Microbiology of food preservation - Texas A&M University

Microbiology of food preservation - Texas A&M University

Microbiology of food preservation - Texas A&M University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

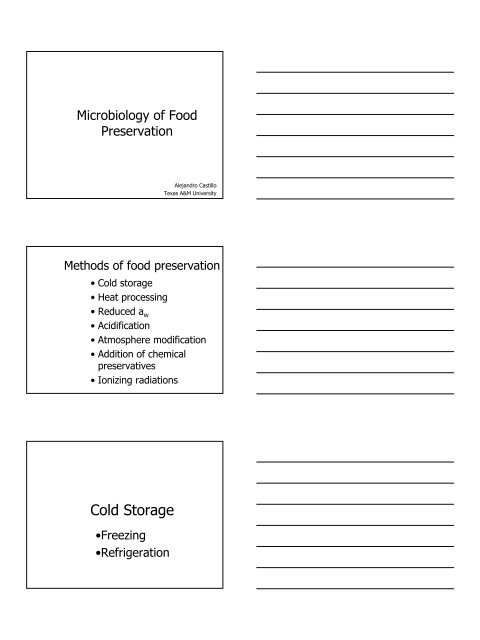

<strong>Microbiology</strong> <strong>of</strong> FoodPreservationAlejandro Castillo<strong>Texas</strong> A&M <strong>University</strong>Methods <strong>of</strong> <strong>food</strong> <strong>preservation</strong>• Cold storage• Heat processing• Reduced a w• Acidification• Atmosphere modification• Addition <strong>of</strong> chemicalpreservatives• Ionizing radiationsCold Storage•Freezing•Refrigeration

Freezing• Needs previousconditioning• Freezing is applied topreviously packaged<strong>food</strong>sFreezing• Vegetables– Selecting/sorting– Washing– Cutting (if any)– Blanching–Packaging• Meats, poultry, sea<strong>food</strong>, eggs etc.– Trimming–PackagingFreezing• Blanching• Enzyme inactivation• Fixing green color in some vegetables• Easing packaging <strong>of</strong> leafy vegetables(by wilting)• Displacing <strong>of</strong> air from plant tissues• Reduction <strong>of</strong> microbial counts

Freezing• Fast freezing– Lower temperature to -20°C within 30min– Blast freezing or immersion•Slow freezing• Lower temperature to -20╖C within3-72 h• Home freezersFreezing• Effects <strong>of</strong> freezing on microorganisms• Sudden mortality immediately onfreezing• Continued mortality rate decreasesgradually during storage• The lower the temperature the lowerthe bacterial declineRefrigeration• The lower the temperature thelower the growth rate• How can psychrotrophs grow atrefrigeration temperatures?

Psychrotrophs and psychrophiles• Greater content <strong>of</strong> unsaturated fatty acids• Slower metabolic rate• Better membrane transport– Still active at low temperatures• Production <strong>of</strong> larger cells– Additional RNA• More efficient flagella synthesis• Favored by aeration• Greater heat sensitivity• Usually do not grow above 35°C– Inactivation <strong>of</strong> respiratory enzymes–Leakage <strong>of</strong> intracellular constituentsHeat processing•Pasteurization•SterilizationPasteurizationTypes <strong>of</strong> milkpasteurizationLow temperaturelong timeAcronymLTLTTreatment63°C/30 minHigh temperatureshort timeUltrahightemperatureHTSTUHT72°C/15 s90°C/0.5 s94°C/0.1 s100°C/0.01 s

PasteurizationMilk pasteurization• Originally designed to targetMycobacterium tuberculosis• Coxiella burnetti is currently thetarget organismPasteurization• Thermoduric organisms–Organisms capable <strong>of</strong> survivingpasteurization–Examples: lactobacilli,micrococci, streptococci,lactococci–Pathogens are not thermoduricFactors affecting heat resistance <strong>of</strong>microorganisms•Water•Fat•Salts– Salts that reduce a w (Na + , K + )more protective than those thatincrease a w Ca +2 , Mg +2 )• Carbohydrates•pH

Factors affecting heat resistance <strong>of</strong>microorganisms (cont.)•Proteins• Numbers <strong>of</strong> microorganisms• Age or microorganisms– Old cells (stationary phase) moreresistant that younger cells (log phase)•Growth temperature• Inhibitory compounds• Time and temperature• Ultrasonic effectCanning• Processing <strong>of</strong> <strong>food</strong> products inhermetically sealed containers–Metal–Glass• Canned products are commerciallysterileSpoilage organisms associated withcanned productsMesophilic• Putrefactive anaerobes– Clostridium botulinum• Butyric anaerobes– C. butyricum•Aciduricflat sour– Bacillus polymyxa• Lactobacilli•Yeasts•Molds

