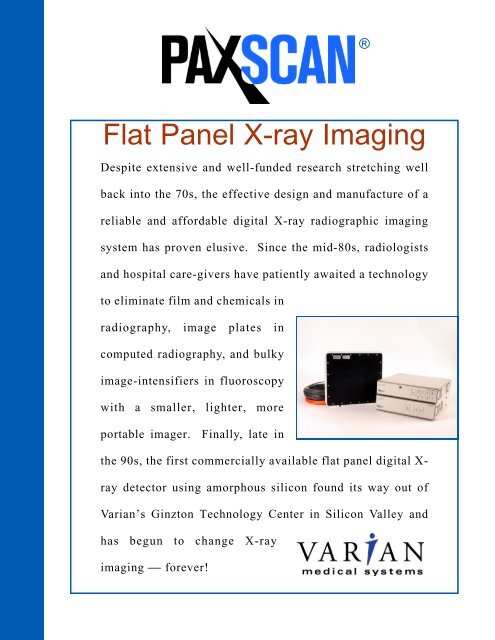

Flat Panel X-ray Imaging - Varian Medical Systems

Flat Panel X-ray Imaging - Varian Medical Systems

Flat Panel X-ray Imaging - Varian Medical Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

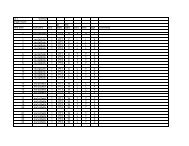

Figure 2 - <strong>Flat</strong> panel detector internal architecture.Because CsI is such an excellentabsorber of X-<strong>ray</strong>s, and covertsthem to visible light photons atenergies that amorphous silicon isbest able to convert to charge carriers,the combination of these twomaterials has the highest-ratedDetective Quantum EfficiencyDQE) in use today. DQE is theyardstick by which the performanceof imagers is measured. Ahigh DQE means images can beacquired with either superior qualityor the same quality at a lowerdose.<strong>Flat</strong> <strong>Panel</strong> ArchitectureµmµmFigure 3 - Absorption efficiency of the primaryscintillators used in FPDs. (Image courtesy ofThales Electron Devices.)The construction of FPDs is similar in many ways to flat panel displays,and uses many of the same technologies. Figure 2 shows the constructionof a typical FPD. At the core is an amorphous-silicon TFT/photodiodear<strong>ray</strong>. Closely coupled to the ar<strong>ray</strong> is the X-<strong>ray</strong> scintillator. Generally, theX-<strong>ray</strong> conversion screen, rare earthscreens such as gadolinium oxysulfide,can be a separate detachablesheet which is mechanically forcedinto close contact with the ar<strong>ray</strong>.However, if a CsI screen is used, thisis often directly deposited on thear<strong>ray</strong>, to give the best optical couplingefficiency. CsI is used in applicationslike low-dose fluoroscopy, where thephoton flux is very low. Figure 3shows a comparison between theabsorption efficiency of CsI andgadolinium oxysulfide. In addition toits much higher absorption efficiency,CsI also produces roughly twice thelight output of a gadolinium screen,which results in more than fourtimes the signal at the photodiode for a4

As is discussed later, the linearity of the detection system is critical tobeing able to efficiently correct for all the sources of non-uniformity in thear<strong>ray</strong> and the electronics.Figure 5 - TFT/Photodiode ar<strong>ray</strong> schematic andview of a single 127µm pixel.The TFT/photodiode matrix is normallyscanned progressively, one line at a timefrom top to bottom. The TFTs areessentially switches. When a largepositive voltage is applied to one of thegate lines, the switches (TFTs) in theselected row are closed, causing them toconduct electricity. With the TFTs energized,each pixel in the selected rowdischarges the stored signal electronsonto the dataline. At the end of eachdataline is a charge integrating amplifierwhich converts the charge packet to avoltage. At this point the electronicsvary by manufacturer, but generallythere is a programmable gain stage andan Analog-to-Digital Converter (ADC),which converts the voltage to a digitalnumber. One important aspect of thescanning is that the FPD is continuouslycollecting the entire incident signal;none is lost even during the discharge ofthe pixel. The FPD is an integratingdetector and the integration time foreach pixel is equal to the frame time.The electronics can be mounted to theside of the ar<strong>ray</strong>, out of the beam, as isdone in higher energy (MeV) applicationsto protect against radiation damage.But for diagnostic and interventionalprocedures, to maintain the bestview of the patient, the electronics can also be mounted behind the ar<strong>ray</strong>and protected by a thin layer of lead. While amorphous silicon has propertiessufficient for the detection electronics, it is not suited to the subsequentsignal processing. For this reason, every column and row of thear<strong>ray</strong> is brought to the edge of the glass, where it is connected to a standardcrystalline silicon chip by means of a TAB (tape automated bonding)package. The TAB package bridges the disparity between the connection6

