Simplifying Connections in Gas Chromatography - SGE Analytical ...

Simplifying Connections in Gas Chromatography - SGE Analytical ...

Simplifying Connections in Gas Chromatography - SGE Analytical ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNICAL ARTICLE<br />

<strong>Simplify<strong>in</strong>g</strong> <strong>Connections</strong> <strong>in</strong> <strong>Gas</strong> <strong>Chromatography</strong><br />

INTRODUCTION<br />

<strong>Analytical</strong> chemists are <strong>in</strong>creas<strong>in</strong>gly turn<strong>in</strong>g to the<br />

use of multi-column capillary GC systems to address<br />

the <strong>in</strong>creas<strong>in</strong>g demand for speed, selectivity, and / or<br />

sensitivity of analysis. Electronic pressure control has<br />

reached a level that has permitted a revival of multicolumn<br />

approaches. However, the success or otherwise<br />

of a GC multi-column approach often depends upon<br />

someth<strong>in</strong>g seem<strong>in</strong>gly mundane: column connections.<br />

Without proper care and sufficient skill, <strong>in</strong>creas<strong>in</strong>g the<br />

number of connections, unions and connect<strong>in</strong>g conduits<br />

<strong>in</strong> the GC system, can <strong>in</strong>crease the likelihood of leaks,<br />

unswept volumes, and active sites. Those us<strong>in</strong>g multicolumn<br />

systems warmly welcome technologies that<br />

alleviate these problems. Here we discuss an approach<br />

us<strong>in</strong>g microfabrication processes to develop a number of<br />

robust solutions ideally suited to the harsh environment of<br />

the GC oven <strong>in</strong>clud<strong>in</strong>g:<br />

• Sta<strong>in</strong>less steel planar micro channel devices,<br />

• Leak free f<strong>in</strong>ger tight metal ferrules,<br />

• Metal surface deactivation.<br />

These technologies will be illustrated by provid<strong>in</strong>g case<br />

studies from experiences develop<strong>in</strong>g multi-column GC<br />

approaches.<br />

Guard Column and GC x GC Connector<br />

Metal ferrules are ideal for<br />

connect<strong>in</strong>g capillary columns<br />

as they provide a leak free<br />

solution <strong>in</strong> thermal gradient<br />

experiments. Figure 1 shows<br />

a sta<strong>in</strong>less steel micro union<br />

(mass < 1 gm) that uses a<br />

double ended ferrule to make a<br />

f<strong>in</strong>ger tight union between two<br />

capillary columns or a guard<br />

column.<br />

Figure 1. The SilTite µ-union.<br />

F<strong>in</strong>ger tight <strong>in</strong>stallation, small<br />

thermal mass and low dead<br />

volume.<br />

The micro union is a convenient connector as it uses f<strong>in</strong>ger<br />

tight fitt<strong>in</strong>gs to connect tub<strong>in</strong>g, mak<strong>in</strong>g it user friendly.<br />

There is no impact on the chromatography when us<strong>in</strong>g a<br />

micro-union and their permanent connection makes them<br />

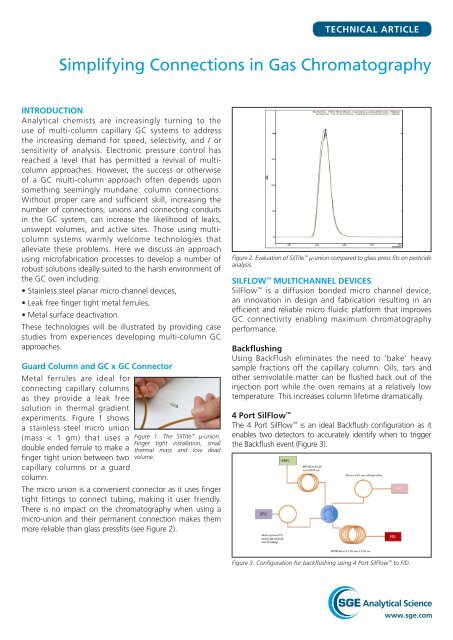

more reliable than glass pressfits (see Figure 2).<br />

Figure 2. Evaluation of SilTite µ-union compared to glass press fits on pesticide<br />

analysis.<br />

SILFLOW MULTICHANNEL DEVICES<br />

SilFlow is a diffusion bonded micro channel device,<br />

an <strong>in</strong>novation <strong>in</strong> design and fabrication result<strong>in</strong>g <strong>in</strong> an<br />

efficient and reliable micro fluidic platform that improves<br />

GC connectivity enabl<strong>in</strong>g maximum chromatography<br />

performance.<br />

Backflush<strong>in</strong>g<br />

Us<strong>in</strong>g BackFlush elim<strong>in</strong>ates the need to ‘bake’ heavy<br />

sample fractions off the capillary column. Oils, tars and<br />

other semivolatile matter can be flushed back out of the<br />

<strong>in</strong>jection port while the oven rema<strong>in</strong>s at a relatively low<br />

temperature. This <strong>in</strong>creases column lifetime dramatically.<br />

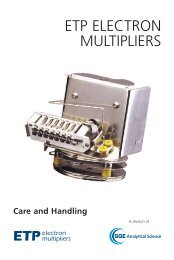

4 Port SilFlow <br />

The 4 Port SilFlow is an ideal Backflush configuration as it<br />

enables two detectors to accurately identify when to trigger<br />

the Backflush event (Figure 3).<br />

Figure 3. Configuration for backflush<strong>in</strong>g us<strong>in</strong>g 4 Port SilFlow to FID.

