strong>the</strong> motorcycle is <strong>in</strong> a steady turn. For all <strong>the</strong> non-sp<strong>in</strong>n<strong>in</strong>g bodies,<strong>the</strong> body reference axes satisfy this requirement. For <strong>the</strong> wheels, <strong>the</strong> parent body’sreference system needs to be used and a moment <strong>of</strong> momentum term for <strong>the</strong> sp<strong>in</strong>added on. For <strong>the</strong> most general case applicable here <strong>in</strong> which I xy and I yz are zerobut I xz is non-zero [9], not<strong>in</strong>g a change <strong>of</strong> sign <strong>of</strong> products <strong>of</strong> <strong>in</strong>ertia, as comparedwith <strong>the</strong> reference, because [9] and Autosim use opposite def<strong>in</strong>itions:H x = I xx ω x + I xz ω z ; H y = I yy ω y ; and H z = I xz ω x + I zz ω z ,<strong>in</strong> which ω x , ω y and ω z are <strong>the</strong> components <strong>of</strong> ω <strong>in</strong> <strong>the</strong> i, j and k directions.Thus, for <strong>the</strong> ma<strong>in</strong> body, this second component <strong>of</strong> rate <strong>of</strong> change <strong>of</strong> moment<strong>of</strong> momentum, that about <strong>the</strong> mass centre, is <strong>of</strong> <strong>the</strong> form:ω ma<strong>in</strong> ×{(I ma<strong>in</strong>x ω x + I ma<strong>in</strong>xz ω z ) · i ma<strong>in</strong>+ I ma<strong>in</strong>y ω y · j ma<strong>in</strong>+(I ma<strong>in</strong>xz ω x + I ma<strong>in</strong>z ω z ) · k ma<strong>in</strong>}.Here, i ma<strong>in</strong>, j ma<strong>in</strong>and k ma<strong>in</strong>denote <strong>the</strong> unit vectors i, j and k for <strong>the</strong> ma<strong>in</strong> body.To deal with <strong>the</strong> rear wheel, its diametral <strong>in</strong>ertia is added to <strong>the</strong> correspond<strong>in</strong>g termsbelong<strong>in</strong>g to <strong>the</strong> sw<strong>in</strong>g arm, its parent body, as if it were part <strong>of</strong> <strong>the</strong> sw<strong>in</strong>g arm.The sp<strong>in</strong> is accounted for by a term: ω sw<strong>in</strong>garm × I rwy ω y · [rwy] and similarly for<strong>the</strong> front wheel, for which <strong>the</strong> lower fork body is <strong>the</strong> parent. For any steady turn,|M error |〈0.02 Nm.The power error is given by:P error = τ · ω sp<strong>in</strong> + ∑ iF i · v i + ∑ kM k · ω k ,<strong>in</strong> which τ is <strong>the</strong> rear wheel driv<strong>in</strong>g torque and ω sp<strong>in</strong> is its sp<strong>in</strong> velocity relativeto <strong>the</strong> sw<strong>in</strong>g arm. v i is <strong>the</strong> velocity <strong>of</strong> <strong>the</strong> po<strong>in</strong>t <strong>of</strong> application <strong>of</strong> force, F i , andω k is <strong>the</strong> absolute angular velocity <strong>of</strong> <strong>the</strong> body to which moment, M k ,isapplied.Describ<strong>in</strong>g <strong>the</strong> power associated with tyre forces requires care also. The velocity<strong>in</strong>volved is that <strong>of</strong> <strong>the</strong> tyre tread base material [30], already calculated <strong>in</strong> connectionwith f<strong>in</strong>d<strong>in</strong>g <strong>the</strong> slip ratio and <strong>the</strong> slip angle. For any steady turn, <strong>in</strong>dicat<strong>in</strong>g amaz<strong>in</strong>gprecision, P error 〈0.3 mW.