density on the glass and what atypical circuit board can handle.The glass side of the TAB packagemay have 128 channels at a100µm pitch, while the boardside connections of the packageare on a pitch of 400µm withroughly forty or fewer connections.The chips that need to bedirectly connected to the ar<strong>ray</strong>,the readout chip and the driverchip, are mounted in these TABpackages. Figure 6 shows apicture of the row driver andreadout chips used in <strong>Varian</strong><strong>Medical</strong> <strong>Systems</strong>’ PaxScan ®4030A, 40x30cm (12”x16”)angiography panel.Figure 6 - Board-side view of TAB packaged row driver andcustom ASIC readout chips.<strong>Flat</strong> <strong>Panel</strong> Operational AdvantagesThe most obvious advantages of flat panel imagers are size and weight.The Image Intensifiers Tubes (IIT) are large and bulky. An FPD with a12”x16” active area (20” diagonal) takes up less than 25% of the volumeof a 12” IIT and less than 15% of that of a 16” IIT. In addition, the FPDtakes the place of not only the IIT, but also the attached image recordingdevices, including the CCD camera, 35mm Cine camera, and the spot filmdevice. The result is vastly improved access to the patient in interventionalprocedures. In addition to the reduction in size, the weight of theflat panel imager is 60% less than that of the IIT-based imaging chain.Traditionally, the IIT side of the mechanical structure is the heaviest. Withflat panels, the heavy side shifts to the X-<strong>ray</strong> tube, which offers the possibilityof a reduction in the bulk and cost of the mechanical superstructure.Mounting a 16” IIT on a mobile C-arm is impractical because of its sizeand weight, but achieving an even larger active area with a flat panelimager on a mobile C-arm is now straightforward.7

Figure 10 - Entrance dose per frame by application.The result is a very flat, uniform“film-like” image fromedge-to-edge. Similar to thedistortion and brightness nonuniformity,the IIT/CCD imagechain also suffers from contrastloss at the edges of theimage, which is why the IITperformance is always specifiedat the center.The ability of flat panel detectorsto encompass multipleX-<strong>ray</strong> modalities is also afunction of their very largedynamic range. Figure 10shows the detector entrancedose per frame by application.An FPD designed for R&Fapplications can cover the entire range, from low-dose fluoroscopy to radiography.Generally, the Analog-to-Digital Converters (ADCs) inside theFPD have a fixed input range. In order to adapt the signal to that range,there is an analog gain stage prior to digitizing. Higher gain is used forsmaller signals, but at the expense of the maximum dose per frame.Because of the very differentresolution, energy and doseFigure 11 - Signal vs. entrance dose for a 194µm, requirements, mammography40x30 cm FPD.requires a specialized flat paneldetector. The large exposurelatitude in flat panel imagingmeans that retakes, due to overand under exposure, are virtuallyeliminated. The large dynamicrange also enables computedtomography applications, wherethe entrance dose per projectioncan vary from the low dosefluoroscopy level to the equivalentof radiography shots.µR/frameFigure 11 shows the signalresponse of an angiography flatpanel in the full resolution mode,10

over the dose range of 1µR to 1.2mR. Particularly for the amorphous siliconTFT/photodiode technology, the response to entrance dose of the FPDis extremely linear. The response of the imager deviates from the straightline curve by less than 0.01%. This degree of linearity is necessary to facilitatethe real-timeoffset and gain correction that is normally performed foreach pixel. Because each pixel in the ar<strong>ray</strong> has its own gain value and zerosignal level, the image would be very non-uniform without normalization.If the imager response is non-linear, the arithmetic for normalizing thepixel response in real-time becomes intractable.Of equal importance is the Signal-to-Noise (SNR) behavior versus dose.The FPD contributes electronicnoise to the image. However, ifthe electronic noise is lowenough, the statistical noise inthe X-<strong>ray</strong> beam is dominant. Thenoise in the beam followsPoisson statistics. In otherwords, the noise is equal to thesquare root of the number of incidentX-<strong>ray</strong> photons.As shown in Figure 12, the SNRof an FPD has a square rootdependence on dose, i.e. is X-<strong>ray</strong>quantum limited over a very largerange. This is an indication thatthe detector contributes effectivelyno noise to the image over thisdose range.Figure 12 - SNR vs. entrance dose for a 194µm,40x30cm FPD.µR/frame11

