LAB INNOVATOR OF 2010 - Luzerne Optical Labs

LAB INNOVATOR OF 2010 - Luzerne Optical Labs

LAB INNOVATOR OF 2010 - Luzerne Optical Labs

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

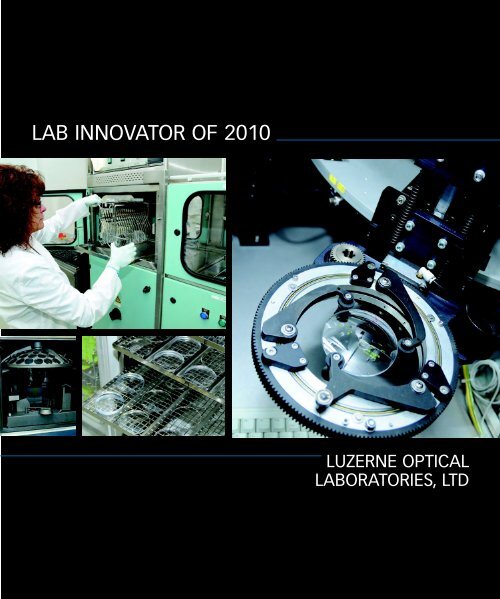

<strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>LUZERNE OPTICAL<strong>LAB</strong>ORATORIES, LTD

A Modelof InnovationWITH THIS, our annual LabInnovator of the Year award, we honor thecore of our industry. Without innovation,the independents could not compete (withapologies to the corporate labs, of course).In order to succeed, an innovative lab musthave a complete understanding of our industry,from vendors through internal needs tocustomers’ desires.This year’s recipient, <strong>Luzerne</strong> <strong>Optical</strong>Laboratories, Ltd., located in Wilkes-Barre,PA, epitomizes all that is necessary for success.Without relying on outside consultantsor business experts, this independentwholesale optical lab has established aculture for success based upon using technologyto serve its customers needs. If Ihave heard it once from <strong>Luzerne</strong> <strong>Optical</strong>,I have heard it again and again, “We oweit to our customers.”That focus, established by the founderJohn P. “Jack” Dougherty and his wifeLorraine, then carried on by the next generation,Neil, John, Renee, and Yvonne,and Neil’s wife Elizabeth, continues tobuild on that success. With almost 200employees, it is still a family business,now an extended family! Jack still worksdaily and even on weekends, edging jobsand checking work on his Vertometer.As Neil Dougherty said, “Even withall our technology, our primary strength isour people. I can’t say enough about ourpersonnel and the great job that they do.They’re a big part of why we’re successful.”Certainly technology is a constantemphasis, investing early to be the first inthe market, and establishing the learningcurve for labs that follow. <strong>Luzerne</strong> was thefirst lab in the U.S. to invest in a Schneidergenerator…way back when Zeiss was thedistributer. It was also the first independentlab (along with Walman) to install the Crizal ®process. While new technology can be disruptiveto the business, Dougherty said, “Weowe it to our customers.” The proof is in thelab. For example, its belief in state-of-the-artdigital technology has led it to install threeautomated, self-contained free-form lines, twoin production and a third, fully operational linewaiting for demand to increase and occasionallyput into use for excess production!<strong>Luzerne</strong> <strong>Optical</strong> is also proactive indeveloping private label products, again,because “We owe it to our customers.”These include house brand progressives,free-form single vision and progressives,photochromic and polarized lenses,house brand AR, and premium asphericand plasma-treated contact lenses…allproducts to help its customers compete.Additionally, <strong>Luzerne</strong> <strong>Optical</strong> is agood citizen, garnering a variety ofawards for itscommitment to thecommunity and, ofcourse, a worthyrecipient of thisyear’s Innovator ofthe Year award.JIM GROOTEGOEDProfessional Editor, <strong>Optical</strong> Lab ProductsOur Heartfelt Congratulationsto <strong>Luzerne</strong> <strong>Optical</strong>Innovative surfacingproducts for theophthalmic andprecision-optic industryNamed “Lab Innovator <strong>2010</strong>” by <strong>Optical</strong> Lab ProductsYour Friends atSchneider <strong>Optical</strong> Machines, Inc.SCHNEIDER <strong>Optical</strong> Machines • 972-247-4000 • www.schneider-om.com

<strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>HISTORY‘Lab Man’ Maintains Lab’s IndependenceJohn P. Dougherty, self-proclaimed ‘lab man,’ went independent in 1973 by founding <strong>Luzerne</strong> <strong>Optical</strong>,a wholesale optical lab that is still family-owned and operated with the help of the second generation.PERHAPS it’s no coincidence that <strong>Luzerne</strong><strong>Optical</strong> was named after the Pennsylvania county inwhich it is located, itself named for a man whocame from France to help the colonies gain theirindependence during the American Revolution—Chevalier de la <strong>Luzerne</strong>.Growth has been steady,and today the lab producesan average of 1,800 jobsper day.In 1973, when corporate lens manufacturersstarted buying up independently owned labsacross the country, John P. “Jack” Doughertyleft his position as production manager foranother lab in Wilkes-Barre, PA, to gain his ownindependence with the founding of <strong>Luzerne</strong><strong>Optical</strong> Laboratories, Ltd. Since then, growthhas been steady, and today the lab produces anaverage of 1,800 jobs per day for sale throughoutthe United States.Founded in the days before plastic lenses, <strong>Luzerne</strong>at first sold glass lenses and the frames to go withthem. At the beginning, <strong>Luzerne</strong> employed three people,Jack and his wife Lorraine and his business partner/brother-in-lawGeorge Albert.The business eventually outgrew the first buildingit shared with some other local businesses, and in1984 <strong>Luzerne</strong> built a million-dollar, 20,000-sq.-ft.,state-of -the-art laboratory facility in the downtownWilkes-Barre Industrial Park. In 1985, the companyadded gas permeable contact lens manufacturing onsite, and now it distributes soft contact lenses as well.To expand its surfacing area, automate its inventoryroom, and add a Crizal anti-reflective facility,<strong>Luzerne</strong> knocked out the walls to its garage in 2002,and then in 2009, the company started processingfree-form lenses in-house.Today <strong>Luzerne</strong> <strong>Optical</strong>processes an average of 1,800jobs per day. After half acentury in the business,Dougherty still comes intothe lab and manages along with his wife andsons. He calls himself a “lab man,” and these days hespends a lot of time at the lensometer, personally checkinga couple hundred jobs every day.When <strong>Luzerne</strong> <strong>Optical</strong> Laboratories, Ltd. was profiledin a report on local companies entitled, TheWyoming Valley: An American Portrait, Dougherty said,“Over the years, I’ve heard again and again that developmentswould be the end of the independently owned lab.With every change, however, came opportunity.”CLOCKWISE FROM TOP LEFT:<strong>Luzerne</strong> <strong>Optical</strong>’s first location shared abuilding with a sewing factory, pool hall, andPennsylvania State liquor store. Mayor Lee A. Namey (r)named March 2, 1995 “John P. Dougherty Day” in Wilkes-Barre, PA. Construction began in 1983 on a new 20,000-sq.-ft. plant in the downtown Wilkes-Barre Industrial Park.John P. Dougherty (l) receives the Wilkes-Barre Chamber ofBusiness and Industry’s “2001 Small Business of the Year”Award from the 2000 winner, Chuck Lawson, president ofthe Lion Brewery.18 november/december <strong>2010</strong>