Spoilage organisms associated withcanned products (cont.)Thermophilic• Anaerobic sulfide producers– Desulfotomaculum nigrificans•Flat-sour spores• B. stearothermophilus, B. coagulans• Anaerobic non-sulfide producers– Thermobacterium thermosaccharolyticumCanningpH categoryExamples <strong>of</strong> <strong>food</strong>sSpoilageLow acid> 4.6Acid3.7-4.0 to 4.6Meats, sea<strong>food</strong>,milk, somevegetablesTomatoes, pears,figs•Thermophilic flatsourgroup•Sulfide spoilers•Gaseous spoilers•Mesophilic spoilers –PutrefactiveanaerobesThermophilic spoilersHigh acid

Foods <strong>of</strong> low and intermediatemoisture•Low moisture– Dry, dessicated–0.65 – 0.70.60-0.652 yearsNo microbialspoilageDrying•Freeze drying–lyophilization•Hot vacuum drying•Hot air drying•Sun dryingDrying depends on temperature andpressure conditions

Effect <strong>of</strong> the a w adjustmentmethodWays <strong>of</strong> adjusting the a w <strong>of</strong> a <strong>food</strong>• Adsorption– Adding water to dry <strong>food</strong>s to adjust a w• Freeze dried <strong>food</strong>s• Egg beaters•Desorption– Eliminate water from the <strong>food</strong> system• Hot vacuum dried or sun dried <strong>food</strong>s• At similar moisture content (% water)desorption tends to produce lower a w

Concentration• Adding solutes to the <strong>food</strong> system– Salting (dry fish)– Adding sugar (jellies, syrups)• Adding solutes and eliminating waterwater– Caramelized condensed milk (cajeta)• The solute plays an important role ina w reductionGrowth <strong>of</strong> Staphylocoucus aureus in mocha cakestored at 25°C as affected by moisturizing agent9Log CFU/g8765432120% Sucrose20% Glucose00 3 6 9 12 15 18Hours <strong>of</strong> storageAcidification•Low pH•Organic acids

Acidification•Fermented <strong>food</strong>s•Acidified <strong>food</strong>s–Acidic <strong>food</strong>s vs.acidified <strong>food</strong>sAtmosphere modification•Controlled atmospheres•Modified atmospheresControlled atmospheres• Substitution <strong>of</strong> air by a gas mixture• Controlling gas concentration during storage• Usually includes CO 2– Greater inhibition <strong>of</strong> microorganisms by CO 2 atrefrigeration temperatures– Lower APC in steaks during storage in 100% CO 2compared to 100% N 2 or air– Shelf life <strong>of</strong> lean beef inoculated with PMA andstored at 5°C in 85% O 2 + 15% CO 2 was 9 dayslonger than beef stored in air.• Reducing O 2 concentration may affect <strong>food</strong>quality–Red meats

Effect <strong>of</strong> CO 2 on microorganisms inmeat packs• Microbiota is shifted• Predominant PMA (aerobic, CO 2sensitive) to lactic acid bacteria (LAB,facultatively anaerobic, CO 2 resistant)• PMA are putrefactive, LAB arefermentative– Some sensorial change is still acceptedby consumersModified atmosphere packaging(MAP)• Substitution <strong>of</strong> air by a gas mixture• Vacuum packaging– 80% <strong>of</strong> fresh beef in the U.S. is vacuumpackaged– Not all O 2 is removed–The O 2 remaining is consumed by themicrobiota and the <strong>food</strong>–CO 2 is also produced by metabolic activity• Inhibitory for microorganisms• Careful selection <strong>of</strong> packaging filmSpoilage <strong>of</strong> vacuum packagedmeats• Long-term refrigeration spoilageassociated with Brocchothrixthermosphacta and lactobacilli• Clostridium laramie is also associatedwith gassy spoilage in vacuumpackaged meats

Food safety concerns• Some researchers believe that MAPresults in a selection <strong>of</strong> potentialpathogens by inhibiting competitivebiota– Aeromonas hydrophila– Listeria monocytogenes• A. hydrophila survives and growsbetter in meat under air packagingcompared to vacuumAddition <strong>of</strong> chemicalpreservativesGRAS substances• Chemical additives must be listed asGRAS by FDA regulations– GRAS = Generally Recognized as Safe• There is a maximum tolerance fortheir concentration in <strong>food</strong>s• Different preservatives target specificorganisms• The effect <strong>of</strong> some preservatives isaffected by <strong>food</strong> characteristics suchas pH

