AANNNOOOTTTHHHEEERRR ... - Berco S.p.A

AANNNOOOTTTHHHEEERRR ... - Berco S.p.A

AANNNOOOTTTHHHEEERRR ... - Berco S.p.A

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Free copy<br />

Quarterly House Organ<br />

Editor: Dr. Giovanni Micheletto Ferrara Law Court registration<br />

n. 17/94 - 05/12/1994<br />

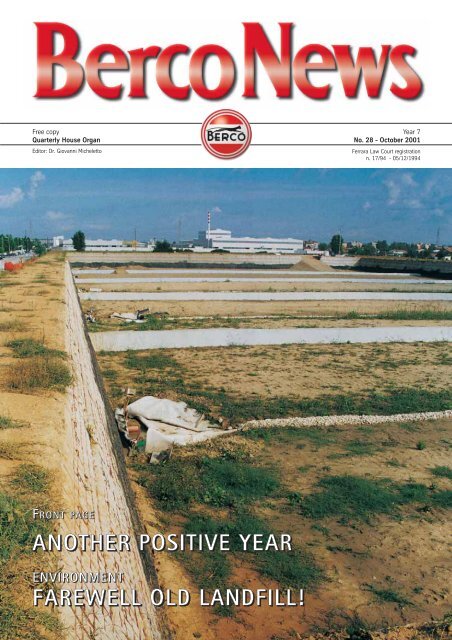

FRONT PAGE<br />

ANOTHER POSITIVE YEAR<br />

ENVIRONMENT<br />

FAREWELL OLD LANDFILL!<br />

Year 7<br />

No. 28 - October 2001

Contents<br />

Editorial<br />

DESTINED FOR RELENTLESS GROWTH<br />

The development path<br />

Front page<br />

ANOTHER POSITIVE YEAR<br />

First details of the financial year ending 30th September 2001<br />

Environment<br />

FAREWELL OLD LANDFILL!<br />

The new landfill nears completion<br />

New technologies<br />

A NEW DESIGN SYSTEM<br />

The evolution of the CAD design system<br />

Inside <strong>Berco</strong><br />

NEARLY 20,000 HOURS OF TRAINING<br />

<strong>Berco</strong>’s continued commitment to the professional<br />

growth of its human resources<br />

Flash News<br />

Dr Cromme returns to <strong>Berco</strong><br />

“Mr Koch’s “Silver Anniversary”<br />

Ctz visits the Copparo factory<br />

Marketing corner<br />

THE “BERCO MERCHANDISE”<br />

PROJECT GETS OFF THE GROUND<br />

Trade fairs<br />

Germany, EMO 2001<br />

Brazil, M&T EXPO 2001<br />

Greece, 1st Construction Machinery<br />

Russia, 5th Russian International Auto Salon<br />

Dealer News<br />

<strong>Berco</strong> News<br />

<strong>Berco</strong> News is a three monthly magazine published in italian and english for<br />

the employees, customers, suppliers and friends of the Company.<br />

Photos and articles, including excerpts, may be reproduced with the written<br />

permission of the editor and provided due reference is made to <strong>Berco</strong>News.<br />

Cover photo: the new landfill<br />

Contributors to this issue:<br />

G. Bertoni, E. Bacilieri, S. Salvi, F. Santinato, D. Mingozzi,<br />

C. Lambertini, S. Di Mauro, B. Guandalini<br />

Publisher:<br />

BERCO S.p.A.<br />

Marketing & Communication Department<br />

Via 1° Maggio - 44034 Copparo (Ferrara) Italy<br />

tel. +39 0532 864431 - fax +39 0532 864259<br />

e-mail: marketing@berco.com<br />

Editor:<br />

Giovanni Micheletto<br />

tel. +39 0532 864116 - fax +39 0532 864259 - e-mail: gim@berco.com<br />

Copy: Marketing & Communication Department<br />

Art editor: Silvia Ungaro<br />

Photos: Antonio Bertacchini and others<br />

Printing: SIACA ARTI GRAFICHE<br />

Circulation: Italian 4,500 - English 3,000<br />

2<br />

3<br />

4<br />

6<br />

8<br />

9<br />

10<br />

10<br />

12<br />

2<br />

Editorial<br />

DESTINED FOR<br />

RELENTLESS<br />

GROWTH<br />

The development path<br />

One of the theoretical laws of<br />

economics, confirmed in the real<br />

world, explains that: "In an<br />

environment of growing competitive<br />

pressure, only those companies able<br />

to maintain a level of growth which<br />

is greater than the average of the<br />

sector in which they operate are<br />

destined to survive". The 80 plus<br />

years’ of <strong>Berco</strong>’s history are more<br />

than a confirmation. This confirmation<br />

comes once again with the recent<br />

closure of the business year, despite<br />

the heavy recession across world<br />

markets. Although <strong>Berco</strong> had a more<br />

modest growth rate than in previous<br />

years, we are still growing, and have grown more than the market in global<br />

decline, and more than the competition. Once again <strong>Berco</strong> has been able<br />

to show its ability to create the profit margins needed to feed its growth,<br />

carry out large-scale investments and satisfy the demands of the workers<br />

and shareholders.<br />

All of this does not happen by chance: "To be a market leader you must<br />

always be one step ahead of the competition, both in terms of product<br />

range, personnel and technology”. And once again the <strong>Berco</strong> history,<br />

especially the most recent one, confirms this. The <strong>Berco</strong> product range is<br />