HISTORY <strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>TIMELINE – THE HISTORY <strong>OF</strong> LUZERNE OPTICAL <strong>LAB</strong>ORATORIES, LTD.1960John P. “Jack”Dougherty joinsBalester <strong>Optical</strong> Co.after four years in theAir Force.1973Jack and LorraineDougherty found<strong>Luzerne</strong> <strong>Optical</strong> withJack’s business partner/brother-in-lawGeorge Albert.1984<strong>Luzerne</strong> <strong>Optical</strong> breaksground on a million-dollar,state-of-the-art,20,000-sq.-ft. laboratoryin Jack’s hometown ofWilkes-Barre, PA.1985<strong>Luzerne</strong> <strong>Optical</strong> startsproduction of custommade hard and gaspermeable contactlenses.1988Jack and his wifeLorraine purchaseGeorge’s share of thebusiness.1992<strong>Luzerne</strong> <strong>Optical</strong> isnamed U.S. Varilux ® Labof the Year.1994<strong>Luzerne</strong> <strong>Optical</strong> investsmore than one milliondollars to install inhouseanti-reflective(AR) facilities.1995Jack Dougherty isnamed president of the<strong>Optical</strong> LaboratoriesAssociation (OLA).1995Wilkes-Barre MayorLee A. Namey proclaimsMarch 2d asJohn P. Dougherty Day.1997 TOPRESENT<strong>Luzerne</strong> <strong>Optical</strong> isawarded the ContactLens ManufacturersAssociation manufacturingSeal of Excellence.2000 & 2001<strong>Luzerne</strong> <strong>Optical</strong> isnamed a Crizal ®Champions lab.2001<strong>Luzerne</strong> <strong>Optical</strong> ishonored as the 2000Corning Laboratoryof the Year.2001Jack Dougherty ishonored as an <strong>Optical</strong>Pioneer Visionary atthe OLA’s <strong>Optical</strong>Pioneers Banquet.2001The Wilkes-BarreChamber of Businessand Industry selects<strong>Luzerne</strong> <strong>Optical</strong> asSmall Business ofthe Year.2002<strong>Luzerne</strong> <strong>Optical</strong> is presentedthe first everEssilor Lenses Lab ofthe Year Award.2002<strong>Luzerne</strong> <strong>Optical</strong> isauthorized to produceCrizal AR lenses.2003<strong>Luzerne</strong> <strong>Optical</strong>employs 180 peoplewith a multi-milliondollarpayroll.2006<strong>Luzerne</strong> <strong>Optical</strong> is honoredas Crizal Lab of theYear by Essilor.2009<strong>Luzerne</strong> <strong>Optical</strong> isnamed The Leader’sChallenge award winnerby Essilor/Transitions.2009<strong>Luzerne</strong> <strong>Optical</strong> beginsproducing free-formlenses in house.<strong>2010</strong><strong>Luzerne</strong> <strong>Optical</strong> ishonored as theVisionWeb Lab ofthe Year.

<strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>Q&A WITH NEIL DOUGHERTYBuilt on an Independent FoundationNow run with the help of the second generation of the Dougherty family, <strong>Luzerne</strong> <strong>Optical</strong> of Wilkes-Barre, PA,continues its tradition of growth as an independent wholesale optical lab.JIM GROOTEGOED: Please tell usabout the history of <strong>Luzerne</strong> <strong>Optical</strong>.NEIL DOUGHERTY: The company wasstarted in 1973 by my mother and father.When my father got out of high school, hewent into the military. His first job out waswith Balester <strong>Optical</strong> in Wilkes-Barre. Hebecame their production manager. He wasthere for 13 years when a large corporationstarted buying independently owned laboratoriesacross the country, and Balesterwas one of those. He saw what was goingon and said, “This is a good time to get outand start my own business.”He felt there was a need for a locallyowned independent wholesale lab thatcould provide personalized service for itscustomers. Most people thought he wascrazy. They said, “You have this great job,five children, why would you want to leavethis position?” But my mother encouragedand supported him, so they started <strong>Luzerne</strong><strong>Optical</strong> in 1973.The name came from the countywe’re in, <strong>Luzerne</strong> County, named afterthe French nobleman and minister tothe U.S., Chevalier de la <strong>Luzerne</strong>, whowas sent to help the American Revolution.Plastic hadn’t arrived yet, so it was glasslenses and frames. The business grewsteadily over the years. We outgrew ourfirst building and in 1984 built a new,20,000-sq.-ft., state-of-the-art facility inthe downtown Wilkes-Barre IndustrialPark. In 1985, we added gas permeablecontact lens manufacturing on site, and in1994, we were the first lab in Pennsylvaniato manufacture anti-reflective (AR) in-house.In 2002, we were so tight we knockedout the walls to our garage and expandedour surfacing room. We also automatedour inventory room, installing Lektrieversystems interfaced with our DVI LMSsoftware. In 2002 we also added the CrizalAR facility, which was the first non-Essilorownedlab installation along with Walman<strong>Optical</strong>.Then, in 2009 we began processingfree-form lenses in house. With the firstSchneider generator distributed at thattime by Zeiss, we probably had free-formequipment before anybody in the U.S.Now we’re on our fourth generation ofSchneider equipment. We were waitingfor the free-form manufacturing processto come along. The software wasn’t ready.The equipment manufacturers weren’tready. So even though we had the technologysitting there years earlier, wecouldn’t implement it until all of thosepieces fell into place around 2009.JG: Why did you choose Schneider?ND: Gunter was so committed to hismachinery, plus they were the first withproven and productive machinery in thefree-form category worldwide before itcame to the U.S.JG: I noticed your product list is verycomprehensive in terms of the manufacturersyou support.ND: We have a vast array of products, justabout every lens line or treatment.That’s one of the things that gives<strong>Luzerne</strong> a competitive advantage.JG: That’s a challenge with new technologies—ARand now free-form.ND: We’re well positioned in AR and freeform.We have two different AR labs withfour AR systems. If one goes down, wehave backup and support. We were one ofthe first with the Zeiss process in 199420 november/december <strong>2010</strong>