Benzoates and parabensHOOCCOOHEffect dependson pHEffect does notdepend on pHBenzoic acidHOCOOHp-Benzoic acidParabensParabens

Other organic acid derivatives• Sorbates– Used as sorbic acid or as calcium or potassiumsorbate (salts more soluble than acid)– Widely used as a preservative– One half the toxicity <strong>of</strong> NaCl– pH dependant– No effect above pH 6.0– May change the taste <strong>of</strong> <strong>food</strong>s if added inexcess (usually no more than 0.2%)– Effective against spoilage and pathogenicbacteria• Propionates– Lower tendency to dissociate– Effective in low-acid <strong>food</strong>sSO 2 and sulfites• SO 2used as a gas or in liquid form• Used as preservative in wines, dried fruits,juices, molasses• Effect greatly favored by low pH• Bacteriostatic against Acetobacter and LAB– Juices and beverages• SO 2can change to sulfurous acid derivativesSO 3-2then to sulfites, bisulfites andmetabisultfites• Sulfites are used as preservatives in juices andbeverages– Also to prevent melanosis in shrimpNitrites and Nitrates• Used in curing formulas for meat• Stabilize red color <strong>of</strong> meat• Inhibit spoilage and pathogenicorganisms• Contribute to flavor development•NO 2 and NO 3 change to HNO 2then to NO

NO 2 and Clostridium botulinum• Prevents germination <strong>of</strong> spores<strong>of</strong> C. botulinum• Also effective against S. aureus• Added to cheeses to preventgassy spoilage caused byclostridiaThe Perigo factor• Question:–Why is C. botulinum almost totally absent incured, canned and vacuum packaged meats?• Perigo and Roberts (1968) found that NO 2was 10 times more effective if addedbefore heat treatment– A chemical factor is thought to be producedduring heating that enhances the inhibitoryeffect <strong>of</strong> NO 2• Several researchers have reported that theantibotulinal effect is interdependent withNO 2 , with other curing ingredients, pH,heat treatment, and temperature/time <strong>of</strong>storageAntimicrobial mechanism•NO 2 inhibits C. botulinum byinterferring with iron-sulfur enzymesthus preventing ATP synthesis– Ferredoxin• Bacteria that lack ferredoxin areresistant to NO 2– LAB lack ferredoxin– Lactobacillus and other LAB spoilage incured meats is reported• Green ham (Sam I am)

Other antimicrobials• Ethylene oxide– Highly toxic, but no residues• Antibiotics and bacteriocins– Nisin, subtilin, tylosin• Antifungals– Natamycin, benomyl, thiabendazoleIonizing radiations•Electron beam•X-rays•Gamma raysFood irradiation“Food Irradiation is a process thatexposes <strong>food</strong> to a carefully controlledamount <strong>of</strong> ionizing energy todamage the DNA <strong>of</strong> parasites, fungi,and bacteria and eventually destroythese organisms.” (IFST, 1999)

Radioactivity vs. Irradiation Radioactivity:Spontaneous emission <strong>of</strong> particles,radiations or both Irradiation:Transmission <strong>of</strong> energy (in the form<strong>of</strong> waves) through spaceFood irradiation in the U.S.In the United States, ionizingirradiation <strong>of</strong> <strong>food</strong> is considered a<strong>food</strong> additive under current lawand thus must be approved byFDAIonizing radiations <strong>of</strong> interest in<strong>food</strong> <strong>preservation</strong>•Electrombeam•Gamma rays•X rays

Electromagnetic spectrumCharacteristics <strong>of</strong> different forms<strong>of</strong> radiation applicable in <strong>food</strong>sElectron Beams:– Effective at converting electrons into high energybeams such as X-rays– Easily applicable on different types <strong>of</strong> <strong>food</strong>s,climatic conditions and harvest seasons– Can turn on and <strong>of</strong>f with ease– Less penetrating than gamma rays– More energy than gamma rays– Electron beams generated by linear accelerator cangenerate 10 3 -10 6 Gy/seg, whereas the dose generated by60Co is 1-100 1-100 Gy/minCharacteristics <strong>of</strong> different forms<strong>of</strong> radiation applicable in <strong>food</strong>s Gamma rays:– Electromagnetic radiations emitted fromexcited nuclei ( 60 Co or 137 Cs )– Relatively inexpensive byproducts <strong>of</strong>atomic fission– Greater penetration power– Half-life <strong>of</strong> 60 Co: 5.27 years– Half-life <strong>of</strong> 137 Cs: ~30 years