the most complete in the market, and despite this, <strong>Berco</strong> continues to introduce<br />

new products and to innovate our existing ones. This includes, but not limited<br />

to, the investments made in the innovation of production methods,<br />

continuous training for the personnel, the acquisition of new technologies,<br />

robots, machine tools, and the Maxi Press among others. This process<br />

cannot be stopped, and despite people’s disbelief it will not stop, even<br />

now in this difficult and unpredictable time for the market.<br />

We will continue to follow this strategic path with our usual commitment,<br />

and above all with the calmness of those who understand their targets and<br />

are certain of being able to reach them. And of course, “it is in the rough<br />

sea that you see the good boats!”<br />

G. Bertoni,<br />

<strong>Berco</strong> Managing Director

ECONOMIC TRENDS<br />

Despite the obvious slowdown of<br />

the world economy and its markets<br />

in the first few months of this year,<br />

the fiscal year that closed on<br />

September 30th 2001 highlighted<br />

the further expansion of our company.<br />

Sales have reached 360 million<br />

Euro, with an increase of 6.5%<br />

with respect to the previous year.<br />

The opening of new markets, the<br />

increase in production volumes and<br />

the favourable exchange rates have<br />

all contributed positively to this<br />

result.<br />

The economic and financial situation<br />

appears to be very satisfactory;<br />

profit margins continue to be<br />

consolidated. The profit forecasts<br />

for the business year just ended are<br />

in line with the budget forecasts,<br />

and slightly higher than the previous<br />

year.<br />

THE COMPANY OBJECTIVES<br />

We are therefore continuing along<br />

that impressive development path<br />

which has marked the life of our<br />

company over the past ten years.<br />

To give our readers an idea of the<br />

size of the changes, we can remember<br />

that:<br />

1. With respect to the beginning of<br />

the 1990s, production volumes have<br />

more than doubled, and the sales<br />

have practically tripled;<br />

2. Over the past ten years investments<br />

in technologies worth 300 million<br />

Euro have been made, a figure which<br />

has been completely financed by the<br />

company itself (through company<br />

cash flow);<br />

3. Since 1995 we have taken on<br />

more than 2,000 new employees, to<br />

cover both the natural staff turnover<br />

and to provide the resources needed<br />

for growth. Today the company has<br />

about 3,000 employees (and around<br />

100 of these have university degrees<br />

and qualifications in a variety of<br />

technical and economic subjects).<br />

Over the years the company policy has<br />

been oriented to the introduction<br />

of new technologies and the widening<br />

of the product range. We have paid<br />

particular attention to economies of<br />

scale, playing on the stimulation of<br />

market demand and the increase in<br />

production through new investments,<br />

as well as new employment.<br />

This approach will continue to be<br />

used in the medium term company<br />

strategy, with the aim of maintaining<br />

our leadership position in the market.<br />

THE FUTURE<br />

In spite of these positive results,<br />

recent economic developments at<br />

world level have made it necessary<br />

to give serious thought to the situation<br />

that the company will have to face<br />

in the future. Increasing fears of a<br />

coming recession have already<br />

overwhelmed the financial markets.<br />

The dramatic acts of terrorism in<br />

the USA together with fears regarding<br />

the start of new conflicts, with<br />

MILLION EUROS<br />

400<br />

350<br />

300<br />

250<br />

390<br />

310<br />

TOTAL SALES<br />

405<br />

338<br />

430<br />

360<br />

452<br />

370<br />

474<br />

385<br />

496<br />

390<br />

1999 2000 2001 2002 2003 2004<br />

<strong>Berco</strong> <strong>Berco</strong> Group<br />

3 <strong>Berco</strong> News<br />

Front page<br />

ANOTHER POSITIVE YEAR<br />

First data of the fiscal year 2000/01<br />

unforeseeable consequences, have<br />

heightened the instability of the<br />

macroeconomic system. The activities<br />

aimed at reaching an increasingly<br />

higher level of efficiency and continuos<br />

cost reduction become even more<br />

important now if we want our<br />

products to continue to be competitive<br />

in the market. On the other hand,<br />

during the 1990’s our company<br />

achieved an undoubted competitive<br />

advantage. Plenty of technology and<br />

know-how stemming from company<br />

investments, the professional growth<br />

of our human resources, together<br />

with the variety of products and the<br />

solid nature of our economic and<br />

financial situation cannot be found in<br />

any other company operating in our<br />

field either in Italy or the rest of the<br />

world. Therefore, we are sure that we<br />

have the necessary commitment and<br />

reliability to face new, ambitious<br />

projects and to guarantee continuity<br />

in our business relations with our most<br />

demanding partners.<br />

Dr E. Bacilieri<br />

Administrator Director

<strong>Berco</strong> News<br />

4<br />

Environment<br />

FAREWELL OLD LANDFILL!<br />

The new landfill nears completion<br />

EVEN WASTE HAS A LIFE CYCLE!<br />

In fact, when we “decide to dispose<br />

of, or are obliged to dispose of a<br />

substance or an object, we become<br />

producers of waste”. This is the<br />

definition given in the law n. 22/97,<br />

otherwise known as the Ronchi Law.<br />

And here starts the “path” of our<br />

waste, which can follow a number of<br />

possible “evolutions”, in line with<br />

the universal principle that “nothing<br />

can be destroyed but everything is<br />

transformed”.<br />

RECYCLING OR DISPOSAL?<br />

Waste can follow two basic paths:<br />

1. Recycling<br />

2. Disposal<br />

Recycling can take the form to be<br />

used as fuel, regeneration, compost,<br />

or spreading onto the soil for<br />

agricultural use. Disposal may be<br />