Q&A WITH NEIL DOUGHERTY <strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>when we combined our plastic and glasssurfacing and finishing areas to make roomfor AR facilities. Then in 2002 we installedCrizal, and they required a Class 100,000Clean Room with a specific footprint, sowe took space from our old glass surfacingarea along with part of our data entry,stockroom, and customer service areas tosatisfy the requirements.Regarding our capacity planning forfree-form, we have three lines. Two are upand producing, and one is on standby in caseone goes down or until production increases,so we’re prepared with a free-form lineready and waiting to put into production.JG: Are you still doing frames?ND: Both dress eyewear and industrialeyewear. We offer package programs anddistribute an array of products—sunglasses,optical supplies, pharmaceuticals, andspecialty products such as binoculars,telescopes, and rifle scopes.We have a nice niche in the low visionarea with all kinds of devices and magnifiersand glasses. That’s a niche my father developedmany years ago with prismatic spectaclesfor people who were considered legallyblind. There were a lot of nice stories overthe years from doctors and their patientswho were so thankful to just havesomething that could help them see.JG: How did the second generationget involved?ND: We’re a family of five kids, and ittruly is a family-owned and operatedbusiness. We started out in the lab asyoung kids helping assemble boxes forshipping. In the summers during ourhigh school years we would work invarious positions in the lab. My fatherJohn (aka Jack/Jake) Dougherty ispresident, my mother Lorraine is vicepresident, my brother John is vice president/purchasing,I am the generalmanager, and my sisters Renee andYvonne along with my wife Elizabethhelp with accounting and payroll.NATIONAL MARKETJG: What about your sales force?ND: We have a large sales force throughoutthe country, most on the East Coast.JG: Where are your primary target areas?ND: <strong>Luzerne</strong> has accounts nationwide.Primarily in the Mid-Atlantic states andwhere we have representation in the sixNew England states, New York, Pennsylvania,New Jersey, Delaware, Maryland, WestVirginia, Virginia, DC, Ohio, North Carolina,South Carolina, Tennessee, Georgia, Florida,Mississippi, Arkansas, Louisiana, Oklahoma,Texas, Nebraska, Wyoming, Colorado,Utah, and California. We expand a littleeach year, but we’re careful about growthso we don’t sacrifice service.JG: How many jobs do you do in a day?ND: Right now, it’s averaging about1,800 jobs a day.JG: How much is finished versus uncut?ND: Pretty close to 50/50, however, we’reseeing the trend changing. More accountsare sending us the complete job to beedged because of the cost involved withdrill mounts, free-form lenses, and AR.JG: That’s a healthy trend for the labs.ND: In the East Coast in particular. Thispart of the country is known to be thebiggest for uncut lenses. More practices haveedgers in this area than in any other region.PRODUCTS AND PROMOTIONSJG: Does your sales force carry aframe bag as well?ND: Some do, some don’t. All of them promoteour frame and lens packages, but thereare many of them who focus on the lenses andtreatments. There are some nice frame linesavailable, and we do support them such asNouveau Eyewear and McGee Eyewear. -november/december <strong>2010</strong> 21

<strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>Q&A WITH NEIL DOUGHERTYThis part of the countryis known to be thebiggest for uncutlenses. More practicieshave edgers in thisarea than in anyother region.JG: What kind of promotions do you run?ND: We participate in manufacturersponsoredprograms, and we haveunique <strong>Luzerne</strong> promotions. We don’twant to be a “me too,” so we come upwith things other labs haven’t done.Our “<strong>Luzerne</strong> Millennium MaximumDiscount Program” is geared towardVarilux ® and Zeiss premium progressivelenses and their AR that we do in-house.There’s a one-time membership fee forECPs. It’s like a Wholesale Club, buy amembership to get the best possible pricingon commonly used items. Members getentered to win money or lunch for theoffice or a travel certificate to go anywherethey want to go. When ECPs join,<strong>Luzerne</strong> gives them certificates to try afree pair of progressives with AR andgas-permeable contact lenses.JG: What percentage of your customersparticipate?ND: Of the customers using those products,99%. It’s been very successful.We also have in-house graphic designcapabilities and will customize brochuresand presentations for our customers.JG: How much do you charge for that?ND: We don’t. It’s based on feedbackfrom our field consultants. It’s how wehelp practices grow.Several trademarked products help usstand out as well, such as our SightStar progressive lenses and our Photo.Fashion photochromics. Shortly, we’re going to bereleasing a new product that is also exclusiveto <strong>Luzerne</strong>—a new free-form product thatis going to be our SightStar 365 free-formlenses available in both progressive andsingle vision.JG: You mentioned your proprietaryPhoto.Fashion lenses. What are those?ND: They are a series of six fashion colorsthat stay the same color but get muchdarker outdoors. We add mirror treatmentsthat turn into a solid mirror outdoors.JG: Any other unique products?ND: Our Polar365 polarized is a seriesof different colors with a special warranty,our house brand EVC (Enhanced VisualClarity) is a premium AR with a twoyearwarranty at a competitive price,our gas-permeable (GP) DuraCurve aspheric contact lens designs are trademarked,and our FeelSoft PlasmaTreatment GP contact lenses provide amore comfortable fit. We’re proud to beone of a select group of contact lens labswho have the Contact Lens ManufacturersAssociation Seal of Excellence Award forthe manufacture of our contact lenses.MANUFACTURING TECHNOLOGYJG: You’re running both Zeiss andEssilor AR plus your own house brand?ND: Yes, plus KODAK, Zeiss Teflon ® ,and Zeiss mirror coatings as well.JG: For standard production, whatkind of generators?ND: We’re using V-Pros and Schneider.We’re constantly upgrading. We justadded a couple new Satisloh PRAblockers in the last two years and a couplenew backside coaters from Satisloh.About two years ago, we installed the“Control and Blocking Unit” fromAutomation & Robotics in Belgium[A&R, U.S. headquarters in Milwaukee].22 november/december <strong>2010</strong>