A more accurate way to look at the sensitivity of an imaging system is toevaluate the Detective Quantum Efficiency (DQE) as a function of spatialfrequency. Particularly for digital X-<strong>ray</strong> technologies, this single measure isa common reference point that accounts for noise, signal-loss mechanisms,sensitivity and resolution. Essentially the DQE is equal to the square of theratio of the imager’s output SNR to its input SNR.SNRout( q,u) 2DQE =SNRin2DQE is typically calculated using the formula:DQE q22d * MTF( )( u), u =q*NPS( q,u)where, for a given input dose, d is the average output signal produced,MTF is the modulation transfer function (a measure of resolution), q is thenumber of incident X-<strong>ray</strong> quanta and NPS is the noise power spectrumproduced by the imager. Because the X-<strong>ray</strong> beam statistics are Poissondistributed, the input SNR 2 is in fact equal to the total number of X-<strong>ray</strong>photons, q. The rest of the equation defines the output SNR 2 as a functionof signal, resolution and noise.The DQE as a function of entrance dose (fluoro and cine range) for anangiographic flat panel imager is shown in Figure 13. This is typical of theindirect TFT/photodiode technology with a CsI scintillator. Because of thelow-loss, high-absorption detection path, the DQE for indirect CsI-basedflat panels is the highest available and is more than double that ofcomputed radiography, film screen and CCD based technologies. HigherDQE translates directly into better imager quality for a given dose.12

So with high DQE detectionsystems, it is possible to getthe same image quality as alow DQE system like screenfilm at a fraction of thedose.Figure 13 - DQE vs. spatial frequency over the fluoroscopicand cine dose range, for a 40x30cmangiographic flat panel.Digital X-<strong>ray</strong>RadiographyThe numerous advantagesof flat panel detectors overX-<strong>ray</strong> film, computedradiography image plates,and image-intensifier tubesis clear. This is evident to the thousands of leading radiologists andcardiologists performing routine X-<strong>ray</strong> examinations, test engineersinspecting for cracks in aircraft structures, and security forces screeningfor and disarming explosives. Digital X-<strong>ray</strong> imaging available instantlyjust like that of modern digital cameras and camrecorders is the future.Please contact your local <strong>Varian</strong> sales office for the latest on our PaxScanfamily of flat panel X-<strong>ray</strong> detectors.13

X-Ray ProductsHeadquartered in Salt Lake City ourflat panel team is committed to meetingthe diverse and growing needs ofDigital Radiography in many markets:<strong>Medical</strong>, industrial/NDT, security,and scientific. World renown forour X-<strong>ray</strong> tubes, flat panel X-<strong>ray</strong>detectors are an important addition toour growing X-Ray business.MISSION STATEMENTTo be the unquestioned worldwide leader in X-<strong>ray</strong>products by achieving superior product quality andcustomer satisfaction.Ginzton Technology CenterThe Ginzton Technology Center acts as <strong>Varian</strong> <strong>Medical</strong> <strong>Systems</strong>’ researchand development facility for breakthrough technologies and operates abrachytherapy business for the delivery of internal radiation to treat cancer.In addition to brachytherapy, current efforts are focused on emergingflat panel technologies. This business also conducts externally fundedresearch related to medical technology, which leads to long-term partnershipsand new business opportunities.14

U.S. SALES OFFICESX-Ray ProductsX-Ray Products - Inte<strong>ray</strong>1678 S. Pioneer Road 3235 Fortune DriveSalt Lake City, UT 84104 North Charleston, SC 29418Tel: (801) 972-5000 Tel: (843) 767-3005Fax: (801) 973-5050 Fax: (843) 760-0079e-mail: inte<strong>ray</strong>.sales@varian.comCustomer ServiceCustomer ServiceTel: (800) 432-4422 Tel: (800) 468-3729Fax: (801) 973-5050 Fax: (843) 760-0079X-Ray Marketing & Product SupportTechnical SupportTel: (801) 973-5073 Tel: (843) 767-3005Fax: (801) 973-5023 Fax: (843) 760-0079INTERNATIONAL SALES OFFICESX-Ray ProductsX-Ray ProductsKokermolen 2Corsa Susa, 299B3994 DH Houten, Netherlands 10098 Rivoli (Torino), ItalyTel: +(31) 30 635 11 05 Tel: +(39) 011 955 03 96Fax: +(31) 30 635 04 46 Fax: +(39) 011 953 62 59e-mail: x<strong>ray</strong>.eu@varian.comX-Ray ProductsX-Ray Products<strong>Varian</strong> <strong>Medical</strong> <strong>Systems</strong> GmbH P.O. Box 38Karl-Arnold-Straße 121714 Heitenried - SwitzerlandD-47877 Willich, Germany Tel: +(41) 26-495 32 58Tel: +(49) 2154-92 49 80 Fax: +(41) 26-495 32 59Fax: +(49) 2154-92 49 94e-mail: sales-x<strong>ray</strong>@varian.comX-Ray ProductsX-Ray Products4F MY ARK Nihonbashi Bldg.B3-1801, Sunshine Plaza10-16 Tomizawa-cho 68 Anli Road, Chaoyang DistrictNihonbashi,Chuo-kuBeijing 100101, P.R.ChinaTokyo 103-0006, Japan Tel. +86-10-6496-1585Tel: +(81) 03 5652 4711Fax.+86-10-6494-0743+(81) 03 5652 4712Fax: +(81) 03 5652 4713www.varian.com11/11/04