done through biodegradation<br />

composting, surface containment<br />

reservoirs, depth injection, incineration,<br />

dumping, etc.<br />

The choice to follow one form rather<br />

than the other depends mainly on<br />

the type of waste and the available<br />

technologies. In our case, given the<br />

many different types of waste present<br />

in our factories, a number of different<br />

disposal methods are used. The<br />

The old landfill that will stop being used and that will be subject<br />

to an environmental rehabilitation program<br />

majority of our waste is handed over<br />

to specialised disposal companies.<br />

The non-recyclable plastic packaging,<br />

the pressing waste, purification<br />

sludge, rubber waste, dirty rags and<br />

other inert materials are sent to our<br />

own landfill. To get an idea of the<br />

quantities involved, external<br />

companies dispose of 21,750 tons<br />

of recyclable waste from us each<br />

year, a smaller quantity of 2,250<br />

tons is collected and sent to the<br />

<strong>Berco</strong> landfill.<br />

WHY THE NEED FOR A NEW<br />

LANDFILL?<br />

At present, after 20 years’ of durability,<br />

we are preparing to close the old<br />

landfill and are about to open a new<br />

one. <strong>Berco</strong>’s adoption of the ISO<br />

14001 certification has motivated<br />

the need to restore the landscape, keep<br />

a check on the environmental impact<br />

and the safety of the old site.<br />

Following the introduction of ISO<br />

14001 and the environmental<br />

management regulations, a study<br />

was performed on the management<br />

of the activities at the old landfill<br />

in Via 2 Giugno, to determine the<br />

environmental impact. The results<br />

of this evaluation (see table) and<br />

the request of the competent<br />

The new landfill, with a view of its five sections<br />

authorities made it clear that we<br />

needed to consider an alternative<br />

to the old landfill, which apart from<br />

anything else was situated in the<br />

middle of a residential area.<br />

An EMP (Environmental Management<br />

Program, a project to improve our<br />

environmental performance) was<br />

thus defined with the main objective<br />

of building a new landfill by the end<br />

of 2001. This new landfill will be<br />

built with the latest technology<br />

which includes waterproofed bottom<br />

and a percolate collection system.<br />

THE PROJECT<br />

The first step in the design of the<br />

new landfill was to find an alternative<br />

site to the old one. The perfect place<br />

was found south of the factory, on<br />

<strong>Berco</strong> property, in an area classified<br />

by the City Plan as Zone D, meaning<br />

an area mainly used for manufacturing<br />

purposes.<br />

A hydro-geological survey was<br />

performed to identify the<br />

characteristics of the soil, its level of<br />

permeability, the depth of the<br />

underground water and the load<br />

bearing capacity of the ground. All<br />

this preliminary information helped<br />

our designers and the authorities to<br />

check the suitability of the site for

The new landfill: a view of the percolate drainage plant.<br />

a landfill. We certainly pay more<br />

attention to environmental problems,<br />

which are now new regulations. The<br />

designers were also able to use the<br />

information to determine the<br />

measures needed to prevent the<br />

percolate (the drippings that may<br />

form as a result of the compaction<br />

and storage of waste) from filtering<br />

into the soil and reaching the<br />

underground water tables. So, having<br />

made sure that the soil had the<br />

necessary characteristics, the bottom<br />

and the perimeter banks were further<br />

protected with layers of clay and<br />

bentonite geocomposites. The internal<br />

surface was divided into five main<br />

sections, each one connected to the<br />

percolate collection system.<br />

ACTIVITY EFFECTS ENVIRONMENTAL IMPACTS NEW LANDFILL<br />

OF THE OLD LANDFILL ENVIRONMENT IMPACTS<br />

Waste Storage<br />

Waste Storage<br />

Waste Storage<br />

Waste Storage<br />

Load handling<br />

Load handling<br />

Precence of liquid waste from<br />

percolation and absence of a<br />

collecting system for liquid<br />

Landscape alteration<br />

Emission of unpleasant smell<br />

Presence of animals<br />

Noise emission<br />

Exhaust gas emission<br />

The percolate will be collected in a<br />

sealed storage tank and removed<br />

periodically. Then, if the chemical<br />

and physical characteristics allow<br />

it, this will be added to our new<br />

liquid waste treatment plant or, if it<br />

is not possible, it will be sent for<br />

disposal by other specialised<br />

companies. To limit possible odours<br />

and a displeasing view, a series of<br />

“cultivation” procedures have been<br />

put into place around the landfill.<br />

These procedures anticipate that<br />

the waste, with the same<br />

characteristics as that collected<br />

today in the old landfill, will be<br />

disposed of in layers, then compacted<br />

and covered over every day. Once<br />

each sector is full, it will be ultimately<br />

Potential contamination of the water table stratum,<br />

due to the infiltration of percolate<br />

Potential landscape degradation<br />

Potential air pollution<br />

Potential trouble for the people of the<br />

neighborhood<br />

Potential acoustic pollution<br />

Potential air pollution<br />

5 <strong>Berco</strong> News<br />

covered with a layer of earth and<br />

grass will be grown.<br />

A project for a new landfill must<br />

always include plans for the closure<br />

and restoration of the site and its<br />

control for several years afterwards.<br />

The <strong>Berco</strong> project includes the<br />

grassing over of the site and its<br />

transformation into a small park…<br />

but as each of the five sectors will<br />

take about four years to fill, we will<br />

talk about this in future issues. For<br />

the time being, the new landfill will<br />

be with us for several years to come…<br />

Environment and Ecology Service<br />