Q&A WITH NEIL DOUGHERTY <strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>It checks powers, curves, thicknesses, placesyour polarized lenses on axis, and then itwill place finishing pads and blocks on thelenses for edging. You program all your lensstyles, and it takes photos of the lenses torecognize them. We installed a separate,interfaced, intelligent conveyor line thatsorts the work. If it’s blocked for edging,it’ll go down one conveyor line. If it’suncut and ready to go out the door, it’ll godown another conveyor line. If it needs tobe inspected before AR, it’ll send it downanother conveyor line. If it doesn’t meetthe standards or is rejected for any reason,it’ll go down another conveyor line.JG: How about edgers?ND: Primarily National Optronics 7Es.We have a robotic edger, the NIDEK/Santinelli AES-1500 system, which is awet cut edger. The NIDEK probably putson the best high luster polished edgethan any other edger.JG: What are your plans for the future?ND: Further automating the finishing roomis definitely in our plans. We beta testedsome systems in the past, and they weren’twhere they needed to be, so we said, “Onthis one we’ll let the other labs work out thebugs.” When it’s where it needs to be, thenwe’ll commit.JG: That’s quite an investment.ND: It’s unbelievable what new technologycosts. Fortunately we’re a beta site formany equipment manufacturers. Weworked with many of them over the yearsto beta test their equipment because wedo such a vast array of lens styles andmaterials in-house. It’s not always easy,but sometimes it’s worth it to get in onthe curve earlier on these technologies.STRENGTH IN EMPLOYEESEven with all our technology, our primarystrength is our people. We have approximately200 employees. I can tell you wehave many people at <strong>Luzerne</strong> who havebeen in the business 20, 30, 40, 50 years.We even have one guy who has been inthe business for 60 years who is still workingfor us. Our in-house lens consultant,Charlie, amazes me. He has worked onthe dispensing side, so he understands itwell. He has eyecare professionals callhim every day from across the country. Hecan answer the most difficult fitting ordispensing questions or give guidance onwhat lenses to use. Of course, my fatherhas been in the business for 50 years now.JG: When Jack comes in, what doeshe do?ND: He loves processing lenses; he’s a labman. These days he spends a lot of time atthe lensometer ensuring quality. He personallychecks a couple hundred jobs himselfevery day. On the weekends he’ll come in,watch sports, and edge a hundred jobs! Justbecause that’s what he loves to do!JG: To me, Jack established the culturethat has made <strong>Luzerne</strong> successful.ND: Absolutely!E-Z Pack Congratulates <strong>Luzerne</strong> <strong>Optical</strong>as Lab Innovator of the Year“E-Z Pack’s custom opticalpackaging helps us promoteour image and adds value toour products by representingour vision of exceptionalquality to our customers.”— <strong>Luzerne</strong> <strong>Optical</strong>E-Z PACKOPTICAL PACKAGING & PRINT SPECIALTIES5 DECADES <strong>OF</strong> SERVICE1-800-950-1351www.ezpack.comdina@ezpack.comnovember/december <strong>2010</strong> 23

<strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>TECHNOLOGYEarly AdoptersAmong the first to install anti-reflective systems and digital surfacing, <strong>Luzerne</strong> <strong>Optical</strong> continuesleading the way in the technology for wholesale optical labs.THE LEVEL of technology variesfrom lab to lab and is dependent upon thenumber of jobs and revenue. What is differentabout <strong>Luzerne</strong> <strong>Optical</strong> is its historicand continuous focus on technology andits willingness to invest and be an earlyadopter. As general manager Neil Doughertysaid, “We learned the hard way. We wentthrough a learning curve and made it easierfor those labs that followed us. It’s not easy.It can really disrupt an organization whenyou install new equipment and systems,but it’s well worth it. We owe it to our customers.”While he said this specificallyabout his lab’s installation of its Crizal ®coating system, these comments couldalso pertain to many of its other “adventures”into new technologies as well.AR & DIGITAL LEADERIn 1994, <strong>Luzerne</strong> installed the Zeiss B-12bell jar anti-reflective (AR) coater, one ofthe first in the U.S. and the first in Pennsylvania.A Satis MC-380 AR coater was added in2002 to support Crizal, making <strong>Luzerne</strong>the first independent wholesaler (alongwith Walman <strong>Optical</strong>) to install the Crizalcoating system. Additionally, <strong>Luzerne</strong> nowprocesses its own AR house brand, EVC (Enhanced Visual Clarity), along withKODAK and Teflon ® . The space andinstallation needs of Crizal required thelab to totally rework its layout, ending upwith two, separate AR facilities. “It wasn’tplanned that way,” said Dougherty, “butthe redundancy is welcomed.”As another illustration of the lab’sredundancy, <strong>Luzerne</strong> now runs two automatedfree-form lines separate from normalproduction, and a third, fully operationalline is waiting for demand toincrease and is occasionally used now forexcess production requirements for eitherstandard or free-form jobs. All of thesefree-form lines are based on generatorsfrom Schneider <strong>Optical</strong> Machines (HSC101, HSC Master, and HSC Smart XP)along with polishers and the CCLC*Mark laser, also from Schneider.<strong>Luzerne</strong> <strong>Optical</strong>’s “standard” workis efficiently handled by PRA blockers,generators (V-PROs, ToromaticCNC-E, and a V95 for glass), andToro-X polishers, all from Satisloh.SURFACING & FINISHINGWhile over half of <strong>Luzerne</strong>’s jobs have traditionallybeen uncuts, the lab’s emphasishas been on surfacing, but with finishedwork growing yearly to about 57% now,future developments will center aroundTechnology in use at <strong>Luzerne</strong> <strong>Optical</strong>includes (clockwise from top) an automatedControl and Blocking Unit fromA&R, rimless lens tape invented by JackDougherty, trays which indicate rightand left lenses, and two coating units.finishing. Currently, <strong>Luzerne</strong> <strong>Optical</strong> isrunning National Optronics 6ESs, 7Es,and a 7E-HLP along with a Santinelli/NIDEK AES-1500 robotic edging system.The first step toward automated finishingwas two years ago when the labput in a Control and Blocking Unitfrom Automation Robotics in Belgium(A&R, U.S. headquarters in Milwaukee,WI). It checks powers, curves, andthickness, places polarized lenses onaxis, and then places finishing pads andblocks on lenses for edging. You programall your lens styles, and it takesphotos of the lenses to recognize them.A separate, interfaced, intelligent conveyorline sorts the work. If it’s blockedfor edging, it will go down one conveyorline. If it’s uncut and ready to go outthe door, it will go down another conveyorline. If it needs to be inspectedbefore AR, it will send it down anotherconveyor line. If it doesn’t meet ANSIstandards or is rejected for any reason,The commitment todigital processingcame early. In 2009<strong>Luzerne</strong> began processingfree-formlenses in-house.it will go down another conveyor line.Some techniques seem basic yet stillimprove efficiency. For example, the locationof left and right lenses are marked oneach tray. In addition, founder Jack Doughertyinvented lens tape specifically for rimlessjobs that is now sold by consumables suppliersto other labs.<strong>Luzerne</strong> <strong>Optical</strong> has a long historyof working closely with suppliers, testing,evaluating and giving feedback onnew products. The lab has beta testedseveral finishing products and is nowin the process of analyzing its experiencesas well as looking at other finishingoptions before committing to itsnext technology “adventure.”Whatever the choice, it will be to providebetter products and service to its customers.As Neil Dougherty stated, “Ourcustomers deserve the best.”24 november/december <strong>2010</strong>