274 R.S. SHARP ET AL.These checks on any equilibrium state are substantially <strong>in</strong>dependent <strong>of</strong> <strong>the</strong> fullequations <strong>of</strong> motion on which <strong>the</strong> simulation model depends and it is reassur<strong>in</strong>gthat <strong>the</strong>y are satisfied.8. Typical ResultsThe ma<strong>in</strong> uses <strong>of</strong> a model such as that described are (a) general simulation <strong>of</strong> responsesto def<strong>in</strong>ed steer<strong>in</strong>g control <strong>in</strong>puts, possibly <strong>in</strong>volv<strong>in</strong>g hardware <strong>in</strong> <strong>the</strong> loop(b) determ<strong>in</strong>ation <strong>of</strong> steady-state equilibrium corner<strong>in</strong>g “trim” states (c) l<strong>in</strong>earization<strong>of</strong> <strong>the</strong> equations to represent small motions <strong>in</strong> <strong>the</strong> neighbourhood <strong>of</strong> a trimstate (d) root locus calculations for constant lean angle and vary<strong>in</strong>g speed or viceversaand (e) frequency response calculations to f<strong>in</strong>d ga<strong>in</strong>s and phases <strong>in</strong> susta<strong>in</strong>edmotion <strong>in</strong>volv<strong>in</strong>g s<strong>in</strong>usoidal forc<strong>in</strong>g from <strong>the</strong> steer<strong>in</strong>g system or from road undulations[30]. The power computations also allow determ<strong>in</strong>ation <strong>in</strong> detail <strong>of</strong> where<strong>the</strong> eng<strong>in</strong>e power is dissipated <strong>in</strong> steady turn<strong>in</strong>g.Trim state determ<strong>in</strong>ation is a necessary forerunner to stability and frequencyresponse computations, to enable <strong>the</strong> l<strong>in</strong>earisation to be done correctly. Also, asdescribed <strong>in</strong> Section 6, speed and lean angle controllers are likely to be needed toallow <strong>the</strong> trim states to be found, over a reasonably full range <strong>of</strong> feasible speeds andlean angles. Some <strong>of</strong> <strong>the</strong>se uses and some behavioural properties <strong>of</strong> <strong>the</strong> mach<strong>in</strong>e <strong>in</strong>focus are illustrated next.The model was first used to simulate a straight l<strong>in</strong>e run from 1 to 75 m/s with avery small constant acceleration <strong>of</strong> 0.05 m/s 2 . This gives <strong>the</strong> trim state, chang<strong>in</strong>gwith <strong>the</strong> speed, from which small perturbations are considered to occur and forwhich a l<strong>in</strong>earised model is appropriate. The l<strong>in</strong>earised model, hav<strong>in</strong>g a free steer<strong>in</strong>gsystem with <strong>the</strong> feedback steer<strong>in</strong>g controller disabled, was <strong>the</strong>n used to obta<strong>in</strong> <strong>the</strong>root locus plot shown <strong>in</strong> Figure 18. The mach<strong>in</strong>e, as represented, is stable for straightrunn<strong>in</strong>g throughout <strong>the</strong> speed range above about 6 m/s. Also shown <strong>in</strong> Figure 18are <strong>the</strong> loci for <strong>the</strong> nom<strong>in</strong>al motorcycle but with <strong>the</strong> rear frame torsional stiffnessdivided by 2 and <strong>the</strong>n 4 with <strong>the</strong> frame twist damp<strong>in</strong>g coefficient reduced by factors<strong>of</strong> 0.7071 and 0.5 respectively.The high speed weave stability is compromised significantly by <strong>the</strong> reduction <strong>in</strong>stiffness and <strong>the</strong> wobble problem is transferred from high speed to medium speedby <strong>the</strong>se changes. This aligns with earlier f<strong>in</strong>d<strong>in</strong>gs, that flexible frames promotemedium speed wobble, while very stiff frames give more <strong>of</strong> a potential problemat high speeds, imply<strong>in</strong>g <strong>the</strong> need for a steer<strong>in</strong>g damper to ensure adequatemarg<strong>in</strong>s.The damp<strong>in</strong>g coefficient associated with <strong>the</strong> rider upper body lean freedom isnow varied, with root loci be<strong>in</strong>g shown <strong>in</strong> Figure 19. Rider damp<strong>in</strong>g can be seento <strong>in</strong>fluence <strong>the</strong> weave mode only where <strong>the</strong> damp<strong>in</strong>g is plentiful but it contributesusefully to <strong>the</strong> stability <strong>of</strong> <strong>the</strong> wobble mode at high speed. The results are consistentwith <strong>the</strong> idea that lighter riders are more likely to suffer wobble oscillations thanheavier ones, <strong>in</strong> accord with anecdotal evidence.