TECHNICAL ARTICLE<br />

Figure 4 demonstrates the analysis of ethanol, benzene and<br />

toluene <strong>in</strong> gasol<strong>in</strong>e on a polar BPX90 capillary column. The<br />

sample was first run on a nonpolar BP1 to identify the time<br />

where the Backflush is <strong>in</strong>tiated to prevent the non-volatile<br />

runn<strong>in</strong>g onto the BPX90 column.<br />

Figure 4 A, separation of gasol<strong>in</strong>e on BP1 (30 m x 0.25 mm<br />

x 0.25 µm, P/N 054044) and BPX90 (60 m x 0.25 mm x<br />

0.25 µm, P/N 054590) with 2-Butanol IS.<br />

Figure 4 B, separation of gasol<strong>in</strong>e on BP1 (30 m x 0.25 mm<br />

x 0.25 µm) and BPX90 (60 m x 0.25 mm x 0.25 µm) with<br />

Backflush triggered at 2 m<strong>in</strong>utes - note the absence of the<br />

semi-volatiles post 10 m<strong>in</strong>utes.<br />

A)<br />

Figure 4. Backflush method - gasol<strong>in</strong>e on BP1 and BPX90 FID Data split with<br />

MS with 2-Butanol IS.<br />

3 Port SilFlow <br />

The 3 Port SilFlow is ideal<br />

for detector splitt<strong>in</strong>g, column<br />

splitt<strong>in</strong>g and also functions<br />

<strong>in</strong> Backflush mode. In natural<br />

gas analysis it is preferred to<br />

backflush if water is present<br />

- the follow<strong>in</strong>g examples<br />

demonstrate mercaptans<br />

spiked <strong>in</strong>to nitrogen.<br />

Figures 5 and 7 illustrate the Backflush set-up for the<br />

3 Port SilFlow us<strong>in</strong>g two different detection systems - FID<br />

and SCD (Sulphur Chemilum<strong>in</strong>escence Detector) for the<br />

analysis of mercaptans <strong>in</strong> natural gas. Figure 6 highlights<br />

the excellent peak shape for the different mercaptans<br />

<strong>in</strong> the FID set-up. While slight peak tail<strong>in</strong>g is obvious <strong>in</strong><br />

Figure 8 for the low ppm levels, this is due to the nonspecific<br />

<strong>in</strong>teractions <strong>in</strong> the detector (alpha-alum<strong>in</strong>a). Figure<br />

9 shows a commercial natural gas sample run us<strong>in</strong>g the<br />

3 Port SilFlow set-up highlight<strong>in</strong>g the chemical <strong>in</strong>ertness<br />

and detection of the sulphur odorants.<br />

B)<br />

3 Port SilFlow <br />

Figure 5. Configuration for backflush<strong>in</strong>g us<strong>in</strong>g 3 Port SilFlow to FID.<br />

1. Methyl mercaptan<br />

2. Ethyl mercaptan<br />

3. Propyl mercaptan<br />

4. Butyl mercaptan<br />

Figure 6. 100 ppm (v/v) methyl, ethyl, propyl, butyl mercaptans <strong>in</strong> nitrogen<br />

by GC/FID.<br />

Figure 7. Configuration for backflush<strong>in</strong>g us<strong>in</strong>g 3 Port SilFlow to SCD.<br />

1. Methyl mercaptan<br />

2. Ethyl mercaptan<br />

3. Propyl mercaptan<br />

4. Butyl mercaptan<br />

Figure 8. 1 ppm (v/v) of methyl, ethyl, propyl and butyl mercaptan <strong>in</strong> nitrogen<br />

GC/SCD.