Ing. S. Salvi<br />

Ing. C. Lambertini<br />

S. Di Mauro<br />

None<br />

None<br />

None<br />

None<br />

None<br />

None

<strong>Berco</strong> News<br />

6<br />

New technologies<br />

A NEW DESIGN SYSTEM<br />

The evolution of the CAD design system<br />

This is the interface of the new Pro-Engineering design system<br />

13 YEARS OF EUCLID-IS<br />

December 1987 saw the start of the<br />

implementation program for the first<br />

CAD system in the <strong>Berco</strong> Engineering<br />

Dept. in Copparo, together with the<br />

installation of the first three<br />

workstations.<br />

A series of activities took place in<br />

spring 1987 for the evaluation and<br />

definition of the system to be used.<br />

These activities included test of the<br />

different CAD systems at the potential<br />

suppliers’ offices.<br />

The final choice was Euclid-is, by<br />

Matra-Datavision. This choice was<br />

made due to the program ability to<br />

produce a solid three-dimensional<br />

model. Besides other features, the<br />

excellent surface modelling capabilities<br />

made it particularly useful for the<br />

preparation of the dies for the chain<br />

links that we produce. In 1987, this<br />

was definitely the best the market had<br />

to offer. During the first half of<br />

1988, the first group of technicians<br />

was set up and trained. This activity<br />

was initially focused on the threedimensional<br />

link modelling and on the<br />

creation of numerical control programs<br />

for machining of dies and electrodes.<br />

At the same time, a large number<br />

of changes were made in the die<br />

machining division with the<br />

introduction of numerically controlled<br />

machinery. At the end of June 1988,<br />

the first programms for rough shaping<br />

and finishing of link dies, created<br />

by using a CAD-CAM, were being<br />

used.<br />

Following these first six months, the<br />

project evolved continuously. From<br />

the first three workstations, we

moved on gradually to the 38<br />

workstations found today in the<br />

various offices of the Engineering<br />

Dept.. Ten workstations are for<br />

undercarriage parts division, twentyone<br />

for tooling division, three for<br />

machine tools, three in Castelfranco<br />

Veneto, and one in Busano Canavese.<br />

During the 13 years of its’ use at<br />

<strong>Berco</strong>, the Euclid-is software has<br />

continued to evolve with various<br />

versions and upgrades. Its current<br />

release is Euclid3. In this period of<br />

time, the software was used to create<br />

approximately 53,000 twodimensional<br />

drawings and 3,000<br />

three-dimensional ones for solids<br />

and surfaces.<br />

WHY A NEW SOFTWARE<br />

A couple of years ago Matra<br />

Datavision, the producer and<br />

distributor of Euclid, merged with<br />

Dassault Systeme, the producer of<br />

the Catia and Cadam CAD software,<br />

which led to the decision to stop<br />

further developments of Euclid.<br />

Although perfectly functional, <strong>Berco</strong><br />

was concerned about using a CAD<br />

package that would never again be<br />

updated. Immediately a decision was<br />

made to analyse the possible<br />

alternatives available on the market.<br />

At the same time, we took advantage<br />

of this situation to find a state-ofthe-art<br />

product that would allow<br />

the <strong>Berco</strong> Engineering Team to make<br />

serious quality improvements.<br />

After a year of both commercial and<br />

technical evaluations, we chose Pro-<br />

Engineering by the Parametric<br />

Technologies Corp., an American<br />

leader in the CAD and wider<br />

engineering software sector.<br />

This top product, whose name is<br />

shortened to Pro-E, has become the<br />

most widely used CAD product in<br />

less than 10 years, thanks to its<br />

specific and highly innovative technical<br />

and functional characteristics.<br />

Many <strong>Berco</strong> customers, such as John<br />

Deere, Fiat Hitachi, Komatsu and<br />

others, use Pro-E to develop their<br />

machinery. This will further simplify<br />

the process and widen the possibilities<br />

for cooperation between the technical<br />

departments by using the same CAD<br />

system.<br />

THE ADVANTAGES<br />

One of the most distinctive<br />

characteristics of the Pro-E software<br />

is its three-dimensional and parametric<br />

setting.<br />

In fact, it is no longer possible, as<br />

it was with the older generation CAD<br />

systems, to draw components by<br />

making two-dimensional tables as<br />

if they were “electronic drawing<br />

machines”, but quite the opposite: Pro-<br />

E obliges the technician to make<br />

three-dimensional drawings in the first<br />

place. Once this phase is completed,<br />

the program automatically generates<br />

the various views, creating the classical<br />

2D drawings used in the workshop.<br />

The second particularly interesting<br />

feature is the possibility to<br />

parameterise all the models created<br />

using Pro-E. This means that every<br />

element used to generate a threedimensional<br />

model during the design<br />

phase is actually a parameter that can<br />

be modified at any time. The<br />

modification of parameter (for<br />

example the dimension of any<br />

mechanical component) causes Pro-<br />

E to automatically regenerate the<br />

whole model and update any drawing<br />

coming from it (such as those relating<br />

to the tooling).<br />

This characteristic is extremely useful<br />

when modifying components designed<br />

using Pro-E and of course when<br />

creating similar components (for<br />

example, pins for track chains all of<br />

a similar shape but with different<br />

diameters and/or lengths). This<br />

feature is particularly useful in the<br />

undercarriage components division.<br />

Numerous benefits are also foreseen<br />

from the use of this new CAD package<br />

in our machine tools design division.<br />

7 <strong>Berco</strong> News<br />

The technicians from the pilot group during a lesson in<br />

the use of Pro-E<br />

IMPLEMENTATION<br />

Training courses for a first pilot group<br />