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 275Figure 18. Root locus plot for straight runn<strong>in</strong>g through speed range 1.1 (squares) to 75 (diamonds)m/s. Nom<strong>in</strong>al mach<strong>in</strong>e, po<strong>in</strong>ts; frame stiffness halved, circles; frame stiffness quartered,crosses (with damp<strong>in</strong>g adjustments).Figure 19. Root locus plot for straight runn<strong>in</strong>g through 1.1 (squares) to 75 (diamonds) m/sspeed for nom<strong>in</strong>al mach<strong>in</strong>e (po<strong>in</strong>ts) and with <strong>the</strong> rider lean damp<strong>in</strong>g coefficient factored by 0.5(circles) and 0.25 (crosses).The behaviour <strong>of</strong> <strong>the</strong> motorcycle <strong>in</strong> quasi-steady turn<strong>in</strong>g at a susta<strong>in</strong>ed lean angle<strong>of</strong> 30 ◦ with a small forward acceleration <strong>of</strong> 0.05 m/s 2 is illustrated <strong>in</strong> Figure 20. Thesteer angle is small, except at low speeds, for which it rises markedly. It changes signat just over 20 m/s, where <strong>the</strong> fixed control motorcycle becomes self-stabilis<strong>in</strong>g [1].

276 R.S. SHARP ET AL.Figure 20. (a) State variables (b) tyre forces (c) steer<strong>in</strong>g torque and tyre align<strong>in</strong>g moments <strong>in</strong>a susta<strong>in</strong>ed 30 ◦ lean angle turn accelerat<strong>in</strong>g at 0.05 m/s 2 from 3.7 to 75 m/s.

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 277The frame twist is imperceptibly small, despite its importance to <strong>the</strong> dynamics. Therider leans <strong>in</strong>to <strong>the</strong> turn to a moderate degree. The tyre loads and shear forces areshown, <strong>in</strong>dicat<strong>in</strong>g that <strong>the</strong> rear tyre will be near to its friction limits at <strong>the</strong> top end<strong>of</strong> <strong>the</strong> speed range covered. The steer torque required can be seen to be somewhatless than <strong>the</strong> front tyre align<strong>in</strong>g moment, all through <strong>the</strong> speed range. Predict<strong>in</strong>g <strong>the</strong>steer<strong>in</strong>g torque accurately apparently depends on modell<strong>in</strong>g <strong>the</strong> front tyre align<strong>in</strong>gmoment well. Close <strong>in</strong>spection <strong>of</strong> <strong>the</strong> motorcycle lean angle record shows that <strong>the</strong>reis some <strong>in</strong>teraction between <strong>the</strong> lean angle controller and <strong>the</strong> acceleration. The leanangle is not ma<strong>in</strong>ta<strong>in</strong>ed precisely on target and <strong>the</strong> greater <strong>the</strong> lean angle and <strong>the</strong>acceleration are, <strong>the</strong> larger <strong>the</strong> errors become. The simplest solution is to use verylow acceleration levels but <strong>the</strong> simulation runs <strong>the</strong>n take a long time to complete.If an unstable condition occurs dur<strong>in</strong>g a run, that run is lost, so that long runs arepotentially problematic.An alternative procedure has been developed. This <strong>in</strong>volves describ<strong>in</strong>g <strong>the</strong> speedtarget by a saturat<strong>in</strong>g ramp, so that true equilibrium is established at <strong>the</strong> f<strong>in</strong>ish <strong>of</strong> arun. A typical run will <strong>in</strong>crement <strong>the</strong> speed by 5 m/s only (less at low speed) and <strong>the</strong>f<strong>in</strong>al state <strong>of</strong> one run is used as <strong>the</strong> <strong>in</strong>itial state for <strong>the</strong> follow<strong>in</strong>g one. A whole series<strong>of</strong> runs constitutes <strong>the</strong> equilibrium data for one lean angle. From such a series for45 ◦ lean, contributions to <strong>the</strong> power dissipated, as functions <strong>of</strong> speed, are shown<strong>in</strong> Figure 21. It will be no surprise to see that most <strong>of</strong> <strong>the</strong> eng<strong>in</strong>e power is used toovercome aerodynamic drag, especially at high speeds, but it is not at all obviousthat each tyre’s align<strong>in</strong>g moment may dissipate 4 kW at high