Power from Heat:<strong>THE</strong> TRIOGEN ORCIn recent years, the urge for utilizing all formsof available energy has increased significantly.One of these sources is waste or residual heat,found in engine exhausts, process heat, flare gasburners, combustion of wood and other residuals.A remarkable way to utilize waste or residual heatis to convert it into electricity using a so-calledOrganic Rankine Cycle (ORC) system, marketedby Triogen B.V. of the Netherlands.The development work of the ORC systemstarted in the early nineties at the LappeenrantaUniversity of Technology in Finland, and the systemwas industrialized and commercialized by Triogen in2002. Deployment took place since 2006, resultingin 21 units built so far, 15 operational units and 10units on order or being commissioned.Figure 1: Cycle scheme and T-s diagramSystem Design of ORCFigure 1 shows the cycle scheme and the processof the ORC system in a T-s diagram. Liquid ispumped from the storage vessel into the mainpump, which is mounted on to the same shaft asthe turbine and the high-speed generator. Therethe liquid will get the maximum working pressureat which it will enter the recuperator and subsequentlythe evaporator.Residual or waste heat is led through the evaporator,where the working fluid is heated up to theboiling point, evaporated and superheated. Expansiontakes place in the turbine, which drives thehigh-speed generator and the main pump. Afterexpansion, the sensible heat in the fluid is re-usedin the recuperator, to preheat the liquid before itenters the evaporator. The condenser is situatedbelow the recuperator, where thevapor is condensed using a liquidcoolant, before it flows back intothe storage vessel.ORC plant designAs can be seen from the cyclescheme, the main componentsof the ORC system include anevaporator, a turbine-generator-mainpump assembly calledHigh Speed Turbo Generator(HTG), a recuperator, a condenserand a storage vessel. Thanks tothe high-speed generator andturbine, the HTG is a very energy-densecompact unit. The other componentsof the ORC process are heat exchangerswith relatively low temperature differences.One of the engineering tasks of Triogen wasto make a compact and, as much as possible,standardized unit for different applications. Asthe evaporator is determined by the propertiesof the residual heat offered, the module can besized accordingly. However, the internal cycle heattransfer in the recuperator and the condenser canbe standardized for all applications, keeping thesystem very compact. For the system, <strong>Vahterus</strong>offered a compact solution based on their standardplate and shell type heat exchangers.The recuperator exchanges heat between vaporleaving the turbine and liquid working fluid beforeit is entering the evaporator, thus serving as a preheater.In the condenser, the working fluid is condensedfrom vapor to liquid at sub-atmosphericpressure, using a coolant, which rejects its heat toany available heat sink or to the atmosphere byexternal table coolers. As the turbine exhaust isvertical, both <strong>Vahterus</strong> heat exchangers are positionedbelow the turbine. After condensing, theworking fluid is stored in an appropriate quantityin the storage vessel, at its turn positioned belowthe condenser.The three vessels, recuperator, condenser andstorage tank, are factory assembled by <strong>Vahterus</strong>,and form the central element in the ORC processmodule. During assembly of the ORC, this <strong>Vahterus</strong>delivered unit serves as the starting point, as shownin Figure 2. The three blue vessels are the mentioned<strong>Vahterus</strong> components, with Triogen turbo-generatorHTG on top. The special connectionflange is delivered by Triogen and welded to therecuperator top by <strong>Vahterus</strong>.The ORC 160 kWe power plantThe complete ORC power plant consists of fourmodules for turnkey delivery:• The standard process module, consisting of HTG,recuperator, condenser, storage vessel, pre-feedpump, valves, including connecting piping andinstrumentation• The heat supply module: an evaporator tuned atthe conditions of the available heat, to be connecteddirectly to the heat source• The heat rejection module: table coolers forthe cooling water which cools the condenser,tuned to the ambient conditions at site. Alternatively,in the presence of a suitable heat consumer,this heat can be delivered up to a temperatureof 80°C.• The standard electrical cabinets, that containthe power preparation module, which connectsthe high speed generator directly to the grid tosupply the power at 400 V, 3 phase, 50 or 60 Hz,the control module to control the unit and theFigure 2: <strong>Vahterus</strong>components as core ofthe ORC process module.independent safety system.A typical turnkey supply of an ORC is connectedto two biogas engines of 800 kWe each, whereasthe process module is centrally positioned. Theheat supply module (evaporator) is connected tothe flue gas outlet of two gas engines through aset of piping and valves, to allow single engineoperation and to isolate the ORC from the runningengines in the unlikely event of an ORC failure.All units are to be used as a typical ‘end-of pipe’solution: the process feeding the ORC is never disturbedby the ORC.Product for a vast range of applicationsAlthough initially set up for the use of exhaustgas from internal combustion engines, a numberof other application possibilities have arisen, suchas