Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

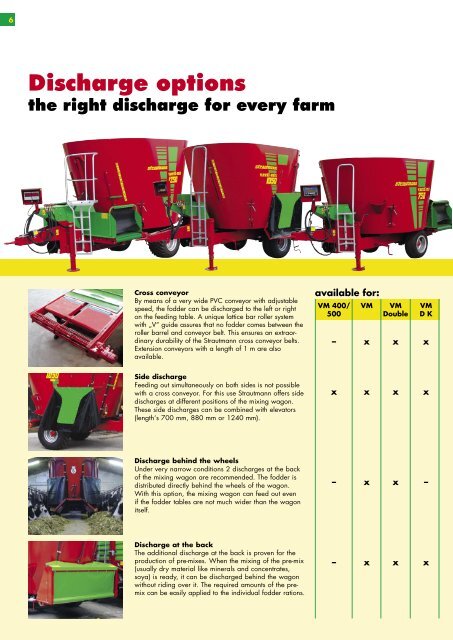

6Discharge optionsthe right discharge for every farmCross conveyorBy means of a very wide PVC conveyor with adjustablespeed, the fodder can be discharged to the left or righton the feeding table. A unique lattice bar roller systemwith „V“ guide assures that no fodder comes between theroller barrel and conveyor belt. This ensures an extraordinarydurability of the Strautmann cross conveyor belts.Extension conveyors with a length of 1 m are alsoavailable.available for:VM 400/ VM VM VM500 Double D K– x x xSide dischargeFeeding out simultaneously on both sides is not possiblewith a cross conveyor. For this use Strautmann offers sidedischarges at different positions of the mixing wagon.These side discharges can be combined with elevators(length‘s 700 mm, 880 mm or 1240 mm).x x x xDischarge behind the wheelsUnder very narrow conditions 2 discharges at the backof the mixing wagon are recommended. The fodder isdistributed directly behind the wheels of the wagon.With this option, the mixing wagon can feed out evenif the fodder tables are not much wider than the wagonitself.– x x –Discharge at the backThe additional discharge at the back is proven for theproduction of pre-mixes. When the mixing of the pre-mix(usually dry material like minerals and concentrates,soya) is ready, it can be discharged behind the wagonwithout riding over it. The required amounts of the premixcan be easily applied to the individual fodder rations.– x x x