Characteristics <strong>of</strong> different forms<strong>of</strong> radiation applicable in <strong>food</strong>s X rays:– Produced by linear accelerator– Essentially the same as electron beambut after passing through a heavy metaltarget– Otherwise, essentially similar to gammaraysForms <strong>of</strong> radiation(from Jay, 1998)Types <strong>of</strong> treatments• Radappertization– 30 - 40 kGy– Commercial sterility• Radicidation–2.5-10 kGy– Pathogen reduction• Radurization– 0.75 – 2.5 kGy– Reduction <strong>of</strong> bacterial populations– Enhancement <strong>of</strong> <strong>food</strong> quality

Fundamentals <strong>of</strong> bacterialdestruction by irradiationGram positive bacteria more resistant than Gramnegative bacteriaMolds less resistant than bacteria (especially G+)– Some yeasts are highly resistant Types <strong>of</strong> microorganisms– Sporeformers are more resistant than non-sporeformers– Some highly resistant non-sporeforming bacteria– Deinococcus, Deinobacter, Rubrobacter, Acinetobacter Most highly resistant bacteria– Sporeformers– Paenibacillus larvae–type A Clostridium botulinum– Non-sporeformers– Enterococcus faecium R53– Hom<strong>of</strong>ermentative lactobacilliFundamentals <strong>of</strong> bacterialdestruction by irradiationFactors affecting irradiationperformance Number <strong>of</strong> microorganisms Composition <strong>of</strong> the <strong>food</strong> Presence or absence <strong>of</strong> oxygen Physical state <strong>of</strong> the <strong>food</strong> Age <strong>of</strong> microorganismsD-values (D 10 ) for selected bacteriaOrganismD 10 (kGy)C. botulinum, type E Beluga0.80C. botulinum type A, toxin production in meat 36.08Escherichia coli0.20Listeria monocytogenes0.42 - 0.55Salmonella typhimuriumStaphylococcus aureusYersinia enterocolitica, beef at 25°CYersinia enterocolitica, beef at -30°C0.500.160.1950.388Adapted from Jay, 1998

D 10 values for selected moldsOrganismAspergillus flavus sporesAspergillus flavusAspergillus nigerPenicillium citrinum, NRRL 5452Penicillium sp.D 10 (kGy)0.660.055-0.060.0420.880.42Adapted from Jay, 1998D 10 value for Salmonella Poona on cantaloupecubes treated by electron beam irradiation987Mean log 10 CFU/g6543210D 10 = 0.203 kGy00.050.10.150.20.250.30.350.40.450.50.550.60.650.70.750.80.850.90.9511.051.1Dose (kGy)D 10 values for selected virusesType <strong>of</strong> virusAdenovirusCoxsackievirusEchovirusHerpes simplexPoliovirusD 10 (kGy)4.1 - 4.94.1 - 5.04.4 - 5.14.34.1 - 5.4Adapted from Jay, 1998

Effect <strong>of</strong> irradiation onmicroorganismsAntimicrobial mechanismBreaking <strong>of</strong> DNA strandsIrradiation breaks 6 chemicalchains out <strong>of</strong> every 10 millionchains present in a cellUses in the United States• Control insects in wheat, wheat flour• Inhibit sprouting in white potatoes• "Sterilize" Trichinella in fresh pork (0.3-1 kGy)• Inhibit mold decay, control insects in freshfruits and vegetables (0.3-1 kGy)• Microbial disinfection <strong>of</strong> spices and herbs (upto 30 kGy)• Radicidation <strong>of</strong> fresh poultry• Recent approval for red meat, shell eggsFoods approved by WHO forirradiationType <strong>of</strong> <strong>food</strong>PotatoesOatmeal flourDried fruitsPoultryFresh fruitsFresh meatsShrimpObjectiveSprout inhibitionInsect eliminationInsect eliminationRadicidationRadurizationRadurizationRadurizationDose (kGy)0.1-0.150.2-0.751.07.0 max.2.56.0-8.00.5-1.0Adapted from Jay, 1998

Effect <strong>of</strong> irradiation onqualityWater radiolisis3H 2 O H + OH + H 2 O 2 + H 2Consumer Acceptance• Most consumers have littleknowledge <strong>of</strong> the process or it’sadvantages.• Concern about <strong>food</strong>borne illness hascreated interest in irradiated <strong>food</strong>s• After receiving educationalinformation market trial consumerswere more likely to purchaseirradiated <strong>food</strong>s

Packaging• Most <strong>food</strong>s are irradiated in theirpackaging• Irradiated <strong>food</strong>s are clearly marked–Radurasymbol– “irradiated for your <strong>food</strong> safety”• Packaging must be approved forirradiation use