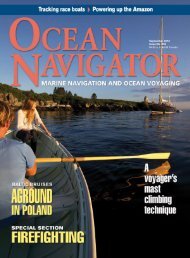

October 2011 Issue No. 197 - Navigator Publishing

October 2011 Issue No. 197 - Navigator Publishing

October 2011 Issue No. 197 - Navigator Publishing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

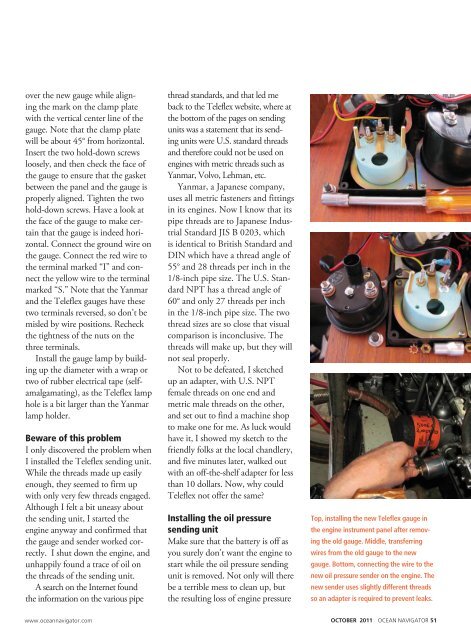

over the new gauge while aligningthe mark on the clamp platewith the vertical center line of thegauge. <strong>No</strong>te that the clamp platewill be about 45° from horizontal.Insert the two hold-down screwsloosely, and then check the face ofthe gauge to ensure that the gasketbetween the panel and the gauge isproperly aligned. Tighten the twohold-down screws. Have a look atthe face of the gauge to make certainthat the gauge is indeed horizontal.Connect the ground wire onthe gauge. Connect the red wire tothe terminal marked “I” and connectthe yellow wire to the terminalmarked “S.” <strong>No</strong>te that the Yanmarand the Teleflex gauges have thesetwo terminals reversed, so don’t bemisled by wire positions. Recheckthe tightness of the nuts on thethree terminals.Install the gauge lamp by buildingup the diameter with a wrap ortwo of rubber electrical tape (selfamalgamating),as the Teleflex lamphole is a bit larger than the Yanmarlamp holder.Beware of this problemI only discovered the problem whenI installed the Teleflex sending unit.While the threads made up easilyenough, they seemed to firm upwith only very few threads engaged.Although I felt a bit uneasy aboutthe sending unit, I started theengine anyway and confirmed thatthe gauge and sender worked correctly.I shut down the engine, andunhappily found a trace of oil onthe threads of the sending unit.A search on the Internet foundthe information on the various pipethread standards, and that led meback to the Teleflex website, where atthe bottom of the pages on sendingunits was a statement that its sendingunits were U.S. standard threadsand therefore could not be used onengines with metric threads such asYanmar, Volvo, Lehman, etc.Yanmar, a Japanese company,uses all metric fasteners and fittingsin its engines. <strong>No</strong>w I know that itspipe threads are to Japanese IndustrialStandard JIS B 0203, whichis identical to British Standard andDIN which have a thread angle of55° and 28 threads per inch in the1/8-inch pipe size. The U.S. StandardNPT has a thread angle of60° and only 27 threads per inchin the 1/8-inch pipe size. The twothread sizes are so close that visualcomparison is inconclusive. Thethreads will make up, but they willnot seal properly.<strong>No</strong>t to be defeated, I sketchedup an adapter, with U.S. NPTfemale threads on one end andmetric male threads on the other,and set out to find a machine shopto make one for me. As luck wouldhave it, I showed my sketch to thefriendly folks at the local chandlery,and five minutes later, walked outwith an off-the-shelf adapter for lessthan 10 dollars. <strong>No</strong>w, why couldTeleflex not offer the same?Installing the oil pressuresending unitMake sure that the battery is off asyou surely don’t want the engine tostart while the oil pressure sendingunit is removed. <strong>No</strong>t only will therebe a terrible mess to clean up, butthe resulting loss of engine pressureTop, installing the new Teleflex gauge inthe engine instrument panel after removingthe old gauge. Middle, transferringwires from the old gauge to the newgauge. Bottom, connecting the wire to thenew oil pressure sender on the engine. Thenew sender uses slightly different threadsso an adapter is required to prevent leaks.www.oceannavigator.comOCTOBER <strong>2011</strong> OCEAN NAVIGATOR 51