TA-0150-A © <strong>SGE</strong> <strong>Analytical</strong> Science Pty Ltd 07/2012<br />

TECHNICAL ARTICLE<br />

GC: Agilent 6890N with split/Splitless <strong>in</strong>let at 250 °C, Focusl<strong>in</strong>er, split ratio 5:1<br />

Detector: Agilent Dual-plasma sulphur chemilum<strong>in</strong>escence detector<br />

Reactor temperature: 850 °C<br />

Hydrogen: 50 mL/m<strong>in</strong> Air: 35 mL/m<strong>in</strong><br />

Reactor vacuum: 310 torr<br />

Ozone reactor vacuum: 10 torr, 5 psig air<br />

Oven profile: 40 °C (2m<strong>in</strong>) – 15 °C/m<strong>in</strong> – 200 °C - 5m<strong>in</strong><br />

1. Methyl mercaptan (trace)<br />

2. Dimethyl sulphide (500 ppb)<br />

3. Methyl ethyl sulphide (200 ppb)<br />

Figure 9. Commercial Alberta Natural <strong>Gas</strong>.<br />

Heart Cutt<strong>in</strong>g with SilFlow Deans’ Switch<br />

Heart cutt<strong>in</strong>g is regularly used <strong>in</strong> multidimensional GC<br />

where a time slice of the elute from a separation <strong>in</strong> the<br />

first dimension is directed onto a second capillary column<br />

of an alternate stationary phase (the second dimension).<br />

Figures 10 and 11 demonstrate a simple example where<br />

the co-elut<strong>in</strong>g peaks of Octenyl Acetate and L<strong>in</strong>alool<br />

L were ‘heart cut’ from the non-polar BPX5 onto the<br />

polar BPX70 highlight<strong>in</strong>g the separation of both these<br />

compounds from Lavender Oil.<br />

P/N 054101<br />

For more <strong>in</strong>formation contact our technical customer support team at techsupport@sge.com<br />

AUSTRALIA & PACIFIC REGION<br />

<strong>SGE</strong> <strong>Analytical</strong> Science Pty Ltd<br />

Toll Free: 1800 800 167<br />

Tel: +61 (0) 3 9837 4200<br />

Fax: +61 (0) 3 9874 5672<br />

Email: support@sge.com<br />

JAPAN<br />

<strong>SGE</strong> Japan Inc<br />

Tel: +81 45 222 2885<br />

Fax: +81 45 222 2887<br />

Email: japan@sge.com<br />

Lavender Oil,<br />

Method: 60 °C, 1 m<strong>in</strong>, 3 °C/m<strong>in</strong> up to 140 °C,<br />

5 °C/m<strong>in</strong> up to 260 °C<br />

FID-280 °C, INJ-250(228) °C, split vent flow 285 mL/m<strong>in</strong>,<br />

0.1 µL <strong>in</strong>jection<br />

P/N 054622<br />

Figure 10. Configuration for heart cutt<strong>in</strong>g us<strong>in</strong>g Deans’ Switch SilFlow to dual FID.<br />

A)<br />

Figure 11. Lavender Oil heart cutt<strong>in</strong>g results.<br />

A) Lavender oil separated on the first dimension BPX5 column - note the<br />

coeultion of octenyl acetate and L<strong>in</strong>alool L.<br />

B) Separation of the BPX5 ‘heart cut’ on BPX70, C) Separation of the rema<strong>in</strong><strong>in</strong>g<br />

lavender oil components on BPX5.<br />

CONCLUSION<br />

• Sta<strong>in</strong>less steel planar microchannel devices provide a<br />

versatile format for multidimensional analysis.<br />

• Each of the metal devices described are optimized for<br />

low thermal mass.<br />

• The chemical surface treatment of the channel devices<br />

and f<strong>in</strong>ger tight fitt<strong>in</strong>gs do not impact chromatography<br />

– even for sulphur conta<strong>in</strong><strong>in</strong>g analytes.<br />

• F<strong>in</strong>ger tight fitt<strong>in</strong>gs provide robust and easy to use<br />

column connectors, simplify<strong>in</strong>g connections <strong>in</strong> the GC.<br />

• Multi-channel fabricated devices simplify column<br />

splitt<strong>in</strong>g, backflush<strong>in</strong>g and heart cutt<strong>in</strong>g.<br />

REFERENCES<br />

1) Mr Okawa (Bruker - Japan) Micro Union comparison<br />

with Glass Press Fit<br />

2) J Luong, R. Gras, R.A. Shellie, H. Cortes – manuscript<br />

<strong>in</strong> preparation. For data on the 3 Port SilFlow work.<br />

EUROPE<br />

<strong>SGE</strong> Europe Ltd<br />

European Head Office<br />

Toll Free: 00800 2790 8999<br />

Toll Free Fax: 00800 2626 2609<br />

Tel: +44 1908 568 844<br />

Fax: +44 1908 566 790<br />

Tel France: +33 1 69 29 80 90<br />

Fax France: +33 1 69 29 09 25<br />

Tel Germany: +49 (0) 6155 / 60746 0<br />

Fax Germany: +49 (0) 6155 / 60746 50<br />

Email: europe@sge.com<br />

B)<br />

C)<br />

UNITED STATES OF AMERICA<br />

<strong>SGE</strong> Incorporated<br />

Toll Free: (800) 945 6154<br />

Tel: +1 512 837 7190<br />

Fax: +1 512 836 9159<br />

Email: usa@sge.com