Systems - ROHMANN

Systems - ROHMANN

Systems - ROHMANN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Systems</strong><br />

Internal Tube Inspection with the IHR-Rotor<br />

Inspection of tubes at the manufacturer<br />

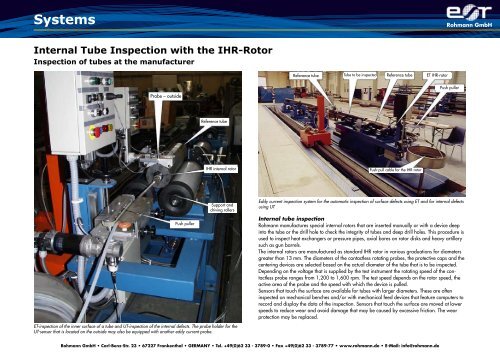

Probe – outside<br />

Push puller<br />

Reference tube<br />

IHR internal rotor<br />

Support and<br />

driving rollers<br />

ET-inspection of the inner surface of a tube and UT-inspection of the internal defects. The probe holder for the<br />

UT-sensor that is located on the outside may also be equipped with another eddy current probe.<br />

Reference tube<br />

Tube to be inspected<br />

Reference tube<br />

Push-pull cable for the IHR-rotor<br />

Eddy current inspection system for the automatic inspection of surface defects using ET and for internal defects<br />

using UT<br />

Internal tube inspection<br />

Rohmann manufactures special internal rotors that are inserted manually or with a device deep<br />

into the tube or the drill hole to check the integrity of tubes and deep drill holes. This procedure is<br />

used to inspect heat exchangers or pressure pipes, axial bores on rotor disks and heavy artillery<br />

such as gun barrels.<br />

The internal rotors are manufactured as standard IHR rotor in various graduations for diameters<br />

greater than 13 mm. The diameters of the contactless rotating probes, the protective caps and the<br />

centering devices are selected based on the actual diameter of the tube that is to be inspected.<br />

Depending on the voltage that is supplied by the test instrument the rotating speed of the contactless<br />

probe ranges from 1,200 to 1,600 rpm. The test speed depends on the rotor speed, the<br />

active area of the probe and the speed with which the device is pulled.<br />

Sensors that touch the surface are available for tubes with larger diameters. These are often<br />

inspected on mechanical benches and/or with mechanical feed devices that feature computers to<br />

record and display the data of the inspection. Sensors that touch the surface are moved at lower<br />

speeds to reduce wear and avoid damage that may be caused by excessive friction. The wear<br />

protection may be replaced.<br />

Rohmann GmbH • Carl-Benz-Str. 23 • 67227 Frankenthal • GERMANY • Tel. +49(0)62 33 - 3789-0 • Fax +49(0)62 33 - 3789-77 • www.rohmann.de • E-Mail: info@rohmann.de<br />

ET IHR-rotor<br />

Rohmann GmbH<br />

Push puller

<strong>Systems</strong><br />

Test systems and accessories:<br />

ELOTEST PL500/LP eddy current inspection instrument for<br />

the inline inspection<br />

EloLine software to document the test results of long<br />

products<br />

IHR40/2-2 rotor featuring a sensor whose diameter<br />

may be adjusted<br />

ELOTEST PL500<br />

Designed as 2-channel unit in a 19”/4HU-rack;<br />

375 mm deep<br />

• Test frequency: 10 Hz to 12 MHz<br />

• Front panel featuring 9”-color display 800 x<br />

480 pixel. 16 : 9-display for the simultaneous<br />

depiction of up to 8 signals with a display rate of<br />

250,000 signal dots/channel<br />

EloLine software:<br />

Standard software to visualize and document test<br />

results during the eddy current inspection of long<br />

products. Simple circumferential coil systems and<br />

complex multi-channel rotor or multiplex applications<br />

are supported. Up to 8 test channels are<br />

processed and combined into a collective result that<br />

may be evaluated in a location-dependent manner.<br />

IHR25 rotor for 33.5 mm Ø with centering device, sensor<br />

protective cap and push pull hose<br />

IRSA and IRSD sensors:<br />

The standard rotating probes for the IHR-rotors are<br />

interchanged based on the diameter of the tube.<br />

One sensor is required per tube diameter. The<br />

probes work contactless and may additionally be<br />

protected against touching the tube. Standard IRSA<br />

absolute probes come with a KA-3 probe element<br />

whilst the IRSD differential probes come with a<br />

KD-7 probe element. The dimensions range from<br />

17.5 mm to 50.0 mm in 0.5 mm-graduations.<br />

RSVF rotating probes:<br />

RSVF-probes are available in various dimensions<br />

and regulating ranges starting at a diameter of 60<br />

mm. The epoxy probe carrier may be equipped<br />

with various probe types (absolute, differential,<br />

multi-differential). An epoxy platelet that 0.3 mm<br />

thick is used as wear protection. Depending on the<br />

rotor the probe carriers may be equipped with 1,<br />

2 or 3 channels and distance compensation. The<br />

spring-loaded holder presses the probes slightly<br />

against the inner wall of the tube thus compensating<br />

for minor ovalities.<br />

Rohmann GmbH<br />

Test systems and accessories:<br />

IHR-rotors<br />

Available standard sizes:<br />

Rotor type internal Ø min. internal Ø max.<br />

IHR16 17.5 mm 25.0 mm<br />

IHR18 23.0 mm 30.0 mm<br />

IHR25 30.0 mm 50.0 mm<br />

IHR40/2-2 starting at 40.0 mm<br />

IHR60/2-2 starting at 60.0 mm<br />

Rohmann GmbH • Carl-Benz-Str. 23 • 67227 Frankenthal • GERMANY • Tel. +49(0)62 33 - 3789-0 • Fax +49(0)62 33 - 3789-77 • www.rohmann.de • E-Mail: info@rohmann.de