SALES & MARKETING <strong>LAB</strong> <strong>INNOVATOR</strong> <strong>OF</strong> <strong>2010</strong>Slow and Steady SalesWith its own promotional programs, in-house graphics department, and quality proprietary products,<strong>Luzerne</strong> <strong>Optical</strong>’s sales and marketing efforts have achieved continuous growth.<strong>Luzerne</strong> <strong>Optical</strong> maintainsits own in-housegraphic design capabilitiesto design andproduce customizedmarketing materials.TO HAVE GROWN from athree-person operation to one of thecountry’s largest labs in the last fourdecades, <strong>Luzerne</strong> <strong>Optical</strong> must be doingsomething right when it comes to salesand marketing. With a salesforce that spans the countryand marketing techniques thatencourage the sale of bothnational brands as well as private-labelproducts, <strong>Luzerne</strong> is currentlyaveraging about 1,800 jobs per day.To make sure that it’s not a “me too”lab from the viewpoint of eyecare professionals(ECPs), <strong>Luzerne</strong> <strong>Optical</strong> notonly participates in specials sponsoredby all the major lens manufacturers, butit also creates its own unique promotionalprograms. “We try to come up withthings that we haven’t seen out therebefore, that other labs haven’t done,”said general manager Neil Dougherty.MEMBER DISCOUNT PROGRAMFor example, the “<strong>Luzerne</strong> MillenniumMaximum Discount Program” is modeledafter a Wholesale Club. ECPs pay a one-timemembership fee and get the best possiblepricing on commonly used items. This particularprogram is geared toward Varilux ®and Zeiss premium progressive lenses andtheir anti-reflective (AR) treatments that<strong>Luzerne</strong> <strong>Optical</strong> saved the shovel used by the mayor of Wilkes-Barre,PA, to take the first scoop when ground was broken on its newbuilding in 1984.<strong>Luzerne</strong> applies in-house. Members are alsoentered to win money or lunch for the officeor a travel certificate to anywhere they wantto go. In addition, when ECPs join, <strong>Luzerne</strong>gives them certificates to try a free pair ofprogressives with AR as well as gas-permeablecontact lenses.Over the years, growth has been steadyfor <strong>Luzerne</strong> <strong>Optical</strong>. “We expand a little biteach year,” said Dougherty, “but we’re verycareful about our growth to make sure wedon’t sacrifice our service.”IN-HOUSE GRAPHICSTo further support its customers, <strong>Luzerne</strong><strong>Optical</strong> maintains its own in-house graphicdesign capabilities to design and producecustomized marketing materials at no chargefor ECPs. By helping its customers succeed,<strong>Luzerne</strong> increases its business as well. Salesconsultants in the field let <strong>Luzerne</strong> <strong>Optical</strong>know which ECPs could benefit from thecreation of customized marketing materials,and the lab’s in-house graphic designers dothe rest. It’s a win-win situation.In some cases, sales and marketingtools come from organizations other than<strong>Luzerne</strong> <strong>Optical</strong> itself. For example, onthe contact lens side, <strong>Luzerne</strong> <strong>Optical</strong> is amember of the Contact Lens ManufacturersAssociation and is among a select groupof contact lens labs across the countrythat have achieved the Seal of ExcellenceAward for the manufacture of its contactEmbedded in the pavement, <strong>Luzerne</strong>’s logogreets those entering the building, and it alsoadorns mouse pads as a marketing tool.lenses. <strong>Luzerne</strong> has achieved this statusby having the contact lenses that itmanufactures put through an array ofdifferent tests by an independent companyconducting an anonymous studywith ECPs to ensure that it meets thehighest quality standards.PROPRIETARY PRODUCTSIn addition, with a catalog of its own uniqueproducts, <strong>Luzerne</strong> <strong>Optical</strong> is able to differentiateitself from the labs it competes with.These trademarked products include Sight-Star progressive lenses, new SightStar 365free-form lenses in both progressives andsingle vision, Photo.Fashion photochromics,Polar365 polarized lenses, the housebrand EVC (Enhanced Visual Clarity)premium AR, DuraCurve aspheric contactlenses, and FeelSoft PlasmaTreatment GP for contact lenses.By combining quality products withproprietary promotions, <strong>Luzerne</strong> <strong>Optical</strong>’ssales and marketing efforts have paid offsubstantially both for itself and for its ECPcustomers throughout the country.november/december <strong>2010</strong> 25

Congratulations<strong>Luzerne</strong> <strong>Optical</strong>on being theLab Innovatorof <strong>2010</strong>Transitions <strong>Optical</strong> recognizes <strong>Luzerne</strong> <strong>Optical</strong>’s dedicationto cutting edge technology, superior availability of AR, digital products,and their superior nationwide distribution.Transitions and the swirl are registered trademarks, and XTRActive is a trademark of Transitions <strong>Optical</strong>, Inc. © <strong>2010</strong> Transitions <strong>Optical</strong>, Inc.Photochromic performance is influenced by temperature, UV exposure and lens material.