SUMMARY Nearly 70 years ago, the first dispersion-strengthened ...

SUMMARY Nearly 70 years ago, the first dispersion-strengthened ...

SUMMARY Nearly 70 years ago, the first dispersion-strengthened ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

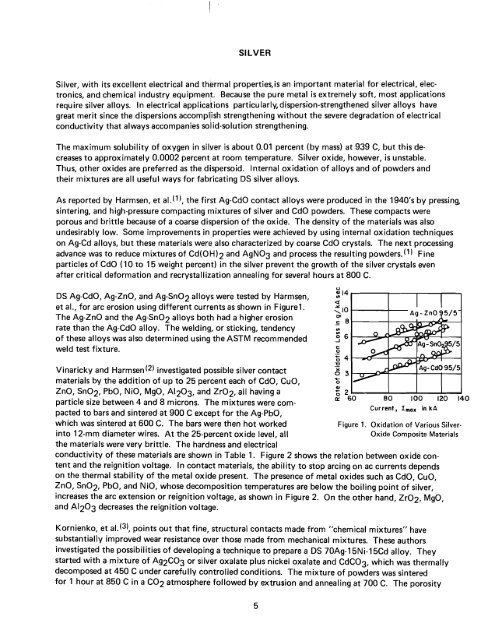

SILVERSilver, with its excellent electrical and <strong>the</strong>rmal properties, is an important material for electrical, electronics,and chemical industry equipment. Because <strong>the</strong> pure metal is extremely soft, most applicationsrequire silver alloys. In electrical applica~ions particularly, <strong>dispersion</strong>-streng<strong>the</strong>ned silver alloys havegreat merit since <strong>the</strong> <strong>dispersion</strong>s accomPI'l'iSh streng<strong>the</strong>ning without <strong>the</strong> severe degradation of electricalconductivity that always accompanies so id-solution streng<strong>the</strong>ning.The maximum solubility of oxygen in silyer is about 0.01 percent (by mass) at 939 C, but this decreasesto approximately 0.0002 percentat room temperature. Silver oxide, however, is unstable.Thus, o<strong>the</strong>r oxides are preferred as <strong>the</strong> dispersoid. Internal oxidation of alloys and of powders and<strong>the</strong>ir mixtures are all useful ways for fabricating DS silver alloys.As reported by Harmsen, et al.(1), <strong>the</strong> <strong>first</strong> Ag-CdO contact alloys were produced in <strong>the</strong> 1940's by pressing,sintering, and high-pressure compacting mixtures of silver and CdO powders. These compacts wereporous and brittle because of a coarse <strong>dispersion</strong> of <strong>the</strong> oxide. The density of <strong>the</strong> materials was alsoundesirably low. Some improvements in properties were achieved by using internal oxidation techniqueson Ag-Cd alloys, but <strong>the</strong>se materials were also characterized by coarse CdO crystals. The next processingadvance was to reduce mixtures of Cd(OH)2 and A9N03 and process <strong>the</strong> resulting powders. (1) Fineparticles of CdO (10 to 15 weight percent) in <strong>the</strong> silver prevent <strong>the</strong> growth of <strong>the</strong> silver crystals evenafter critical deformation and recrystallization annealing for several hours at 800 C.DS Ag-CdO, Ag-ZnO, and Ag-Sn02 alloys were tested by Harmsen,et aI., for arc erosion using different currents as shown in Figure1.The Ag-ZnO and <strong>the</strong> Ag-Sn02 alloys both had a higher erosionrate than <strong>the</strong> Ag-CdO alloy. The welding, or sticking, tendencyof <strong>the</strong>se alloys was also determined using <strong>the</strong> ASTM recommendedweld test fixture.Figure 2 shows <strong>the</strong> relation between oxide conIn contact materials, <strong>the</strong> ability to stop arcing on ac currents dependson <strong>the</strong> <strong>the</strong>rmal stability of <strong>the</strong> metal oxide present. The presence of metal oxides such as CdO, CuO,ZnO, Sn02, PbO, and NiO, whose decomposition temperatures are below <strong>the</strong> boiling point of silver,increases <strong>the</strong> arc extension or reignition voltage, as shown in Figure 2. On <strong>the</strong> o<strong>the</strong>r hand, Zr02, MgO,and AI203 decreases <strong>the</strong> reignition voltage.Vinaricky and Harmsen(2) investigated possible silver contactmaterials by <strong>the</strong> addition of up to 25 percent each of CdO, Cuo,ZnO, Sn02, PbO, NiO, MgO, AI203, and Zr02, all having aparticle size between 4 and 8 microns. The mixtures were compactedto bars and sintered at 900 C except for <strong>the</strong> Ag-PbO,which was sintered at 600 C. The bars were <strong>the</strong>n hot workedinto 12-mm diameter wires. At <strong>the</strong> 25-percent oxide level, all<strong>the</strong> materials were very brittle. The hardness and electricalconductivity of <strong>the</strong>se materials are shown in Table 1.tent and <strong>the</strong> reignition voltage.u::: 14 ,...------r------r-----..,,...----,