biomass combustion and residual heat fromindustrial processes like incinerators. Applicationsenvisaged are:• Gas engines running on natural gas, bio-gas, landfillgas, mine gas• Diesel engines• Small gas turbines• CHP for green houses, district and residentialheating• Combustion of biomass, wood, residuals and waste• Flares for landfill gas or other industrial flares• Process heat from e.g. (petro)chemical, metallurgical,glass or brick production plantsNearing 200 000 running hoursAfter having demonstrated more than 4000hours successful operation of the prototype,Triogen delivered their first commercial ORC in 2007for a greenhouse cogeneration plant equipped witha 2 MW e Deutz gas engine. After that, 19 plantsfollowed, gathering up to almost 200 000 runninghours. Demonstrated availability amounts to morethan 97 %. The fleet leader has now run more than36 000 hours.From the beginning, <strong>Vahterus</strong> components havebeen very valuable in setting up the standard andcompact process module of the ORC system. Productionis now well under way, and continuousproduct development has already led to severalimprovements. The first unit was contracted for 145kW e , now also 165 kWe has been demonstrated.In future, power range will be extended stepwisefrom the current 60 – 170 kWe towards 1000 kW e.Jos van Buijtenenwww.triogen.nl12

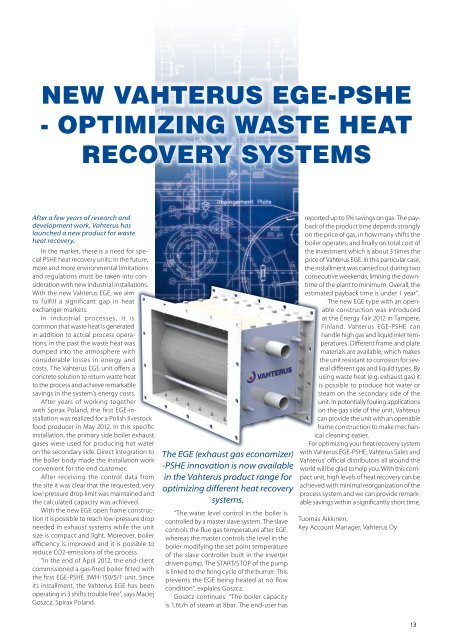

NEW VAHTERUS EGE-PSHE- OPTIMIZING WASTE HEATRECOVERY SYSTEMSAfter a few years of research anddevelopment work, <strong>Vahterus</strong> haslaunched a new product for wasteheat recovery.In the market, there is a need for specialPSHE heat recovery units: In the future,more and more environmental limitationsand regulations must be taken into considerationwith new industrial installations.With the new <strong>Vahterus</strong> EGE, we aimto fulfill a significant gap in heatexchanger markets.In industrial processes, it iscommon that waste heat is generatedin addition to actual process operations;in the past the waste heat wasdumped into the atmosphere withconsiderable losses in energy andcosts. The <strong>Vahterus</strong> EGE unit offers aconcrete solution to return waste heatto the process and achieve remarkablesavings in the system’s energy costs.After years of working togetherwith Spirax Poland, the first EGE-installationwas realized for a Polish livestockfood producer in May 2012. In this specificinstallation, the primary side boiler exhaustgases were used for producing hot wateron the secondary side. Direct integration tothe boiler body made the installation workconvenient for the end customer.After receiving the control data fromthe site it was clear that the requested, verylow-pressure drop limit was maintained andthe calculated capacity was achieved.With the new EGE open frame constructionit is possible to reach low-pressure dropneeded in exhaust systems while the unitsize is compact and light. Moreover, boilerefficiency is improved and it is possible toreduce CO2-emissions of the process.“In the end of April 2012, the end-clientcommissioned a gas-fired boiler fitted withthe first EGE-PSHE 3WH-150/5/1 unit. Sinceits installment, the <strong>Vahterus</strong> EGE has beenoperating in 3 shifts trouble free”, says MaciejGoszcz, Spirax Poland.The EGE (exhaust gas economizer)-PSHE innovation is now availablein the <strong>Vahterus</strong> product range foroptimizing different heat recoverysystems.“The water level control in the boiler iscontrolled by a master slave system. The slavecontrols the flue gas temperature after EGE,whereas the master controls the level in theboiler modifying the set point temperatureof the slave controller built in the inverterdriven pump. The START/STOP of the pumpis linked to the firing cycle of the burner. Thisprevents the EGE being heated at no flowcondition”, explains Goszcz.Goszcz continues: “The boiler capacityis 1,6t/h of steam at 8bar. The end-user hasreported up to 5% savings on gas. The paybackof the product time depends stronglyon the price of gas, in how many shifts theboiler operates, and finally on total cost ofthe investment which is about 3 times theprice of <strong>Vahterus</strong> EGE. In this particular case,the installment was carried out during twoconsecutive weekends, limiting the downtimeof the plant to minimum. Overall, theestimated payback time is under 1 year”.The new EGE type with an openableconstruction was introducedat the Energy Fair 2012 in Tampere,Finland. <strong>Vahterus</strong> EGE-PSHE canhandle high gas and liquid inlet temperatures.Different frame and platematerials are available, which makesthe unit resistant to corrosion for severaldifferent gas and liquid types. Byusing waste heat (e.g. exhaust gas) itis possible to produce hot water orsteam on the secondary side of theunit. In potentially fouling applicationson the gas side of the unit, <strong>Vahterus</strong>can provide the unit with an openableframe construction to make mechanicalcleaning easier.For optimizing your heat recovery systemwith <strong>Vahterus</strong> EGE-PSHE, <strong>Vahterus</strong> Sales and<strong>Vahterus</strong>’ official distributors all around theworld will be glad to help you. With this compactunit, high levels of heat recovery can beachieved with minimal reorganization of theprocess system and we can provide remarkablesavings within a significantly short time.Tuomas Aikkinen,Key Account Manager, <strong>Vahterus</strong> Oy13