of seven technicians were started<br />

some time ago. In mid-September,<br />

the first models and drawings were<br />

created with the new CAD system<br />

and were ready for use. We forecast<br />

that by the end of October/beginning<br />

of November, it will be possible to<br />

develop the first models for track<br />

links together with the relative dies.<br />

Once the pilot group is fully<br />

operational, the number of Pro-E<br />

workstations will be increased and<br />

further training will be given. The end<br />

of the first half of 2003 foresees a full<br />

change over to the new system.<br />

The Pro-E implementation schedule<br />

also includes upgrading hardware<br />

to use with this new CAD package,<br />

which includes replacing the older<br />

workstations.<br />

Last but not least, concerning the<br />

implementation of Pro-E, regards<br />

the possibility to re-use the<br />

drawings/models created in the past<br />

using Euclid. A customised interface<br />

procedure is currently being developed<br />

and it will allow us, with some<br />

limitations, to use all of the drawing<br />

and three-dimensional models created<br />

in the past in which we used the<br />

previous CAD system<br />

Franco Santinato<br />

System Manager CAD

<strong>Berco</strong> News<br />

8<br />

Inside <strong>Berco</strong><br />

NEARLY 20,000 HOURS OF TRAINING<br />

<strong>Berco</strong> continuous commitment to the professional growth of its human resources<br />

The quality certification, the<br />

environmental management<br />

certification, the important<br />

technological innovations in the<br />

production departments and being<br />

a part of a multi-national group<br />

have all contributed to the increased<br />

attention that <strong>Berco</strong> pays to the<br />

training of its human resources.<br />

It is for this reason that in 2000 we<br />

revised and updated all the company<br />

training procedure. The HR<br />

Department plans the training<br />

activities on a yearly basis for all<br />

the departments, that in turn identify<br />

and select the personnel in their<br />

department that need training. The<br />

HR department then organizes and<br />

manages the courses and records<br />

all the training activities on an<br />

individual and company basis.<br />

The training program is organized<br />

in courses which range from<br />

instruction in the management and<br />

control of new systems to more<br />

precise requirements such as training<br />

for staff assigned to new tasks or<br />

refresher courses and updating for<br />

quality and environmental<br />

management and safety at work.<br />

Individual courses are also available<br />

for employees with specific<br />

requirements.<br />

During the training year October<br />

2000/September 2001, the total<br />

hours of training were 20,500 and<br />

1,107 employees were involved in<br />

these activities.<br />

TRAINING NEW TECHNICIANS<br />

In these few years of notable growth,<br />

<strong>Berco</strong> has had difficulty recruiting<br />

qualified staff for its specific<br />

production activities. Therefore, the<br />

company has committed to work<br />

with local professional training<br />

institutions and centers for the<br />

development of training programs.<br />

This satisfies, on the one hand, specific<br />

training requirements which come<br />

from the general population and,<br />

on the other, the need for specialized<br />

and qualified workers in local industry.<br />

With this aim the project “Industrial<br />

Automation Technician” was born,<br />

through the will of and created by<br />

the Copparo council, <strong>Berco</strong>, the<br />

University of Ferrara, the Technical<br />

High School of Ferrara and Cesta,<br />

and approved and financed by the<br />

Emilia Romagna Regional Council.<br />

The course, designed for 20 students<br />

with technical high school diploma,<br />

lasts 1,800 hours, 600 of which are<br />

practical work. 15 students already<br />

joined the in <strong>Berco</strong> staff between<br />

November 13th 2000 and August<br />

1st 2001 working in the different<br />

company departments.<br />

Another training project organized<br />

by <strong>Berco</strong> and Cesta Professional<br />

Training Center in 2000/01 is the<br />

course for “Production Expert”, which<br />

through the work experience program<br />

has led to the recruitment of nearly<br />

HOURS<br />

HOURS OF TRAINING FROM 1992 TO 2001<br />

20000<br />

19000<br />

18000<br />

17000<br />

16000<br />

15000<br />

14000<br />

13000<br />

12000<br />

11000<br />

12000<br />

1992<br />

13000<br />

14000<br />

15000<br />

16000<br />

all participants by <strong>Berco</strong> (13 out of<br />

the 14 participants in both years).<br />

There is also a course for<br />

“Maintenance Operators”, again in<br />

collaboration with the Cesta<br />

Professional Training Centre, which<br />

has led to the recruitment of 6 out<br />

of the 10 participants.<br />

PLANS FOR A NEW SCHOOL<br />

Again as part of the company’s<br />

interest and commitment to training,<br />

a plan for a new senior high school<br />

in Copparo was presented last January.<br />

<strong>Berco</strong> will provide an important<br />

contribution to its design and creation.<br />

For the financial year 2001/02 a<br />

growth in training needs is forecasted,<br />

in order to ensure that all personnel<br />

is updated on the new systems and<br />

technologies as well as support the<br />

commitment of the company to<br />

quality in the production processes,<br />

the environment and safety at work.<br />

16500<br />

18300<br />

19200<br />

Daniele Mingozzi<br />

HR Manager<br />

19500<br />

20500<br />

1993 1994 1995 1996 1997 1998 1999 2000 2001

THE RETURN OF DR CROMME<br />

The ThyssenKrupp Chairman pays a visit with 2 important guests<br />

July 13th we had the pleasure of welcoming Dr. Cromme<br />

and his two important guests Dr Hans-Peter Keitel and<br />

Dr Klaus Liesen, two key figures of German industry. It<br />

has been six years since Dr Cromme’s last visit for <strong>Berco</strong>’s<br />

