The Proteus Framebuilding Book - Proteus Bicycles

The Proteus Framebuilding Book - Proteus Bicycles

The Proteus Framebuilding Book - Proteus Bicycles

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

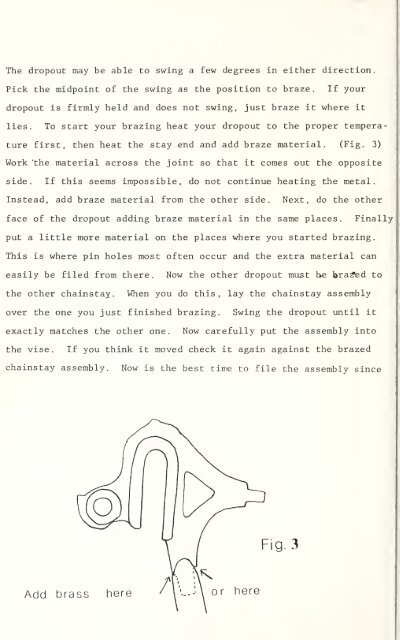

<strong>The</strong> dropout may be able to swing a few degrees in either direction.Pick the midpoint of the swing as the position to braze. If yourdropout is firmly held and does not swing, just braze it where itlies. To start your brazing heat your dropout to the proper temperaturefirst, then heat the stay end and add braze material. (Fig. 3)Work "the material across the joint so that it comes out the oppositeside. If this seems impossible, do not continue heating the metal.Instead, add braze material from the other side. Next, do the otherface of the dropout adding braze material in the same places. Finallyput a little more material on the places where you started brazing.This is where pin holes most often occur and the extra material caneasily be filed from there. Now the other dropout must he bra^d tothe other chainstay. When you do this, lay the chainstay assemblyover the one you just finished brazing. Swing the dropout until itexactly matches the other one. Now carefully put the assembly intothe vise. If you think it moved check it again against the brazedchainstay assembly. Now is the best time to file the assembly sinceFig. 3Add brass hereorhere