speed. Also, at highspeed, <strong>the</strong> rear tyre driv<strong>in</strong>g force accounts for a relatively high power dissipationthrough longitud<strong>in</strong>al slipp<strong>in</strong>g.Us<strong>in</strong>g a quasi-steady run at 15 ◦ lean, <strong>the</strong>n <strong>the</strong> results above for 30 ◦ and aga<strong>in</strong>correspond<strong>in</strong>g results for 45 ◦ for <strong>the</strong> trim state data used <strong>in</strong> <strong>the</strong> l<strong>in</strong>earization, <strong>the</strong> rootloci for <strong>the</strong> nom<strong>in</strong>al mach<strong>in</strong>e are shown <strong>in</strong> Figures 22–24. Each figure also conta<strong>in</strong>ssimilar results, similarly obta<strong>in</strong>ed, for <strong>the</strong> motorcycle with half <strong>the</strong> frame torsionalstiffness and 0.7071 times <strong>the</strong> frame damp<strong>in</strong>g coefficient. Damp<strong>in</strong>g <strong>of</strong> <strong>the</strong> oscillatorymodes improves with corner<strong>in</strong>g except that <strong>the</strong> medium speed wobble damp<strong>in</strong>gat 45 ◦ lean becomes quite small. In each case, it is clear that halv<strong>in</strong>g <strong>the</strong> framestiffness is detrimental to <strong>the</strong> stability properties. The more elaborate procedure forestablish<strong>in</strong>g steady-state equilibria yields root loci which are <strong>in</strong>dist<strong>in</strong>guishable fromthose shown; that is, <strong>the</strong> <strong>in</strong>fluence <strong>of</strong> <strong>the</strong> small acceleration employed is negligible<strong>in</strong> <strong>the</strong>se cases.If <strong>the</strong> corner<strong>in</strong>g motorcycle is excited by regular road undulations, <strong>the</strong> responseis potentially dangerous if resonance <strong>in</strong> connection with a lightly damped mode<strong>of</strong> oscillation occurs [30]. It was found <strong>in</strong> earlier work that about 15 ◦ lean islikely to represent a worst case, s<strong>in</strong>ce, for smaller angles, <strong>the</strong> road forc<strong>in</strong>g couplesonly weakly to <strong>the</strong> lateral oscillatory responses, while for larger angles, <strong>the</strong>modal damp<strong>in</strong>g is likely to <strong>in</strong>crease. Such a 15 ◦ lean case is illustrated, for aconstant speed <strong>of</strong> 65 m/s, <strong>in</strong> Figure 25. The plot shows <strong>the</strong> steer angle to road displacementforc<strong>in</strong>g frequency response ga<strong>in</strong> relative to 1 rad/m, account<strong>in</strong>g properly

278 R.S. SHARP ET AL.Figure 21. Power contributions as functions <strong>of</strong> speed <strong>in</strong> steady turn<strong>in</strong>g with 45 ◦ lean angle.Figure 22. <strong>Motorcycle</strong> root locus plot for 15 ◦ lean angle through speed range 3.3 (squares) to75 (diamonds) m/s. Nom<strong>in</strong>al case – po<strong>in</strong>ts; frame stiffness halved – circles.for <strong>the</strong> time delay between <strong>the</strong> forc<strong>in</strong>g act<strong>in</strong>g on <strong>the</strong> front wheel and on <strong>the</strong> rearwheel, <strong>the</strong> so-called wheelbase filter<strong>in</strong>g effect. Resonance <strong>of</strong> <strong>the</strong> corner<strong>in</strong>g weaveis evident at 26 rad/s forc<strong>in</strong>g frequency, while <strong>the</strong> wobble is most responsive at50 rad/s.

ADVANCES IN THE MODELLING OF MOTORCYCLE DYNAMICS 279Figure 23. <strong>Motorcycle</strong> root locus plot for 30 ◦ lean angle through speed range 3.8 (squares) to75 (diamonds) m/s. Nom<strong>in</strong>al case – po<strong>in</strong>ts; frame stiffness halved – circles.Figure 24. <strong>Motorcycle</strong> root locus plot for 45 ◦ lean angle through speed range 5.8 (squares) to75 (diamonds) m/s. Nom<strong>in</strong>al case – po<strong>in</strong>ts; frame stiffness halved – circles.9. ConclusionsSubstantial improvements to an advanced motorcycle dynamics model have beenmade, relat<strong>in</strong>g to (a) tyre/road contact geometry; (b) <strong>the</strong> tyre shear force and momentsystem; (c) tyre relaxation properties and (d) <strong>the</strong> monoshock rear suspension