75th anniversary, when he welcomed more than 200<br />

guests. Dr. Cromme strongly praised the <strong>Berco</strong> management<br />

for its positive results and the impressive improvements<br />

in production technology that <strong>Berco</strong> has undertaken<br />

over the past 6 years. Also, Dr Cromme’s two guests,<br />

both experts in company management, were very<br />

impressed with the technological level within the factory<br />

and were pleased with the warm welcome they received.<br />

CTZ IN BERCO<br />

The manufacturers of the T-170 pay<br />

a visit to the Copparo factory<br />

On September 27th Professor KHANIF MINGAZOV (Vice<br />

President) and Dr SERGEJ TIKHONOV (Technical Director)<br />

of CTZ "Chelyabinsk Tractor Plant", paid a visit to our<br />

Copparo factory with Carlo Gherzi, General Manager of<br />

Ralot, dealer for Russia and the countries of the ex-Soviet<br />

Union. With a facility located in a 450 hectars area, CTZ<br />

was founded in 1933 and, already in the thirties was<br />

producing 40 “C60” a day. After World War II, the range<br />

of tractors included the C80, the C100, the T100 and the<br />

DT250, and in 1965, with a yearly output of 32,000<br />

tractors, CTZ built alone more machines than all the other<br />

producers in the world put together. At the beginning of<br />

the 80ies, production began for a new range of machines<br />

which included the DET350 and the T130, the predecessor<br />

of the present day T170. Today CTZ employs 23,000 people<br />

and produces more than 300 tractors per month, with a<br />

foreseen increase to 400 pieces by 2002, when tractor exports<br />

to neighboring countries (currently around 7-8%), are<br />

expected to increase. It is estimated that in Russia alone,<br />

there are more than 95,000 machines, of which at least<br />

50% are in use. <strong>Berco</strong>, following the suggestions of Ralot,<br />

has supplied a kit for retrofitting the T170 undercarriage,<br />

that also includes the final drive. CTZ was particularly<br />

satisfied with the results and performance of the <strong>Berco</strong><br />

undercarriage mounted on their<br />

machines in the Russian mines and<br />

they are taking into consideration the<br />

possibility of offering to their<br />

customer the <strong>Berco</strong> undercarriage<br />

already in the first fit.<br />

“SILVER ANNIVERSARY”<br />

Mr. Koch celebrates his 25 years at <strong>Berco</strong><br />

On 1st October the Managing<br />

Director of our sister company<br />

Krupp BERCO Deutschland GmbH,<br />

Wulf Koch, celebrated 25 years<br />

with <strong>Berco</strong>. After obtaining his<br />

degree in Mechanical Engineering<br />

in 1968, he began his professional<br />

career at Timken Roller Bearing<br />

Inc., and then moved to Hoesch<br />

Rothe Erde Schmiedag AG and again to DELACHAUX.<br />

Finally on October 1st 1976, Koch started distributing<br />

<strong>Berco</strong> products in Germany by becoming head of the<br />

Equipment Sales Department of TEG. At the beginning<br />

of 1977 he was given the power of attorney for the<br />

company and in the mid 80ies became Vice President.<br />

In 1986 he was sent to Italy to manage the Sales &<br />

Marketing department of <strong>Berco</strong>. At the beginning of<br />

1990, he returned to Germany to become Managing<br />

Director of our German sister company TEG (Traktor-<br />

Ersatzteil-Gesellschaft), which in 1998 became Krupp<br />

BERCO Deutschland GmbH. <strong>Berco</strong> would like to thank<br />

Mr. Koch for his commitment and the enthusiasm he has<br />

always put into his work over the past 25 years in order<br />

to grow the <strong>Berco</strong> name in the German market.<br />

NEWS NEWS NEWS NEWS NEWS NEWS NEWS

Marketing Corner<br />

THE “BERCO<br />

MERCHANDISE”<br />

PROJECT GETS OFF<br />

THE GROUND<br />

Following the requests and suggestions coming from<br />

our dealers, personnel and friends, <strong>Berco</strong> has finally<br />

published its first brochure of <strong>Berco</strong> branded give aways<br />

and promotional items.<br />

The purpose of this publication is not only to show<br />

the products available in Italy and abroad, but also<br />

it hopes to solicit your comments and suggestions<br />

for “new” <strong>Berco</strong> products to be included in the range.<br />

We would like to widen and improve the range of<br />

products in order to<br />

make it more<br />

interesting, to further<br />

increase the quality of<br />

the products and to<br />

give you the best<br />

value. These products,<br />

already available for<br />

purchase at the<br />

official <strong>Berco</strong> dealers,<br />

will soon be available<br />

for the members of<br />

the <strong>Berco</strong> Personnel<br />

Association. We are studying other ways to make<br />

the merchandise available in the simplest and most<br />

convenient way. Your suggestions, questions and<br />

advice are of course most welcome. Please send the<br />

form by fax or write your comments via e-mail.<br />

Reader survey<br />

We would first like to thank the more than 130<br />

readers who found the time to help us with their<br />

advice and suggestions. We would then like to<br />

apologize to our readers of the English issue who, due<br />

to the summer shutdown, received the questionnaire<br />

a little late. For this reason we have postponed the<br />

survey deadline to December 1st, 2001, in order to<br />

allow as many readers as possible to send us their<br />

precious comments by filling in the questionnaire<br />

published in the <strong>Berco</strong> News n. 27 and thus taking<br />

part in the great prize drawing.<br />

Send us the questionnaire by mail, fax or deliver<br />

it yourself in person. Thanks in advance for cooperation.<br />

EMO 2001 HANNOVER<br />

Lynx2000 presented at the largest<br />

machine tools trade fair in the world<br />

The <strong>Berco</strong> participation in EMO 2001<br />

happened to be a very interesting<br />

experience not only because of the<br />

presence at the fair of the most<br />

important producers of machine tools<br />

in the world (and in particular those<br />

of the grinding sector) but also because<br />

<strong>Berco</strong> presented the Lynx2000 within<br />

the “ThyssenKrupp Production Systems”<br />

booth, where all the companies of<br />

the ThyssenKrupp group, which operate<br />

in the machine tools sector, such as<br />

Gidding & Lewis, Hüller Hille, Cross<br />

Hüller, Witzig & Frank and Fadal were<br />

gathered. Lynx2000 generated great<br />

M&T EXPO2001<br />

interest in the many visitors who<br />

visited the booth during the 8 days of<br />

the fair. This interest was confirmed<br />

also by the many contacts with<br />

potential customers who were very<br />

impressed with the highly innovative<br />

technical solutions offered by our<br />

orbital grinder. We would like to thank<br />

our colleagues from ThyssenKrupp<br />

for their collaboration throughout<br />

the event. They were also very<br />

impressed by the potential and<br />

functionality of the Lynx2000 in terms<br />

of flexibility, precision and its high<br />

level of technology.<br />

<strong>Berco</strong> do Brasil at the San Paolo fair<br />

From September 18th to the 22nd the<br />

bi-annual trade fair for construction<br />

and mining machinery was held in San<br />

Paolo. This is the largest fair of its kind<br />

in Latin America, and welcomed<br />

more than 30,000 visitors and 120<br />

exhibitors spread over 50,000 m2<br />

of exhibition space. The main<br />

producers of earth moving machinery,<br />

like Fiat Allis and Komatsu(both<br />

BERCO customers) were present. Fiat<br />

Allis exhibited its new tractor models<br />

FD110, FD130 and the FX215<br />

excavator manufactured at the factory<br />

in Contagem (Belo Horizonte).<br />

Komatsu do Brasil presented its<br />

tractors D41, D61 and the PC200<br />

excavator, constructed at the Komatsu<br />

do Brasil factory in Suzano (San<br />

Paolo).<br />

<strong>Berco</strong> do Brasil was present at this<br />

important event with Robrasa Rothe<br />

Erde (company in the ThyssenKrupp<br />

group), a leader in Brazil and in the<br />

world for the production of slew<br />

rings for excavators. Our booth had<br />

a very distinctive design and attracted<br />

a lot more public interest than we had

(…continued)<br />

expected. Among the products on<br />

display, the BMP - <strong>Berco</strong> Mining<br />

Products – line produced the greatest<br />

interest among the visitors and in<br />

particular the models D8 and D10,<br />

currently being used successfully in<br />

the largest iron mines in the world,<br />

in the Minas Gerais state, and serviced<br />

by our distributor CMR.<br />

<strong>Berco</strong> do Brazil carries out assembly<br />

and just-in-time delivery of<br />

11 <strong>Berco</strong> News<br />

CONSTRUCTION MACHINERY 2001<br />

Karnaros-Melissis at the first edition in Athens<br />

The first edition os “Construction Machinery”, a trade<br />

fair dedicated to plant and construction machinery,<br />

took place in Athens from September 20th through the<br />

23rd. The fair was a great success despite the fact it<br />

was the first edition, and despite the dramatic events<br />

that happened in the United States, which caused many<br />

exhibitors and visitors to cancel their visit.<br />

Over an area of 70,000m 2 , of which 55,000 under roof,<br />

more than 100 exhibitors displayed their products.<br />

During the four days of the fair more than 6,000 visitors<br />

crowded the various booths and viewed the products on<br />

display.<br />

Among the exhibitors was Karnaros-Melissis, leader in<br />

the field of undercarriage spare parts supply in the<br />

greek market and who has been our official dealer since<br />

1983. The 250 m 2 booth displayed professionalism and<br />

style which helped to ‘conquer’ many visitors, and the<br />

fair organizers that praised it as one of the best booths<br />

at the fair.<br />

For Karnaros-Melissis this was a great chance not only<br />

FOR THE FIRST TIME IN MOSCOW<br />

5th Russian International Autosalon<br />

From August 23rd to the 29th the<br />

most important Russian trade fair<br />

for cars and workshop equipment<br />

was held in Moscow. <strong>Berco</strong>, through<br />

the company Ralot, <strong>Berco</strong> dealer for<br />

the countries of the ex-Soviet Union<br />

for both spare parts and machine<br />

tools, displayed the machines RTM270,<br />

RV20, SB450 and CM250.<br />

Cars and trucks, of both Russian and<br />

foreign production, took up about<br />

two thirds of the exhibition area,<br />

while the remaining third was<br />

undercarriage products to the main<br />

OEMs in Brazil that manufacture<br />

machines not only for the Brazilian<br />

market but for the whole of South<br />

America. Thanks to its modern<br />

information technology systems and<br />

close coordination with our<br />

headquarters, <strong>Berco</strong> do Brazil offers<br />

its OEM customers a high quality<br />

logistic support and service in-line<br />

with those offered to the same<br />

customers in Europe and in America.<br />

dedicated to vehicle repair equipment<br />

and spare parts. This participation<br />

in the fair was particulary interesting<br />

because it gave the chance to make<br />

a first contact with the Russian<br />

market and also because it generated<br />

several contacts with the many<br />

potential customers that visited the<br />

Ralot/<strong>Berco</strong> booth.<br />

We would like to thank Mr. R. Valoti<br />

and Mr. A. Gaidash from RALOT for<br />

their contribution to the success of<br />

the fair.<br />

to display the full range of products<br />

and explain the products to their<br />

clients, but also to make several<br />

new and promising contacts.<br />

We hope that for Karnaros-Melissis<br />

their presence at the fair was an<br />

important step to further strengthen<br />

their position in the market.

A NEW DEALER<br />

IN GREAT BRITAIN<br />

On September 3rd, 2001 Midland<br />

Steel Traders Ltd. joined the <strong>Berco</strong><br />

family by signing a contract for the<br />

distribution of <strong>Berco</strong> undercarriage<br />

products in Great Britain. Present<br />

at the signing ceremony were the<br />

brothers Mr. Paul Whithall and<br />

Mr. John Whitehall, company<br />

directors, G. Bertoni, Managing Director of <strong>Berco</strong>, W.<br />

Schmitz-Meimbresse, <strong>Berco</strong> General Manager Commercial<br />

and Mauro Fabbri, <strong>Berco</strong> Commercial Director.<br />

MST (Midland Steel Traders) was founded in April 1971<br />

by the Whitehall family with the aim of marketing<br />

undercarriage products in Northern England and Scotland.<br />

Their first service center was in Washington, although<br />

three years later it was moved to Birtley where a large<br />

press was also installed for the repair and replacement<br />

of undercarriages for all of their customers. Despite the<br />

fact that they were not an official <strong>Berco</strong> dealer, over<br />

their 30 year history, MST have sold <strong>Berco</strong> products,<br />

purchasing them from other <strong>Berco</strong> distributors with<br />

whom they have developed good working relations. It was<br />

only when Peter Strickland ceased his activities in the<br />

aftermarket that MST felt that the time had come to discuss<br />

with <strong>Berco</strong> the possibility of becoming an official <strong>Berco</strong><br />

Dealer for Great Britain.<br />

MST have approximately 60 people working for them in<br />

the service centers of Birtley and Airdrie, although they<br />

intend to expand their activities towards the South,<br />

opening a new service center in Birmingham in a few<br />

months’ time.<br />

For further information you can contact MST:<br />

Mr. Paul Whitehall<br />

Midland Steel Traders Ltd.<br />

Portobello Industrial Estate<br />

Birtley, County Durham, DH3 2SW - UK<br />

Tel. +44 (191) 4105311 - Fax +44 (191) 410 0482<br />

e-mail: paul.whitehall@mst-tracks.co.uk<br />

CONQUERING<br />

THE WEST<br />

Olympic Tracks open a branch in Las Vegas<br />

In the desert landscape of Nevada, a new <strong>Berco</strong> sign has<br />

been raised by Olympic Tracks, Inc. (OTI). Olympic Tracks,<br />

affiliated company of <strong>Berco</strong> of America, which has been<br />

our U.S. dealer for the Pacific Northwest in the Seattle area<br />

since 1993, recently announced its expansion into the<br />

Southwest.<br />

The new Nevada location, in North Las Vegas, will occupy<br />

20,000 square feet (1858 sq. meters) of warehouse space<br />

and 1400 square feet of office space (130 sq. meters).<br />

Besides offering the complete range of <strong>Berco</strong> undercarriage<br />

components, OTI’s new facility will have the full service<br />

capability to refurbish and maintain crawler construction<br />

equipment.<br />

This important step in the continuous growth of <strong>Berco</strong><br />

throughout the world has created new excitement and<br />

evident enthusiasm. As confirmed by Scott Kellogg,<br />

General Manager of OTI, “We are very excited about the<br />

opportunity to better serve our customers in Nevada,<br />

Southern California, Arizona and Utah as North Las Vegas<br />

is centrally located in the Southwest region of the USA.”<br />

Tom Rodrigues is the Branch Manger of this new North<br />

Las Vegas facility. Tom has over 16 years experience<br />

within the heavy construction market working as a<br />

Business Manager. Dave Williams is the Parts and Service<br />

Manager. Dave has been a professional in this industry<br />

for 32 years. His expertise has a wide range with a<br />

concentration on Marketing and Product Support.<br />

OTI North Las Vegas can be reached by phone at 1-888-<br />

810-4802 or by fax at 702-507-0970.<br />

EALER NEWS DEALER NEWS DEALER NEWS DEALER NEWS D